Top 10 Classic Car Wiring Harness Manufacturers | Full Guide

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

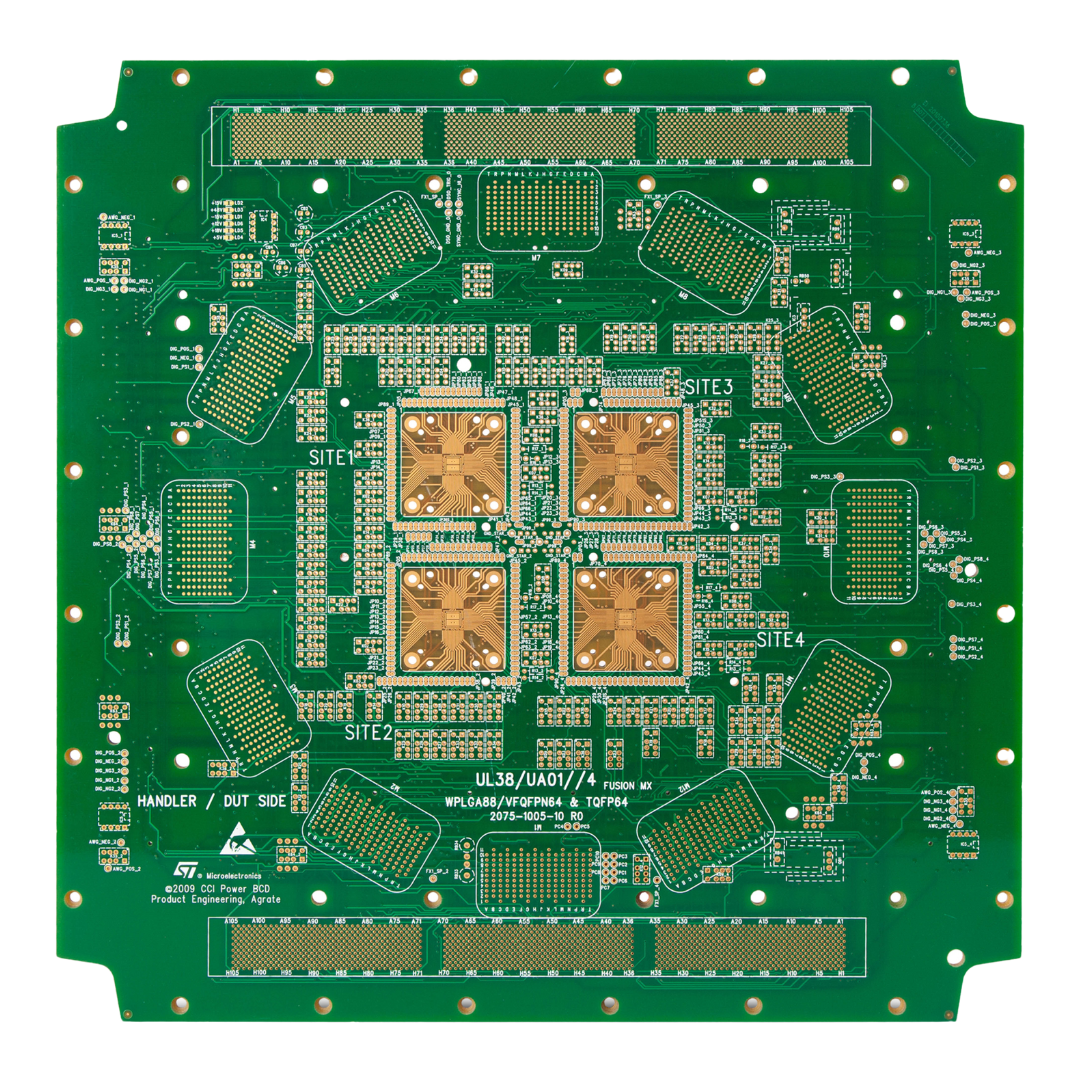

Automotive PCB assembly creates circuit boards for vehicles. It involves placing electronic parts on printed circuit boards for use in cars. OurPCB offers premium-quality automotive PCB assembly services. We also take pride in catering to various needs within the automotive industry.

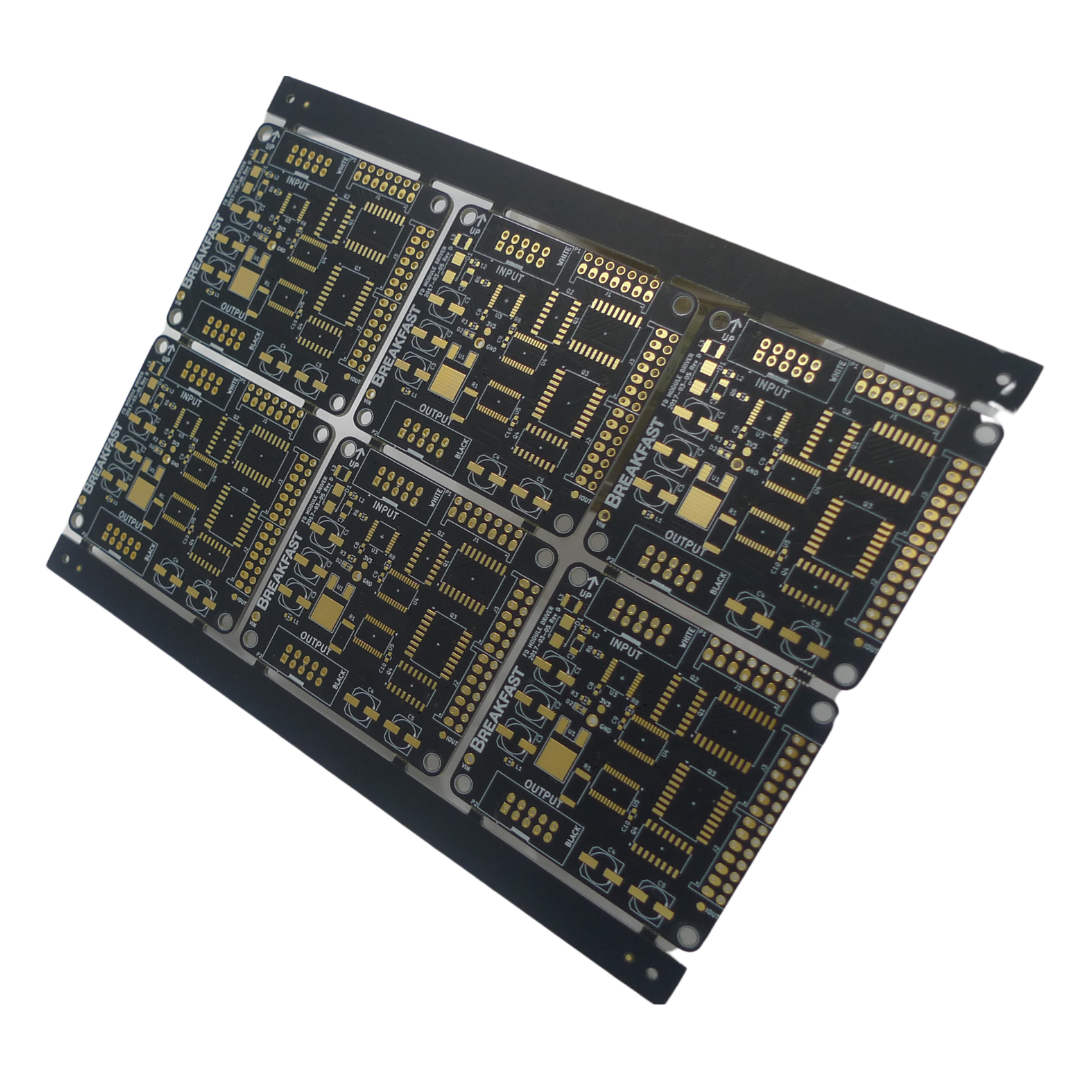

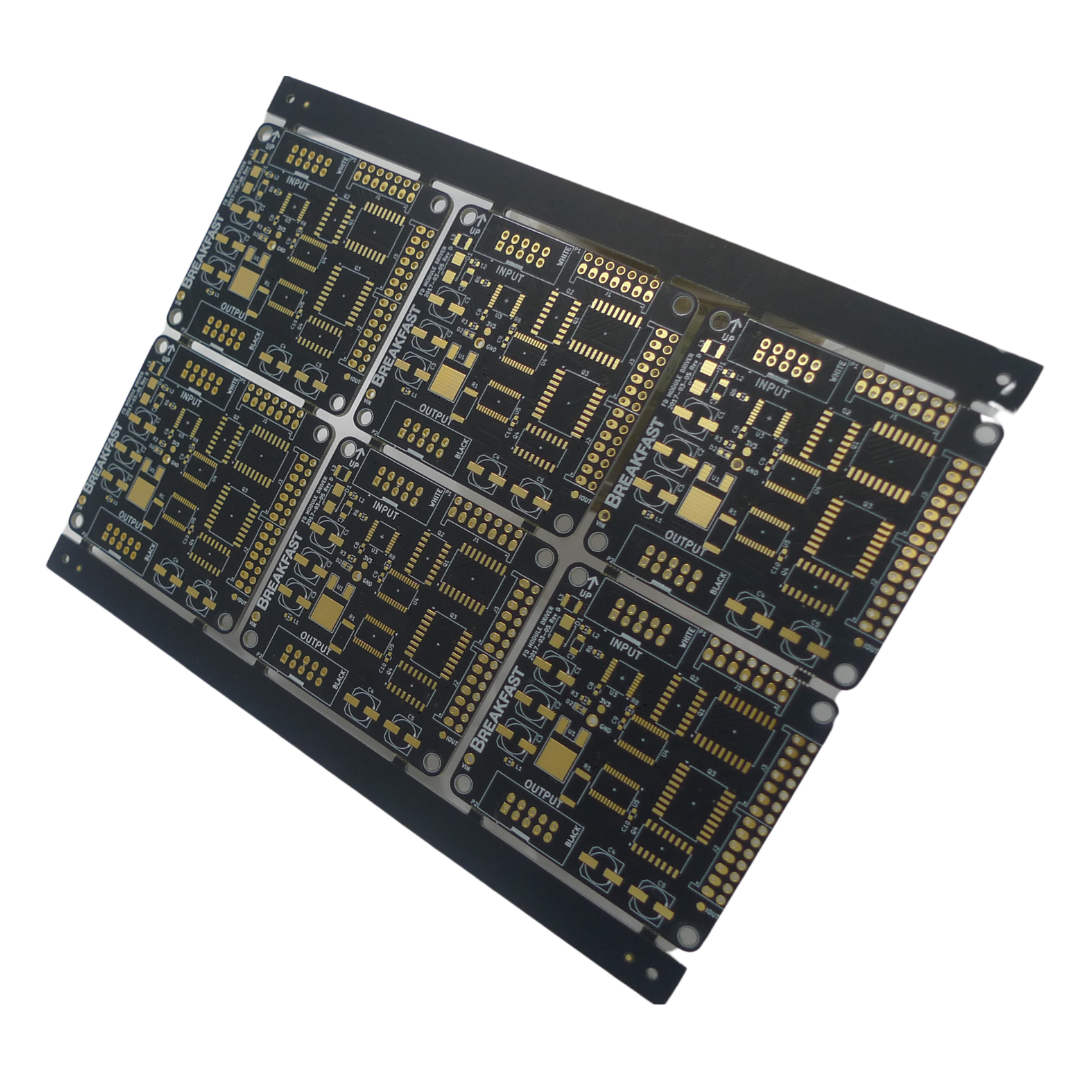

Wholesale automotive PCB assembly offers cost savings for large-scale production. By ordering in bulk, car manufacturers can reduce per-unit costs. This approach is ideal for mass-produced vehicle models.

Our factories can handle high-volume orders with consistent quality. We use advanced equipment to ensure each PCB meets strict automotive standards. This allows car companies to streamline their supply chain and maintain product reliability.

Choosing OurPCB as your automotive PCB assembly partner brings many advantages. We offer expertise, quality, and efficiency in every project. Here are the key benefits:

Automotive PCB assembly suppliers bring specialized skills to vehicle production. We understand the unique challenges of car electronics. Here’s why we’re essential:

Our PCB assembly services cover a wide range of specifications. We offer solutions for various automotive applications, including:

We use Surface Mount Technology for compact, high-performance car PCBs. This method allows for dense component placement, ideal for modern vehicle electronics.

We work with your supplied parts or offer full-service solutions. Our turnkey option covers everything from sourcing to the final delivery of assembled PCBs.

We create PCBs tailored to your specific car design needs. Our team can handle unique layouts and special requirements for all automotive applications.

We deliver fast, high-quality PCB assembly for urgent automotive projects. Our efficient process ensures quick turnaround without compromising on quality.

We build PCBs that meet strict IPC Class 3 standards. This level of quality is crucial for critical automotive systems and safety features.

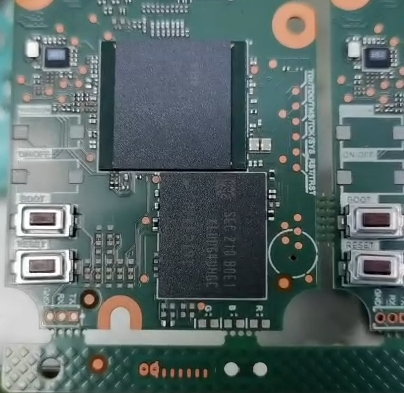

We assemble all types of IC packages with precision. This includes BGAs, QFNs, and other complex components used in advanced car electronics.

Our technical capabilities cover a broad spectrum of automotive PCB needs. We handle both through-hole and surface-mount assembly techniques. Our pick and place machines can work with minuscule components. We use lead-free solder to comply with environmental regulations. Our facilities are equipped for functional testing and thermal management solutions. This ensures that each PCB meets the high reliability standards required in the automotive sector.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

IATF 16949 mandates automotive PCB assembly factories to establish and maintain rigorous quality management systems. The standard emphasizes continuous improvement, defect prevention, and minimizing process variation, all critical for automotive electronics. For PCB assembly operations, IATF 16949 ensures adherence to the highest quality and reliability standards, which are essential for the automotive sector. It requires factories to implement efficient quality control measures, conduct regular audits, and prioritize customer satisfaction. This leads to consistent production of high-quality automotive PCBs, mitigates risks related to faulty components, and enhances overall operational efficiency.

PCB design and fabrication involve PCBA creation, while automotive PCB assembly factories handle component placement. Fabrication forms raw PCBs, whereas the printed circuit board assembly process completes the assembly lead phase. Notably, PCB assembly costs include both material and labor-intensive manufacturing services. Customers can get a quote for each stage of the design services process.

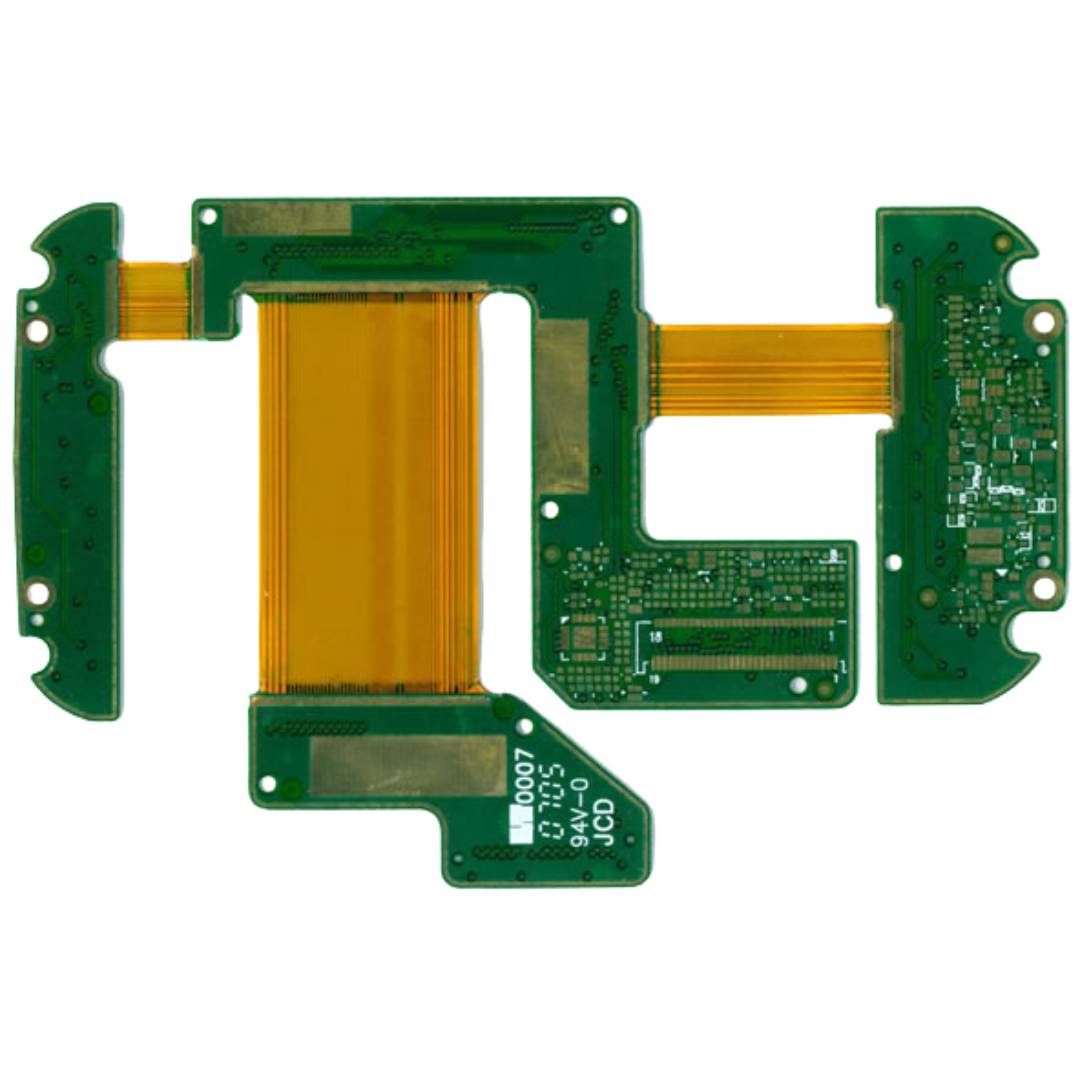

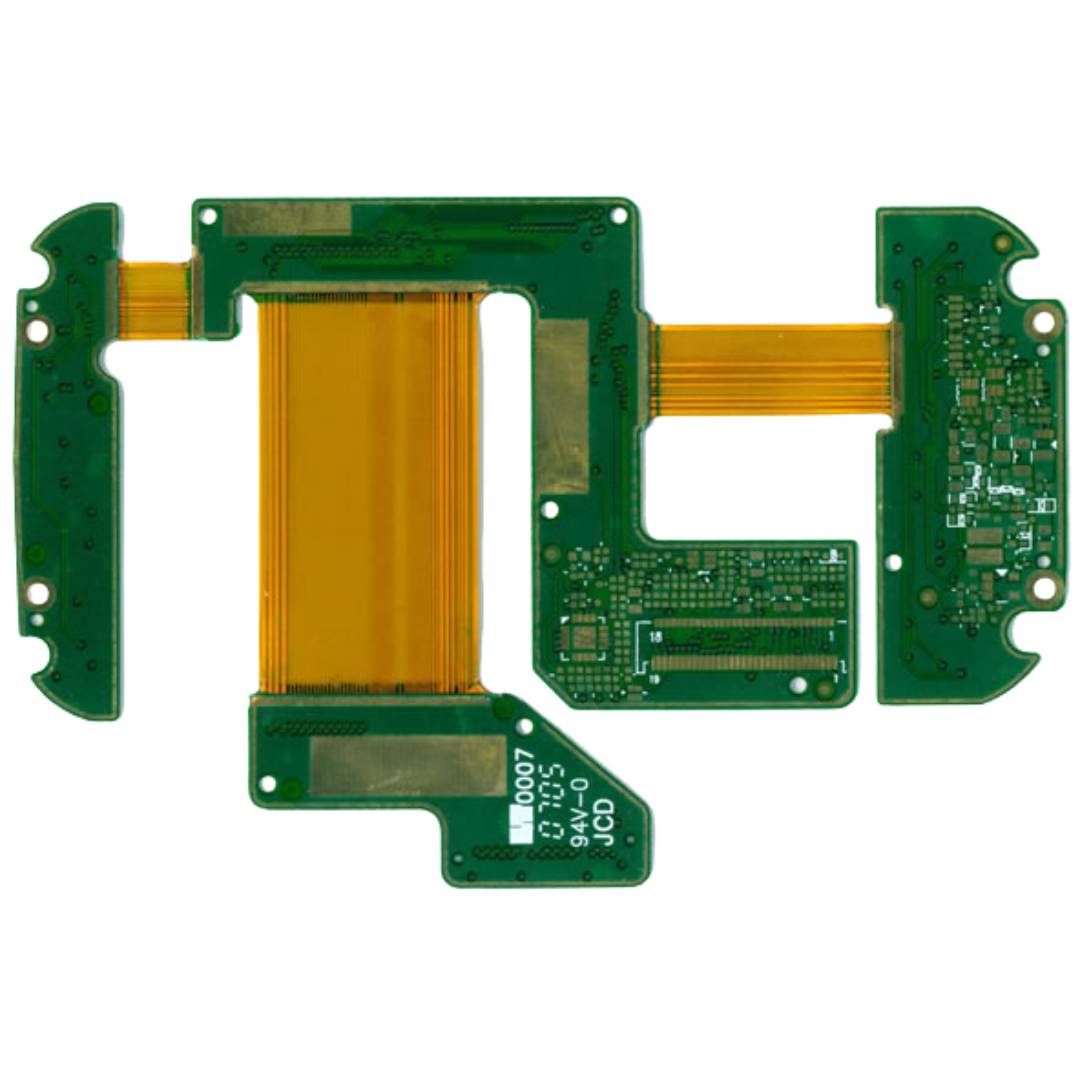

Under-the-hood PCBs’ ratings often range from -40 to 150 °C in automotive PCB assembly factories. These PCBs must withstand high temperatures in aerospace-grade conditions. Moreover, rigid-flex designs improve durability in extreme environments during the PCB assembly process. To determine your exact needs, you should request a PCB assembly quote.

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree