Robot Wire Harness Manufacturer

Robot wire harnesses take a beating like nothing else in the electrical world. The constant twisting, bending, exposure to lubricants, and extreme temperatures would destroy standard wiring in no time. That’s why OurPCB specializes in custom harness solutions built specifically for the demanding environments robotics need to endure.

We don’t just talk a good game. We back it up with manufacturing processes that produce harnesses that last under stress. Each assembly undergoes rigorous testing before it leaves our facility, ensuring your automation keeps running without those mysterious electrical gremlins that plague inferior systems.

If you need wire harnesses for manufacturing robots, our team delivers solutions that balance performance, durability and cost-effectiveness. Your robots deserve wiring that works as hard as they do.

What is a Robot Wire Harness?

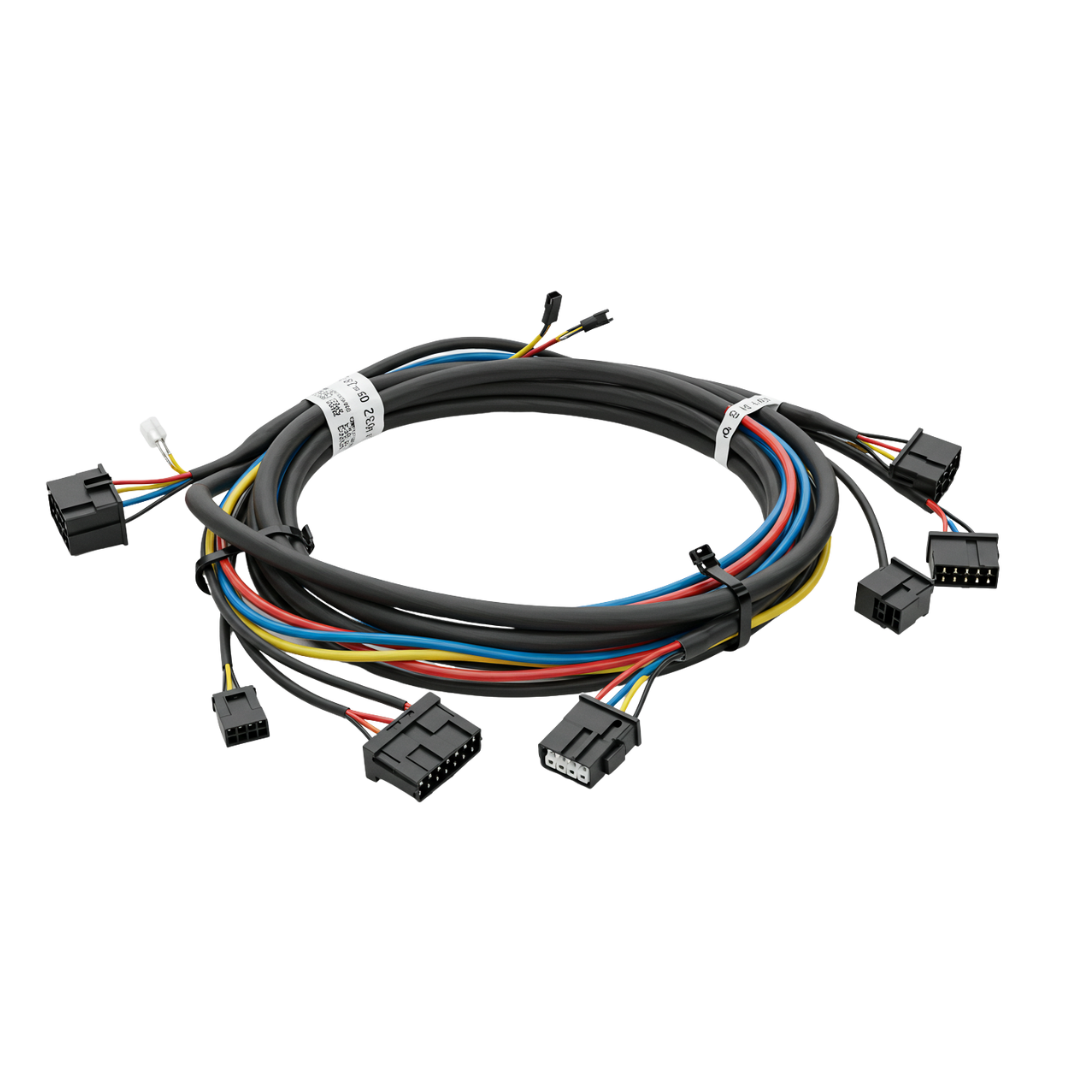

A robot wire harness is the main system for your automation equipment. It’s a specialized bundle of cables and connectors designed specifically to handle what regular wiring simply can’t — constant motion, twisting, vibration, and strenuous environmental conditions. Unlike standard harnesses that might work fine in stationary equipment, robot wiring needs to maintain perfect electrical connections and signal integrity while being bent and flexed thousands of times a day.

What are the Benefits of Robot Wire Harnesses?

The benefits of robot wire harnesses include their extraordinary robustness, greater signal integrity, and streamlined installation and maintenance. Robot wire harnesses blow conventional wiring solutions away, especially in automation, where constant movement would destroy standard cables. They’re the difference between reliable operation and constant downtime.

- Our harnesses survive over 1 million flex cycles without failing — when regular wiring would have given up months ago

- Every harness undergoes intense testing for twist resistance, abrasion protection, and vibration tolerance to ensure your robots keep running when it matters most

- We don’t just throw wires together — we use shielding and grounding techniques that protect against that pesky electromagnetic interference (EMI) that loves to mess with your robot’s brain

- Our connector systems aren’t your basic hardware store stuff — they’re precision-engineered to keep electrical connections rock-solid even while your robot twists and turns thousands of times daily

- Our custom wire routing slashes assembly time considerably

- When something eventually needs attention, our color-coded wires and clearly labeled connectors make diagnosing the problem easy and getting your robots back online easier

- Our compact, flexible harness designs accommodate the tight spaces and moving joints common in robotics applications.

- Custom routing solutions eliminate unnecessary wire length, reducing weight and improving robot performance while lowering material costs.

Superior Field Reliability

- IP67-rated connectors resist complete dust ingress and withstand water immersion up to 1 m for 30 minutes.

- Marine-grade insulation materials provide chemical resistance against fertilizers, pesticides, and fuel exposure.

Extended Equipment Lifespan

- Temperature-resistant components function reliably from -40 °C to 105 °C, preventing heat damage in engine compartments.

- Reinforced strain relief and secure terminal connections prevent failures from constant diesel engine vibration.

Simplified Troubleshooting

- Color-coded wiring with clear detail reduces diagnostic time by up to 60%.

- Comprehensive documentation includes wiring diagram specifications specific to your tractor model.

Customization Options

- Exact-fit design ensures perfect compatibility with your specific Farmall or Cub Cadet restoration.

- Additional capacity options accommodate future implements or aftermarket electrical accessories you may add later.

Why Choose OurPCB for Robot Wire Harnesses

Picking the right partner for your robot wiring isn’t just about getting cables — it’s about finding someone who actually understands automation challenges. OurPCB brings decades of hands-on experience to the table when other suppliers are still figuring out the basics of robotics.

- Our engineering team hasn’t just read about robotics — they’ve spent over 15 years in the trenches designing harnesses specifically for industrial automation

- We don’t work in isolation — we collaborate directly with your development team to create solutions tailored to your robot’s specific movements and working environment

- We don’t just hope our harnesses work — every single one undergoes serious testing including continuity checks, physical pull testing, and those brutal flex cycle tests that simulate years of robot movement

- Our manufacturing processes meet all the alphabet soup of standards — ISO 9001, IATF 16949, and IPC/WHMA-A-620 – which basically means we’re officially certified to build stuff that doesn’t fail when you need it most

- Whether you need one prototype harness or thousands for your production line, our setup handles it all without breaking a sweat

- We don’t believe in making you wait months — our streamlined process delivers prototypes in just 2 weeks and full production runs in 4–5 weeks, all while maintaining the quality that keeps your robots running

- We offer copper conductors, various insulation options, and terminal types to meet specific application requirements.

- Our technical team selects optimal materials based on your robot’s operating environment, whether it faces high temperatures, chemical exposure, or extreme mechanical stress.

Our Custom Wiring Harness Features

ROHS-Compliant Materials

Safe, approved, and eco-friendly materials

Custom Materials to Suit the Environment

Customized materials for abrasion-, oil-, heat-, or water-resistance

Your Choice of Coverings

Choose from PVC, nylon, XLPE, rubber, braided sleeving, heat shrink tubing, and more!

Variable Wire Options

We offer various wire thicknesses and lengths to meet your exact needs

Across Many Industries

We serve almost every industry you can think of! Contact us today.

Millions of business and innovators use OurPCB

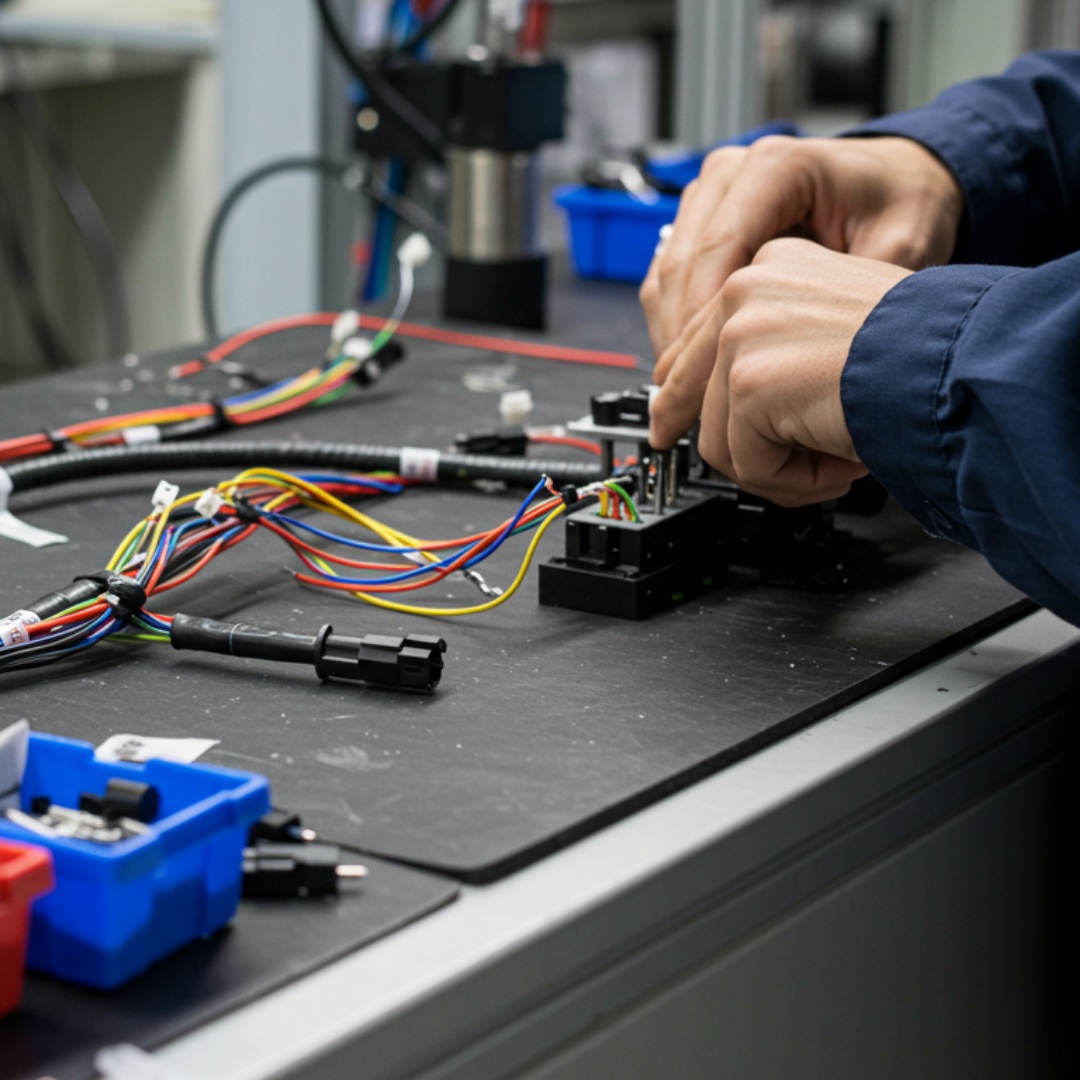

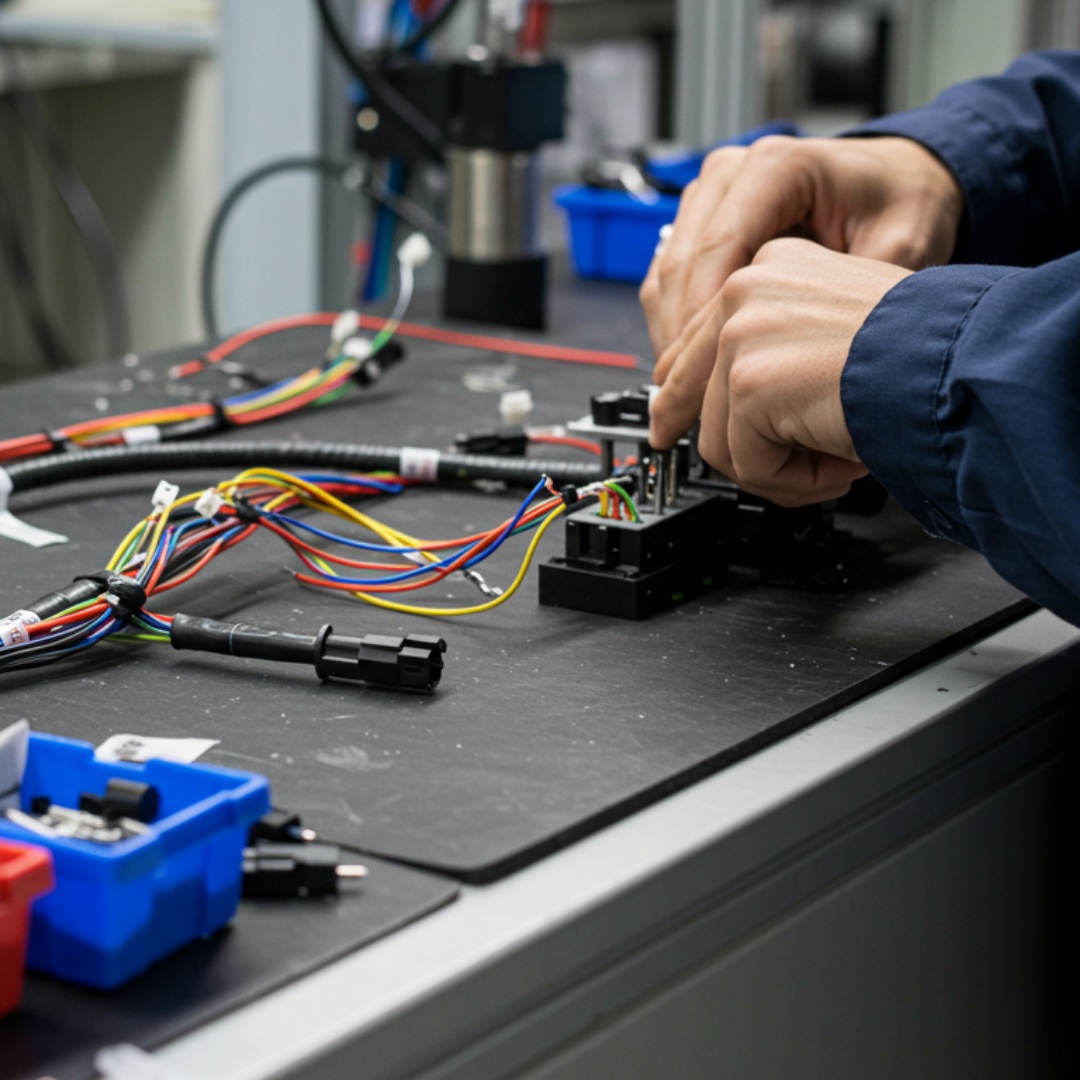

Our Custom Wiring Harness Process

Fast, free, and includes a production timeline

Our engineers create your design schematic and select the right materials

We’ll manufacture a high-quality prototype within 7 days

The prototype goes through various functionality and stress tests

Cutting, stripping, and assembly to the highest standard

After final testing and packaging, your custom wiring harnesses are delivered

Technical Capabilities

When it comes to robot wire harnesses, we don’t mess around with our capabilities. Our China facilities combine cutting-edge equipment with technicians who’ve been building these specialized harnesses for years. This isn’t just about meeting specs – we create harnesses that handle the abuse of robotics dishes out daily, all without the eye-watering prices you might expect from this level of quality.

We work with every robot type out there – industrial arms, cobots, autonomous platforms, you name it. Our partnerships span automotive assembly lines, electronics manufacturing, medical equipment, and general industrial applications. The bottom line? When your robots have reliable wiring, your entire operation runs smoother. It’s that simple.

Capabilities & Services

- Wire Gauge: 40AWG-120mm²

- Production Capacity: 10,000 pieces/hour

- Wire Cutting Service

- Wire Stripping Service

- Wire Marking Service

- Label Types

- Wire Ends Treatment

Custom Wire/Cable Service:

- Wire/Cable types

- Wire gauge

- Wire/Cable length

- Insulation/Jacket color

- Core numbers etc.

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

- Electrical cable assembly

- Coaxial cable assembly

- Multi-core cable assembly

- Connector to board cable assembly

- Automobile communication cable assembly

- Power transmission cable assembly

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Robot Wire Harness Manufacturer FAQs

How do I determine the right bend distance for robot wire harnesses?

Finding the right bend distance depends on how your robot actually moves. For constantly moving applications, stick to a minimum bend radius of 8-10 times the cable diameter to prevent premature failure. Static bends can get away with 4-6 times since they’re not constantly flexing.

Multi-axis robots that twist in every direction need specialized high-flex cable with finer stranding and more flexible insulation, which allows for tighter bends without internal damage after thousands of cycles. Getting this right from the start prevents those middle-of-the-night maintenance calls when production is down because a cable finally gave up.

What inspection systems should we use for robot wire harnesses?

Don’t wait until your robots go down to discover wiring problems. Start with regular visual inspections (at least quarterly) to catch obvious damage, but don’t stop there. Add those advanced 3D vision systems that spot issues human eyes miss completely.

For robots where failure means disaster, implement electrical testing – continuity checks and resistance measurements catch internal deterioration before catastrophic failures happen. The beauty of these automated systems isn’t just better detection – they free up your maintenance team from endless manual inspections so they can focus on fixing actual problems instead of just looking for them.

Can OurPCB help reduce supply chain risks for our robotics projects?

Yes — our China-based manufacturing reduces labor bottlenecks, while our strategic component inventory prevents common delays. When shortages inevitably hit, our ECAD system quickly adapts designs to use available alternatives without compromising performance. This comprehensive approach protects your production schedule from the delays that typically happen when wire harnesses become the overlooked critical path component in robotics projects.