Online CNC Machining Services Custom Parts Manufacturer

✅ Precision Manufacturing: Offers high accuracy with tolerances as tight as ±0.01 mm.

✅ Material Versatility: Works with various materials, including metals, plastics, and composites.

✅ Complex Geometries: Capable of creating intricate shapes and features.

✅ Rapid Prototyping: Enables quick turnaround for testing designs before full production.

✅ Scalable Production: Suitable for both low and high-volume manufacturing.

✅ Reduced Lead Times: Delivers parts faster than traditional methods.

✅ Cost-Effectiveness: Optimizes material usage and reduces labor costs.

✅ Consistent Quality: Ensures repeatable quality with minimal defects.

✅ Customization: Offers additional services like assembly and finishing for tailored solutions.

Looking for Cost-effective, High-quality CNC Machining Services?

Are you looking for world-class CNC machining service provider? OurPCB specialize in delivering high-precision CNC machining with a focus on quality, efficiency, and customer satisfaction. As a premier CNC machining partner trusted by industry leaders across the United States, we deliver precision-engineered solutions that drive innovation and efficiency in American manufacturing.

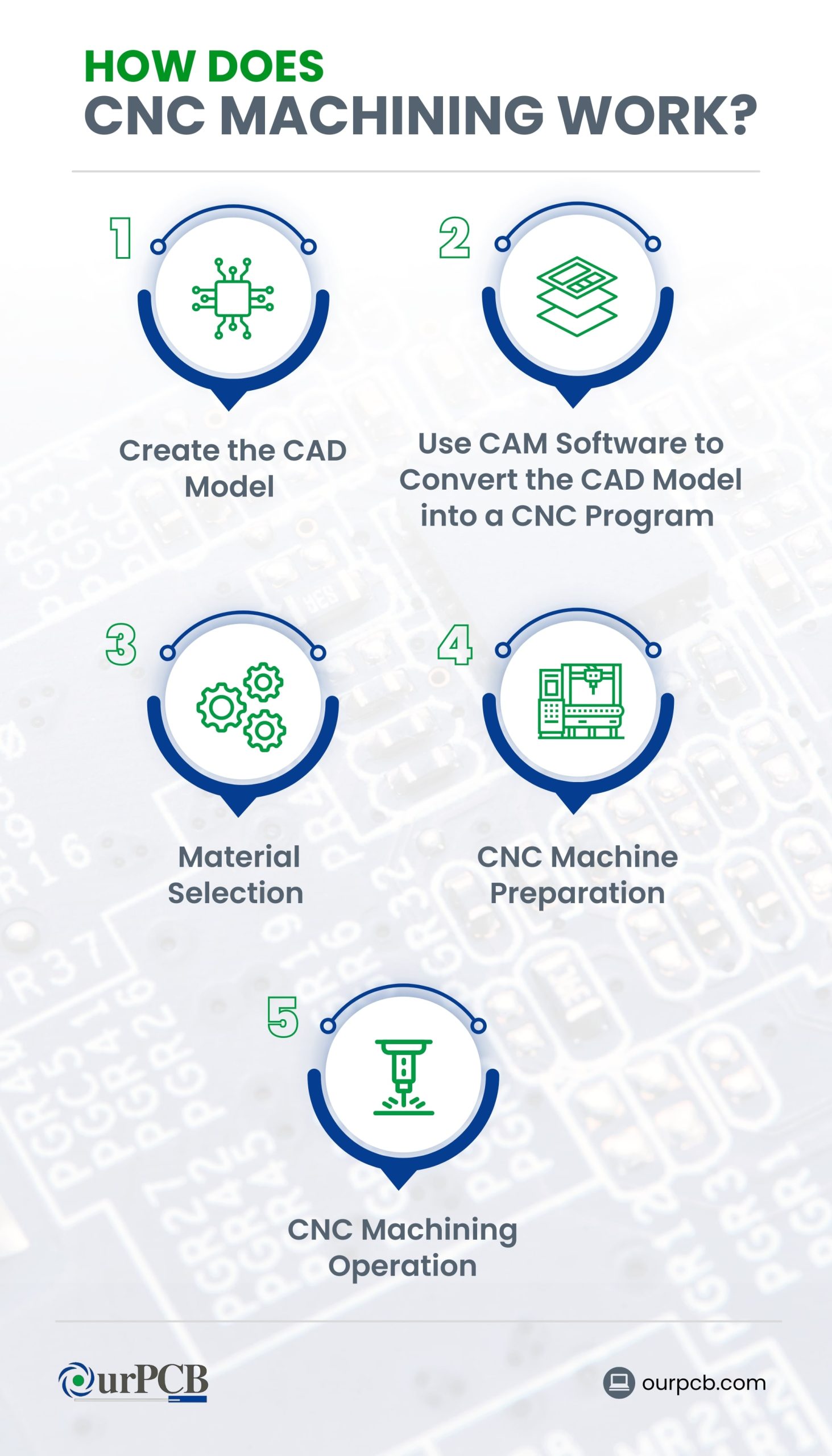

How Does the CNC Machining Process Work?

The CNC machining processes at OurPCB are as follows:

Create detailed 2D or 3D computer-aided design models with precise dimensions and specifications. This foundation ensures accurate manufacturing and helps identify potential design issues before production begins

Convert CAD models into executable CNC machine instructions using computer-aided manufacturing software. CAM software translates designs into G-code that controls machine movements with precision

Select appropriate materials based on thermal, mechanical, and cost requirements for your application. Prepare CNC machines by loading tools, mounting workpieces securely, and configuring all parameters

Execute cutting, drilling, milling, shaping, and finishing processes through automated computer-controlled movements. Monitor operations continuously to ensure accuracy while maintaining high-quality standards throughout production

Our CNC Machining Capabilities

Metal CNC Machining Products

Metal CNC Product Processing: We prepare the raw materials and set up machine programs. This is followed by rough machining, fine machining, and second-side machining. The process is wrapped up by completing machining, and 3D inspection. We can produce 200 pieces in 7 days.

Machining Precision: ±0.1mm/100mm

Maximum Part Size: 2000×800×580mm

Materials: Aluminum alloy, titanium alloy, copper (purple luster), stainless steel, zinc alloy, magnesium alloy

Plastic CNC Machining Products

Plastic CNC Product Processing: We fix the raw materials, set up machine programs, rough machine the first side, and fine machine of the first side. Then, we rough machine the second side and fine machine the second side. Finally, we complete machining, conduct manual finishing, and complete both manual inspection and 3D inspection. We can produce 200 sets in 3 days.

Machining Precision: ±0.1mm/100mm

Maximum Part Size: 1780×1180×240mm

Materials: ABS (off-white/black/transparent), PMMA acrylic (colorless transparent / colored transparent / pearl / embossed), bakelite (opaque dark, brown/black), Polycarbonate (PC), PA nylon, PA+ glass fiber, POM (white/black), PP (opalescent)

- 15+ Years of Experience

Our team has extensive experience creating both standard and custom wiring harnesses.

- Competitive Pricing

Well-priced and payable via PayPal, bank transfer, Western Union, or Moneygram.

What are the Common Surface Finish Options?

Surface finishes refer to the process of applying treatments to the surface after the manufacturing process to change the appearance, hardness, surface roughness, and other properties. Common surface finishes for CNC include as-machined, polishing, bead blasting, painting, plating, anodizing, silk screen, and powder coating.

Standard Surface Finishing for Plastic Products

Machining Precision: ±0.05mm/100mm

Surface Finishing Options: Standard surface finishing services for plastics include grinding, polishing, electroplating, wire drawing, spraying painting, laser engraving, and screen printing. Additionally, transparent PMMA and transparent PC finishes can achieve a fully transparent effect by spraying transparent oil. Spraying options include normal gloss and matte oil, spraying with sand, and rubber oil (UV gloss and matte oil, which provides stronger protection).

Standard Surface Finishing for Metal Products

Machining Precision: ±0.05mm/100mm

Surface Finishing Options: Deburring, grinding, polishing, sandblasting, oxidation, electroplating, black oxide, wire drawing, screen printing, laser engraving, spraying metal paint, spraying powder, chromate, spraying rubber paint, heat treatment, passivation, etc.

What are the Benefits and Limitations of Using CNC Machining?

Advantages

- Precision: CNC machines can produce highly precise and accurate parts with tight tolerances, leading to high-quality surface finish products.

- Repetitive Tasks: CNC machining is ideal for repetitive tasks, as it ensures consistent quality across multiple parts or components.

- Various Production Volumes: CNC machining is suitable for prototyping, low-volume and large-scale manufacturing.

- Flexibility and Versatility: CNC machines can be programmed to produce a wide range of shapes and designs, from simple to highly complex designs, making them suitable for diverse manufacturing needs.

- Efficiency: CNC machine automation allows continuous operation without constant human intervention, leading to faster production times.

Limitations

- Structure and Size Limitations: CNC machining is sometimes limited to producing parts with certain shapes and sizes, such as interlocking and hollowed structures.

- Material Limitations: Some materials, due to their hardness or other properties, may not be suitable for use with certain types of CNC machines.

- Highly Skilled Operator Limitations: CNC machines require highly skilled operators, which can also increase labor costs.

Millions of business and innovators use OurPCB

What are the Applications of Our CNC Machining Services?

Engine Components, Transmission Systems, Brake System Parts, Suspension and Steering Components, Chassis and Body Components

Robot Arms, Jigs and Fixtures, Controllers and Sensors, Robotic Loaders, Surface Finishing Components

Engine Components, Structural Components, Avionics and Electrical Components, Composite Structures, Propulsion System Parts

Structural Parts, Propeller Systems, Engine Components, Electronic Housings, Landing Gear

Kitchen Appliance Parts, Washing Machine Components, Dishwasher Parts, Refrigeration Systems, Small Appliance Housings

Surgical Tools, Orthopedic Implants, Diagnostic Equipment Parts, Dental Implants, Prosthetic Components

Smart Thermostat Housings, Security System Components, Smart Lock Mechanisms, Home Automation Hubs, Smart Lighting Controls

Measurement Instruments, Laboratory Equipment, Testing Equipment, Optical Instruments, Control Systems

Base Station Components, Server Enclosures, Heat Sinks, GPS Device Components, Connector Systems

Circuit Board Components, Semiconductor Housings, Electronic Enclosures, Heat Dissipation Components, Precision Connectors

Machine Tool Components, Hydraulic System Parts, Conveyor System Components, Quality Control Fixtures, Custom Tooling

LED Heat Sinks, Fixture Housings, Reflector Components, Mounting Systems, Control Panel Housings

ATM Components, Vault Hardware, Card Reader Components, Safe Mechanisms, Kiosk Hardware

Wheel and Axle Systems, Brake Components, Bogie Components, Coupling Systems, Structural Elements

Propeller and Shaft Systems, Engine Components, Hull Fabrication, Navigation Equipment Housings, Deck Hardware

Why Choose Us as Your CNC Machining Service Provider?

With advanced CNC machining, 3D printing, silicone molding, rapid molding and injection molding, sheet metal processing, and various surface treatment technologies, we combine multiple processes and offer one-stop prototype and product processing services.

As your best CNC machining service provider, our professional team guarantees quick quotations and real-time tracking of order status.

Our well-established quality control system has led to our ISO 9001, ISO 14001, IATF 16949, and ISO 27001 certifications. Moreover, we strive to be the top choice for all your CNC machining needs through high customer satisfaction, high-quality products and competitive pricing.

Contact us today for a personalized pcb quotation or consultation. We look forward to partnering with you on your next project!

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Injection Molding FAQs

What is CNC Machining?

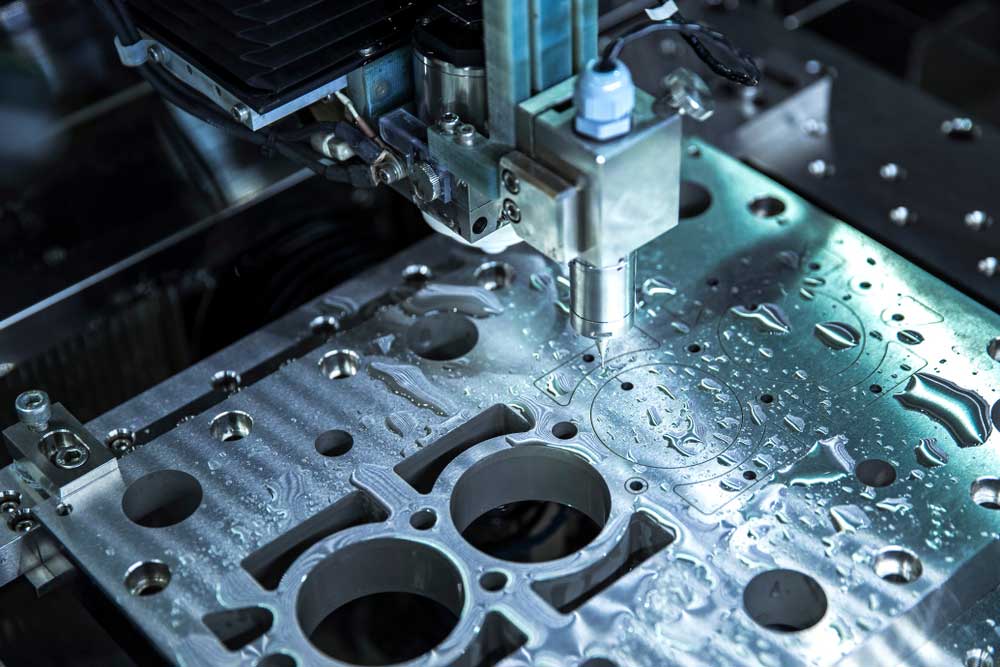

Computer numerical control (CNC) machining is a manufacturing process that dictates the movement of factory tools and machinery with pre-programmed computer software. This process can control a variety of complex machines, such as CNC millings, CNC lathes, CNC plasma cutting machines, CNC electric discharge machines (EDM), and printed circuit board fabrication 3D printers. It can produce parts and components with complex geometries and high accuracy for prototyping and low-to-high volume end-use.

CNC Machining vs. 3D Printing: What are the Differences?

CNC machining and 3D printing are both manufacturing technologies, but they have some key differences.

| CNC Machining | 3D Printing |

|---|---|

| Subtractive Manufacturing: It cuts away material from solid blocks to create the final shape | Additive Manufacturing: It adds materials layer by layer to form final products based on digital files |

| CNC machining can process various materials, including metals, plastics, wood, stone, and composite materials | Limited layering materials such as plastics (like PLA, ABS), resins, metals (like stainless steel, titanium), and ceramics |

| High precision and excellent surface finish | Lower accuracy and rougher surface finish compared to CNC machining |

| Suitable for both prototyping and large-volume production | Suitable for prototyping and producing small batches or personalized parts |

| Widely used in various industries such as aerospace, automotive, machinery, and mold making | Can manufacture models with complex shapes and unique structures, making it suitable for fields such as health care and artistic design |

| Higher initial setup costs but lower per-unit costs | Lower initial setup costs but higher per-unit costs |

However, the choice between CNC machining vs. 3D printing ultimately depends on your specific project requirements, such as component complexity, volume, and material properties.

If you’re unsure about whether to choose CNC machining or 3D printing for your project, reach out to us. We’ll help assess your specific requirements and provide expert advice on the best manufacturing method for your needs.

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree