Top 10 Classic Car Wiring Harness Manufacturers | Full Guide

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Are you looking for reliable, precision-driven PCB assembly services? OurPCB delivers industry-leading PCB component assembly with IPC-certified quality standards, advanced automation, and comprehensive inspection protocols. As a trusted PCB components assembly manufacturer, our China-based manufacturing facility combines cutting-edge technology with expert engineering support to deliver assembled PCB with components that meet your exact specifications.

PCB component assembly is the process of attaching electronic components to printed circuit boards to create functional electronic devices. This critical manufacturing stage transforms bare circuit boards into working electronic products through precise component placement and soldering operations. At OurPCB, we utilize both Surface Mount Technology (SMT) and Through-Hole Technology (THT) in our PCBA to accommodate all types of components and provide flexible assembly solutions for everything from prototype to high-volume production runs.

The assembly of components on PCB includes comprehensive Design for Assembly (DFA) verification, precision component placement, controlled soldering processes, and multi-stage inspection to ensure exceptional quality and reliability in your finished products. Our electronics PCB components assembly expertise ensures optimal performance for all your electronic manufacturing needs.

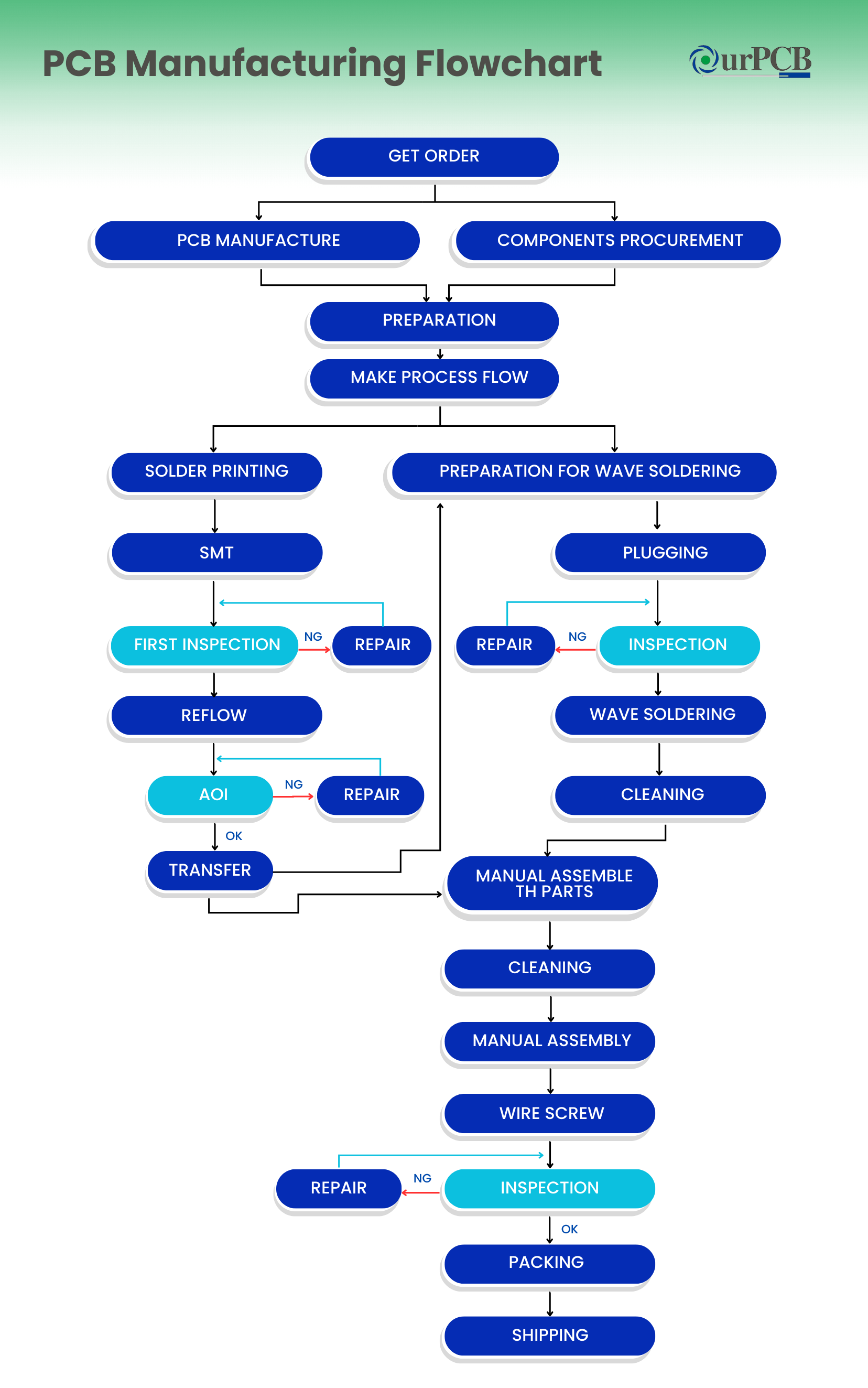

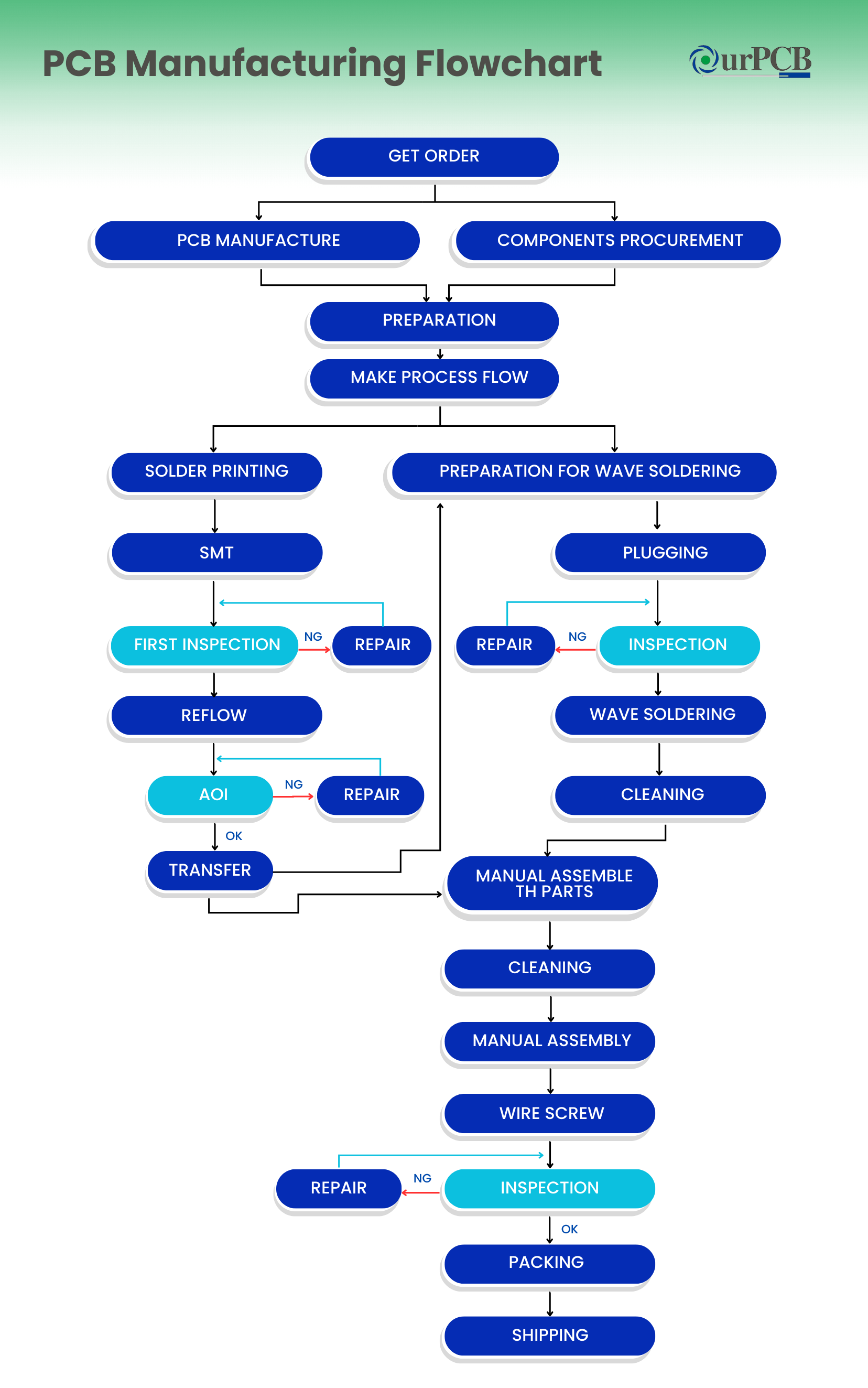

Our PCB components assembly process follows a systematic, quality-focused workflow designed to deliver exceptional results every time:

This comprehensive PCB assembly with components process ensures consistent quality, minimizes defects, and delivers fully functional electronic products that meet your specifications and timeline requirements. From solder paste application to wave soldering, every step receives meticulous attention.

This comprehensive PCB assembly with components process ensures consistent quality, minimizes defects, and delivers fully functional electronic products that meet your specifications and timeline requirements. From solder paste application to wave soldering, every step receives meticulous attention.

Our assembling components on PCB services provide significant advantages that directly impact your product quality, time-to-market, and overall success. We focus on delivering value through effective assembly at every stage of the process. Our efficient automated assembly processes accelerate your product development and manufacturing timeline. Additionally, we use a state-of-the-art PCB components assembly machine that handles even the most challenging assembly requirements with precision.

OurPCB stands apart from other PCB assembly companies through our commitment to quality, technical expertise, and customer-focused approach. As a leading supplier of PCB, we offer complete circuit assembly solutions with exceptional attention to detail at every stage. Our PCB assembly rotation component suppliers have been carefully vetted to ensure all components mounted on circuit boards meet stringent quality requirements.

As a contract manufacturer specializing in electronic manufacturing, we’ve invested in advanced assembly equipment that enables us to work with components such as resistors, capacitors, and integrated circuits with exceptional precision. Our PCB assembly rotation component factories utilize both automated processes and skilled manual techniques when assembling components on boards.

Our pick-and-place process achieves industry-leading component placement accuracy of ±0.015 mm, significantly exceeding IPC-9850 requirements. For ultra-miniature applications, we employ vacuum-assisted pick heads with optical centering verification to ensure precise alignment of 01005 and 008004 package sizes.

| Technology | Applications | Advantages | Capabilities |

|---|---|---|---|

| Surface Mount Technology (SMT) | High-density designs, Consumer electronics, Telecommunications equipment | Higher component density, Smaller finished PCB, Automated assembly | Surface mount components down to 01005 size, Fine-pitch BGAs, QFN packages |

| Through-Hole Technology (THT) | Industrial equipment, Power systems, High-reliability applications | Superior mechanical strength, Better performance in harsh environments | Through-hole components like connectors, transformers, large capacitors, DIP ICs |

| Selective Soldering | Mixed technology boards, High-reliability applications | Precise solder control, Reduced thermal stress | Programmed multipoint soldering, Component-specific parameters |

| Mixed Assembly | Complex electronic systems, Medical devices, Automotive electronics | Combines benefits of both SMT and THT, Optimal design flexibility | Simultaneous SMT/THT on single PCB, Complex component integration |

Our flexible technology enables our PCB components assembly factory to accommodate virtually any requirement, from simple single-sided boards to complex multilayer designs with both SMD components and plated through-hole components.

Quality is built into every stage of our PCB component assembly machine operations. We adhere to rigorous international standards to ensure consistent, reliable results in our PCB manufacturing process:

| Standard | Description | Implementation at OurPCB |

|---|---|---|

| IPC-A-610 | Acceptability of Electronic Assemblies | Class 2 (standard) and Class 3 (high-reliability) options available |

| IPC-J-STD-001 | Requirements for Soldered Electrical and Electronic Assemblies | Strict adherence to soldering quality requirements for all assembly types |

| IPC-7711/7721 | Rework, Modification, and Repair | Standardized procedures for any necessary rework operations |

| ISO 9001 | Quality Management System | Comprehensive quality management across all operations |

| ISO 14001 | Environmental Management System | Environmentally responsible manufacturing practices |

Our technicians are IPC-certified and regularly undergo skills verification to maintain exceptional workmanship standards across all projects. This commitment makes us a leading printed circuit board assembly electronic components’ provider in the industry.

Our PCB components assembly manufacturers capabilities extend from simple boards to the most complex electronic systems:

| Industry | Application Examples | Special Requirements Addressed |

|---|---|---|

| Consumer Electronics | Smart devices, Audio equipment, Home appliances | High-volume capacity, Cost-effective solutions |

| Industrial Controls | PLC systems, Motor controls, Sensor assemblies | Extended temperature ratings, Vibration resistance |

| Medical Devices | Patient monitoring, Diagnostic equipment, Implantable electronics | Class 3 quality standards, Enhanced cleanliness |

| Automotive | Engine control units, Infotainment systems, Safety components | Temperature cycling resistance, Conformal coating |

From prototypes to production, our scalable PCB fabrication and assembly capabilities accommodate virtually any electronic product requirement. Whether you need a simple PCB board or a complex two-sided PCB with a variety of components, we deliver superior results.

OurPCB offers a comprehensive range of PCB assembly services designed to meet a wide variety of project requirements. We emphasize accuracy, efficiency, and robust quality assurance in every assembly we deliver.

We are experts in Surface Mount Technology (SMT) assembly, making us the ideal choice for compact and high-performance electronics. Our use of advanced pick-and-place machinery ensures components are positioned with exceptional precision.

We provide flexible assembly solutions to match your preferences. You can supply your own components for assembly, or choose our turnkey service, where we handle everything from sourcing parts to assembling and delivering your finished boards.

Our custom PCB assembly service is tailored to your specific designs and requirements. We are equipped to manage complex layouts and specialized needs, working closely with you to guarantee your expectations are met.

We are dedicated to providing fast and dependable PCB assembly. Our quick turn service ensures you receive high-quality boards within short timeframes, all while maintaining strict quality standards.

We build PCBs to IPC Class 3 standards, which are essential for industries like aerospace and medical devices. Our Class 3 assemblies are engineered for maximum reliability in the most critical applications.

We have the expertise to assemble all types of integrated circuit (IC) packages, such as BGAs, POPs, CGAs, QFNs, DFNs, and CSPs. Our advanced technology allows us to handle even the most complex IC assemblies with precision.

Our PCB components assembly factories feature cutting-edge equipment that enables precise and reliable assembly outcomes. Our pick-and-place machines achieve component placement accuracy of ±0.025 mm, ensuring even the smallest components are positioned with exceptional precision onto the circuit board. The solder paste printing process utilizes laser-cut stencils with aperture control that delivers consistent solder volume for reliable connections. Our Type 4 solder paste (20-38μm particle size) provides superior printing consistency for ultra-fine pitch components compared to standard Type 3 pastes (25-45μm).

For effective assembly of complex boards, we employ multiple types of components assembly machines that handle everything from fine-pitch integrated circuits to plated through-hole components with specialized requirements. Our PCB assemblies feature both standard and custom solder profiles developed by our engineering team to match specific board designs and component thermal sensitivities. Our thermal profiling system employs K-type thermocouples with ±1.1 °C accuracy to maintain optimal reflow parameters across 8-12 distinct heating zones.

When components to be soldered require extra protection, our nitrogen-atmosphere reflow ovens minimize oxidation and enhance solder flow characteristics. Each step of PCB assembly in an automated environment undergoes real-time monitoring to maintain strict process control throughout the manufacturing cycle.

As a contract manufacturer specializing in electronic manufacturing, we’ve invested in advanced assembly equipment that enables us to work with components such as resistors, capacitors, and integrated circuits with exceptional precision. Our PCB assembly rotation component factories utilize both automated processes and skilled manual techniques when assembling components on boards.

Our pick-and-place process achieves industry-leading component placement accuracy of ±0.015 mm, significantly exceeding IPC-9850 requirements. For ultra-miniature applications, we employ vacuum-assisted pick heads with optical centering verification to ensure precise alignment of 01005 and 008004 package sizes.

| Technology | Applications | Advantages | Capabilities |

|---|---|---|---|

| Surface Mount Technology (SMT) | High-density designs, Consumer electronics, Telecommunications equipment | Higher component density, Smaller finished PCB, Automated assembly | Surface mount components down to 01005 size, Fine-pitch BGAs, QFN packages |

| Through-Hole Technology (THT) | Industrial equipment, Power systems, High-reliability applications | Superior mechanical strength, Better performance in harsh environments | Through-hole components like connectors, transformers, large capacitors, DIP ICs |

| Selective Soldering | Mixed technology boards, High-reliability applications | Precise solder control, Reduced thermal stress | Programmed multipoint soldering, Component-specific parameters |

| Mixed Assembly | Complex electronic systems, Medical devices, Automotive electronics | Combines benefits of both SMT and THT, Optimal design flexibility | Simultaneous SMT/THT on single PCB, Complex component integration |

Our flexible technology enables our PCB components assembly factory to accommodate virtually any requirement, from simple single-sided boards to complex multilayer designs with both SMD components and plated through-hole components.

Quality is built into every stage of our PCB component assembly machine operations. We adhere to rigorous international standards to ensure consistent, reliable results in our PCB manufacturing process:

| Standard | Description | Implementation at OurPCB |

|---|---|---|

| IPC-A-610 | Acceptability of Electronic Assemblies | Class 2 (standard) and Class 3 (high-reliability) options available |

| IPC-J-STD-001 | Requirements for Soldered Electrical and Electronic Assemblies | Strict adherence to soldering quality requirements for all assembly types |

| IPC-7711/7721 | Rework, Modification, and Repair | Standardized procedures for any necessary rework operations |

| ISO 9001 | Quality Management System | Comprehensive quality management across all operations |

| ISO 14001 | Environmental Management System | Environmentally responsible manufacturing practices |

Our technicians are IPC-certified and regularly undergo skills verification to maintain exceptional workmanship standards across all projects. This commitment makes us a leading printed circuit board assembly electronic components’ provider in the industry.

Our PCB components assembly manufacturers capabilities extend from simple boards to the most complex electronic systems:

| Industry | Application Examples | Special Requirements Addressed |

|---|---|---|

| Consumer Electronics | Smart devices, Audio equipment, Home appliances | High-volume capacity, Cost-effective solutions |

| Industrial Controls | PLC systems, Motor controls, Sensor assemblies | Extended temperature ratings, Vibration resistance |

| Medical Devices | Patient monitoring, Diagnostic equipment, Implantable electronics | Class 3 quality standards, Enhanced cleanliness |

| Automotive | Engine control units, Infotainment systems, Safety components | Temperature cycling resistance, Conformal coating |

From prototypes to production, our scalable PCB fabrication and assembly capabilities accommodate virtually any electronic product requirement. Whether you need a simple PCB board or a complex two-sided PCB with a variety of components, we deliver superior results.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Surface Mount Technology (SMT) involves placing components directly onto the surface of the PCB with solder paste and reflow soldering, allowing for higher component density and automated assembly. Through-Hole Technology (THT) involves inserting component leads through pre-drilled holes and soldering on the opposite side, creating stronger mechanical connections ideal for components subjected to mechanical stress.

We implement specialized high-temperature assembly processes for applications operating in elevated temperature environments. This includes using high-temperature solder formulations with melting points above 280 °C, selecting components with appropriate temperature ratings, and applying thermal management techniques like strategic component placement and enhanced copper pour designs for effective heat dissipation.

We employ real-time X-ray inspection systems that examine hidden solder joints, identifying issues like voiding, bridging, or insufficient solder. This is complemented by thermal profile analysis during reflow and In-Circuit Testing (ICT) for electrical verification. For critical applications, we can also perform dye-and-pry tests on representative samples.

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree