Top 7 Truck Wiring Harness Manufacturers

Truck wiring harnesses are the electrical backbone of commercial vehicles, from long-haul trucks to construction fleets and emergency vehicles. They must withstand continuous vibration, thermal

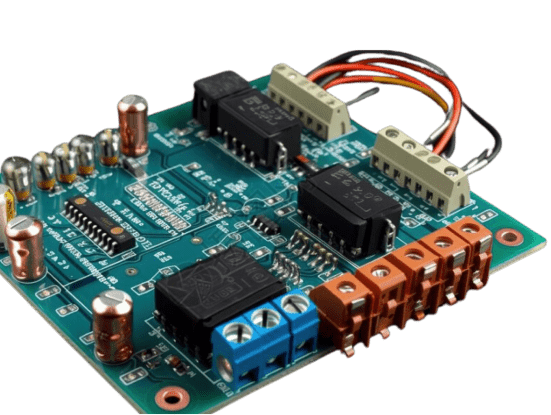

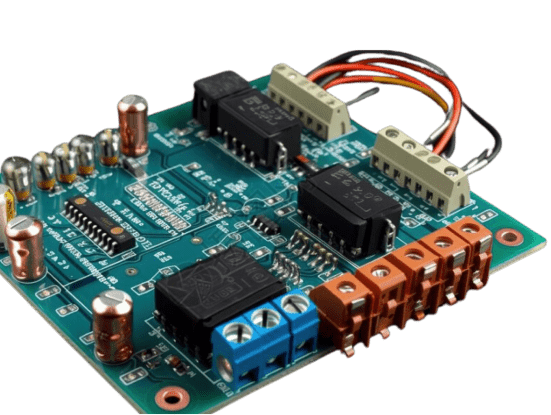

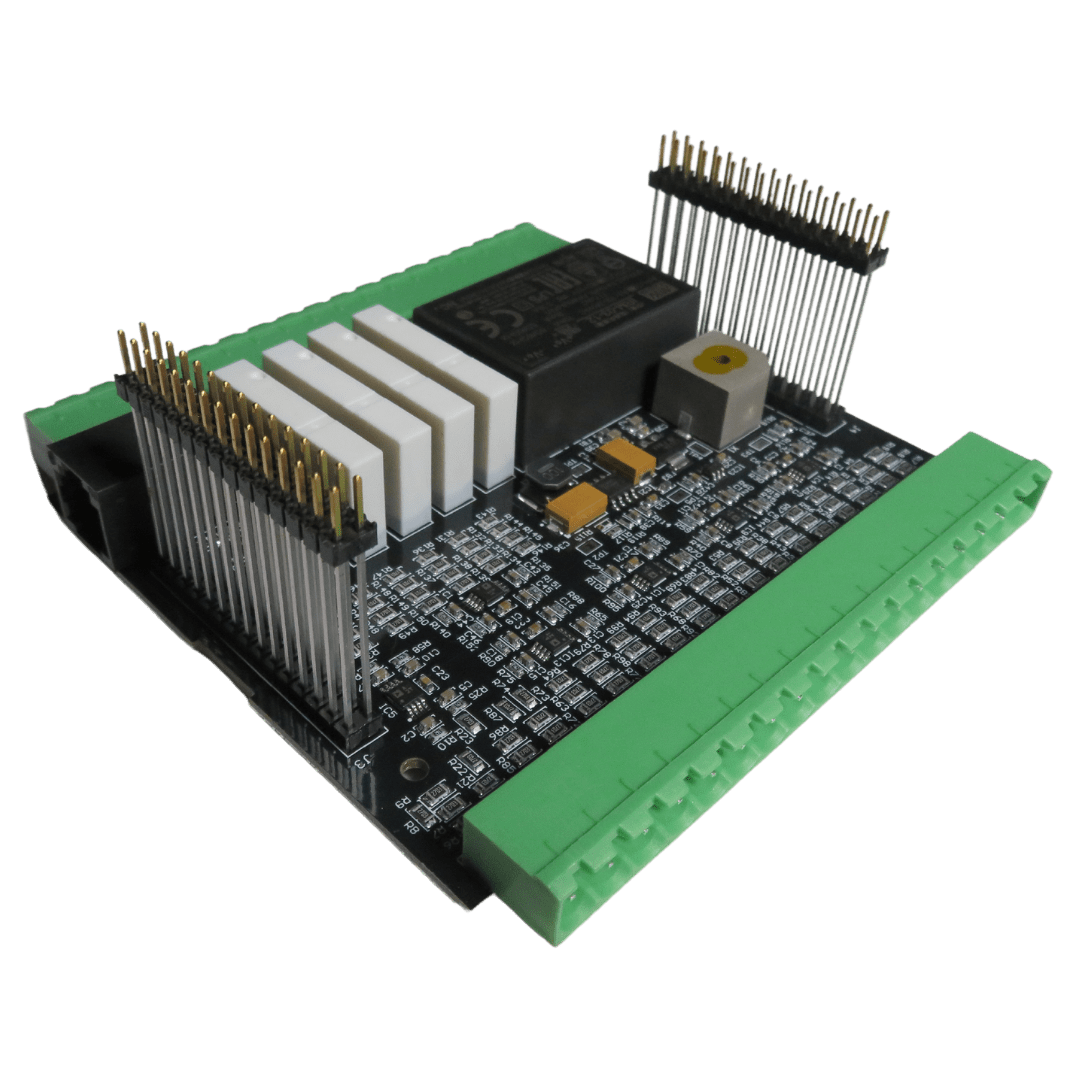

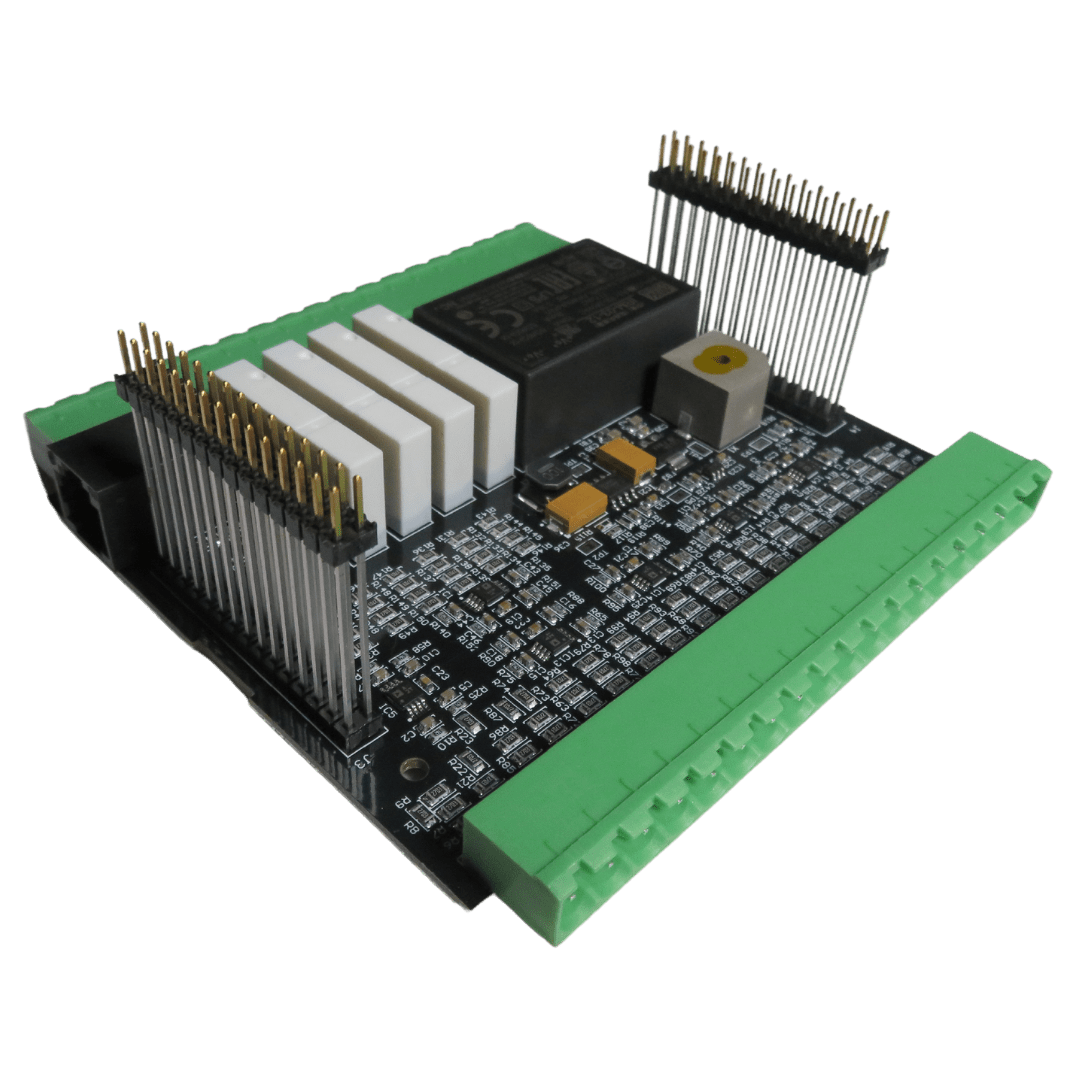

At OurPCB, we offer high-quality PCB prototype services with up to 50 layers, available in 5, 10, and 20 units. As a trusted PCB manufacturer from China, we serve customers worldwide, including the USA, delivering reliable and precise PCB assembly solutions tailored to your electronic needs.

A specific grade of combined fiberglass and reinforced epoxy laminate.

A synthetic polymer, known for its high tensile strength, flexibility, and durability.

A family of high-performance laminate materials.

Made of woven glass fabric surfaces and a non-woven glass core, bonded together with an epoxy resin binder.

Used in conductive traces and planes, as well as heat management.

A dielectric material used to bind and insulate the copper layers within a multilayer PCB.

China PCB services offer a cost-effective approach. We provide rapid prototyping and diverse capabilities, allowing for quick design iteration and testing.

Choosing a China prototype PCB service can speed up development and lower your overall expenses. These services offer a wide range of options, helping you meet specific project needs.

| Quantity: 5 | 50 cm² | 100 cm² | 200 cm² | 400 cm² | 600 cm² |

|---|---|---|---|---|---|

| 1-Layer | $17 | $21 | $26 | $36 | $46 |

| 10-Layer | $259 | $279 | $308 | $359 | $412 |

Your final cost will depend on how many PCB prototypes you need. Request a free online pcb quote for your prototype project now. New customers get $100 off their first project with us!

| Number of Layers | Number of Days |

|---|---|

| 1-12 layers | within 72 hours |

| 12+ layers | within 120 hours |

Lead time may extend depending on the quantity of PCB orders. Contact us today for a free quote to get an accurate estimation of the lead time you can expect.

Provide us with your Gerber file for a custom quote.

Our experts will analyze your design and suggest changes if necessary.

We’ll send you a final quote for approval before we go ahead with the production process.

Once approved, we’ll begin manufacturing your PCB prototype.

Our rapid turnaround services and our trusted courier partners will get you your sample in record time.

| Quantity: 5 | 50 cm² | 100 cm² | 200 cm² | 400 cm² | 600 cm² |

|---|---|---|---|---|---|

| 1-Layer | $17 | $21 | $26 | $36 | $46 |

| 10-Layer | $259 | $279 | $308 | $359 | $412 |

Your final cost will depend on how many PCB prototypes you need. Request a free online pcb quote for your prototype project now. New customers get $100 off their first project with us!

| Number of Layers | Number of Days |

|---|---|

| 1-12 layers | within 72 hours |

| 12+ layers | within 120 hours |

Lead time may extend depending on the quantity of PCB orders. Contact us today for a free quote to get an accurate estimation of the lead time you can expect.

Provide us with your Gerber file for a custom quote.

Our experts will analyze your design and suggest changes if necessary.

We’ll send you a final quote for approval before we go ahead with the production process.

Once approved, we’ll begin manufacturing your PCB prototype.

Our rapid turnaround services and our trusted courier partners will get you your sample in record time.

A prototype is the ideal way to detect and fix errors before full-scale production. Creating and testing a batch of 5 to 20 products is much more cost-effective than producing hundreds or thousands without realizing there’s a flaw. Addressing these issues early prevents performance problems and ensures the final product meets quality standards.

Prototyping allows engineers to validate the design and ensure all components interact correctly. Any discrepancies between expected and actual behavior can be identified and resolved early. This process optimizes functionality, reduces the risk of defects, and improves overall product reliability.

Fixing errors at the prototype stage speeds up production. Even going through several iterations of prototype PCBs is faster than discovering flaws during large-scale manufacturing. A streamlined development process allows businesses to launch their products sooner and start generating revenue faster.

By catching errors early, prototypes help prevent costly mistakes in mass production. Fixing issues at this stage is much cheaper than recalling and reworking faulty products later. While multiple iterations may seem like an extra cost, they ensure high-quality, optimized products that perform reliably under real-world conditions.

Low-volume prototype PCB production allows for quick design modifications without wasting valuable time or resources. Engineers can refine product features, test new ideas, and make necessary adjustments on the go. This flexibility enhances innovation and ensures that the final product meets market demands.

Taking the time to prototype and optimize before going to market gives companies a competitive edge. Businesses that prioritize quality over speed can avoid costly mistakes, build a better reputation, and allocate savings toward marketing or product enhancements. In a competitive industry, early testing and refinement can be a game-changer.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

PCB prototyping is the process of creating a preliminary version of a printed circuit board to test its functionality and design. This prototype allows engineers to identify and rectify any issues before the final production run.

After prototyping, the next steps typically include:

Truck wiring harnesses are the electrical backbone of commercial vehicles, from long-haul trucks to construction fleets and emergency vehicles. They must withstand continuous vibration, thermal

Medical cable assemblies sit at the intersection of electrical safety, biocompatibility, and sterilization durability. For regulated medical devices, OEMs must work with manufacturers that understand

Robotics cable assemblies are unlike ordinary cables, they must survive continuous motion, tight bend radii, torsion, vibration, electrical noise, and often harsh industrial or outdoor

Waterproof cable assemblies have to do more than just “keep water out.” For outdoor, marine, industrial washdown, and transportation platforms, assemblies are expected to survive

Aerospace cable assembly manufacturers work under standards such as AS9100, ISO 9001, and RTCA/DO-160, and many also maintain ITAR registration to support flight-critical and space-qualified

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree