Top 7 Truck Wiring Harness Manufacturers

Truck wiring harnesses are the electrical backbone of commercial vehicles, from long-haul trucks to construction fleets and emergency vehicles. They must withstand continuous vibration, thermal

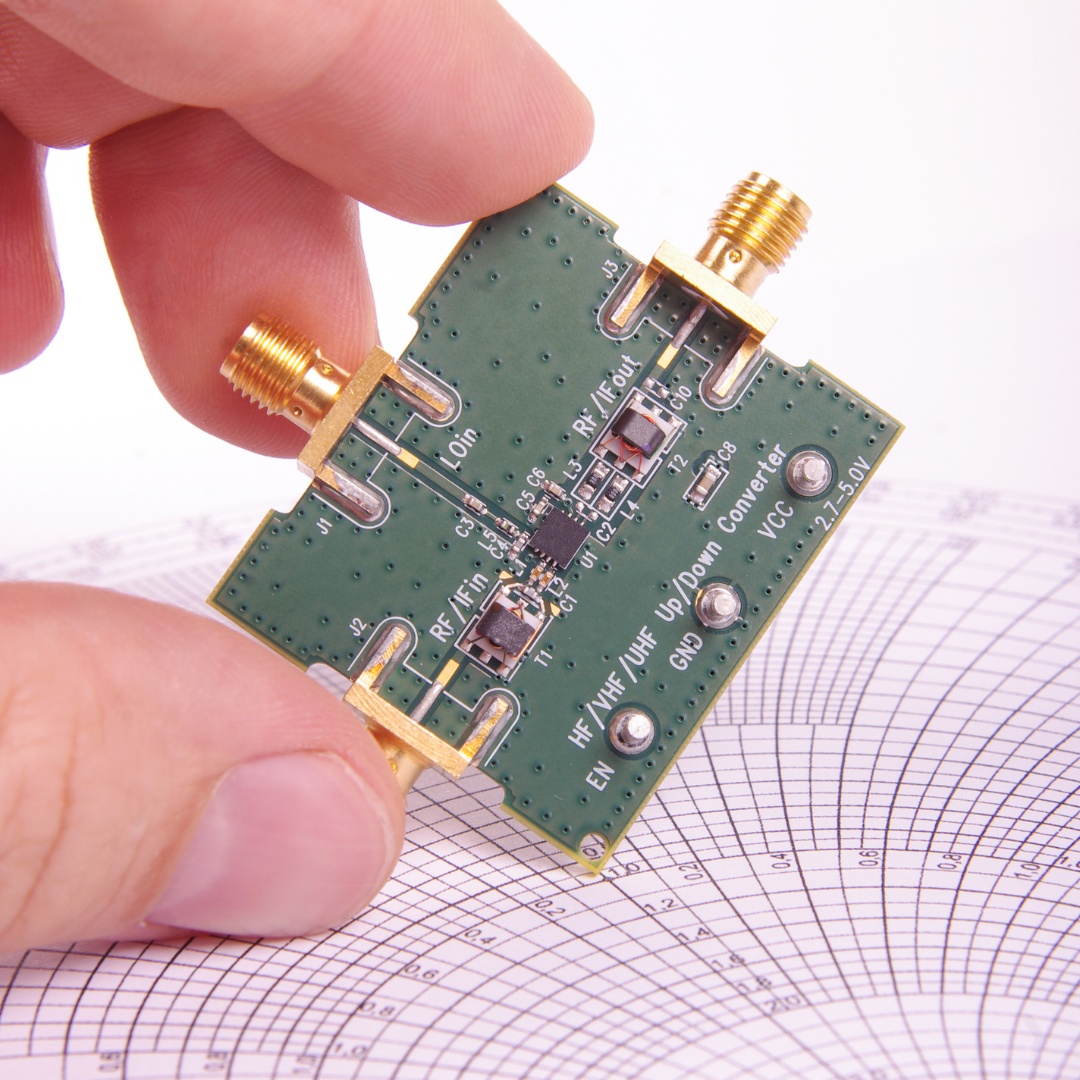

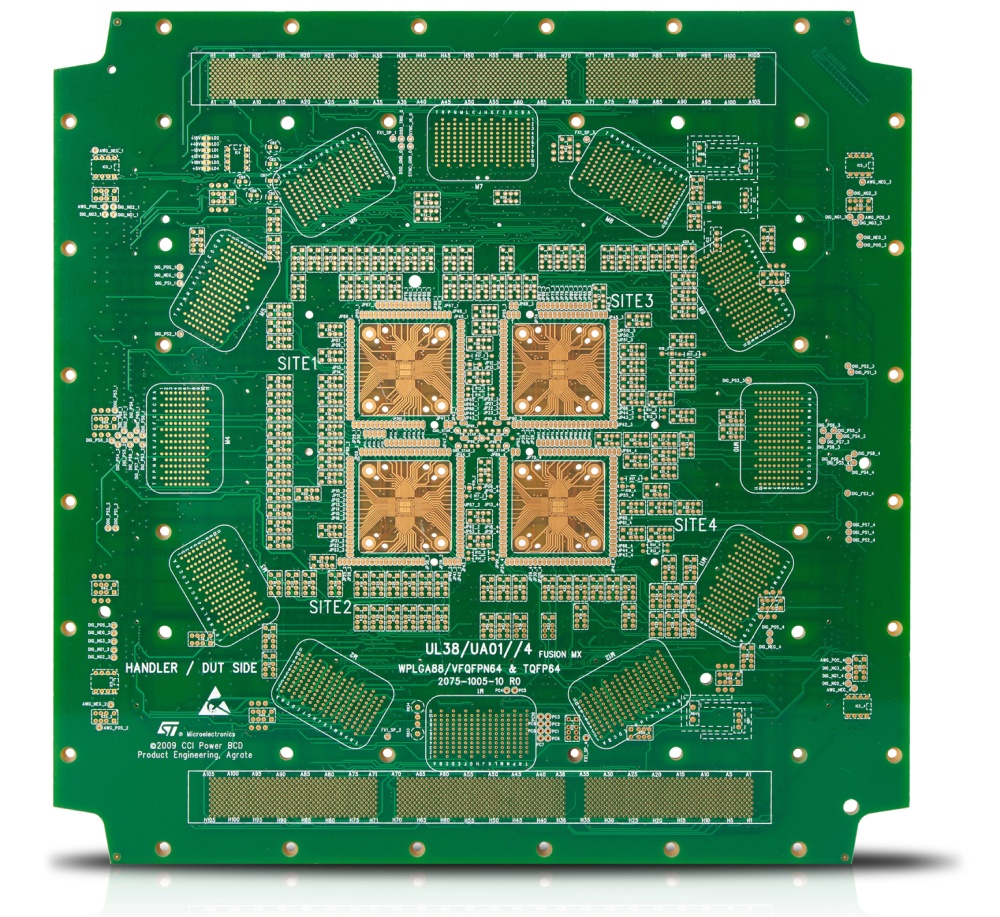

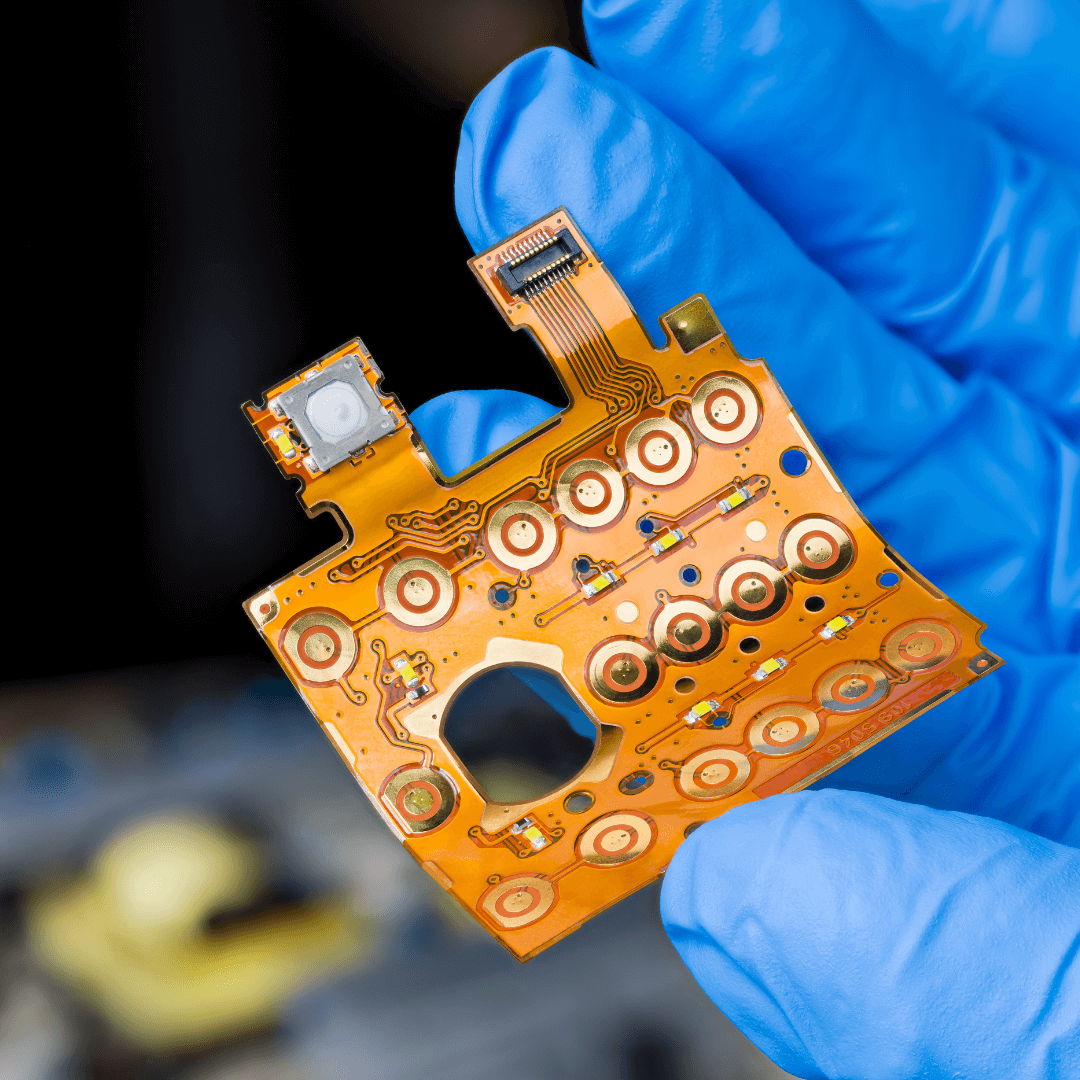

PCB reverse engineering is the process of analyzing and recreating circuit board designs. It involves extracting schematics, layouts, and component data from existing PCBs. OurPCB offers expert PCB reverse engineering services in China, helping clients recreate or improve circuit designs efficiently.

PCB reverse engineering in China involves analyzing physical circuit boards to extract their design information. This process includes examining board layers, tracing connections, and identifying components. Skilled engineers use specialized tools and software to recreate accurate schematics and layouts.

China’s PCB reverse engineering industry has grown rapidly due to its strong electronics manufacturing base. Many companies, like OurPCB, offer advanced reverse engineering services. These firms combine technical expertise with cost-effective solutions, making China a global hub for PCB reverse engineering projects.

OurPCB offers top-notch PCB reverse engineering services in China. Our team combines technical skills with industry experience to deliver accurate results. Here are the key benefits of choosing us:

PCB reverse engineering in China offers unique advantages for businesses worldwide. It combines technical expertise with cost-effective solutions. Here’s why China stands out:

OurPCB offers comprehensive PCB assembly services to complement our reverse engineering expertise. We ensure high-quality production of recreated or modified designs. Our services include:

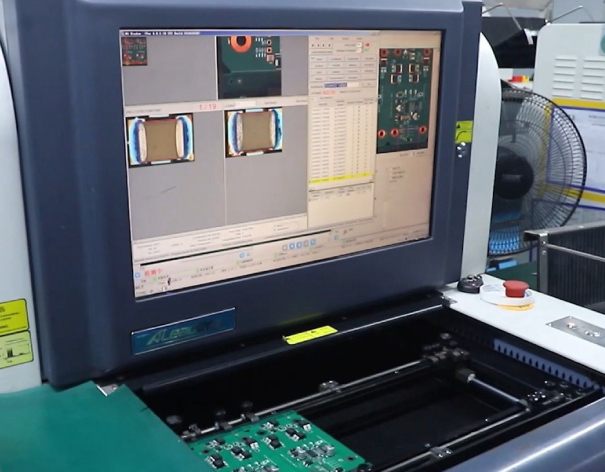

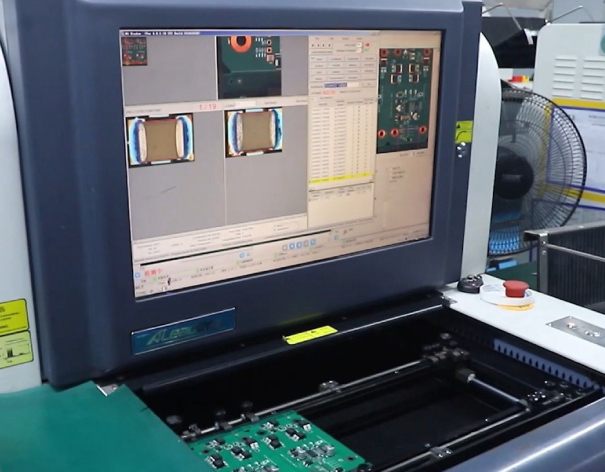

We use Surface Mount Technology for compact and high-performance PCB assembly. Our SMT process ensures precise component placement and soldering.

We offer flexible options for PCB assembly. We can work with your supplied components or provide full turnkey solutions, handling sourcing and assembly.

Our team delivers tailored assembly services to meet unique project needs. We adapt our processes to accommodate special designs or requirements.

We provide fast PCB assembly services without compromising quality. Our efficient processes ensure quick turnaround times for urgent projects.

We adhere to strict IPC Class 3 standards for high-reliability PCB assembly. This service is ideal for aerospace, medical, and other critical applications.

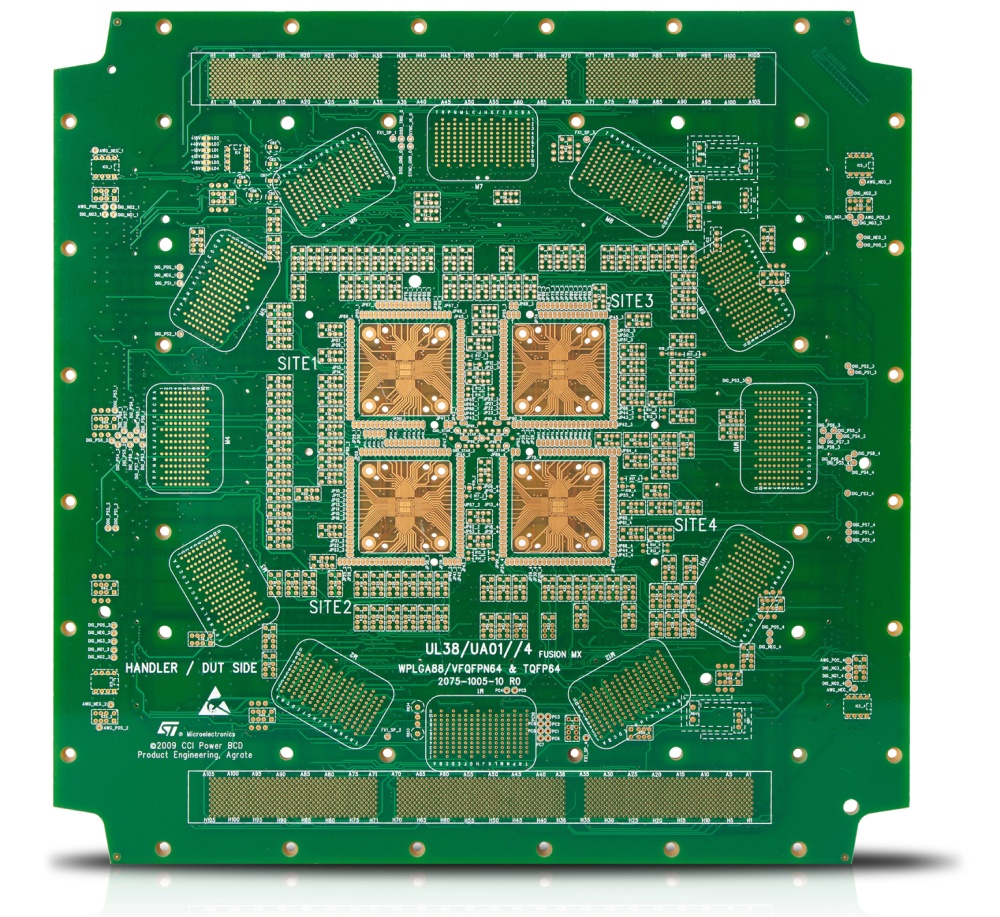

We handle assembly for all types of IC packages. Our expertise covers BGAs, QFNs, CSPs, and other complex package types.

OurPCB boasts advanced technical capabilities for PCB reverse engineering. We use high-resolution X-ray systems and 3D scanning technology for detailed board analysis. Our software suite includes industry-standard tools for schematic capture and PCB layout recreation. We can handle boards up to 50 layers and work with various PCB materials. Our team is skilled in decoding complex circuits and identifying obsolete components.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

A PCB copy can replicate an original PCB design, using engineering files. However, slight variations can occur during PCB manufacturing, despite using precise Gerber file inputs. The PCB board may differ slightly from the original PCB due to production limitations. Multilayer and PCB module specifics can affect PCB production accuracy.

The reverse engineering process uncovers the PCB schematic diagram, BOM list, and design. It helps understand the original PCB functionality for future PCB design improvements. It also enables IC unlock to modify or improve the electronic product. Reverse engineering allows accurate replication of similar or new board designs.

A physical PCB sample is typically not reusable due to potential wear during PCB service. However, the PCB file or Gerber file can be reused for PCB production. In some cases, a multilayer PCB may be reworked or modified for use. Engineering files are crucial for evaluating the reusability of a PCB board.

Truck wiring harnesses are the electrical backbone of commercial vehicles, from long-haul trucks to construction fleets and emergency vehicles. They must withstand continuous vibration, thermal

Medical cable assemblies sit at the intersection of electrical safety, biocompatibility, and sterilization durability. For regulated medical devices, OEMs must work with manufacturers that understand

Robotics cable assemblies are unlike ordinary cables, they must survive continuous motion, tight bend radii, torsion, vibration, electrical noise, and often harsh industrial or outdoor

Waterproof cable assemblies have to do more than just “keep water out.” For outdoor, marine, industrial washdown, and transportation platforms, assemblies are expected to survive

Aerospace cable assembly manufacturers work under standards such as AS9100, ISO 9001, and RTCA/DO-160, and many also maintain ITAR registration to support flight-critical and space-qualified

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree