China Custom Cable Assembly Manufacturer

✅ 15+ years of experience

✅ ISO 9001 and IATF 16949 certified

✅ One-stop wiring harness shop

✅ 12-hour quotations

Looking for Custom Cable Assemblies from China?

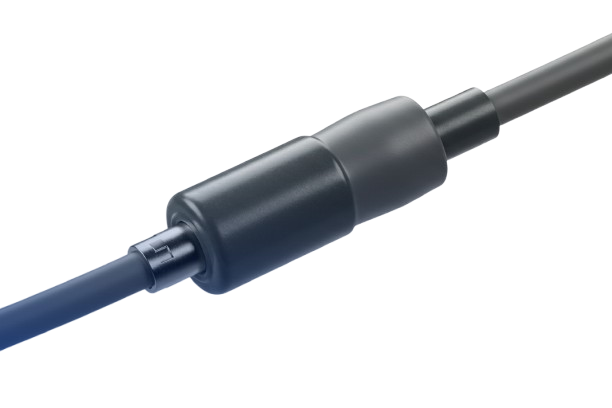

OurPCB is a China Custom Cable Assembly Manufacturer specializing in custom designs, cable harnesses, and waterproof assemblies for industries like automotive, EV, and robotics. We provide high-quality solutions and reliable service to customers in the USA and globally.

OurPCB is proud to own Cloom Tech, a professional custom cable assemblies company. Our ISO-certified factory has been in business for more than 2 decades and can handle all your commercial or personal cable needs under one roof.

We offer a wide range of customized cable services, hybrid cables, and harnesses. For quick cost estimates, you can request an online cable assembly quote, making it easy to get pricing based on your specific requirements.

If you’re looking for off-the-shelf cable assemblies for a fast turnaround, we also stock a wide inventory of high-speed, ready-manufactured cable assemblies for your every need.

Our Custom Cable Services

Tailored cable solutions for your unique needs

Expert craftsmanship for reliable connections

Organized wiring for efficient systems

Combining power and data transmission seamlessly

Rigorous testing for peace of mind

Off-the-shelf solutions for quick turnaround

Premium materials for optimal performance

All your cable needs met under one roof

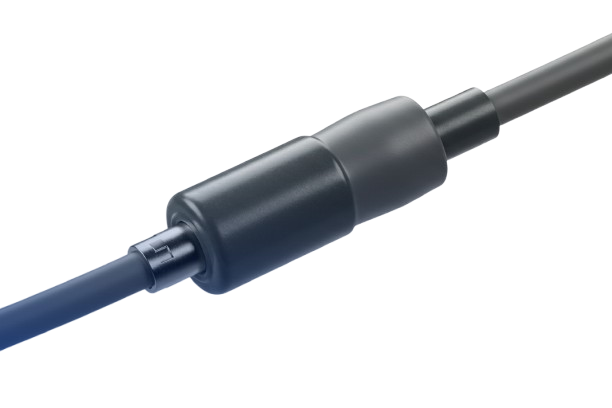

Durable protection against the elements

Enhanced strain relief and durability

Strengthening cables for extended lifespan

Precision manufacturing for superior quality

Why Choose Our Custom Cable Assembly Solutions?

Our highly skilled team have crafted thousands of custom cable assemblies over their decades of experience.

Our factory has been in business for over 20 years, uses advanced technology, and meets all industry certifications.

Our computer-aided design services allow us to create your product to meet your every request.

Whatever you need, we’ll manufacture and assemble it for you. Fully customizable to meet your requirements.

Our custom cable assemblies are competitively priced and built to last.

Fast, free quoting means we can get started on your project as soon as possible.

- 15+ Years of Experience

Our team has extensive experience creating both standard and custom wiring harnesses.

- Competitive Pricing

Well-priced and payable via PayPal, bank transfer, Western Union, or Moneygram.

Our Custom Cable Capabilities

Only ROHS-compliant materials

Orange or OEM color

TUV, ISO9001, T/S16949, ROHS-approved

Prototypes can be provided for assessment

Small quantities accepted

100% TT or PayPal for convenience

As fast as possible based on production capacity

Custom Cables vs. Standard Cables

Custom cable assemblies are designed and manufactured to meet the exact needs of the project or application. They are not universal, one-size-fits-all solutions – they are tailored to fit unique needs.

Standard cables come in predetermined lengths and wiring configurations. This is ideal if you know exactly what you’re looking for, or if you want to match other cables you’re currently using, but it’s limiting if you require more creative cabling options.

Here’s why custom cables could be the better choice for many applications, including military, telecommunications, medical, automotive, industrial, and consumer electronics.

Unlike standard cables, which come in set sizes and configurations, custom cables allow you to choose the exact length, connector types, wire gauge, shielding, and other features you want. Custom cables also get rid of unnecessary components, saving you money and reducing clutter.

By using high-quality materials and construction methods, custom cable assemblies can give you better signal integrity, reduced interference, and better durability than standard cables. This ensures better performance and reliability, as well as less chance of failure.

With custom lengths and connectors, cables can be routed more efficiently, minimizing excess cable length and reducing the risk of tangles or damage. This can be especially handy in tight spaces or in applications where cable management is key.

While the cost of custom cables may be higher than standard cables, they can end up being more cost-effective over time. Their performance, reliability, and longevity can reduce the need for replacements and repairs, so you don’t spend too much in the future.

Working with a reputable custom cable manufacturer can streamline your production process. They often provide faster turnaround times for a new product compared to sourcing standard cables, which may have longer lead times or need modifications.

Millions of business and innovators use OurPCB

The Custom Cable Assembly Process

Our process begins with a comprehensive consultation to fully understand your project’s specific needs. We collaborate closely with you to gather detailed information on the application, environment, electrical requirements, desired features, and any unique challenges.

Based on the information gathered, our experienced engineers create your cable design and select materials, connectors, and components that meet your performance and budget requirements. We then produce a prototype for your review and approval.

If necessary, we’ll reach out to our trusted suppliers to source the best quality components for your design. We’re proud to work with some of the most renowned suppliers, ensuring quality components for best performance.

Our state-of-the-art manufacturing facility employs skilled technicians and advanced equipment to assemble your custom cables with precision and care. We follow strict quality control standards throughout the process. Rigorous testing, including electrical, mechanical, and environmental tests, is performed on each cable for quality assurance.

We’re committed to delivering your custom cable assemblies with speed and within budget. We offer flexible shipping options to meet your needs and provide ongoing customer support to address any questions or concerns that may arise. Our goal is to build a long-lasting relationship with you and provide reliable cable solutions for your future projects.

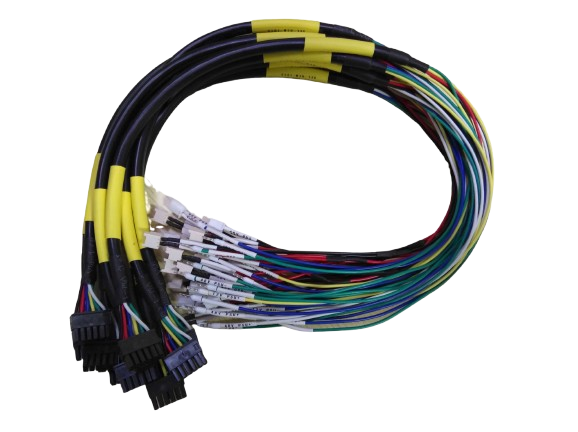

Our Products

As a custom cable assembly manufacturer, we design and produce all manner of high-quality cable configurations. Here are some of the selection of some of the cable and connector products in our wide range.

Our Custom Cable Assembly Production Facilities

Our wire and cable production factory is based in China, which keeps the highest quality standards while maintaining low costs. Our ISO-certified factories have been operating for over 20 years, and employ staff with high levels of expertise. When you buy custom cables from us, you’re getting the best.

More Custom Cable Assembly Manufacturing Services

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Custom Cable Assembly Manufacturer FAQs

What Types of Custom Cable Assemblies Can You Create?

We can manufacture and assemble a diverse range of cable types, including coaxial, multi-conductor, electrical and fiber optic pigtail, flat, high-flex, ribbon, and more. We also offer custom connectors including standard, proprietary, and military connectors.

How Long Do Custom Cable Assemblies Take?

Custom cable assembly lead time can vary based on a variety of different factors. The more complex the design, the longer it will take to create. In the same vein, the higher the quantity you order, the longer it will take to fulfill that order.

In some cases, choosing specific materials may add time to your order if we need to source them from specific suppliers. Generally, simple projects could be completed in a few days, while more complicated projects could take as much as several weeks.

How Much Do Custom Cable Assemblies Cost?

The cost of customized cables can also vary depending on numerous factors. The type of cable and connectors, how long you want the cable to be, the materials you want to use, and the complexity of the cable assembly can all add time.

The only way to get an accurate idea of how much your custom cable design may cost is to request a free quote. We’ll be able to analyze your design and give you an as-accurate-as-possible estimation for your project.

What is your production capacity?

We can handle small orders as well as large-scale production requirements without compromising on quality. No order is too big or too small.

What’s the difference between custom wire harness assembly and cable assembly?

Wire harnesses focus on organization, bundling wires with ties, tape, or sleeves for controlled environments. Cable assemblies provide robust protection with a durable outer jacket, shielding wires from moisture, heat, and friction in demanding conditions. When selecting solutions for your specific application, partnering with an experienced custom wiring harness manufacturer ensures you get the right assembly type designed for your environmental and performance requirements.