Making wire harnesses isn't complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process, we've simplified it to just 7 steps.

Our factory in China handles both PCB assembly and cable harness manufacturing in one place. This means we have the capacity to take care of your entire electronic project while making sure each individual wire connection works perfectly. Let’s dive into how we’ve mastered this process.

Contents

- Key Takeaways

- What's a Wire Harness?

- Why Quality Matters in Wire Harnesses

- Our 7-Step Wire Harness Making Process

- Step 1: Design & Planning

- Step 2: Wire Preparation

- Step 3: Adding Terminals & Connectors

- Step 4: Assembly & Routing

- Step 5: Adding Protection

- Step 6: Testing

- Step 7: Packaging & Shipping

- Materials We Use for Wire Harnesses

- Wire Types

- Insulation Materials

- Connector Types

- How We Ensure Quality

- Industries That Need Custom Wire Harnesses

- Automotive

- Medical Equipment

- Industrial Machinery

- Ready for Your Wire Harness Project?

- Frequently Asked Questions

- What is the standard for wire harness manufacturing?

- What is a 7 wire harness?

- How do environmental factors affect wire harness design?

Key Takeaways

- Our 7-step wire harness production process meets all industry standards

- Every wire harness assembly gets full electrical continuity testing

- We help select the right type of wire for your specific needs

- Save money with our combined PCB and wire harness manufacturing

What's a Wire Harness?

A wire harness is a bundle of wires that carry electrical power and signals. Wire harnesses work much better than loose wires. We use design tools to create wiring diagrams showing exactly where everything connects.

The main harness components include wire, insulation, terminals, connectors, and protective coverings. Each part keeps your electrical connection points working properly.

Why Quality Matters in Wire Harnesses

Poor wire harnesses cause expensive problems. Good quality wire harness production prevents electrical failures that cost money and create safety hazards. The manufacturing process ensures we use the right wires, make solid electrical connections, and protect against electrical interference. This stops shorts, opens, and loose contacts.

Pre-made wire harnesses make installation faster. The wire harness assembly process creates units that install quickly and consistently. You save labor costs and avoid mistakes.

Quality becomes critical for specialized equipment. Medical devices, automotive wiring, and factory controls need reliable performance, making proper cable and wire harness production essential.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

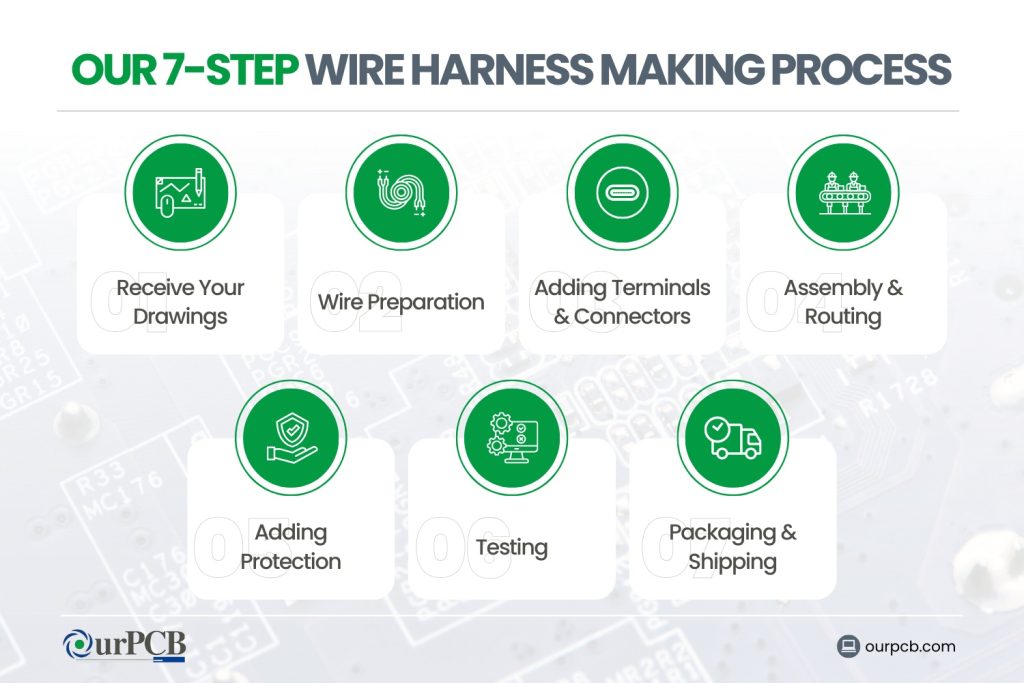

Our 7-Step Wire Harness Making Process

We've perfected our wire harness production process through years of experience. Each step builds on the last one to create reliable, high-quality products. The pros say that the wire harness market is probably going to grow to around 147.5 billion US dollars by 2034. That's a huge market, and that's why the process matters! Here's how we turn individual wires into professional wire harness assemblies:

Step 1: Design & Planning

After receiving your detailed drawings and fabrication instructions, we will review them and then begin sourcing the necessary materials if there is no problem.

We can assist with selection and provide alternatives, and customize connectors and cables.

We consider:

- Power needs (voltage, current)

- Environment conditions (temperature, moisture, vibration)

- Space constraints

- Connector types

- Safety regulations

Step 2: Wire Preparation

We cut wires using specialized wire cutting and stripping machines with 1 mm precision. We strip wire ends carefully to preserve the metal conductor. Our automated wire cutting equipment adjusts for different wire thickness and insulation types.

We identify wires with colors, labels, or heat-shrink markers. This helps with assembly and future maintenance or troubleshooting.

Step 3: Adding Terminals & Connectors

The crimping process connects terminals to wires using techniques that create secure electrical connections. Our assembly services follow strict standards with specific measurements for each wire/terminal combination. We monitor crimping force in real-time.

For quality control checks, we examine sample crimps by cutting them in half. This shows how wire strands and terminal metal connect internally.

We test all crimped connections with pull testing:

| Wire Size (AWG) | Required Strength (N) |

|---|---|

| 22 | 40 |

| 20 | 60 |

| 18 | 90 |

| 16 | 135 |

| 14 | 200 |

Step 4: Assembly & Routing

We arrange wires according to design specifications using special fixtures. These assembly systems keep wires in the correct position. Our technicians follow the diagram exactly for all paths and branch points.

We:

- Bundle main wires together

- Create branches where needed

- Add strain relief at connectors

- Separate different signal types

This process ensures signal types stay separated to prevent interference. Critical signal wires receive extra protection.

Step 5: Adding Protection

We protect wire bundles from damage with several methods. We add heat shrink tubing at connection points to prevent strain and keep moisture out. We also use:

- Plastic tubing for physical protection

- Braided sleeving to prevent wear

- Waterproof heat shrink

- Shielding materials for sensitive circuits

For high-vibration equipment, we secure the wire harness with cable ties, tapes, or adhesives to prevent movement.

Step 6: Testing

We test every wire harness thoroughly. The completed harness is inspected with several methods:

| Test Type | Method | Purpose |

|---|---|---|

| Continuity | Resistance measurement | Verify connections work |

| Isolation | Circuit resistance testing | Find potential shorts |

| High-Voltage | 1,000+ volt application | Test insulation |

| Pull Testing | Mechanical force | Verify crimp strength |

| Visual Inspection | Standards comparison | Check workmanship |

For critical applications, we perform environmental testing including temperature cycling (-40 °C to +125 °C), humidity exposure, and vibration testing.

Step 7: Packaging & Shipping

We package the final harness carefully for safe shipping and storage using:

- Custom trays for complex shapes

- Anti-static bags for electronics

- Edge protectors for connectors

- Sealed packaging for moisture protection

Each wire harness includes identification labels with part numbers and tracking information. We provide complete documentation, including test reports and certifications.

Materials We Use for Wire Harnesses

We select materials based on your specific application:

Wire Types

- Copper (standard choice)

- Tinned copper (better corrosion resistance)

- Silver-plated copper (for high-frequency applications)

- Stranded wire (flexible, resists vibration)

- Solid core (for tight spaces)

Insulation Materials

| Material | Temperature Range | Best Uses |

|---|---|---|

| PVC | -20 °C to +105 °C | General use, flame resistant |

| PE | -55 °C to +125 °C | Chemical resistance, low smoke |

| PTFE | -65 °C to +260 °C | High heat, chemical resistant |

| Silicone | -55 °C to +200 °C | Flexible, medical applications |

| Kapton | -269 °C to +400 °C | Aerospace, extreme temperatures |

Connector Types

- Standard connectors (Molex, TE Connectivity, JST)

- Automotive connectors (Deutsch, Delphi)

- Military connectors (MIL-DTL-38999, MIL-DTL-26482)

- Specialized connectors for medical, industrial, aerospace

How We Ensure Quality

We ensure wire harnesses meet quality standards through comprehensive quality systems. Harness manufacturers like us use special analysis methods to catch problems before production starts.

Our quality control includes:

- Checking materials on arrival

- Inspections during manufacturing

- Testing every harness electrically

- Random pull-testing connections

- Regular equipment calibration

We track every component from raw material to finished product. This allows us to trace any part back to its source.

Industries That Need Custom Wire Harnesses

Wire harnesses work in almost every industry. Different fields have unique requirements for these electrical bundles. Our manufacturing experience covers all these industries with custom solutions.

Automotive

Automotive wiring harness manufacturers produce extensively for automotive applications. These large wire assemblies handle extreme temperatures (-40° C to +125° C), constant vibration, and fluid exposure. Modern vehicles contain up to 4 km of wiring in multiple harnesses.

Medical Equipment

Medical devices require special wire harnesses compatible with human contact and sterilization. These typically use silicone or PTFE insulation and maintain perfect signal quality. Patient safety depends on reliable performance.

Industrial Machinery

Factory equipment needs harnesses that resist oils, chemicals, and constant vibration. These industrial harnesses use special jacket materials and sealed connectors to block contamination. Connection reliability directly affects production uptime in automated assembly environments.

Ready for Your Wire Harness Project?

OurPCB provides complete wire harness manufacturing services with a focus on quality and technical excellence. Our integrated design and manufacturing approach gives you significant advantages. We handle everything from designing wire assemblies to testing and shipping.

Contact us today about your project. We'll help optimize your cable harness design for performance, manufacturability, and cost. Email us at [email protected] for a quote or technical advice.

Frequently Asked Questions

What is the standard for wire harness manufacturing?

The IPC/WHMA-A-620 standard guides the wire harness industry. It defines quality requirements in three different classes based on end-use applications. The standard covers all connection methods including crimping, soldering, and other techniques with specific requirements for each.

What is a 7 wire harness?

A 7 wire harness contains seven separate wires bundled together, typically used for trailer connections or factory controls. Each wire serves a specific function like ground, power, brake signals, or turn indicators. This standardization ensures components work together properly.

How do environmental factors affect wire harness design?

The operating environment determines material selection and protection methods. Hot areas require special insulation like PTFE instead of standard PVC. Wet locations need sealed connectors and waterproof coverings. Vibration-prone applications need secure mounting methods to keep the harness in place during operation.

Back to Top: Wire Harness Manufacturing Process | Our 7 Simple Steps

Special Offer: Get $100 off your order!

Email [email protected] to get started!