- Home

- Custom Wire Harness

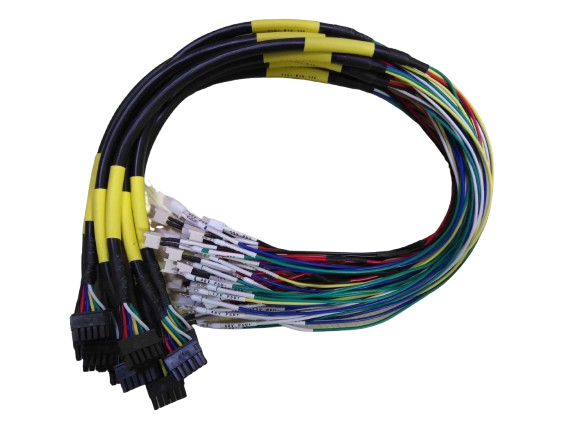

Custom Wiring Harness Manufacturer | Wire Harness Assemblies

As a leading wire harness manufacturer, OurPCB connects your electronic systems with reliable, organized cable assemblies built to your exact specs. Our wiring harness factory crafts precision wire harnesses that protect your electrical connections while simplifying installation and maintenance. Our China-based cable harness manufacturer combines technical expertise with rigorous quality standards for every project.

What are Custom Wire Harnesses?

Custom wire harnesses are organized bundles of electrical wire, connectors, and terminals that transmit power and signals between electronic components. These precision-engineered assemblies replace disorganized wiring with structured pathways that protect connections from environmental damage and abrasion. Wire harness and cable systems act like the circulatory system of your electronics, delivering essential power and data where needed while maintaining signal integrity across a wide range of applications.

The Benefits of Custom Wire Harnesses

Custom wiring offers critical advantages for electronic systems across various industries. These benefits directly impact your products’ reliability, assembly efficiency, and long-term performance.

- Organized wiring eliminates short circuits and connection failures that cause electromagnetic interference and system malfunctions

- Protected interconnect systems resist environmental damage from moisture, heat, chemicals, and vibration

- Plug-and-play connections reduce assembly time by up to 60% compared to loose cable assemblies

- Clear wire identification and routing make troubleshooting and repairs faster for any installer

- Compact, organized bundles maximize space efficiency in tight installation areas

- Optimized routing reduces overall wire length and weight—critical for aerospace and automotive applications

- Faster assembly streamlines manufacturing and reduces labor costs

- Improved reliability decreases warranty claims and field repair expenses for OEMs

Why Choose OurPCB For Custom Wire Harnesses

As an experienced wire harness assembly manufacturer, OurPCB delivers harness solutions that exceed industry standards for quality and performance. Our specialized harness manufacturing capabilities ensure your wire harness assemblies perfectly match your customers’ requirements.

- One-stop wire harness supplier eliminates compatibility issues between circuit boards and connecting harnesses

- Streamlined supply chain reduces coordination problems and ensures on-time delivery

- 100% electrical testing on every project ensures perfect continuity and connection

- Our quality management system includes cross-section analysis technology that verifies crimping quality at microscopic levels

- High-quality wire harnesses for electric vehicle battery cables and industrial power applications

- Advanced shield techniques for sensitive signal protection that meet or exceed industry standards

- Quick-turn prototype development with first articles delivered within days rather than weeks

- Scalable manufacturing from small runs to high-volume production across a wide variety of industries

- 15+ Years of Experience

Our team has extensive experience creating both standard and custom wiring harnesses.

- Competitive Pricing

Well-priced and payable via PayPal, bank transfer, Western Union, or Moneygram.

Our Custom Wiring Harness Features

Safe, approved, and eco-friendly materials

Customized materials for abrasion-, oil-, heat-, or water-resistance

Choose from PVC, nylon, XLPE, rubber, braided sleeving, heat shrink tubing, and more!

We offer various wire thicknesses and lengths to meet your exact needs

We serve almost every industry you can think of! Contact us today.

Millions of business and innovators use OurPCB

Our Custom Wiring Harness Process

Fast, free, and includes a production timeline

Our engineers create your design schematic and select the right materials

We’ll manufacture a high-quality prototype within 7 days

The prototype goes through various functionality and stress tests

Cutting, stripping, and assembly to the highest standard

After final testing and packaging, your custom wiring harnesses are delivered

Technical Capabilities

Our 10,000 square foot facility maintains ISO 9001, IATF 16949, and IPC/WHMA-A-620 standards from the Wire Harness Manufacturer’s Association, ensuring consistent quality across all manufacturing services. Our wire processing capabilities include wire gauge ranges from 30 AWG to 4 AWG, voltage ratings up to 600V, and temperature resistance from -65 °C to +200 °C.

As a manufacturer of high-quality assemblies, we support all major connector types including JST, Molex, TE Connectivity, and Hirose, with custom overmolded options for automotive, agricultural equipment, and medical applications.

The wire harness industry demands excellence, and our wire harness design and application engineering processes deliver. We offer precision cutting and stripping, automated crimping with force monitoring, and custom made automotive wiring harness solutions with specialized shielding for the industry’s most demanding environments.

Our team is dedicated to providing the best value through rigorous testing for continuity, insulation resistance, and dielectric strength. With years of combined experience, our final design verification includes pull-testing for mechanical integrity and premium wire harnesses that protect against the harshest conditions.

Capabilities & Services

- Wire Gauge: 40AWG-120mm²

- Production Capacity: 10,000 pieces/hour

- Wire Cutting Service

- Wire Stripping Service

- Wire Marking Service

- Label Types

- Wire Ends Treatment

Custom Wire/Cable Service:

- Wire/Cable types

- Wire gauge

- Wire/Cable length

- Insulation/Jacket color

- Core numbers etc.

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

- Electrical cable assembly

- Coaxial cable assembly

- Multi-core cable assembly

- Connector to board cable assembly

- Automobile communication cable assembly

- Power transmission cable assembly

More Custom Wire Harness Manufacturing Services

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Custom Wiring Harness Manufacturer FAQs

What are your lead times?

For rapid prototypes, the expected lead time is 7 days. For mass production, your order is delivered in 15 to 20 days.

How does OurPCB ensure wire harness quality?

OurPCB implements IPC/WHMA-A-620 workmanship standards, with certified technicians performing all critical operations in the wire harness manufacturing industry. Every product undergoes 100% electrical testing for continuity, with documented results for traceability. We perform regular cross-section analysis to verify proper compression at microscopic levels, ensuring reliability beyond visual inspection.

Do you offer non-disclosure agreements (NDAs)?

Yes. We respect your privacy, and we’re happy to provide an NDA if you’d like one.

What is your production capacity?

We can handle small orders as well as large-scale production requirements without compromising on quality. No order is too big or too small.

Can OurPCB integrate wire harnesses with PCB assembly?

OurPCB specializes in combined PCB and wire harness manufacturing, offering complete electronic assemblies designed to meet your production needs. This integration eliminates compatibility issues while simplifying your supply chain. Our application engineering team optimizes the entire system, ensuring perfect electrical and mechanical compatibility between all components for on-time delivery of your mission-critical products and services.

What information do I need to provide for a wire harness quote?

Provide your application environment details including temperature range, moisture exposure, and vibration conditions for cables built to your specifications. Include electrical requirements like voltage, current needs, and signal types, along with connector preferences and quantities. Drawings significantly improve accuracy, as does information about certification requirements for your wire harness assembly needs.