Top 7 Truck Wiring Harness Manufacturers

Truck wiring harnesses are the electrical backbone of commercial vehicles, from long-haul trucks to construction fleets and emergency vehicles. They must withstand continuous vibration, thermal

OEM power bank PCB assembly suppliers produce custom circuit boards for portable chargers. We handle design, component sourcing, and assembly. OurPCB offers high-quality OEM power bank PCB assembly services with quick turnaround times.

OEM power bank PCB assembly creates custom circuit boards for portable chargers. It starts with designing the PCB layout based on client specifications. Manufacturers then source components and assemble the boards using automated equipment.

The PCB assembly process includes applying solder paste, placing components, and reflow soldering. Quality control checks ensure proper functionality. OEM suppliers often offer additional services like testing and packaging to deliver ready-to-use power bank PCBs.

Partnering with OurPCB for OEM power bank PCB assembly offers several advantages. Our expertise, advanced technology, and commitment to quality set us apart. Here are the key benefits:

OEM power bank PCB assembly suppliers offer specialized expertise in portable charger production. We provide end-to-end solutions for manufacturers. Here’s why choosing an OEM supplier is beneficial:

OurPCB offers a range of PCB assembly services tailored to power bank manufacturing. We ensure high-quality results for every project. Our services include:

We use Surface Mount Technology for compact and efficient power bank PCBs. Our SMT process ensures precise component placement and reliable connections.

We work with customer-supplied parts or provide full turnkey solutions. Our team handles sourcing, assembly, and delivery for a seamless experience.

We create tailored PCB assemblies for unique power bank designs. Our experts work closely with clients to meet specific project requirements.

We offer fast PCB assembly services without sacrificing quality. Our efficient processes ensure quick turnaround times for urgent projects.

We produce PCB assemblies that meet strict IPC Class 3 standards. This ensures reliability for high-performance power banks.

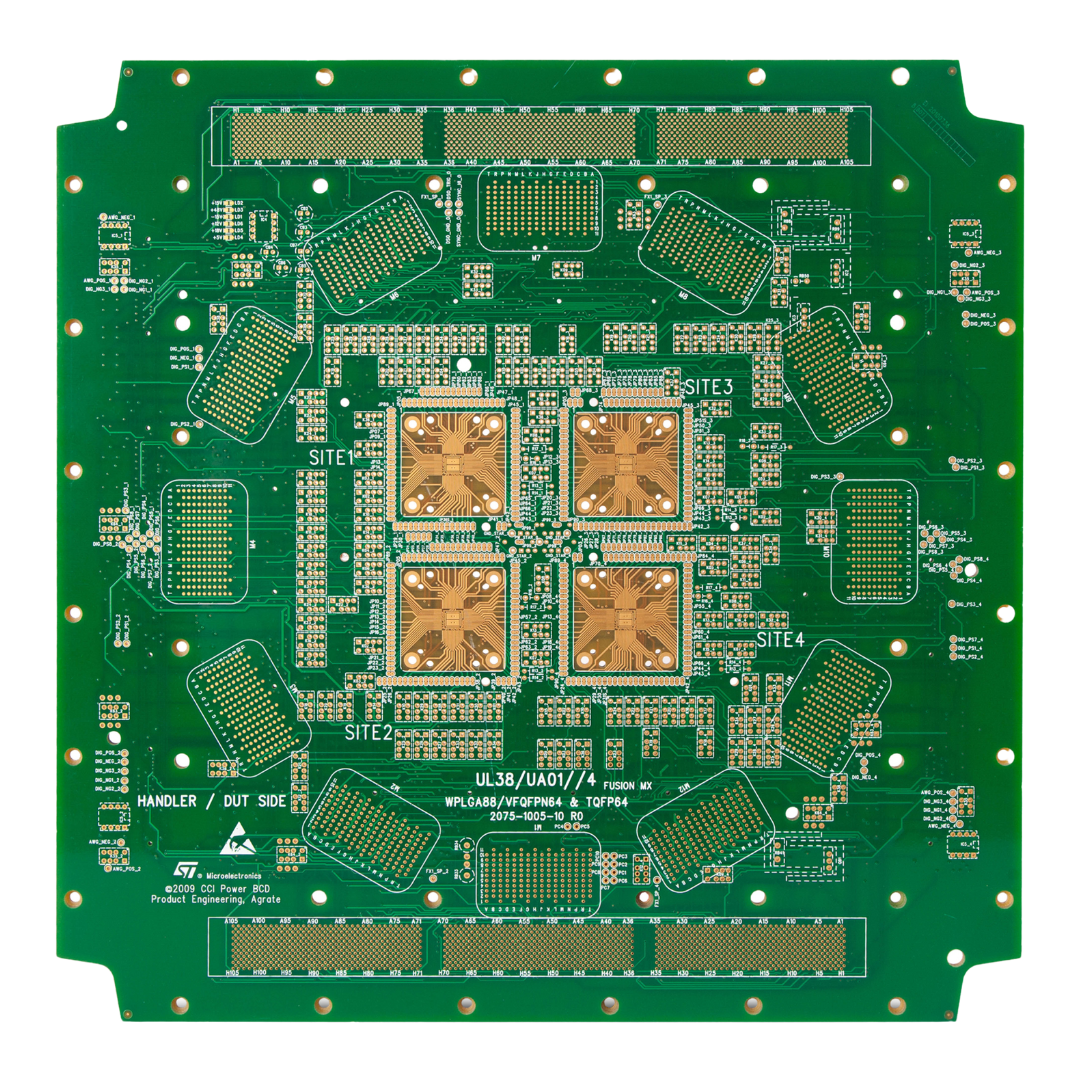

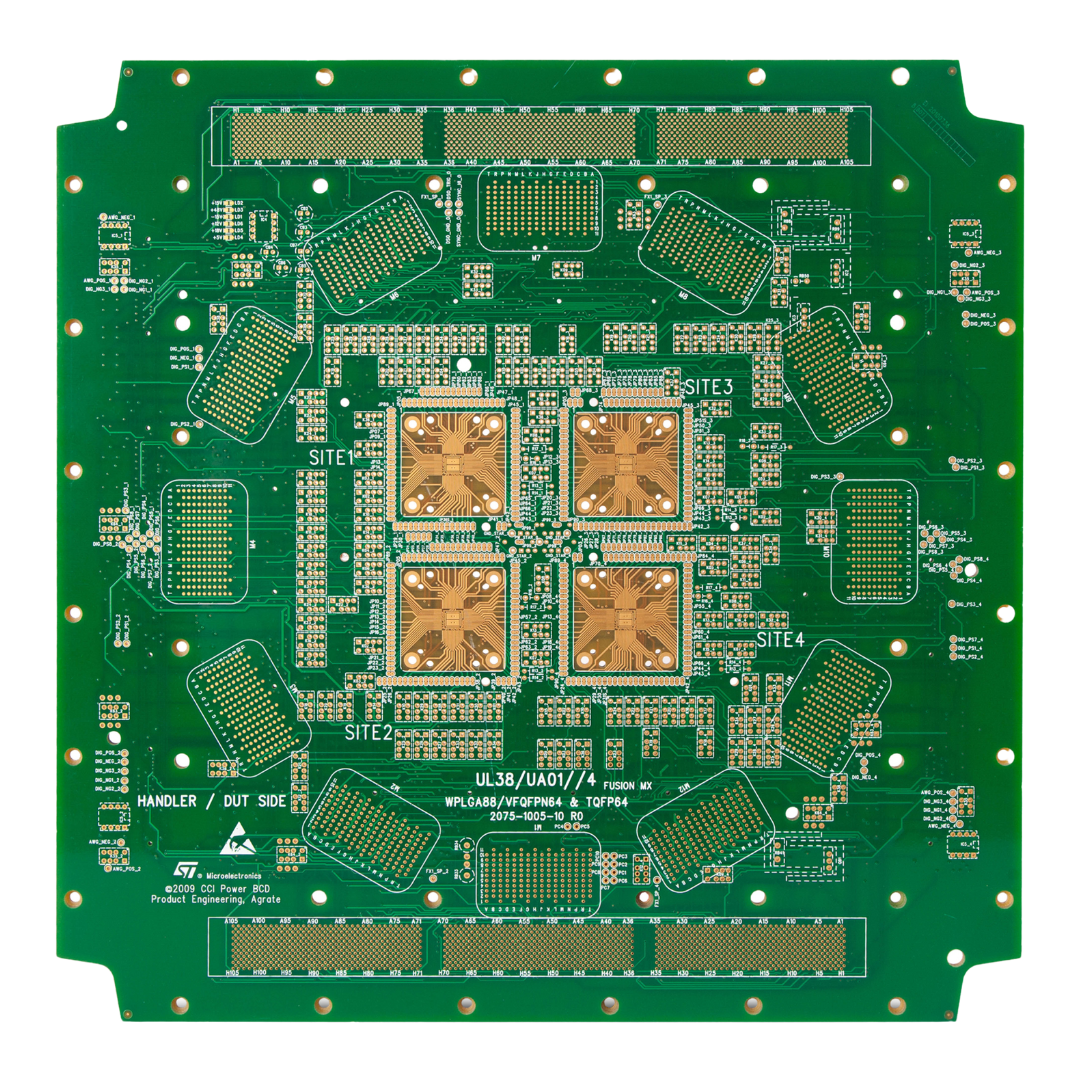

We assemble all types of IC packages, including BGAs, QFNs, and CSPs. Our advanced equipment ensures precise and reliable assembly for complex designs.

OurPCB boasts advanced technical capabilities for OEM power bank PCB assembly. We use innovative equipment for precise component placement. Our facilities can handle multilayer PCBs and complex designs. Plus, we offer both through-hole and surface-mount assembly techniques. Our team stays up to speed on the latest industry standards and technologies.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

To reduce PCB assembly PCBA costs, optimize the PCB design, and minimize unnecessary multilayer PCB layers, choose a PCB manufacturer with competitive pricing and bulk discounts offered for sale by suppliers. Select cost-effective PCB and PCBA materials, like flexible PCB instead of rigid-flex PCB, where possible. Work with an assembly factory that specializes in PCB for power to streamline PCB production.

An OEM PCB is manufactured by the PCB board manufacturer that originally designed it, ensuring quality and compatibility. In contrast, a non-OEM electronic PCB is made by third-party PCB suppliers and manufacturers, often as a more affordable alternative. OEM printed circuit board assembly manufacturing guarantees that parts match the original PCB circuit board, whereas non-OEM board PCBA assembly may have slight variations. The choice between OEM PCB and non-OEM depends on budget, reliability, and intended use.

Manufactured OEM power bank board PCB assembly is often more expensive due to proprietary PCB designs. Limited customization options make it harder to create a customized printed circuit board for specific needs. OEM printed circuit board PCBA orders may have longer lead times compared to third-party PCBA manufacturer options. Additionally, some PCBA factory restrictions prevent modifications to control PCB features or LED PCB configurations.

Truck wiring harnesses are the electrical backbone of commercial vehicles, from long-haul trucks to construction fleets and emergency vehicles. They must withstand continuous vibration, thermal

Medical cable assemblies sit at the intersection of electrical safety, biocompatibility, and sterilization durability. For regulated medical devices, OEMs must work with manufacturers that understand

Robotics cable assemblies are unlike ordinary cables, they must survive continuous motion, tight bend radii, torsion, vibration, electrical noise, and often harsh industrial or outdoor

Waterproof cable assemblies have to do more than just “keep water out.” For outdoor, marine, industrial washdown, and transportation platforms, assemblies are expected to survive

Aerospace cable assembly manufacturers work under standards such as AS9100, ISO 9001, and RTCA/DO-160, and many also maintain ITAR registration to support flight-critical and space-qualified

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree