Aerospace Wire Harness Manufacturing Assembly

In the high-stakes world of aerospace, wire harnesses aren’t just components — they’re literal lifelines. At OurPCB, we’ve spent years perfecting these critical systems for aviation, defense, and space applications where even the smallest failure can lead to disaster. Our harnesses don’t just meet specs — they’re crafted with an obsessive level of precision that most manufacturers would find excessive.

We’ve assembled a team with decades of hands-on aerospace electronics experience because we understand what’s really at stake. Reliability isn’t some nice-to-have feature — it’s absolutely non-negotiable when lives and multi-million dollar missions hang in the balance. That’s exactly why we test every harness using procedures that would seem ridiculously thorough in any other industry. When failure simply isn’t an option, our verification process delivers the one thing aerospace engineers need most: absolute confidence in every connection.

What are Aerospace Wire Harnesses?

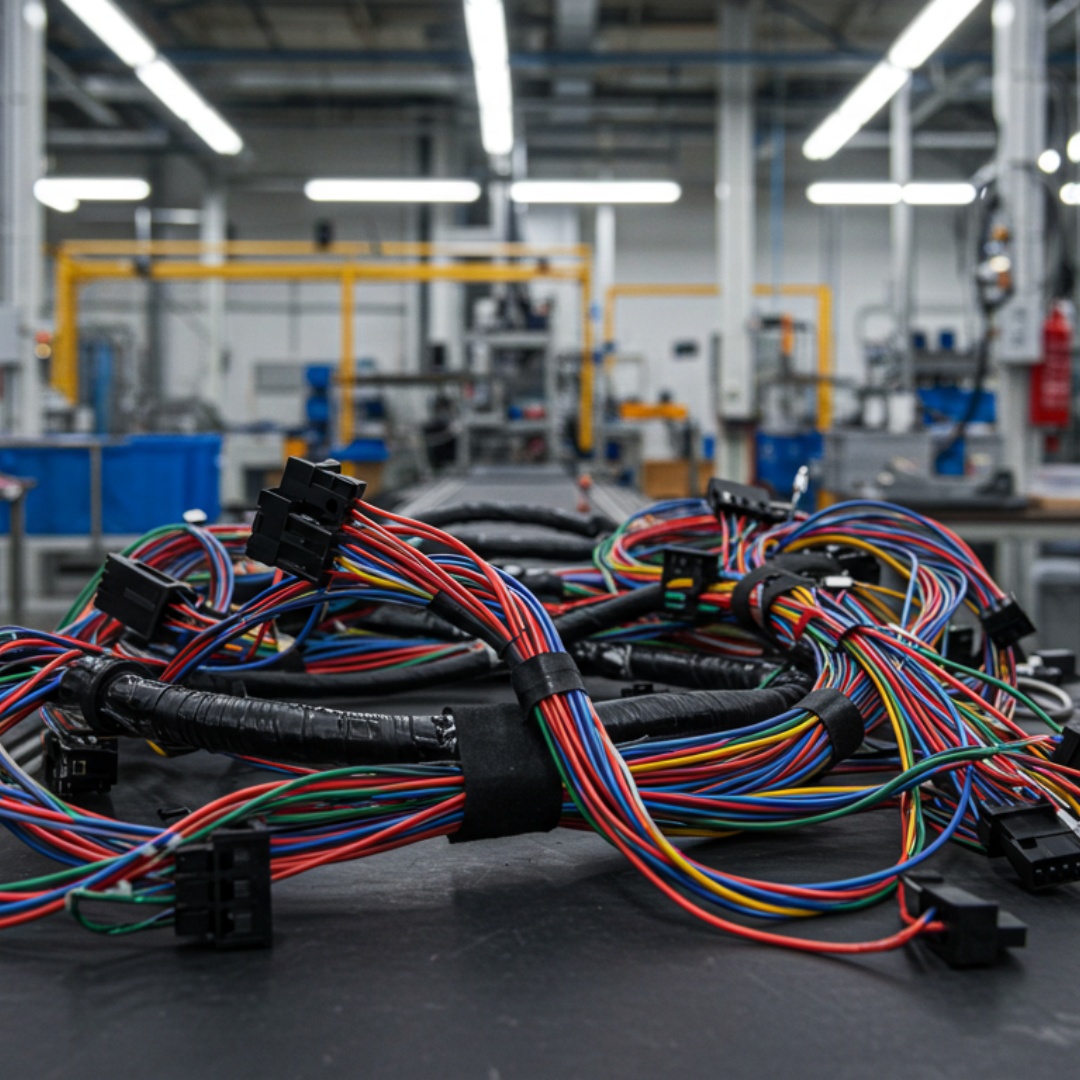

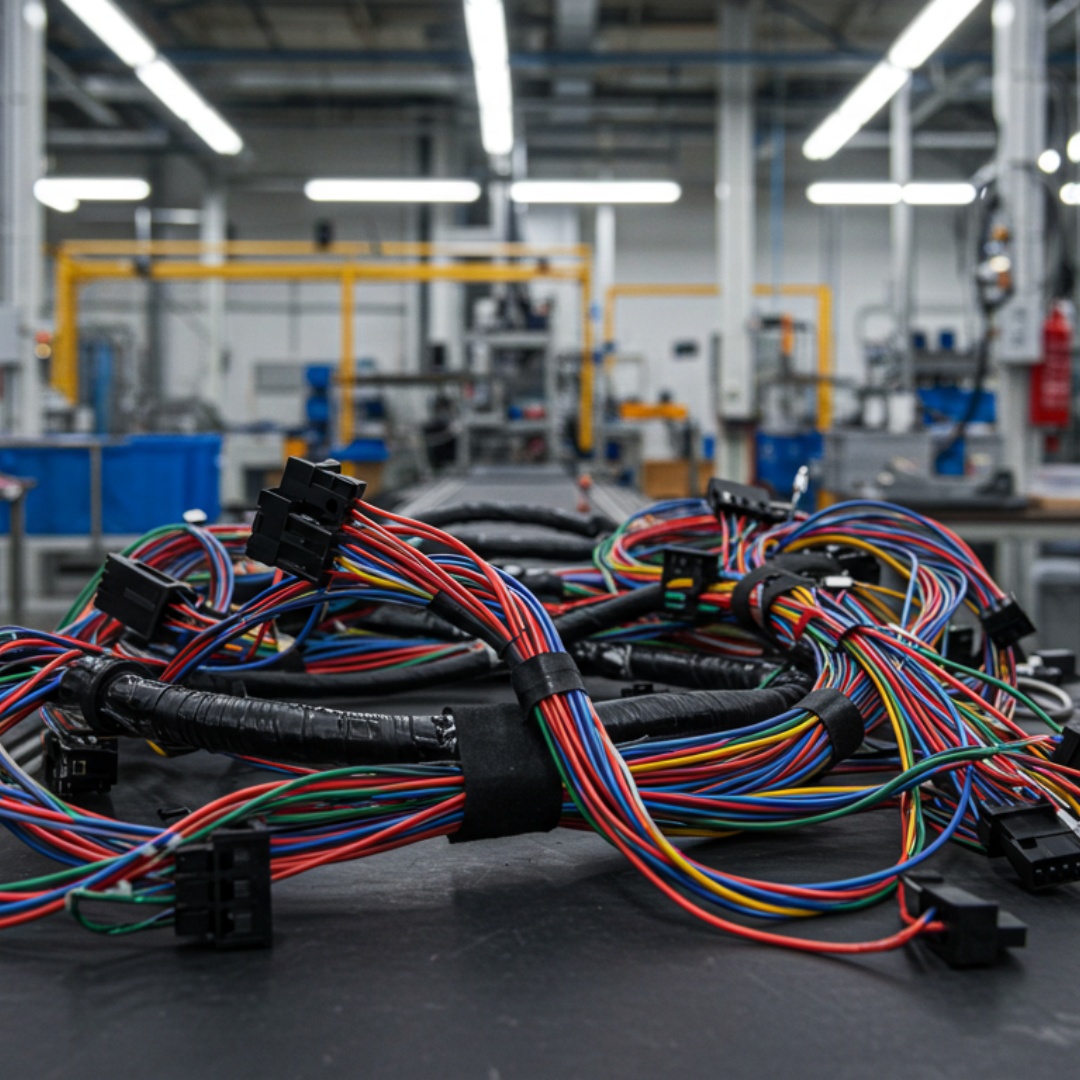

Aerospace wire harnesses are essentially the nervous system running through aircraft and spacecraft. They’re not just fancy wire bundles — they’re meticulously engineered networks that route power and critical data to everything that keeps these machines in the air or orbit. What makes them special is their ability to survive conditions that would destroy regular wiring. We’re talking about wiring that functions perfectly through extreme vibration, temperature swings from -65 °F to 350 °F, and even high-altitude radiation.

Our manufacturing process has zero tolerance for errors because the consequences are too severe. Every component from the smallest connector to the main power cables must meet specifications that would seem ridiculous in consumer electronics. But when you’re building something that will carry astronauts to the ISS or keep a 787 with 300 passengers safely cruising at 35,000 feet, those standards suddenly make perfect sense.

What are the Benefits of Aerospace Wire Harnesses?

The benefits of aerospace wire harnesses are their greater reliability in extreme conditions, superior weight optimization, and compliance with a higher degree of standards. Our specialized manufacturing approach ensures you receive high-quality wire products that maximize performance while minimizing potential points of failure.

- Each harness application is built with specialized materials designed to withstand temperature extremes from -65 °C to +200 °C without performance degradation.

- Our rigorous testing protocols simulate flight conditions to verify operational integrity under stress, ensuring systems maintain functionality during critical operations.

- Strategic material selection and routing design reduce harness weight by up to 30% compared to standard commercial solutions.

- Our engineering team specializes in lightweight aerospace-grade conductors and insulation that maintain electrical performance while minimizing mass impact.

- Every harness manufacturer must follow ISO 9001, and IPC/WHMA-A-620 requirements, which we consistently meet.

- Full material traceability and batch tracking ensure regulatory compliance and facilitate FAA certification.

Superior Field Reliability

- IP67-rated connectors resist complete dust ingress and withstand water immersion up to 1 m for 30 minutes.

- Marine-grade insulation materials provide chemical resistance against fertilizers, pesticides, and fuel exposure.

Extended Equipment Lifespan

- Temperature-resistant components function reliably from -40 °C to 105 °C, preventing heat damage in engine compartments.

- Reinforced strain relief and secure terminal connections prevent failures from constant diesel engine vibration.

Simplified Troubleshooting

- Color-coded wiring with clear detail reduces diagnostic time by up to 60%.

- Comprehensive documentation includes wiring diagram specifications specific to your tractor model.

Customization Options

- Exact-fit design ensures perfect compatibility with your specific Farmall or Cub Cadet restoration.

- Additional capacity options accommodate future implements or aftermarket electrical accessories you may add later.

Why Choose OurPCB for Aerospace Wire Harnesses

When selecting a partner for your aerospace cable assemblies, experience and attention to detail make all the difference. Our specialized approach delivers superior results for the most demanding applications.

- Our team brings decades of combined expertise in aerospace electrical systems to every project we undertake.

- We’ve successfully delivered wire harness solutions for commercial aviation, military aircraft, satellite systems, and ground support equipment.

- 100% electrical testing on every harness verifies perfect functionality before shipment.

- Automated optical inspection and X-ray examination of critical connections ensure zero defects in critical applications.

- Complete control over the manufacturing processes from design through testing ensures consistency.

- Our facility in the Philippines maintain all required aerospace certifications and security clearances for defense projects.

- Dedicated aerospace technicians provide design optimization recommendations that improve performance and reduce costs.

- Rapid prototyping capabilities allow for design validation before full production, reducing development time and risk.

Our Custom Wiring Harness Features

ROHS-Compliant Materials

Safe, approved, and eco-friendly materials

Custom Materials to Suit the Environment

Customized materials for abrasion-, oil-, heat-, or water-resistance

Your Choice of Coverings

Choose from PVC, nylon, XLPE, rubber, braided sleeving, heat shrink tubing, and more!

Variable Wire Options

We offer various wire thicknesses and lengths to meet your exact needs

Across Many Industries

We serve almost every industry you can think of! Contact us today.

Millions of business and innovators use OurPCB

Our Custom Wiring Harness Process

Fast, free, and includes a production timeline

Our engineers create your design schematic and select the right materials

We’ll manufacture a high-quality prototype within 7 days

The prototype goes through various functionality and stress tests

Cutting, stripping, and assembly to the highest standard

After final testing and packaging, your custom wiring harnesses are delivered

Technical Capabilities

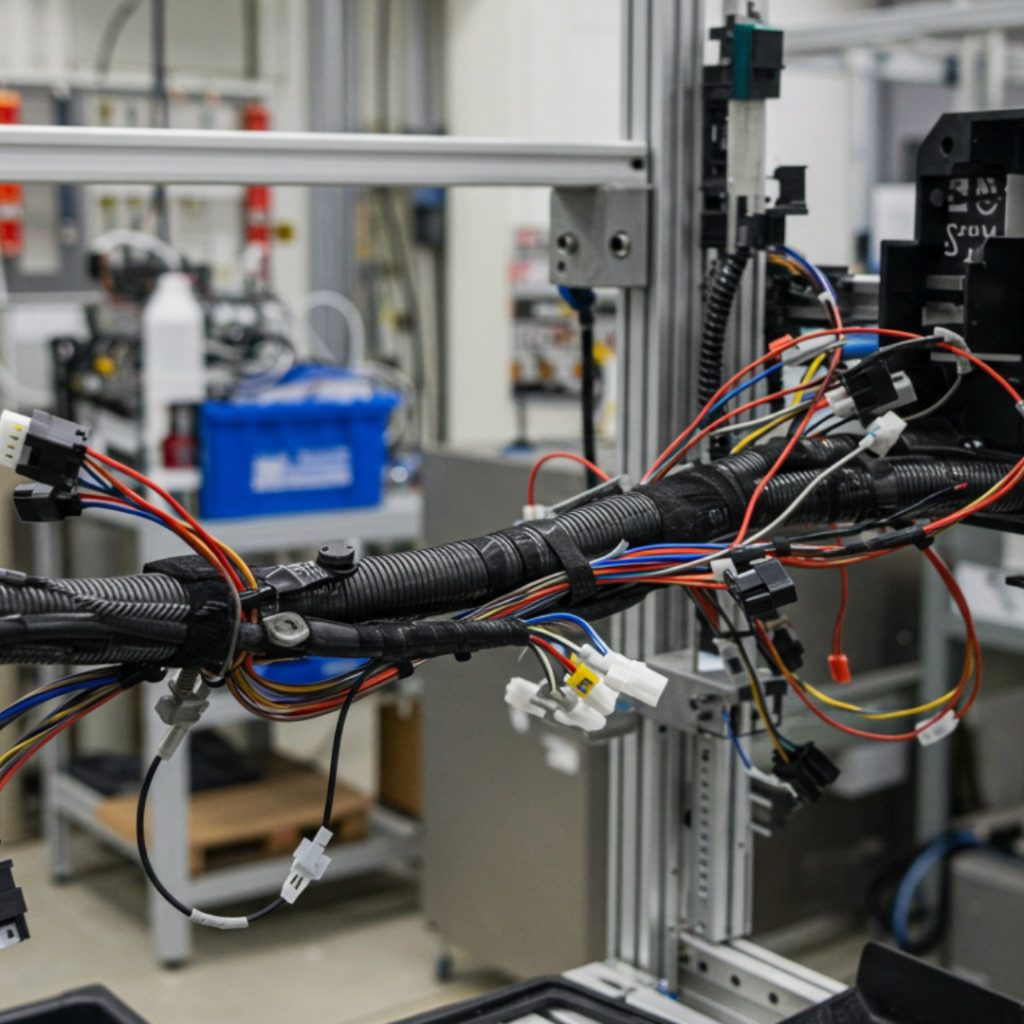

Our innovative aerospace wire harness manufacturing facility is equipped with specialized tools and equipment designed specifically for high-reliability applications. From automated wire cutting and processing to advanced crimp force monitoring and pull-testing equipment, our technical capabilities ensure consistent quality across every production run.

We maintain an extensive inventory of aerospace-grade electrical wires, connectors, terminals, and protective components from manufacturers approved for aviation and defense industries. All materials are lot-tracked and tested to ensure compliance with applicable specifications.

Capabilities & Services

- Wire Gauge: 40AWG-120mm²

- Production Capacity: 10,000 pieces/hour

- Wire Cutting Service

- Wire Stripping Service

- Wire Marking Service

- Label Types

- Wire Ends Treatment

Custom Wire/Cable Service:

- Wire/Cable types

- Wire gauge

- Wire/Cable length

- Insulation/Jacket color

- Core numbers etc.

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

- Electrical cable assembly

- Coaxial cable assembly

- Multi-core cable assembly

- Connector to board cable assembly

- Automobile communication cable assembly

- Power transmission cable assembly

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Aerospace Wire Harness Manufacturing Assembly FAQs

What certifications does OurPCB maintain for aerospace wire harness manufacturing?

OurPCB maintains ISO 9001 quality management certification, and IPC/WHMA-A-620 workmanship certification specifically for cable and wire harness manufacturing. Our facility is also ITAR registered for defense projects and complies with DFARS requirements for military applications.

How does OurPCB ensure traceability for aerospace wire harnesses?

We implement comprehensive material traceability protocols that track every component from receipt through manufacturing and delivery. Each wire, connector, terminal, and protective component is documented with manufacturer information, lot numbers, and test results. This traceability chain supports airworthiness certification and provides complete documentation for regulatory compliance.

What testing procedures are used to verify aerospace wire harness quality?

Every aerospace harness undergoes 100% electrical testing including continuity verification, insulation resistance measurement, and dielectric strength testing where applicable. We also perform mechanical tests including pull testing on crimp connections and environmental simulation for temperature extremes and vibration resistance. All test results are documented and included with harness deliveries.