PCB Types List

Below is a comprehensive list of PCB types, mentioning the most common kinds of Printed Circuit Boards, including their descriptions, features, and applications.

| PCB Type | Description | Features | Applications |

|---|---|---|---|

| Single-Sided PCBs | PCBs with copper traces on only one side of the substrate. | - One conductive copper layer on the substrate - Simplest and most cost-effective type - Components and traces on one side only - Lowest production cost among all PCB types |

- Calculators - Electronic toys - Timing circuits - LED lighting systems |

| Double-Sided PCBs | PCBs with copper traces on both sides of the substrate. | - Two conductive layers (top and bottom) - Components can be mounted on both sides - Connected through plated holes (vias) - Allows for more complex circuits |

- Cell phones - Amplifiers - HVAC systems - Industrial controls |

| Multilayer PCBs | PCBs with three or more conductive layers, separated by insulating material. | - Minimum of three conductive layers - Current capability up to 40 layers - Common configurations: 4, 6, or 8 layers - High circuit density - Reduced electromagnetic interference (EMI) |

- Computers - Medical equipment - GPS technology - Satellite systems |

| Rigid PCBs | PCBs made from solid substrate materials that prevent the board from bending. | - Made from solid substrate material (typically FR-4) - Durable and stable - Provides excellent mechanical stability - Cost-effective for standard applications |

- Motherboards - Memory modules - Telecommunication devices |

| Flexible PCBs | PCBs made of flexible substrate materials like polyimide. | - Can be bent, folded, or shaped - Excellent for space-constrained applications - Reduces weight compared to rigid boards - Made from flexible materials like polyimide |

- Wearable devices - Flexible connectors - Medical equipment |

| Rigid-Flex PCBs | Combines rigid and flexible PCB technologies in a single board. | - Combines rigid and flexible board materials - Allows for three-dimensional configurations - Reduces the need for connectors and cables - Improves reliability |

- Aerospace and military equipment - Consumer electronics - Smartphones |

| High-Density Interconnect (HDI) PCBs | PCBs with a higher wiring density per unit area compared to traditional PCBs. | - Higher circuitry density per unit area - Features laser-drilled microvias, blind and buried vias - Uses microvias and finer lines/spaces - Allows for miniaturization - Improved electrical performance - Operates above 1 GHz frequency |

- Smartphones - Tablets - Wearable technology - Complex routing applications |

| High-Frequency PCBs | Designed to handle signals in the gigahertz (GHz) range. | - Specialized materials for RF applications - Uses materials like PTFE (Polytetrafluoroethylene) - Low dielectric constant and loss tangent - Controlled impedance - Low signal loss - Superior moisture resistance |

- RF communication systems - Microwave antennas - Telecommunications equipment - High-speed digital applications |

| Aluminum PCBs | PCBs with an aluminum metal substrate for better heat dissipation. | - Metal core for superior heat dissipation - Excellent thermal conductivity - Reduces thermal stress on components - High mechanical strength - Better thermal management - More expensive than standard FR-4 boards |

- LED lighting - Power converters - Automotive electronics |

| Metal Core PCBs | PCBs that use a metal core (usually aluminum or copper) to improve thermal management. | - Contains a metal base layer (usually aluminum) - Excellent thermal conductivity - Superior heat dissipation properties - Reduces thermal expansion - Increases mechanical strength |

- High-power applications - Power equipment - Automotive lighting |

| Embedded Component PCBs | Components are embedded within the PCB layers. | - Reduces overall board size - Provides better protection for components - Improved EMI shielding capabilities |

- Miniaturized devices - High-reliability applications - Medical implants |

| Sequential Lamination PCBs | Built up layer by layer in sequence through multiple lamination cycles. | - Allows for more complex multilayer designs - Better control of impedance - Supports high-density interconnects (HDI) |

- Advanced electronics - Aerospace systems - Military equipment |

| Mixed Technology PCBs | Combines different PCB technologies within a single board. | - Includes both through-hole and surface mount components - Offers design flexibility - Can integrate rigid, flex, and rigid-flex sections |

- Complex applications requiring diverse components - Industrial machinery - Communication systems |

| Thick Copper PCBs | PCBs with copper thickness greater than 3 ounces (oz). | - Superior current-carrying capacity - Better heat distribution - Enhanced mechanical strength at connector sites |

- High-power applications - Power supply systems - Solar power converters |

| Heavy Copper PCBs | PCBs with copper thickness between 4 oz to 20 oz. | - Excellent current handling capabilities - Superior thermal management - Supports high-density and high-power circuits |

- Power distribution applications - Electric vehicle charging stations - Industrial load testers |

| Backplane PCBs | Used to connect several PCBs together to form a complete system. | - High-speed signal integrity - Complex routing capabilities - Supports multiple connectors and slots |

- Servers and mainframes - Networking equipment - Data centers |

| Opto-Electronic PCBs | Integrates optical and electronic components on the same board. | - Uses special materials for optical transmission - Higher data transmission rates - Reduces signal loss |

- Fiber optic communications - High-speed data links - Optical sensors |

| Hybrid PCBs | Combines different material types and technologies in one PCB. | - Can mix rigid, flex, and other materials - Customized for specific applications - Offers unique design solutions |

- Specialized industrial equipment - Medical devices - Advanced consumer electronics |

| Microvia PCBs | Utilize very small vias (holes) to connect layers in multilayer PCBs. | - Enables higher component density - Enhances signal integrity - Reduces signal delays |

- High-speed circuits - Compact electronic devices - HDI applications |

| Ceramic PCBs | Made using ceramic substrates like alumina or aluminum nitride. | - Superior thermal conductivity - Excellent dimensional stability - High-temperature resistance - High-frequency performance |

- High-temperature environments - RF applications - Aerospace and military systems - Extreme environment applications |

| High-Tg PCBs | PCBs with a high glass transition temperature (Tg), indicating higher thermal resistance. | - Better performance at elevated temperatures - Improved mechanical stability - Enhanced chemical resistance |

- Automotive electronics - Industrial controls - Power converters |

| RF PCBs | Designed specifically for radio frequency applications. | - Specialized materials to minimize signal loss - Precise impedance control - Low dielectric constant and loss tangent |

- Wireless communication devices - Radar systems - Satellite communication |

| High-Speed PCBs | Designed for high-speed signal transmission with minimal loss. | - Controlled impedance traces - Low dielectric constant materials - Careful layout to minimize crosstalk |

- Telecommunications - High-speed data processing - Computing equipment |

| Halogen-Free PCBs | PCBs manufactured without the use of halogenated flame retardants. | - Environmentally friendly - Compliant with RoHS standards - Reduced toxic emissions when heated - Growing in popularity due to environmental regulations |

- Consumer electronics - Eco-friendly products - Devices where environmental impact is a concern |

| PTFE PCBs | PCBs made using PTFE materials for high-frequency applications. | - Low dielectric constant - Excellent for high-frequency applications - Superior moisture resistance - Stable electrical properties over a wide frequency range |

- RF and microwave circuits - Satellite communication - High-speed communication devices |

| Polyimide PCBs | PCBs made using polyimide materials known for high-temperature resistance. | - High-temperature resistance (up to 260°C) - Excellent dimensional stability - Good chemical resistance |

- Flexible circuits - Aerospace and military electronics - High-temperature environments |

| High-Temperature PCBs | Designed to operate reliably at high temperatures. | - Made from materials like polyimide or ceramic - Enhanced thermal stability - Resistant to thermal degradation |

- Oil and gas industry - Aerospace applications - Industrial machinery |

| Antenna PCBs | Specialized PCBs that function as antennas for wireless communication. | - Precise patterning for specific frequencies - Uses low-loss materials - Compact and integrated design |

- Mobile devices - GPS systems - Wireless networking equipment |

| Photoimageable PCBs | Use photoimageable solder masks for fine-line circuitry. | - High-resolution patterning - Ideal for fine-pitch components - Improved aesthetics and functionality |

- HDI PCBs - Microelectronics - Precision instrumentation |

| LED PCBs | Specifically designed for mounting Light Emitting Diodes (LEDs). | - Excellent heat dissipation - Often use metal cores like aluminum - Optimized for thermal performance |

- LED lighting fixtures - Automotive lighting - Display backlighting |

| Transparent PCBs | Made from transparent substrate materials. | - Aesthetic appeal for certain applications - Allows light transmission through the PCB - Limited to low-temperature applications |

- Display technologies - Innovative consumer products - Decorative electronics |

| Custom PCBs | PCBs designed and manufactured to meet specific customer requirements. | - Tailored materials, layer counts, and designs - Meets unique performance needs - Can combine multiple PCB technologies |

- Specialized industrial equipment - Bespoke electronics - Prototyping and R&D projects |

Special Offer: Get $100 off your order!

Email [email protected] to get started!

PCB Types by Substrate Material

| PCB Material Types | Description | Features | Applications |

|---|---|---|---|

| FR-4 | Standard glass-reinforced epoxy laminate. | - Most common PCB material - Good electrical insulation properties - Cost-effective solution |

- Standard PCBs - Consumer electronics |

| Polyimide | High-performance polymer material. | - High-temperature resistance (up to 260°C) - Excellent dimensional stability - Good chemical resistance |

- Flexible circuits - High-temperature applications |

| PTFE (Polytetrafluoroethylene) | High-frequency substrate material. | - Low dielectric constant - Superior moisture resistance - Excellent for high-frequency applications |

- RF and microwave circuits - High-speed communication devices |

| Aluminum | Metal substrate used for thermal management. | - Excellent thermal conductivity - Superior heat dissipation |

- Metal Core PCBs - LED lighting |

| Ceramic | Substrate material with high thermal conductivity. | - Superior thermal conductivity - High-temperature resistance - Excellent dimensional stability |

- High-temperature PCBs - Extreme environment applications |

| PEEK (Polyetheretherketone) | High-performance engineering thermoplastic. | - Excellent mechanical and chemical resistance - High-temperature stability |

- Specialized applications - High-temperature environments |

Copper PCB Types & Thickness

| Copper Thickness | Description | Features | Applications |

|---|---|---|---|

| Standard (1 oz/ft²) | Approximately 35 micrometers thickness. | - Standard copper thickness for general-purpose PCBs | - General electronic devices - Consumer electronics |

| High Power (2-3 oz/ft²) | Increased thickness for higher current capacity. | - Better current carrying capacity - Improved heat dissipation |

- Power supplies - High-power applications |

| Thick Copper (>3 oz/ft²) | Copper thickness greater than 3 oz. | - Superior current-carrying capacity - Enhanced mechanical strength |

- High-power applications - Solar power converters |

| Heavy Copper (4-20 oz/ft²) | Copper thickness between 4 oz to 20 oz. | - Excellent current handling - Superior thermal management |

- Power distribution - Industrial load testers |

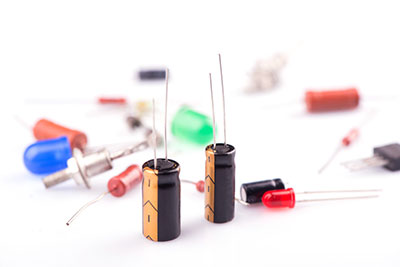

(Printed circuit board and component diagram)

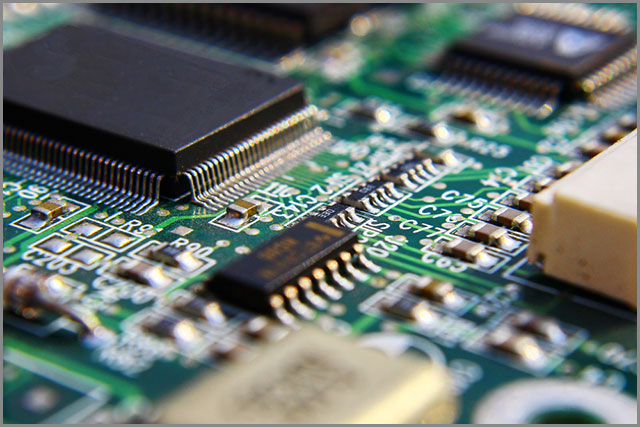

(High computer technology on abstract circuit board)

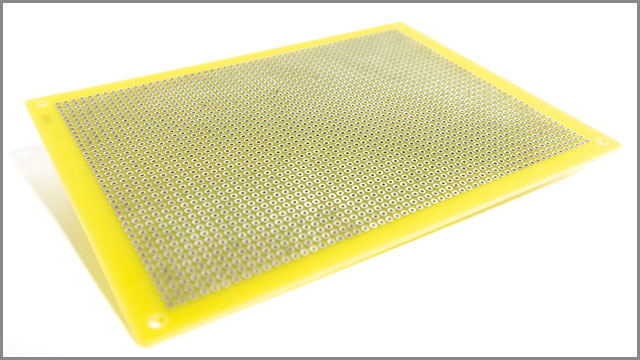

(An insight of a Breadboard)

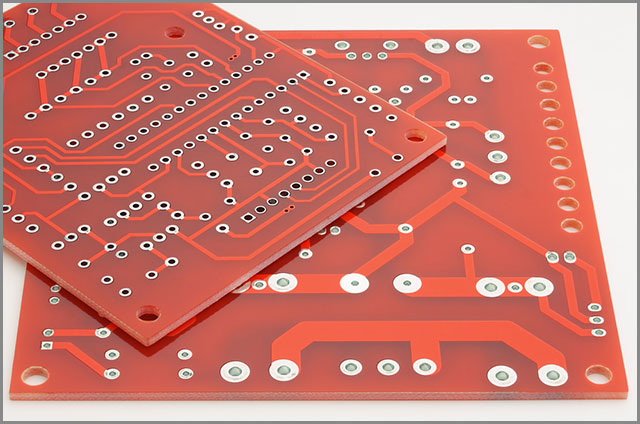

(Circuit board type-single panel picture)

(Double-sided welded board on white background)

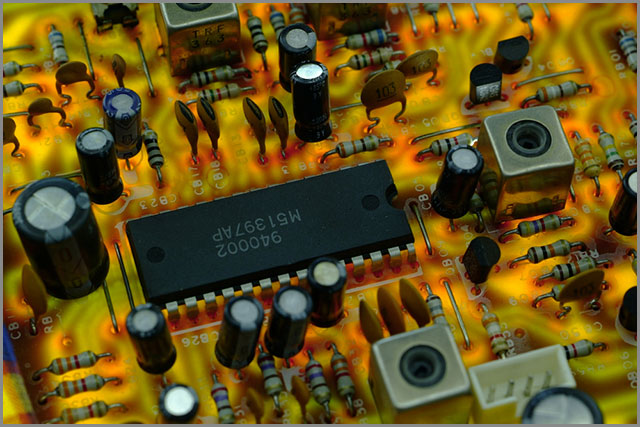

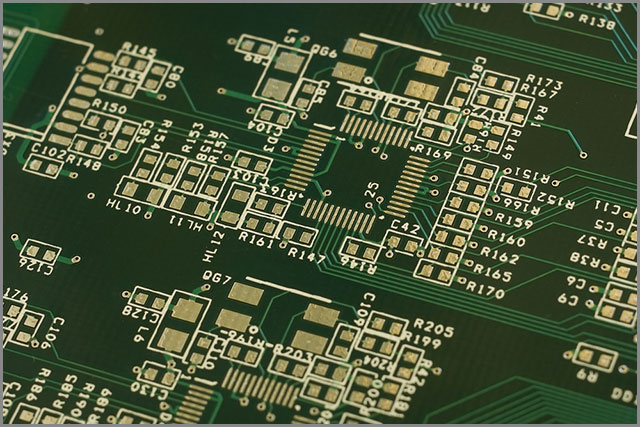

(PCB Type-Picture of Multilayer Circuit Board)

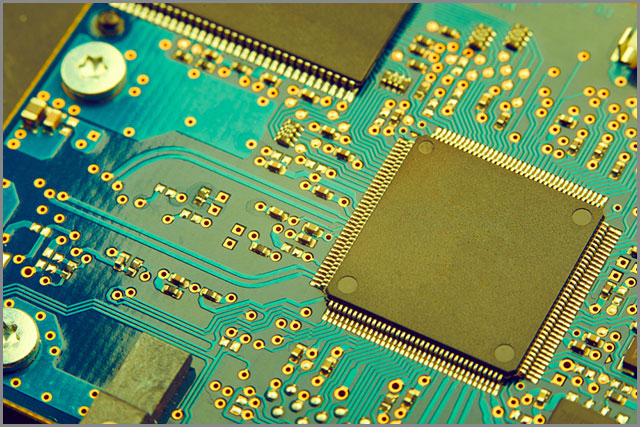

(A close-up on the use of a PCB In a motherboard)

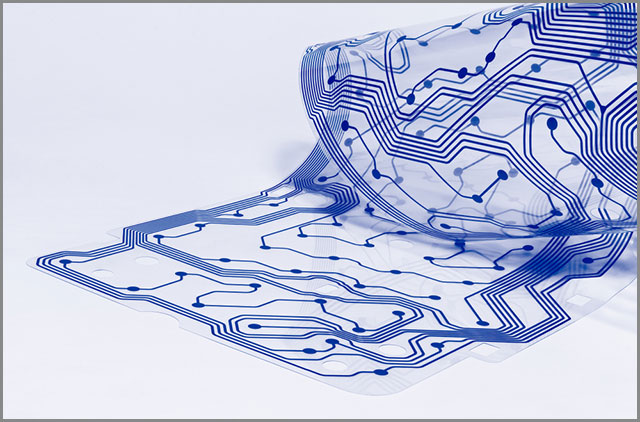

(Circuit board type-electronic flexible circuit board)

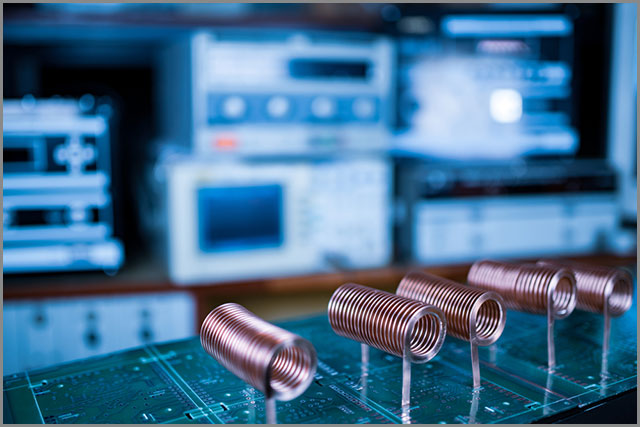

(High-frequency copper wire on the circuit board)

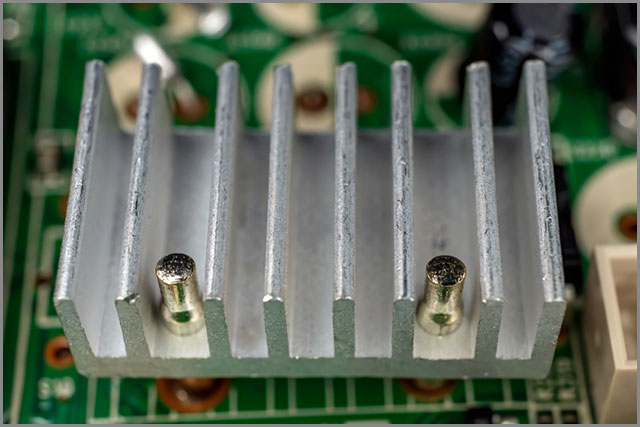

(An aluminum radiator prototype)

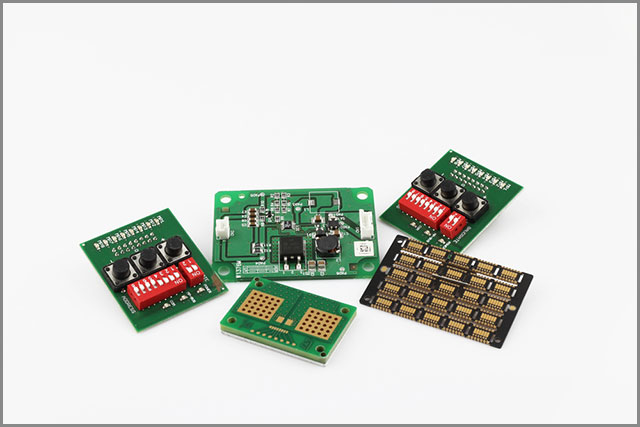

(Display a plurality of types of circuit boards)

Special Offer: Get $100 off your order!

Email [email protected] to get started!