Top 10 Classic Car Wiring Harness Manufacturers | Full Guide

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Medical cable assemblies give you the vital electrical connections necessary for life-saving healthcare equipment. This is cardinal across hospitals, surgical centers, and equipment manufacturers. As a trusted custom cable assembly manufacturer, OurPCB provides custom medical cable assemblies that reach regulatory standards. This includes quality management systems and safety requirements for the medical industry.

Medical cable assembly is made up of tons of different insulated conductors, all together with special healthcare connectors. These custom medical cables send electrical signals, power, and data between medical devices. It does this while keeping biocompatibility standards needed for patient contact. Medical cable assemblies have the latest materials like thermoplastic elastomers (TPE). This is because they can handle autoclave sterilization cycles.

Custom medical cable assemblies support multiple communication standards including RS-485, RS-422, RS-423, and RS-232 protocols for data transmission between patient monitors and hospital information systems. Advanced assemblies feature modular LAN interfaces, serial cable connections, and fiber optic communication links for high-speed imaging data transfer in modern healthcare facilities.

All medical assemblies adhere to ISO 10993-1 biocompatibility standards, ensuring materials remain safe during direct patient contact. Compliance includes REACH and RoHS environmental regulations plus comprehensive insulation testing that meets IEC 60601-1 electrical and mechanical requirements.

Medical cable assemblies deliver essential performance advantages that directly impact patient care and device reliability in healthcare industry environments.

OurPCB combines advanced manufacturing capabilities with comprehensive regulatory expertise to deliver medical cable assemblies that exceed rigorous standards.

Medical cable assembly testing protocols validate electrical safety, mechanical durability, and biocompatibility through standardized procedures. Insulation resistance testing measures electrical isolation between conductors and ensures values exceed 10 megohms at 500 VDC as required by IEC 60601–1 standards to meet the stringent requirements of the medical field.

Biocompatibility evaluation follows ISO 10993-1 testing protocols including cytotoxicity assessment, sensitization studies, and irritation testing for materials in direct patient contact. Chemical resistance testing exposes cable assemblies to sterilization agents, cleaning solutions, and bodily fluids to verify material compatibility and prevent infection.

Medical device cables enable critical functionality across diverse healthcare applications requiring specialized performance characteristics and regulatory compliance for various types of medical equipment.

| Application | Cable Requirements | Key Features |

|---|---|---|

| ECG/EKG Monitors | Biocompatible leads, EMI shielding | Patient contact safety, signal clarity |

| Pulse Oximetry | Flexible cables, autoclave resistance | Sensor connectivity, sterilization compatibility |

| Blood Pressure Monitors | Pressure-resistant harness | Durability under mechanical stress |

Advanced connector technologies enable reliable interconnect solutions between medical devices while maintaining biocompatibility and sterilization resistance. Medical-grade connector types include specialized designs for specific healthcare applications to ensure functionality and reliability.

Fiber optic connectors including LC, FC, ST, MU, MTP, and MT-RJ types support high-speed data transmission in modern medical equipment. These connectors feature medical-grade polishing and specialized ferrule components that maintain signal integrity during repetitive flexing in robotic surgical systems used in medical applications.

Advanced materials engineering enables medical cables to withstand harsh clinical environments while maintaining electrical and mechanical performance for a broad range of medical devices.

| Material | Temperature Range | Chemical Resistance | Biocompatibility |

|---|---|---|---|

| TPE | -40 °C to +105 °C | Excellent | ISO 10993-1 |

| FEP | -200 °C to +200 °C | Superior | USP Class VI |

| Medical PVC | -40 °C to +85 °C | Good | ISO 10993-1 |

Conductor specifications include oxygen-free copper for optimal electrical conductivity and silver-plated copper for enhanced corrosion resistance in humid environments. Fiber optic cores utilize medical-grade glass fibers with specialized coatings that maintain signal integrity during repetitive flexing while supporting size and weight requirements for portable medical instrumentation.

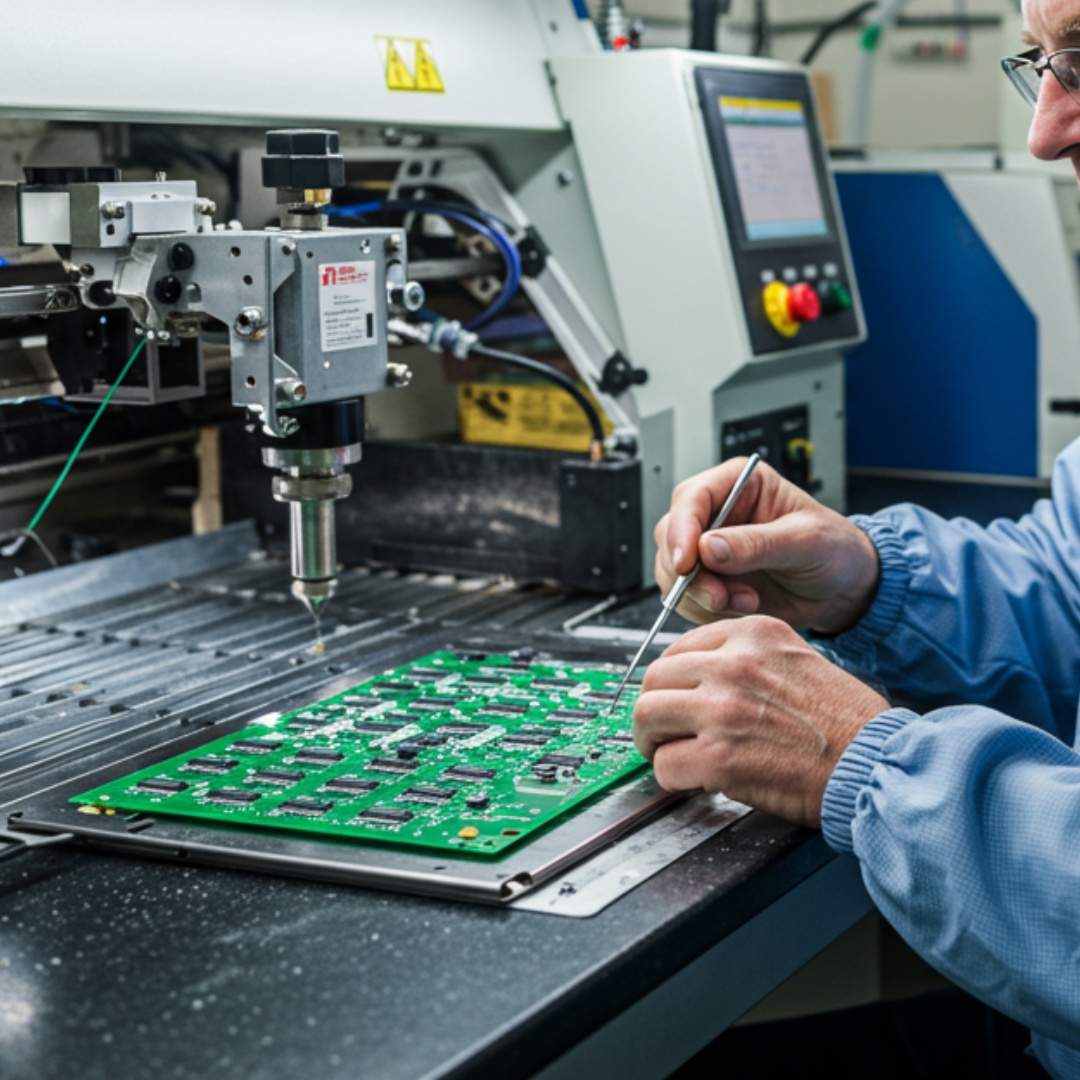

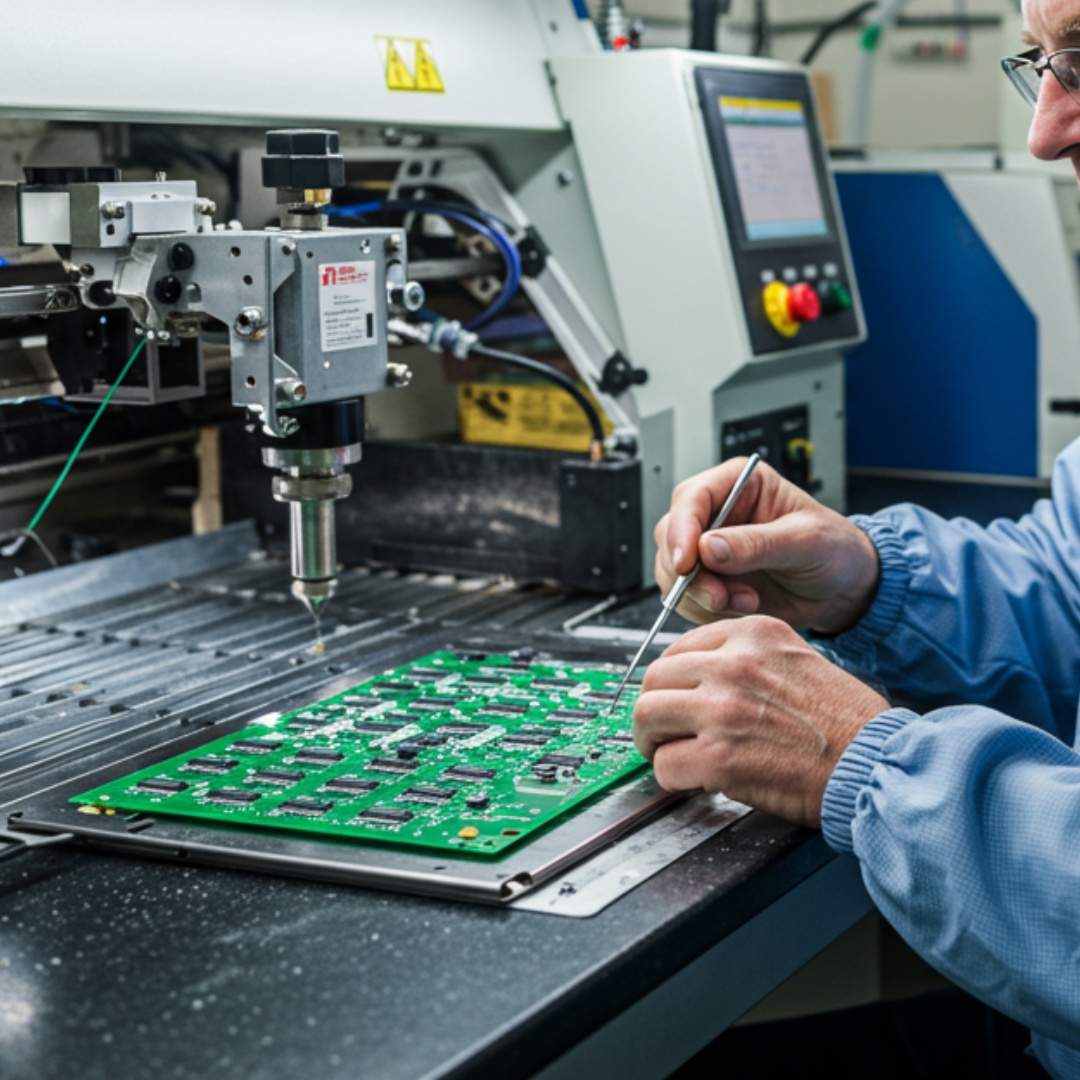

Our manufacturing facility features advanced cable assembly equipment including automated wire processing systems, precision connector insertion machines, and comprehensive electrical testing stations. Environmental testing capabilities include temperature cycling chambers, humidity exposure systems, and chemical resistance evaluation equipment that validates cable performance under clinical conditions.

Quality control systems incorporate automated optical inspection (AOI), in-circuit testing (ICT), and functional verification procedures that ensure every assembly meets specified performance parameters. Our cable assembly manufacturer documentation systems provide comprehensive test reports, material certifications, and manufacturing solutions required for medical device regulatory submissions.

Custom Wire/Cable Service:

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

OurPCB’s medical cable assembly services combine technical expertise with regulatory compliance to deliver connectivity solutions that meet the demanding requirements of healthcare applications. Our ISO 13485 certified manufacturing processes ensure consistent quality while our comprehensive testing protocols validate electrical safety and mechanical durability for life-critical medical devices.

Contact our engineering team today to discuss your range of medical device cable requirements and receive a detailed quotation for your project. We offer a variety of custom medical cable assemblies with complete support from initial design consultation through final product delivery, ensuring your medical devices receive the right cable assemblies that meet all applicable safety standards and performance specifications.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Our medical cable assemblies withstand multiple sterilization methods including autoclave steam sterilization at 134 °C for 18 minutes, ethylene oxide (EtO) gas sterilization, and gamma radiation sterilization up to 25 kGy. Material selection ensures compatibility with hospital sterilization protocols while maintaining electrical and mechanical properties throughout repeated sterilization cycles for cables used in medical environments.

We implement comprehensive EMC design strategies including twisted pair conductor configurations, multi-layer shielding with aluminum foil and tinned copper braid, and proper grounding techniques. Testing validates electromagnetic emissions compliance with IEC 60601-1-2 standards and immunity to electromagnetic interference from medical equipment operating in hospital environments using coaxial and specialized cable configurations.

Our documentation package includes material biocompatibility certificates, electrical safety test reports, mechanical performance validation data, and manufacturing quality records. We provide FDA 510(k) submission support documentation, ISO 13485 quality management certificates, and complete traceability records required for medical device regulatory approval processes including harness assemblies and wire harness specifications.

Request a quote and get a custom testing plan tailored to your design, BOM, and inspection needs. We provide PCB testing services with full traceability, calibrated measurement systems, and certified workflows for Class II and Class III assemblies.

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree