Custom Engine Wiring Harness Assembly

When it comes to engine wiring, there’s no space for shortcuts. At OurPCB, we’ve built our reputation on creating custom engine wiring harnesses that deliver when it matters most. Whether you’re looking to upgrade a classic car, optimize an industrial workhorse, or power specialized machinery, our harnesses are engineered to handle the punishment engines dish out daily.

Our team brings decades of hands-on experience to every harness we build. We’ve seen firsthand what happens when inferior wiring fails in high-stress environments — it’s not pretty. That’s why we obsess over using only premium-grade materials and advanced manufacturing techniques that create harnesses tough enough for the harshest conditions.

Before any harness leaves our facility, it undergoes testing that would seem excessive in other industries, but is absolutely necessary when your engine’s reliability is on the line.

What is a Custom Engine Wiring Harness?

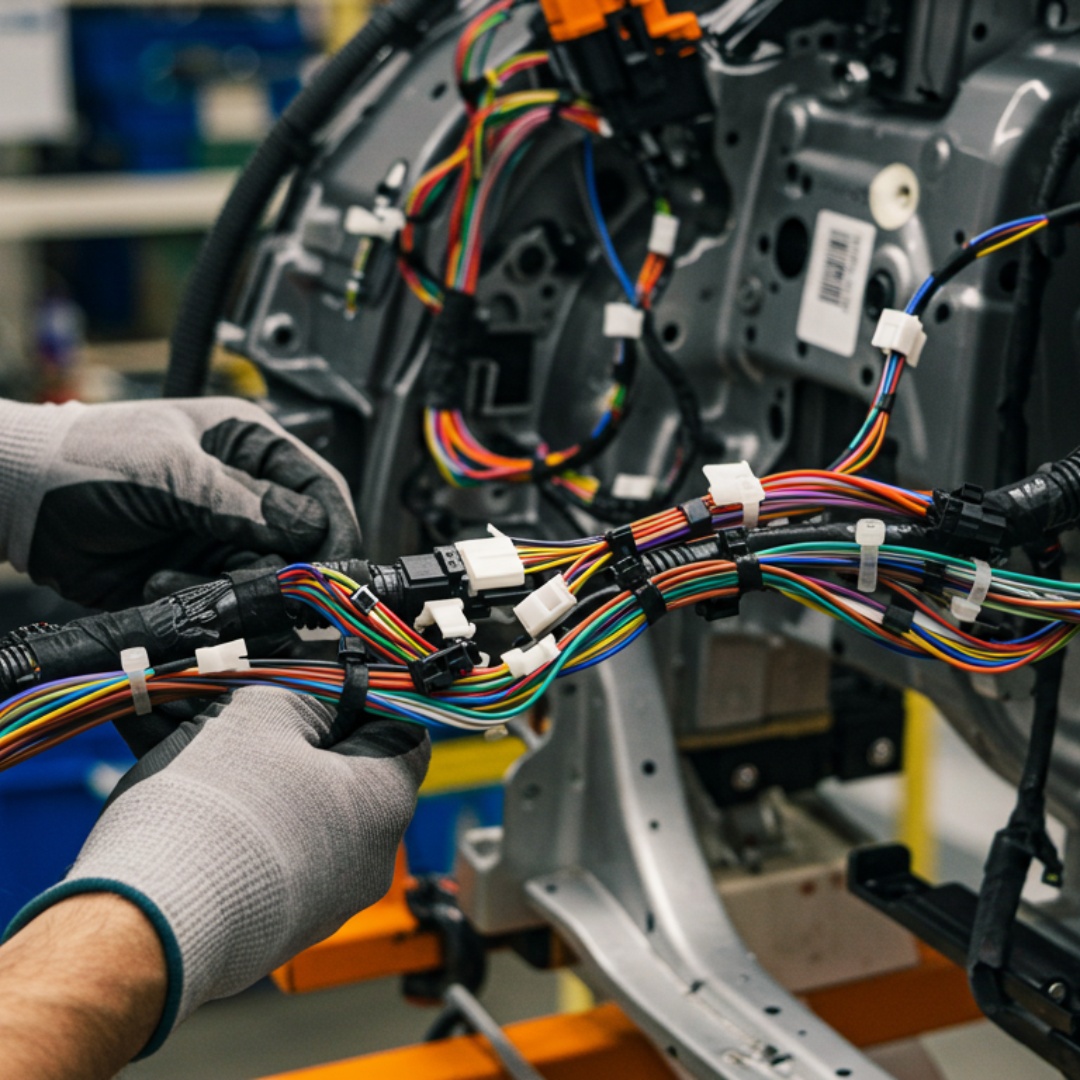

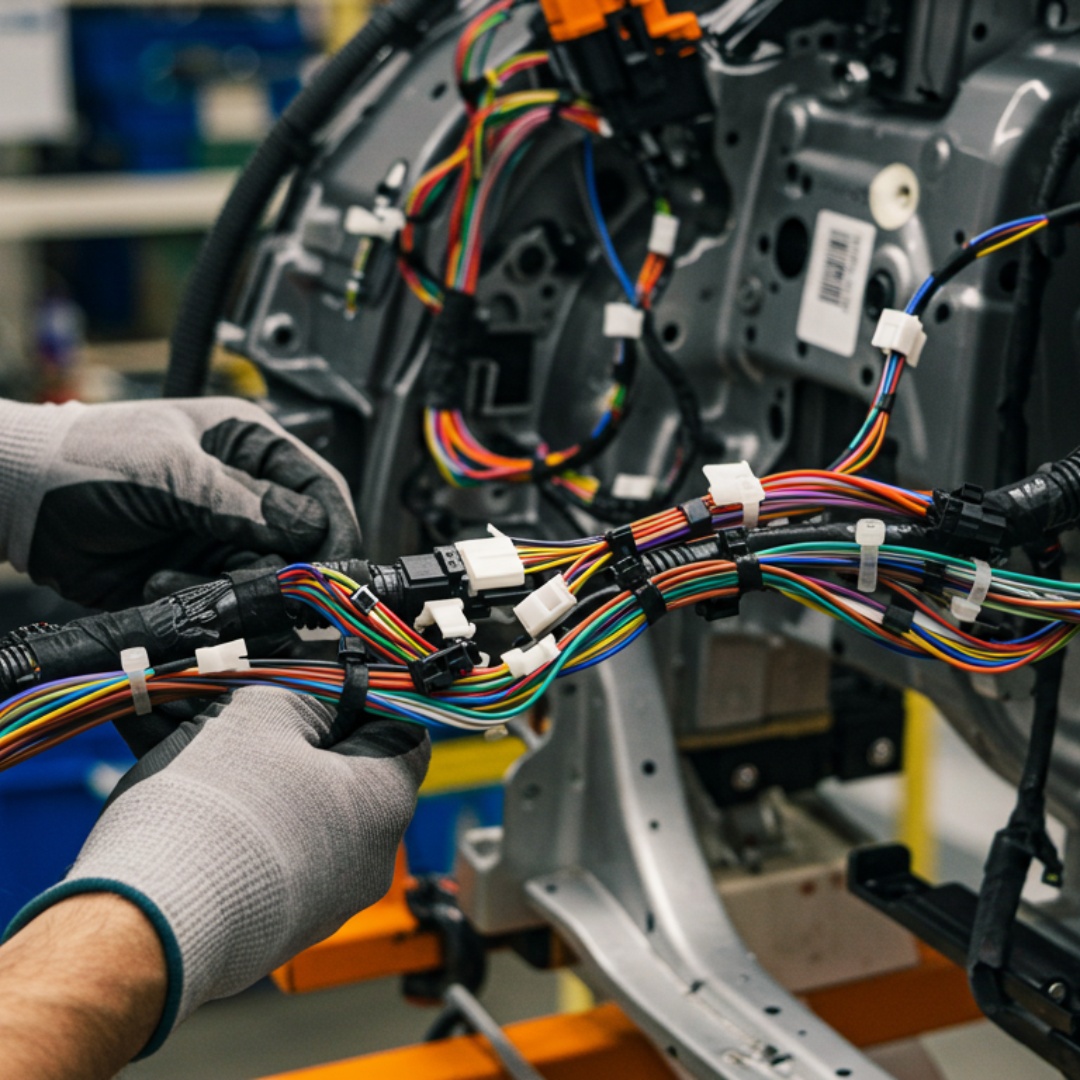

A custom engine wiring harness is basically the electrical backbone of your entire power system. Unlike those one-size-fits-all harnesses that never quite fit right, our custom solutions are built specifically for your engine’s unique setup — whether you’re running a classic muscle car, a modern performance builds, or specialized industrial equipment.

We carefully organize and route every wire, connector, and terminal exactly where it needs to be. This precision doesn’t just make installation cleaner and faster — it dramatically reduces those frustrating electrical gremlins and eliminates potential fire hazards that keep mechanics up at night.

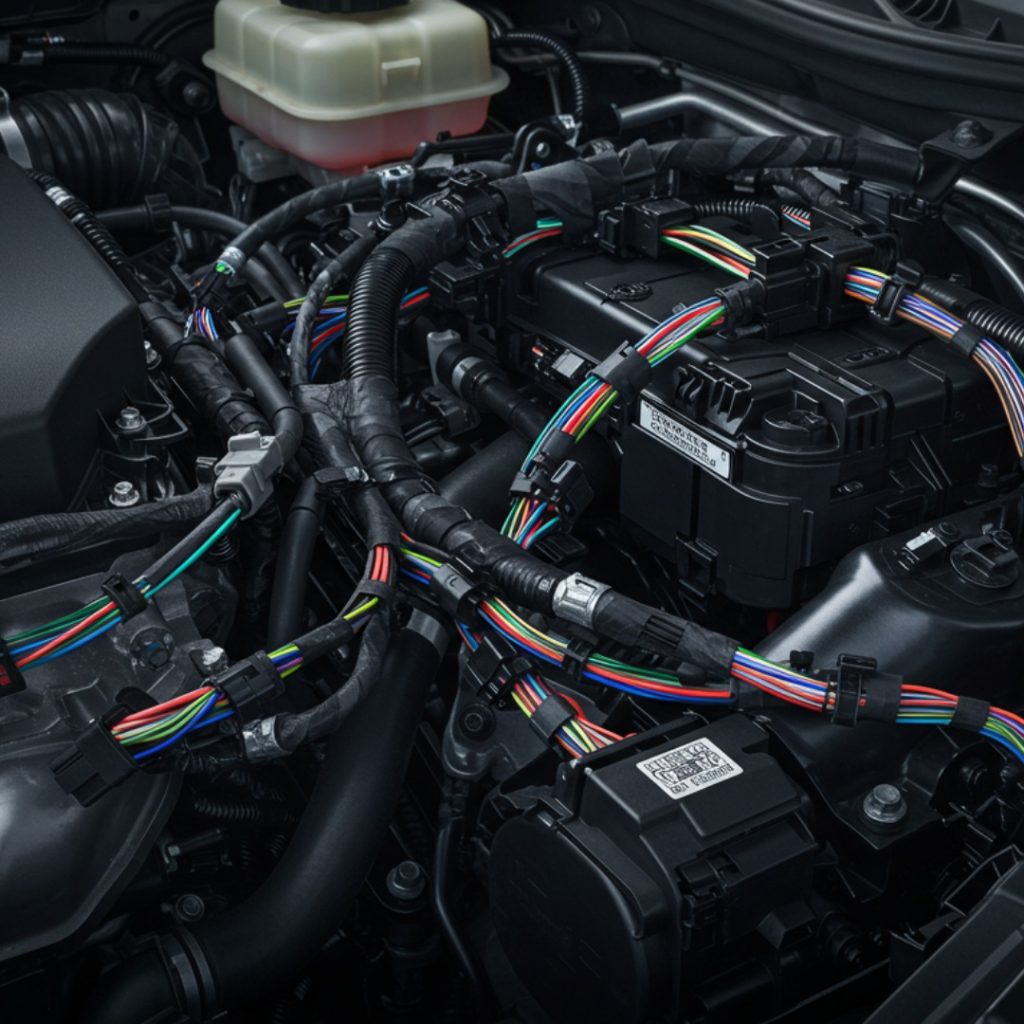

Think of these harnesses as the central nervous system for your engine — they transmit both raw power and crucial data signals between all those critical components: your ECU brain, fuel injectors, various sensors, ignition system, and everything else that makes your engine tick. We build these systems to handle whatever you’re working with — traditional gas engines, complex hybrid setups, or cutting-edge electric powertrains. The difference between a generic harness and a custom-built one becomes immediately obvious the first time you start your engine and everything just works, without mysterious check engine lights or intermittent failures that drive diagnostics crazy.

The Benefits of Custom Engine Wiring Harnesses

Our custom-made engine wiring harness delivers significant advantages over generic solutions or DIY approaches. From enhanced performance to streamlined installation, these purpose-built electrical systems form the backbone of reliable engine operation.

- Each engine cable harness undergoes comprehensive testing for electrical continuity, insulation resistance, and tensile strength to ensure consistent performance.

- Premium materials like high-temperature insulation and corrosion-resistant terminals withstand harsh engine bay conditions including heat, vibration, and chemical exposure.

- Engine harness wire is custom-designed to match exact specifications, eliminating excess wire length and routing complications found in universal harnesses.

- Connector types and terminal selections are optimized for your specific engine control unit and sensor package.

- Reduced electrical resistance through optimized wire gauge selection and high-quality crimping techniques.

- EMI (electromagnetic interference) mitigation through proper shielding and twisted-pair construction where needed.

- Clear wire marking and logical bundling make installation straightforward, even for complex wiring setups.

- Pre-installed protective sleeving and factory-quality terminations eliminate guesswork during fitting.

Superior Field Reliability

- IP67-rated connectors resist complete dust ingress and withstand water immersion up to 1 m for 30 minutes.

- Marine-grade insulation materials provide chemical resistance against fertilizers, pesticides, and fuel exposure.

Extended Equipment Lifespan

- Temperature-resistant components function reliably from -40 °C to 105 °C, preventing heat damage in engine compartments.

- Reinforced strain relief and secure terminal connections prevent failures from constant diesel engine vibration.

Simplified Troubleshooting

- Color-coded wiring with clear detail reduces diagnostic time by up to 60%.

- Comprehensive documentation includes wiring diagram specifications specific to your tractor model.

Customization Options

- Exact-fit design ensures perfect compatibility with your specific Farmall or Cub Cadet restoration.

- Additional capacity options accommodate future implements or aftermarket electrical accessories you may add later.

Why Choose OurPCB for Custom Engine Wiring Harnesses

When selecting a wire harness manufacturer for your engine wiring needs, experience, technical capability, and quality control processes make all the difference. Here’s why leading engine builders and automotive professionals trust OurPCB with their critical harness requirements.

- Our engineering team specializes in both modern ECU systems and classic/retrofit applications across multiple platforms.

- Extensive experience designing aftermarket engine wiring harness solutions for racing, performance, restoration, and industrial engine applications.

- Detailed requirements gathering ensures every connection and routing consideration is addressed before production.

- Advanced wire harness design software validates electrical performance and identifies potential issues before physical assembly.

- We use only automotive-grade wire and cable with temperature ratings appropriate for engine room harness conditions.

- High-quality connectors from industry-leading manufacturers ensure reliable connections over thousands of heat/cool cycles.

- Multi-stage testing protocols verify both electrical integrity and mechanical durability of every harness.

- 100% inspection of crimp connections, terminal insertion, and protective features before shipment.

Our Custom Wiring Harness Features

ROHS-Compliant Materials

Safe, approved, and eco-friendly materials

Custom Materials to Suit the Environment

Customized materials for abrasion-, oil-, heat-, or water-resistance

Your Choice of Coverings

Choose from PVC, nylon, XLPE, rubber, braided sleeving, heat shrink tubing, and more!

Variable Wire Options

We offer various wire thicknesses and lengths to meet your exact needs

Across Many Industries

We serve almost every industry you can think of! Contact us today.

Millions of business and innovators use OurPCB

Our Custom Wiring Harness Process

Fast, free, and includes a production timeline

Our engineers create your design schematic and select the right materials

We’ll manufacture a high-quality prototype within 7 days

The prototype goes through various functionality and stress tests

Cutting, stripping, and assembly to the highest standard

After final testing and packaging, your custom wiring harnesses are delivered

Technical Capabilities

Our engineering and manufacturing capabilities cover the full spectrum of engine wiring harness replacement requirements. From prototype development to production runs, we maintain consistent quality and precision throughout our wire harness manufacturing process.

Our manufacturing plants are equipped with advanced wire processing equipment including wire cutting machines, precision crimping tools, and computerized testing systems. This technology, combined with our skilled technicians who adhere to the highest standards of quality, ensures every engine harness replacement meets our exacting standards for both electrical performance and mechanical durability.

We comply with key industry standards including IPC/WHMA-A-620 for cable assemblies and IATF 16949 quality management systems. This commitment to standardization ensures our engine wiring harness manufacturers create quality products compatible with leading OEM and aftermarket systems.

Capabilities & Services

- Wire Gauge: 40AWG-120mm²

- Production Capacity: 10,000 pieces/hour

- Wire Cutting Service

- Wire Stripping Service

- Wire Marking Service

- Label Types

- Wire Ends Treatment

Custom Wire/Cable Service:

- Wire/Cable types

- Wire gauge

- Wire/Cable length

- Insulation/Jacket color

- Core numbers etc.

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

- Electrical cable assembly

- Coaxial cable assembly

- Multi-core cable assembly

- Connector to board cable assembly

- Automobile communication cable assembly

- Power transmission cable assembly

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Custom Engine Wiring Harness Assembly FAQs

What is an engine harness and why might I need to replace engine wiring harness components?

An engine harness is the central nervous system of your vehicle, connecting all electrical components to your engine control unit. You might need an engine harness replacement when dealing with electrical issues, upgrading to performance components, or restoring classic vehicles. The engine harness cost is justified by improved reliability and performance compared to repairing aging wiring.

How long does it take to produce a custom engine wiring harness near me?

Production time varies based on complexity and current workload, but typical lead times range from 2 to 3 weeks for standard projects to 4–6 weeks for complex systems with hundreds of harnesses. We offer engine wire harness replacement cost estimates upfront so you can plan accordingly. For customers seeking engine wiring harness for sale options with quicker delivery, we may have expedited services available.

What information do you need to create custom wire harness solutions for my engine?

For an accurate quote on harness for engine applications, we typically need details about your engine type, ECU/management system, sensor package, and any special requirements like environmental conditions or certification needs. Photos or diagrams of your engine bay and existing wiring help our OEM customers receive exactly what they need for their automotive applications.