Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no lights, no engine starts, no radio — nothing. They're like the blood vessels of your vehicle.

Choosing a manufacturer for such an important role is extremely difficult. We've made it our mission to find out who makes the best harnesses today. You'll see why they matter for your vehicle, no matter whether you drive a regular car or an electric vehicle, this guide helps you understand what's connecting everything in your automobile.

Contents

- Key Takeaways

- What's a Wire Harness Anyway?

- 15 Wire Harness Makers

- 1. OurPCB

- 2. Yazaki Corporation

- 3. Sumitomo Electric

- 4. Aptiv

- 5. Leoni

- 6. Furukawa Electric

- 7. Lear Corporation

- 8. Kromberg & Schubert

- 9. Fujikura

- 10. Motherson/PKC Group

- 11. Yura Corporation

- 12. Kyungshin

- 13. Draexlmaier

- 14. Coroplast/WeWire

- 15. Renhotec

- How do They Make Wire Harnesses?

- What Makes a Good Quality Wire Harness?

- How to Choose the Wire Harness Maker?

- Ready for Better Wire Harnesses Today?

- Frequently Asked Questions

- How do they test harness quality?

- How are harnesses different between regular and electric cars?

- What makes a wire harness design work well?

Key Takeaways

- Wire harnesses connect everything electrical in your car

- OurPCB tops the list for custom wire harness solutions

- Electric vehicle harnesses need special high-voltage protection

- Better materials make your harness last longer

What's a Wire Harness Anyway?

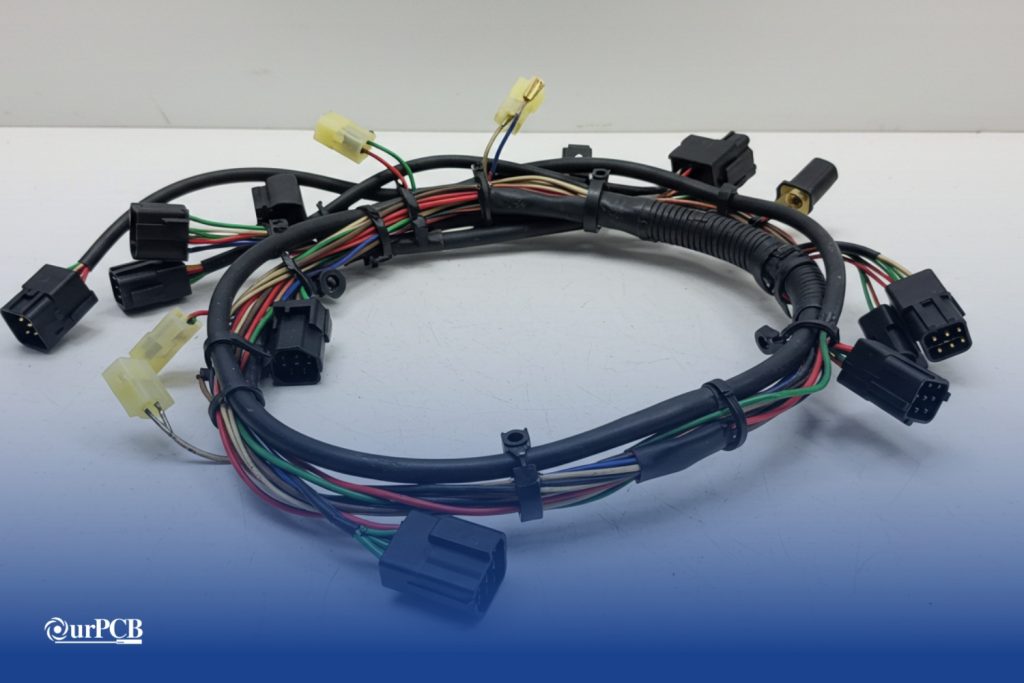

A wire harness is just a bunch of wires bundled together neatly. It carries electrical power through your car. It includes the wire and cable, plus terminals, connectors, and protective coverings.

It's crazy how much wiring is in cars nowadays! We're talking about 4 miles of wire in most vehicles. Every harness has different stuff — copper wires, aluminum bits, all kinds of connectors, and protective coverings. Car makers have to design these things specially for each model. Without proper harnesses, you'd open your hood and just see a jumbled wire nightmare!

15 Wire Harness Makers

1. OurPCB

OurPCB As one of the leading car wire harness manufacturers, we make the best car wire harnesses around. When you need quality, you need OurPCB. We create custom wire products for all types of vehicles — regular cars, sports cars, and electric ones too.

Here’s what makes us special:

- Our manufacturing capabilities include advanced crimping, cutting, soldering, and ultrasonic wire welding.

- We offer fully integrated services, including PCB manufacturing, assembly, and custom wire harness fabrication.

- OurPCB’s factory holds multiple key certifications: IATF 16949, ISO 9001, ISO 14001, UL, RoHS, and REACH.

2. Yazaki Corporation

Yazaki has 468 plants in 44 countries with over 200,000 employees. They started back in 1941 and now control about 30% of the global market. Most major car makers use their wire harnesses and electrical parts.

Their best features:

- Huge global production network

- Advanced design for complex vehicles

- Special EV harness production

- Green manufacturing practices

3. Sumitomo Electric

Sumitomo Electric has been making wire harnesses since 1917. They're one of the oldest and most respected manufacturers around. This Japanese company holds about 20% of the global market, focusing on Japanese vehicles like Toyota and Honda.

| Quick Facts | Details |

|---|---|

| Started | 1917 |

| Market Share | About 20% |

| Specializes In | Japanese vehicles |

| Big Clients | Toyota, Honda, Nissan |

4. Aptiv

Formerly known as Delphi, this UK company makes cutting-edge harnesses for advanced vehicle systems. Aptiv leads in wiring for self-driving cars and electric vehicle power systems. They work in over 45 countries.

What they do best:

- Driver assistance system harnesses

- High-voltage EV power distribution

- Connected vehicle data systems

- Lightweight designs for better fuel economy

5. Leoni

Leoni comes from Germany. They've got more than 100,000 people working for them around the world. They make really good wire harnesses for fancy European cars. When you drive a BMW or Mercedes-Benz, you're probably using their products. Their stuff doesn't break easily, even in cars that go superfast.

6. Furukawa Electric

Furukawa Electric started way back in 1896. That's more than 125 years of making wires! This Japanese company cares about not hurting the environment. They use all the latest wire technology too. Their newest products go into electric and hybrid cars with extra safety features.

7. Lear Corporation

Born in Detroit in 1917, Lear makes both seats and electrical systems, including wire harnesses. Their products are in over 400 vehicle models worldwide, with a strong focus on American and European manufacturers.

| Strengths | What It Means For You |

|---|---|

| Integration | Better compatibility between systems |

| Wide Reach | Parts available for most vehicles |

| Research | Latest technology in your car |

| Many Factories | Faster production and delivery |

8. Kromberg & Schubert

K&S started back in 1902. They're German. Now they have over 50 factories all over the world. They make wire harnesses for expensive cars with lots of electrical stuff. They're super careful about how they make things. That's why fancy car brands love them.

They make wires for:

- Audi

- Mercedes-Benz

- BMW

- Volkswagen

- Porsche

9. Fujikura

Fujikura has been around since 1885. They know everything about connectors and cables for cars. They have 18 factories just in China. They're really good at making complicated wire harnesses. These go in modern cars with fancy electronics and entertainment systems.

10. Motherson/PKC Group

This Indian manufacturer leads in making harnesses for commercial vehicles globally. Motherson partnered with companies like Sumitomo to improve their technical abilities, creating a powerful mix of size and expertise.

What they make harnesses for:

- Commercial trucks (heavy, medium, light)

- Farm machinery

- Construction equipment

- Two-wheelers and recreational vehicles

- Medical equipment

11. Yura Corporation

A Korean specialist started in 1993 making advanced wiring systems. Yura has expanded globally with operations in Europe, North America, and Asia. They focus on next-generation vehicle electrical systems that meet tomorrow's needs.

12. Kyungshin

Kyungshin started in 1974. They mostly make wire harnesses for Hyundai and Kia cars. They've got factories all over the place — China, India, USA, Mexico, and Honduras. That means they can make wires pretty much anywhere in the world.

| Quick Facts | The Details |

|---|---|

| Started | 1974 |

| Main Customers | Hyundai, Kia |

| Global Presence | 5 countries |

| Partner | Sumitomo Electric |

13. Draexlmaier

This German company started in 1958 specializing in premium harnesses for luxury vehicles. With more than 60 locations in over 20 countries, they've built a reputation for exceptional quality in high-end applications.

What they're great at:

- Interior light harnesses

- High-density connector systems

- Custom-designed protection

- Premium vehicle electrical systems

14. Coroplast/WeWire

German family-owned company with global operations. Running since 1928, they supply to major European brands through their WeWire division. They know technical tapes, wire and cable, and complete harness assemblies inside and out.

15. Renhotec

This Chinese manufacturer started in 2005 specializing in electronic connectors and wire harnesses. Renhotec has grown fast, with products exported to 81 countries worldwide. They focus heavily on new energy vehicle applications for the future of transportation.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

How do They Make Wire Harnesses?

Making wire harnesses isn't complicated, but it needs precision. First, designers use special computer software to create the plan. Then machines cut and strip wires to exact lengths.

Special crimping machines attach terminals with just the right pressure. Final assembly involves bundling wires according to the design, adding protective coverings, and installing connectors. Manufacturers check everything works properly before shipping to car makers.

What Makes a Good Quality Wire Harness?

Good wire harnesses need to perform well electrically, physically, and in tough environments. The most important quality factor is proper crimping—how the wire connects to the terminal. Good crimping requires precise pressure to create connections that won't fail over time.

Materials really matter too. The best harnesses use tinned copper wires that fight corrosion, special insulation that handles heat up to 125 °C, and connectors with locking mechanisms that stay connected no matter what. The pros say that more and more electric and hybrid cars are being made.

How to Choose the Wire Harness Maker?

First, check if they have quality certificates. These can be like IATF 16949 and IPC/WHMA-A-620 Class 3. These prove they know what they're doing. Then ask how they check their work and test their products.

Also make sure they can actually make what you need. Do they have experience with your kind of project? Can they design what you want? Can they handle special stuff like really hot environments or weird connector types? Good manufacturers can do all this without problems.

Ready for Better Wire Harnesses Today?

Bad wire harnesses cause all sorts of electrical problems in your car. Don't risk it. Wire harnesses keep everything electrical working right. You need them made properly with good materials by people who know what they're doing.

Contact OurPCB now for your wire harness needs. See for yourself why we're the #1 choice for automotive wire harnesses.

Frequently Asked Questions

How do they test harness quality?

They check wire harnesses in lots of ways. First, they run electrical tests to make sure everything connects right. Then they do high-voltage tests to check the insulation isn't leaking. They also pull on the wires really hard to make sure the crimps hold tight.

They put harnesses through hot and cold temperatures and shake them around. Then splash car fluids on them. Some companies even cut the crimps in half and look at them under microscopes. That's how they make sure your harness won't fail.

How are harnesses different between regular and electric cars?

Regular car harnesses use 12-24 volt circuits with standard insulation. Electric vehicle harnesses need high-voltage sections (up to 1000 volts) with special thick insulation. EV harnesses have extra safety features like interlock circuits. They also usually, most of the time, have touch-proof connectors and monitoring systems. They use thicker wires, more shielding, and often have cooling systems.

What makes a wire harness design work well?

Good design starts with choosing the right wire size based on how much power it needs to carry, with extra safety margin. Connector choice needs to consider water resistance, vibration resistance, and proper terminal design. The routing plan must keep proper bend radius, avoid heat sources, and secure the harness to prevent movement and damage.

Back to Top: Best 15 Automotive Wire Harness Manufacturers 2025

Special Offer: Get $100 off your order!

Email [email protected] to get started!