Top 10 Classic Car Wiring Harness Manufacturers | Full Guide

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

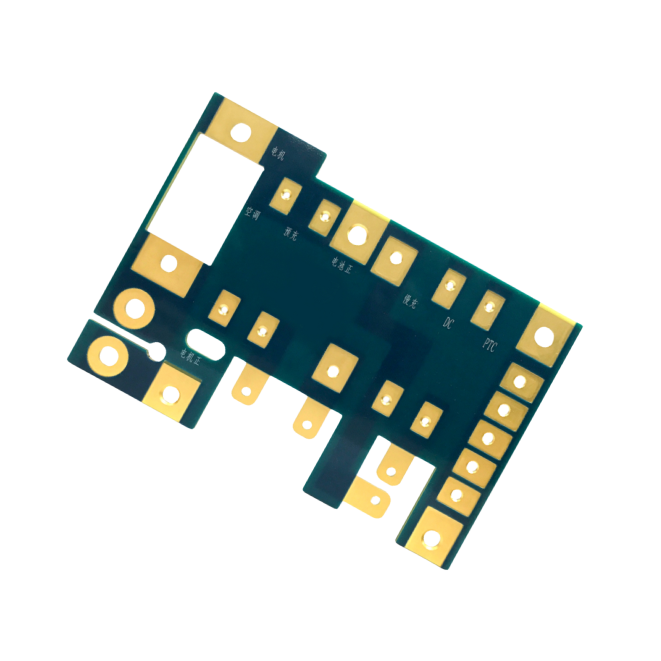

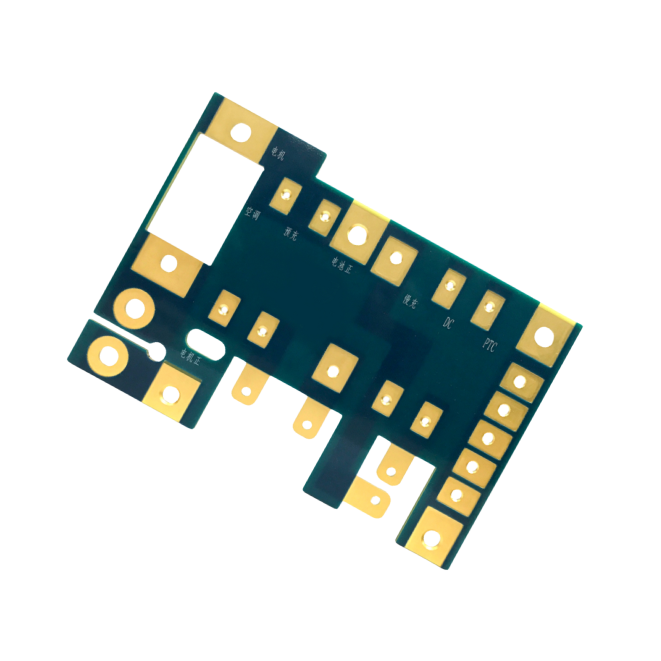

Ball grid array (BGA) PCBs use hidden solder balls instead of visible leads, making them ideal for compact, high-performance electronics. As a professional BGA PCB assembly manufacturer, we combine precision placement, advanced inspection, and expert rework to ensure strong, reliable connections.

We deliver precision BGA PCB assembly services with advanced equipment, skilled technicians, and comprehensive testing capabilities. Our specialized processes ensure reliable connections and optimal performance for your most complex BGA-based circuit designs.

With specialized BGA placement equipment, advanced X-ray inspection systems, and dedicated rework stations, OurPCB provides comprehensive BGA assembly services that ensure precise alignment, reliable solder connections, and thorough verification.

OurPCB combines advanced BGA PCB assembly technology with extensive technical expertise to deliver reliable, high-performance BGA-based circuit assemblies for demanding electronic applications.

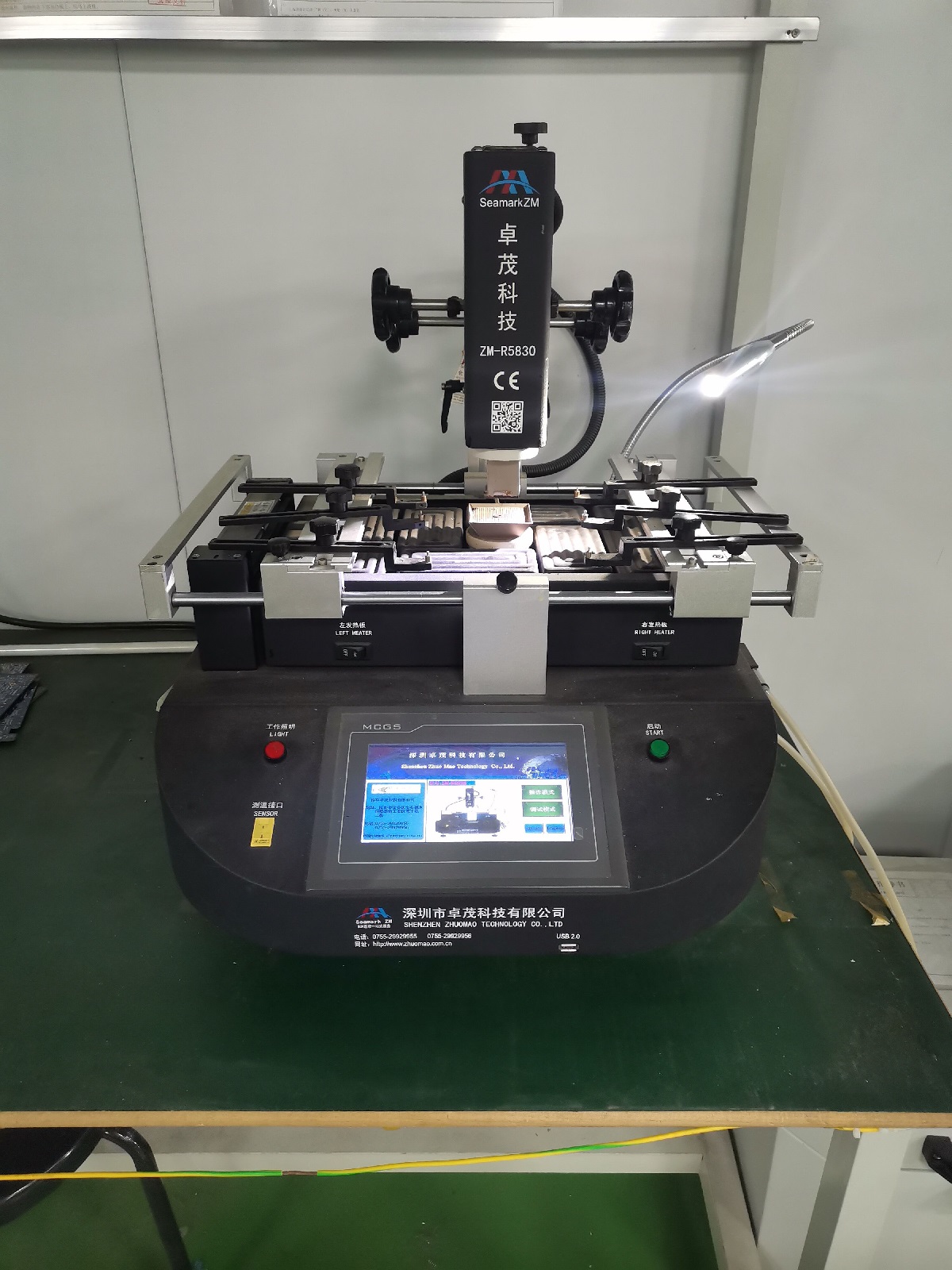

OurPCB employs specialized BGA assembly techniques supported by advanced manufacturing equipment including precision pick and place machines, controlled reflow ovens, X-RAY inspection systems, and dedicated ball grid array rework stations to ensure quality and reliability across all BGA PCB fabrication and assembly projects.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

We can do plastic BGAs (PBGA), ceramic BGAs (CBGA), tape BGAs (TBGA), micro BGAs (μBGA), fine-pitch BGAs (FBGA), package-on-package (PoP) BGAs, and thermally enhanced BGAs for specialized applications.

We implement a comprehensive quality assurance process to check for voids in solder joints, bridging between balls, defects, misalignment, and incomplete reflow. The process includes precision equipment setup, controlled reflow profiles, X-RAY inspection for solder joint verification, and electrical testing to ensure reliable connections and optimal performance.

Yes, our facilities include specialized BGA rework stations operated by skilled technicians. We offer professional BGA replacement, reballing, and repair services for both prototype and production assemblies.

We can support BGA assembly on boards ranging from simple 2-layer to complex multilayer designs (12+ layers), accommodating various substrate materials and board densities according to your specific requirements.

We use advanced X-RAY inspection systems that allow non-destructive verification of BGA solder joints, including checking for proper alignment, solder ball formation, and the absence of voids or bridges to ensure reliable electrical connections.

Thermal profiling is the process of measuring and controlling the temperature of a PCB during solder reflow. It helps make sure the board reaches the correct temperatures at the right times to form strong, reliable solder joints without damaging components.

Start by choosing a suitable ball pitch—larger pitches like 1.0 mm are easier to route and inspect than fine-pitch BGAs. Use non-solder mask defined (NSMD) pads to improve solder joint quality and avoid open vias under pads unless they’re filled and capped to prevent solder wicking.

Maintain proper trace width and spacing based on your manufacturer’s design rules, and plan your layer stackup to allow clean escape routing—using microvias for high-density layouts. Keep solder mask alignment tight, apply the right paste volume, and leave space for test points or JTAG access since BGA joints can’t be visually inspected.

Our lead times vary from 4 days for simple 2-layer PCBs to 25+ days for large, multi-layer designs. Your specific project’s lead time will be based on the complexity of your BGA PCB design and the volume of your order.

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree