Top 10 Classic Car Wiring Harness Manufacturers | Full Guide

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

5 Star Rating on

5 Star Rating on

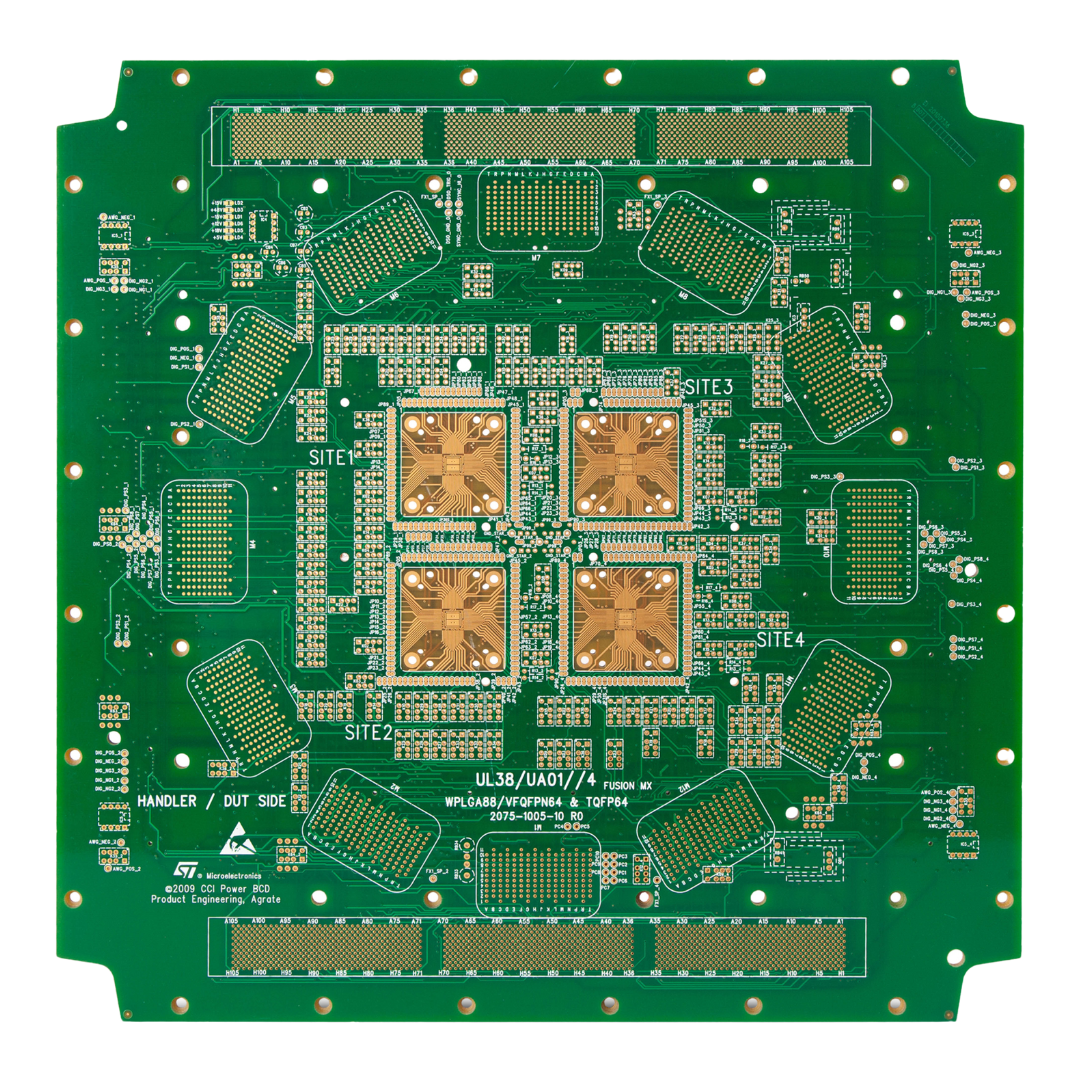

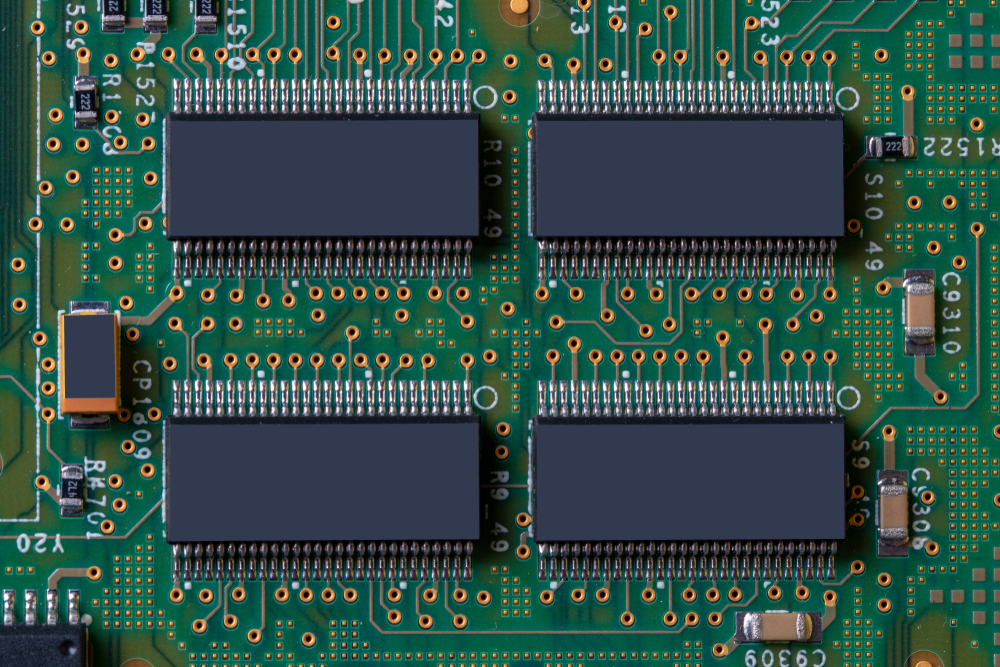

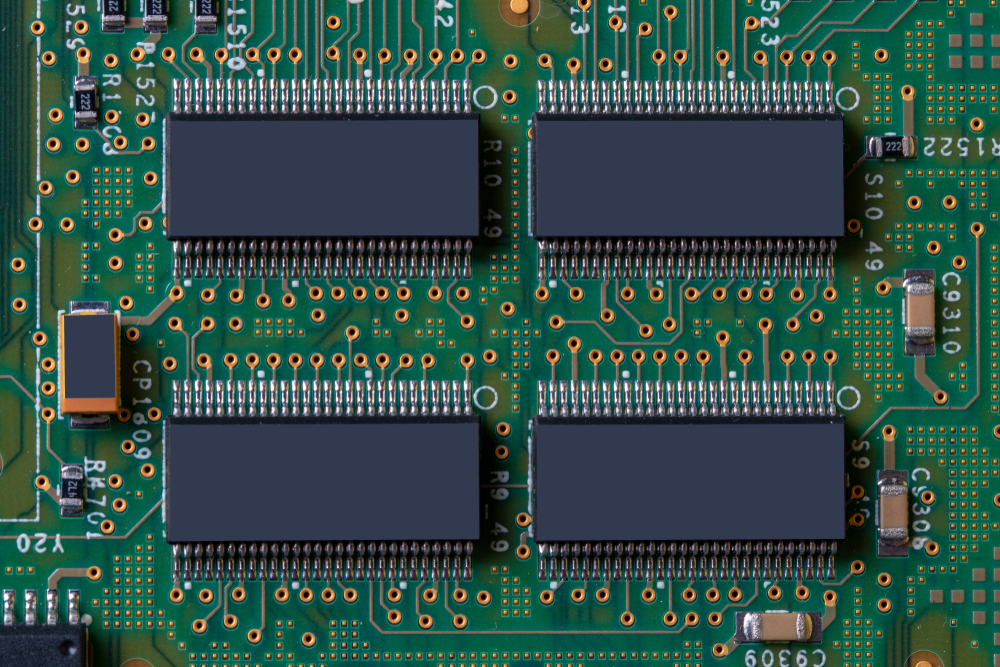

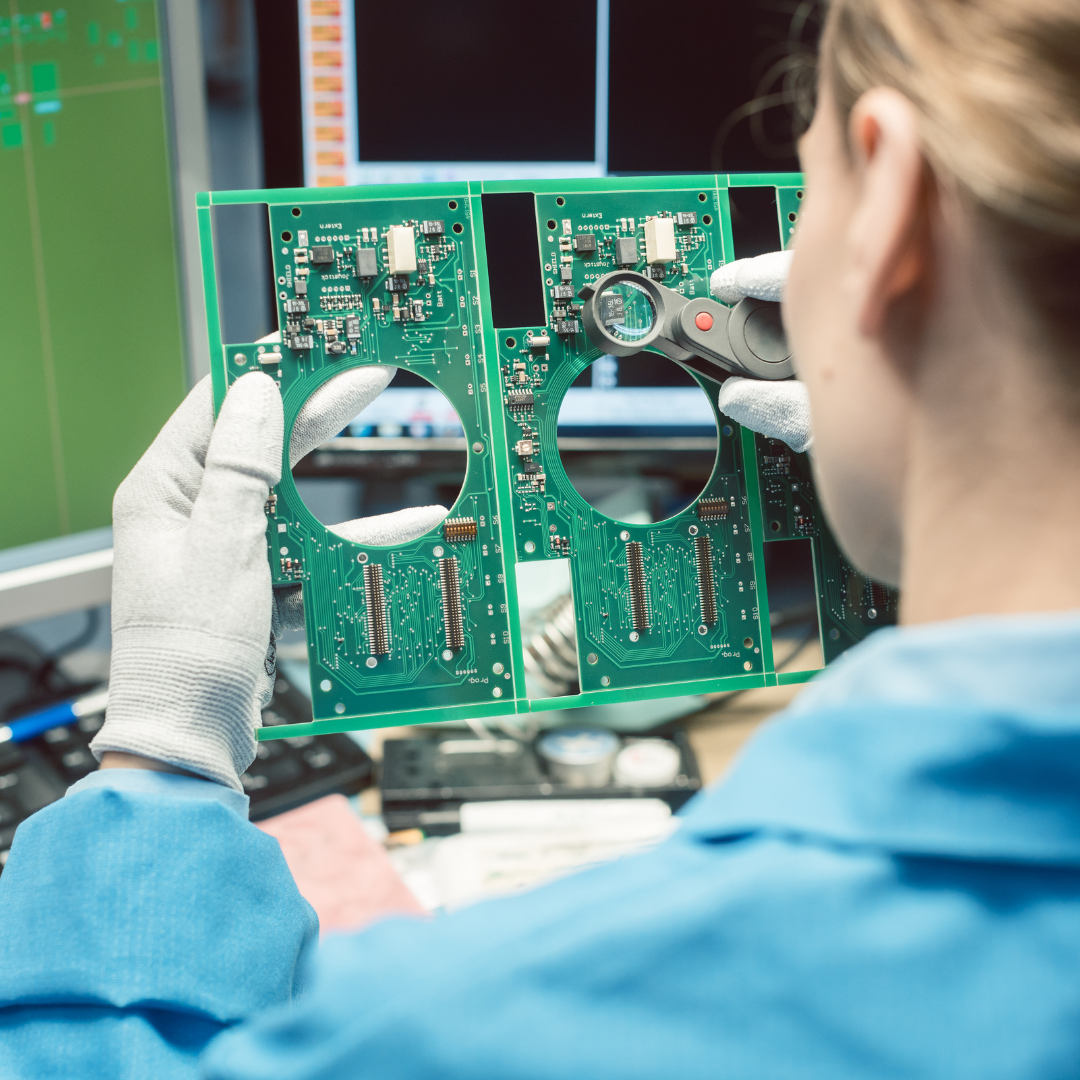

Double sided PCB assembly is the process of placing and soldering components on both sides of a printed circuit board. This method maximizes board space and functionality. OurPCB offers expert double sided PCB assembly services, delivering high-quality results for various industries and applications.

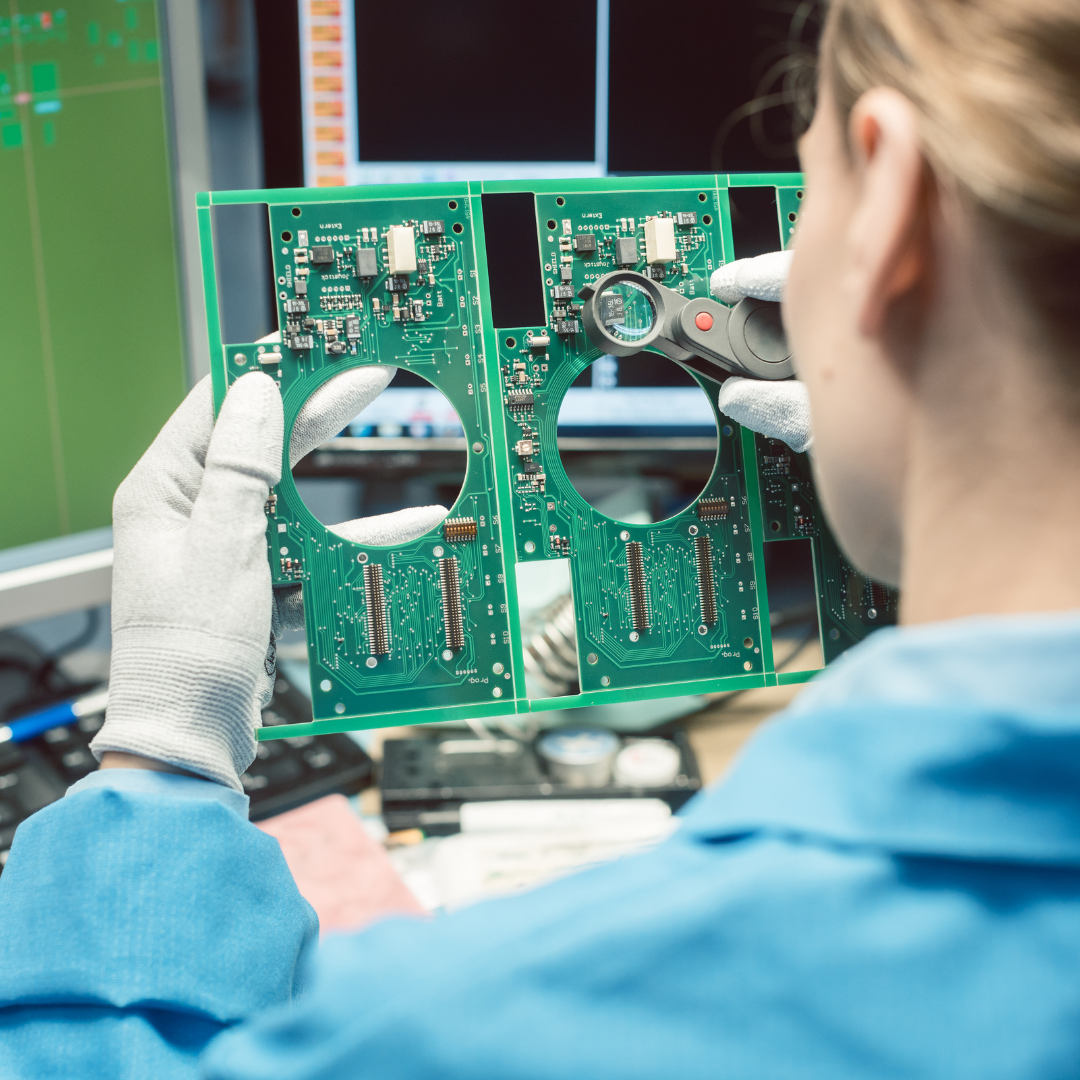

Double-sided PCB fabrication and assembly represent two distinct phases in the creation of electronic devices. Fabrication focuses on creating the bare board with copper traces and necessary features, while assembly transforms this board into a functional electronic unit by adding components.

| Aspect | Double-Sided PCB Fabrication | Double-Sided PCB Assembly |

|---|---|---|

| Starting Material | Copper-clad laminate (CCL) | Bare manufactured PCB |

| Primary Nature | Chemical and mechanical processing | Mechanical placement and thermal processing |

| Major Process Steps | DFM check, cutting, drilling, copper plating, etching, solder masking, testing | Preparation, solder paste application, component placement, reflow soldering, inspection |

| Duration | Typically longer (multiple chemical processes) | Relatively shorter (mechanical placement) |

| Equipment | Drilling machines, plating equipment, etching tanks, screen printers | Pick-and-place machines, reflow ovens, inspection systems |

| Primary Focus | Creating conductive pathways and preparing connection points | Placing components and establishing electrical connections |

OurPCB offers premium double sided PCB manufacturing services. We combine cutting-edge technology with skilled technicians to deliver superior results. Our focus on quality and efficiency makes us a trusted partner for your PCB needs.

Double sided circuit boards offer more design flexibility than single sided options. They allow for higher component density and more complex circuits. Choosing a reliable supplier ensures you get the most from this technology.

OurPCB provides a full range of PCB assembly services to meet diverse client needs. We use state-of-the-art equipment and follow strict quality control measures. Our team is committed to delivering reliable and efficient PCB solutions.

We use advanced Surface Mount Technology for high-density, compact PCB designs. Our SMT process ensures precise component placement and reliable solder joints. This method is ideal for modern electronics that require small form factors.

We offer flexible assembly options to suit your needs. You can provide your own components, or we can handle the entire process. Our turnkey service covers component sourcing, assembly, and final delivery. This saves you time and streamlines your production.

Our team works closely with you to create tailored PCB solutions. We can accommodate unique designs and special requirements. Our custom assembly service ensures your specific project needs are met with precision.

We understand the importance of fast turnaround in today’s market. Our quick-turn service delivers high-quality PCBs in short timeframes. We maintain our commitment to quality even under tight deadlines.

For industries with strict reliability requirements, we offer IPC Class 3 compliant assembly. This standard is crucial for aerospace, medical, and other critical applications. Our Class 3 assemblies meet the highest quality and reliability standards.

We have the expertise to handle all types of IC packages. This includes BGAs, POPs, CGAs, QFNs, DFNs, and CSPs. Our advanced equipment and skilled technicians ensure reliable assembly of these complex components.

OurPCB boasts modern facilities for double sided PCB assembly. We use advanced pick-and-place machines for accurate component placement. Our reflow ovens ensure optimal solder joint formation, and we perform automated optical inspection (AOI) and in-circuit testing for quality assurance. Our capabilities include handling boards up to 20 x 24 inches and components as small as 01005. We can assemble boards with high component density and fine-pitch BGAs.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

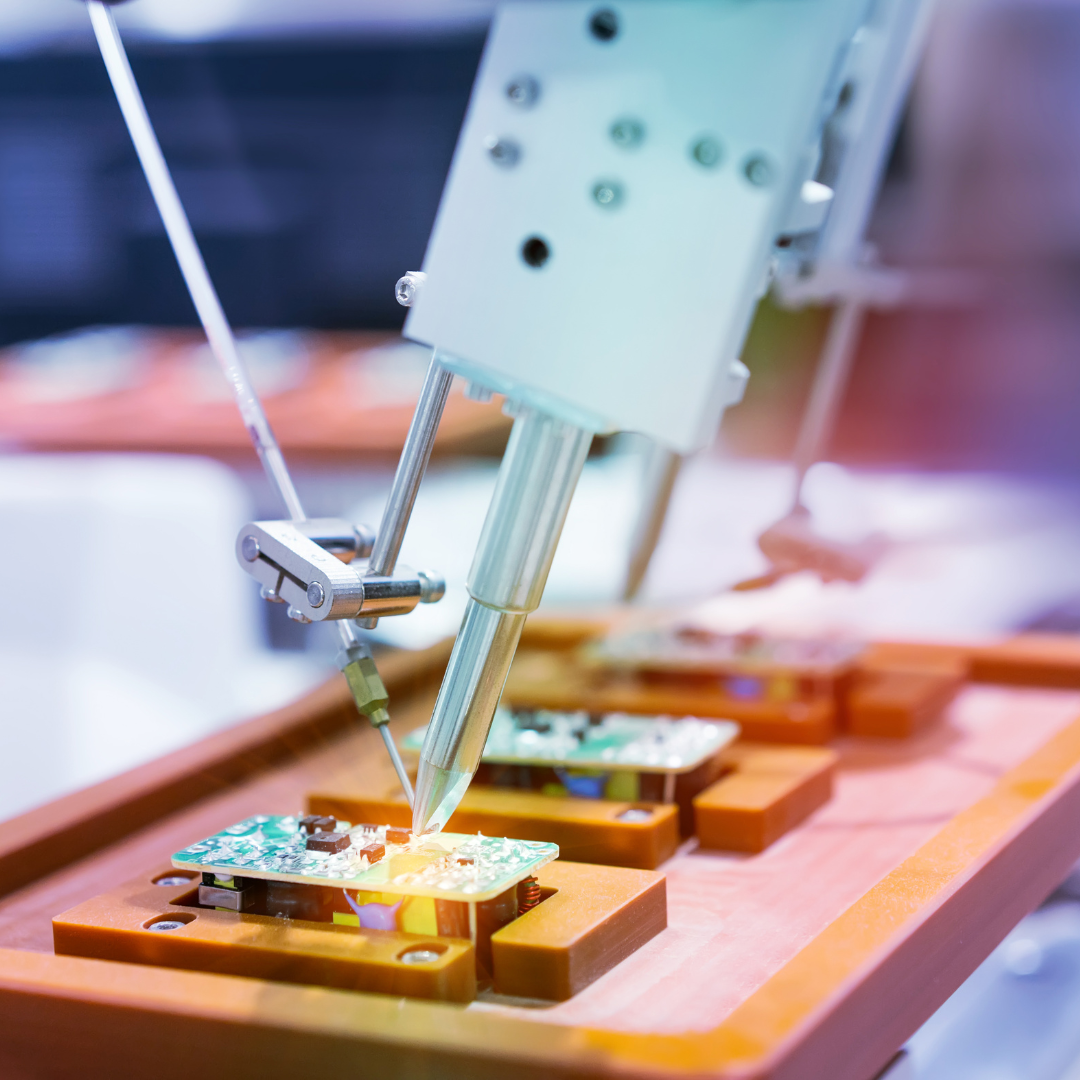

The double-sided PCB assembly process starts with designing a prototype and preparing the BOM. The PCB boards are then fabricated, and vias are drilled to connect layers. Electronic components are placed on both sides using surface-mount technology, followed by soldering. Functional testing ensures the printed circuit board assembly meets requirements.

Double-sided SMD boards are assembled by placing components on each side sequentially. The PCB assembly process involves stencil printing, pick-and-place machines, and reflow soldering. On-site PCB assembly and turn-key PCB services streamline this process. Volume PCB assembly costs depend on complexity, components, and production scale.

To identify SMD components, double sided PCB factories examine the PCBA for labeled markings and package types. Use the BOM to cross-reference part numbers and specifications. Check the assembly process for orientation and polarity indicators. Proper identification is crucial for accurate repair and testing.

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree