Top 10 Classic Car Wiring Harness Manufacturers | Full Guide

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

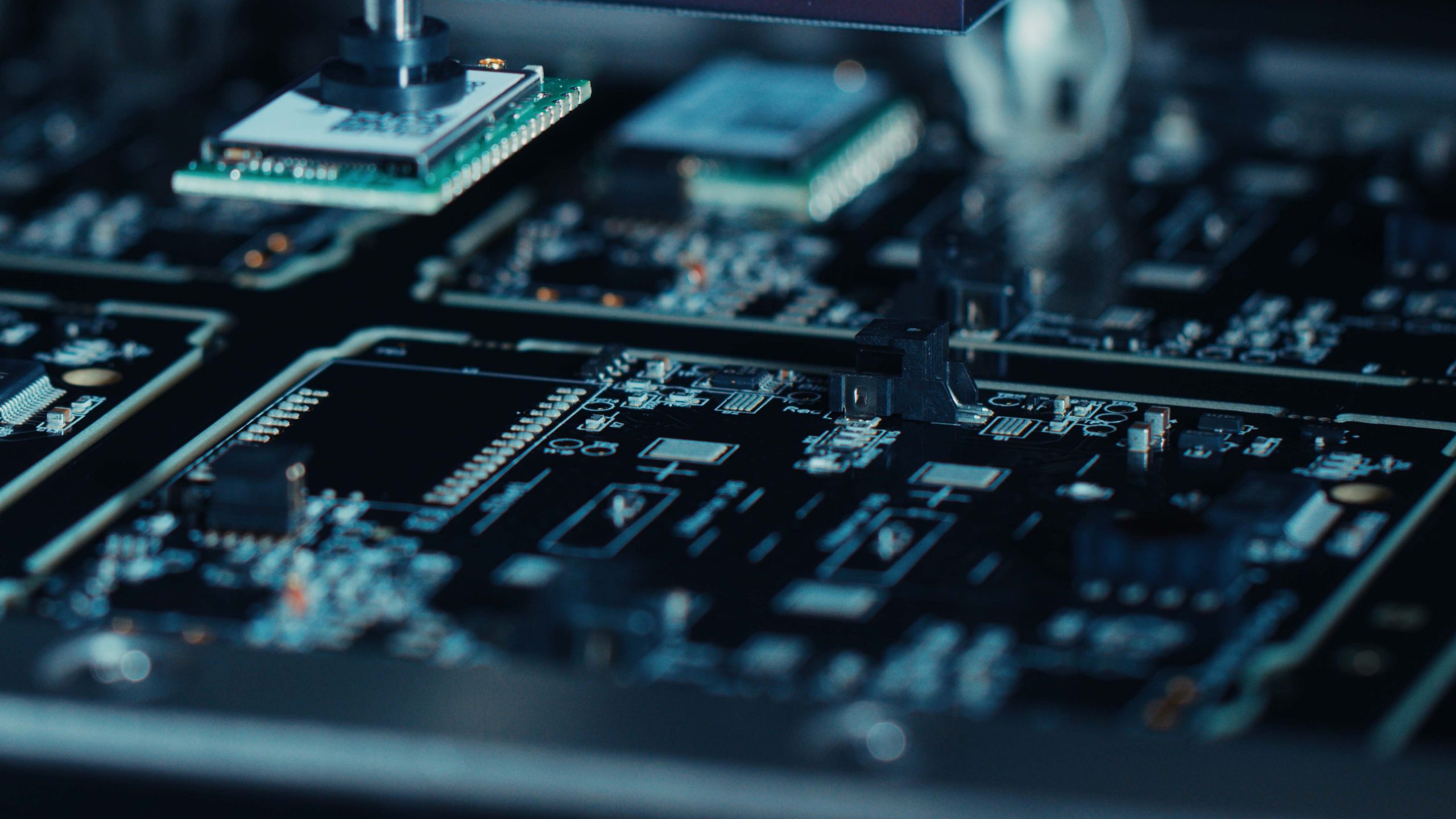

OurPCB specializes in high-temperature PCB manufacturing, ensuring reliability in extreme environments. As a leading high-Tg PCB manufacturer and PCB supplier, we provide high-temperature PCB fabrication using advanced materials that withstand thermal stress. Our high-temperature PCB factories deliver durable solutions for industries that rely on high-Tg PCBs, including those in the USA. We also share valuable Electronics Manufacturing Insights to help engineers and procurement teams make informed choices.

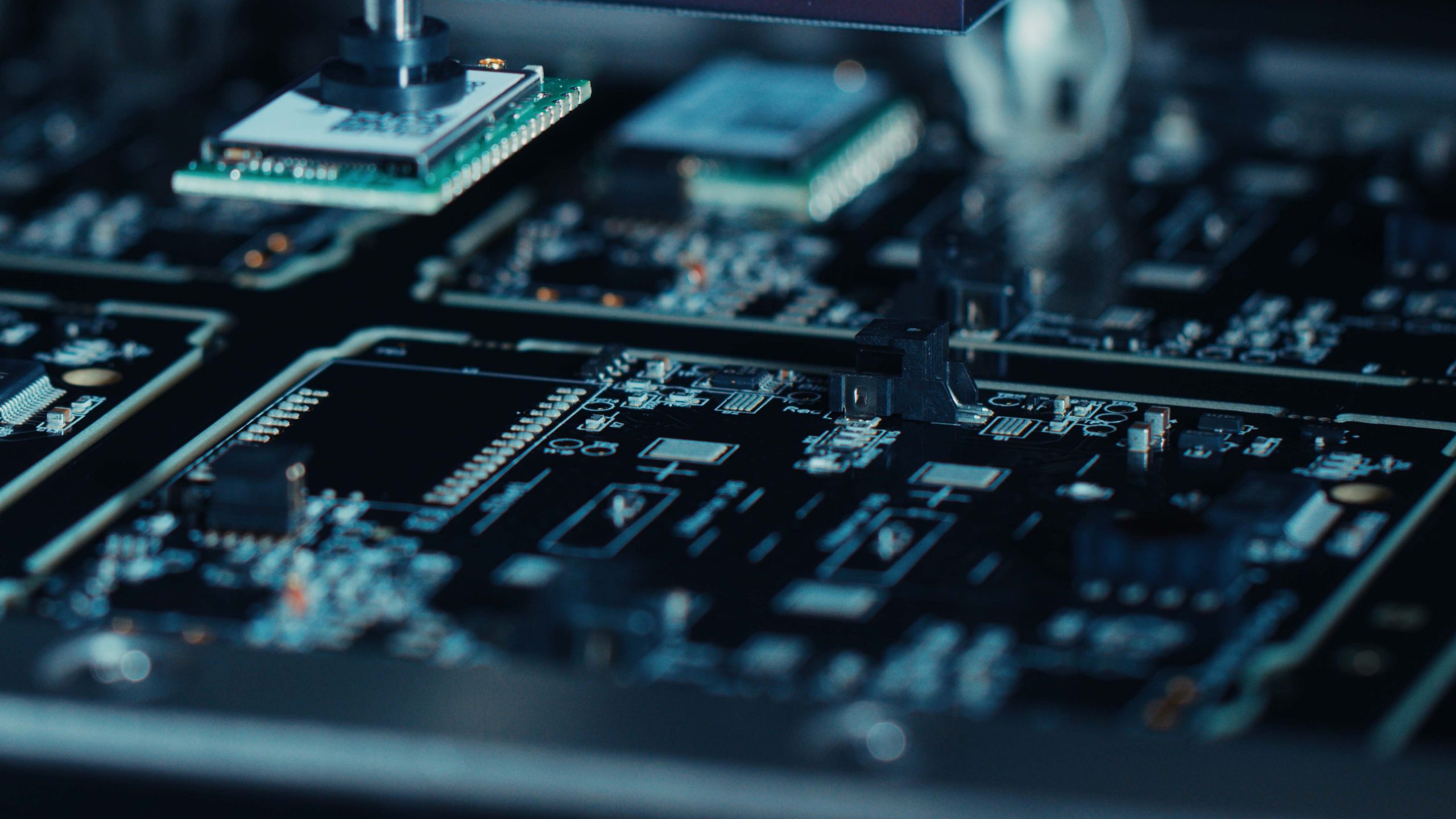

High-Tg PCBs are circuit boards with a glass transition temperature (Tg) above 170°C, making them ideal for high-temperature environments. If you’re new to the basics, our guide on what is a printed circuit board? explains how these essential components work before diving into high-Tg specifics. When a PCB exceeds its Tg, it softens, affecting performance. High-Tg materials offer better mechanical strength, chemical stability, and heat resistance, making them suitable for thermally intensive applications like CPU and GPU circuits.

Common high-Tg materials include Shengyi S1000-2, ISOLA 370HR, and ITEQ-IT 180L. For cost-effective solutions, FR4 TG130 balances thermal performance and affordability.

For wholesale high-Tg PCB solutions, including advanced, durable options directly from China, explore our China High-Tg PCB Manufacturer.

High-Tg PCBs are essential for high-performance electronics due to their superior thermal and mechanical properties. Their key features include:

Ensures strong plated through-hole connections.

Withstands extreme temperatures without degradation.

Provides strength and reliability in demanding applications.

Prevents layer separation over time.

Operates efficiently in extreme heat conditions — important when working with power systems where proper circuit protection is needed. Our resource on choosing the right fuse type can help you select components that complement high-Tg boards for maximum safety.

Reduces warping and maintains stability.

| Material | CTE-z (ppm/℃) | Td (Wt, ℃) | Tg (DSC, ℃) | Td288 (min) | Td260 (min) |

|---|---|---|---|---|---|

| IT180 | 45 | 345 | 180 | 20 | 60 |

| S1141 (FR4) | 55 | 300 | 175 | / | 8 |

| Rogers 4350B | 50 | 390 | 280 | / | / |

| S1000-2M (FR4) | 45 | 345 | 180 | 20 | 60 |

High-Tg PCBs help protect electronics from excessive heat. There are three primary methods for dissipating heat in high-temperature PCBs:

Transfers heat through direct contact with a heat sink, similar to electricity flowing through a system. Learn more about effective conduction techniques in conductive paint.

Uses electromagnetic waves to direct heat away from components. For further details, check out RF Amplifier, which explains how radiation aids in heat management.

Convection dissipates heat by moving it through air or liquid, either naturally or with forced airflow from fans or pumps. This method enhances heat transfer efficiency, preventing overheating and ensuring the reliability of high-Tg PCBs.

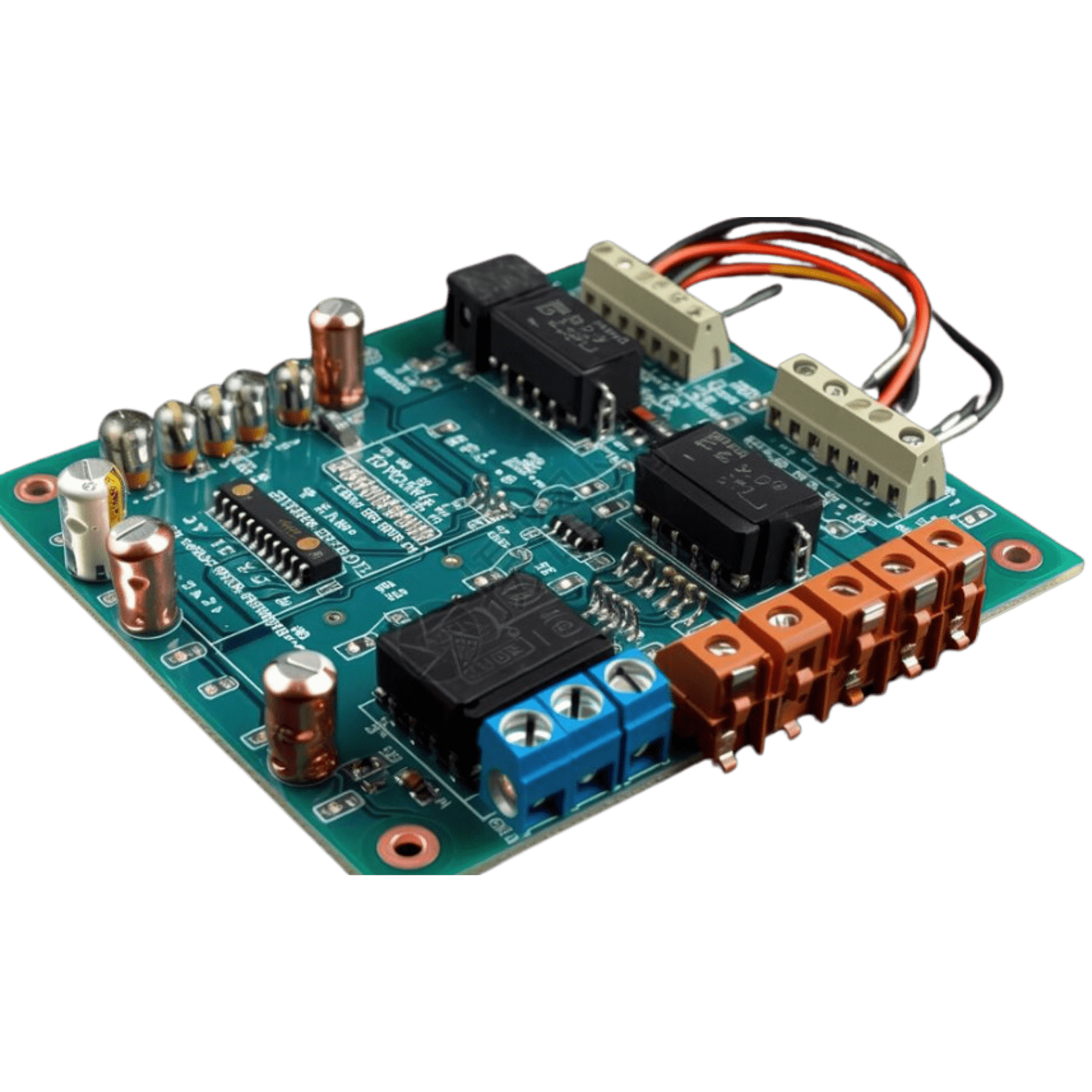

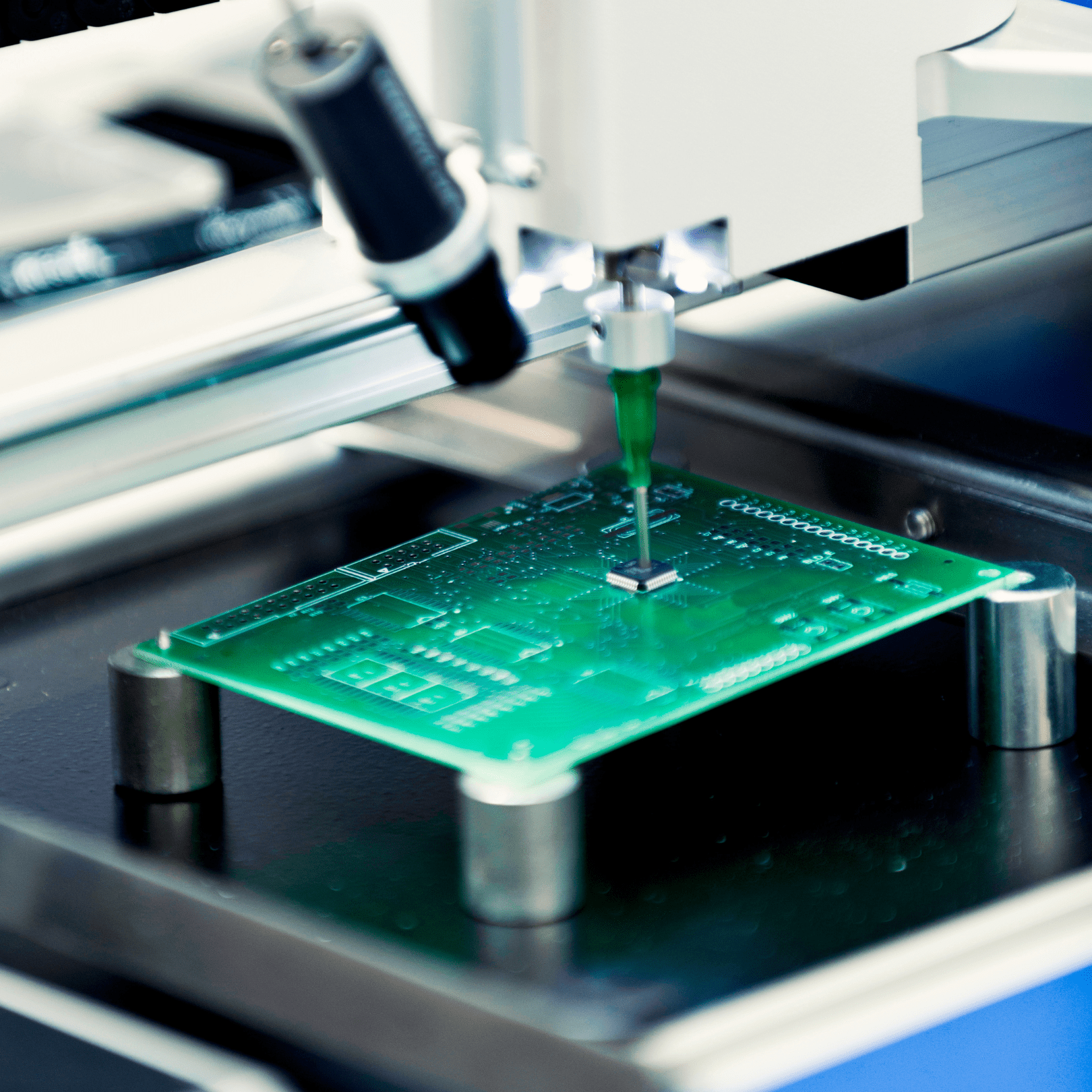

We handle everything from parts sourcing to final assembly, providing a hassle-free experience that ensures top-quality boards every time.

Whether you need a few prototypes or large-volume batches, our flexible assembly services adapt to your project’s scope and timeline.

Stay environmentally responsible with our compliant assembly processes, offering RoHS and lead-free options for safe, reliable builds.

No matter the complexity, we can assemble boards of all configurations—single-layer, multi-layer, or a mix—to match your exact specifications.

From one-off prototypes to bulk orders, we accommodate projects of all sizes without compromising on quality or turnaround time.

Join our growing community of satisfied clients who rely on our dependable assembly expertise and dedicated customer support.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

High TG (Glass Transition Temperature) PCBs offer several benefits, especially for applications that require durability under high temperatures:

High TG PCBs are best suited for high-power applications, automotive electronics, aerospace, and environments with extreme temperature variations.

Its resistance to heat, humidity, and chemicals prevents degradation, ensuring long-term performance and reliability.

Absolutely. While they’re often associated with industrial or high-power applications, high-Tg PCBs can also support compact electronics that require stable performance under heat. For instance, our 10 Minute Timer Circuit Design demonstrates how thermal stability ensures precise operation even in enclosed or warm environments.

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree