Top 10 Classic Car Wiring Harness Manufacturers | Full Guide

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

OurPCB delivers fast, high-quality PCB fabrication and assembly in 24 hours to 7 days, depending on design guidelines, board layers, order quantity, and surface finish. As a trusted PCBA manufacturer, we serve clients worldwide, especially in the USA, ensuring speed, precision, and reliability.

Quick-turn PCB assembly refers to a process where printed circuit boards are manufactured and assembled in a short time, usually within 24 hours to 7 days max.

Fab houses initially used this quick-turn assembly process for low-volume PCB production and prototyping. However, changing user requirements and recent advancements in PCB manufacturing have made it possible to use quick-turn production on high-volume orders.

Consequently, as an electronics designer or manufacturer, you can now use this process to get your products to market faster and gain a competitive edge. Let’s say you’ve discovered a new feature that has the potential to revolutionize the electronic product you’re selling. Someone else might have a similar idea, or your project might leak to the competition if it takes too long to implement. However, with quick-turn PCB assembly, you can execute and actualize your idea faster, and gain more market share before other players enter your space.

| Number of Layers | Number of Days |

|---|---|

| 1-12 layers | within 72 hours |

| 12+ layers | within 120 hours |

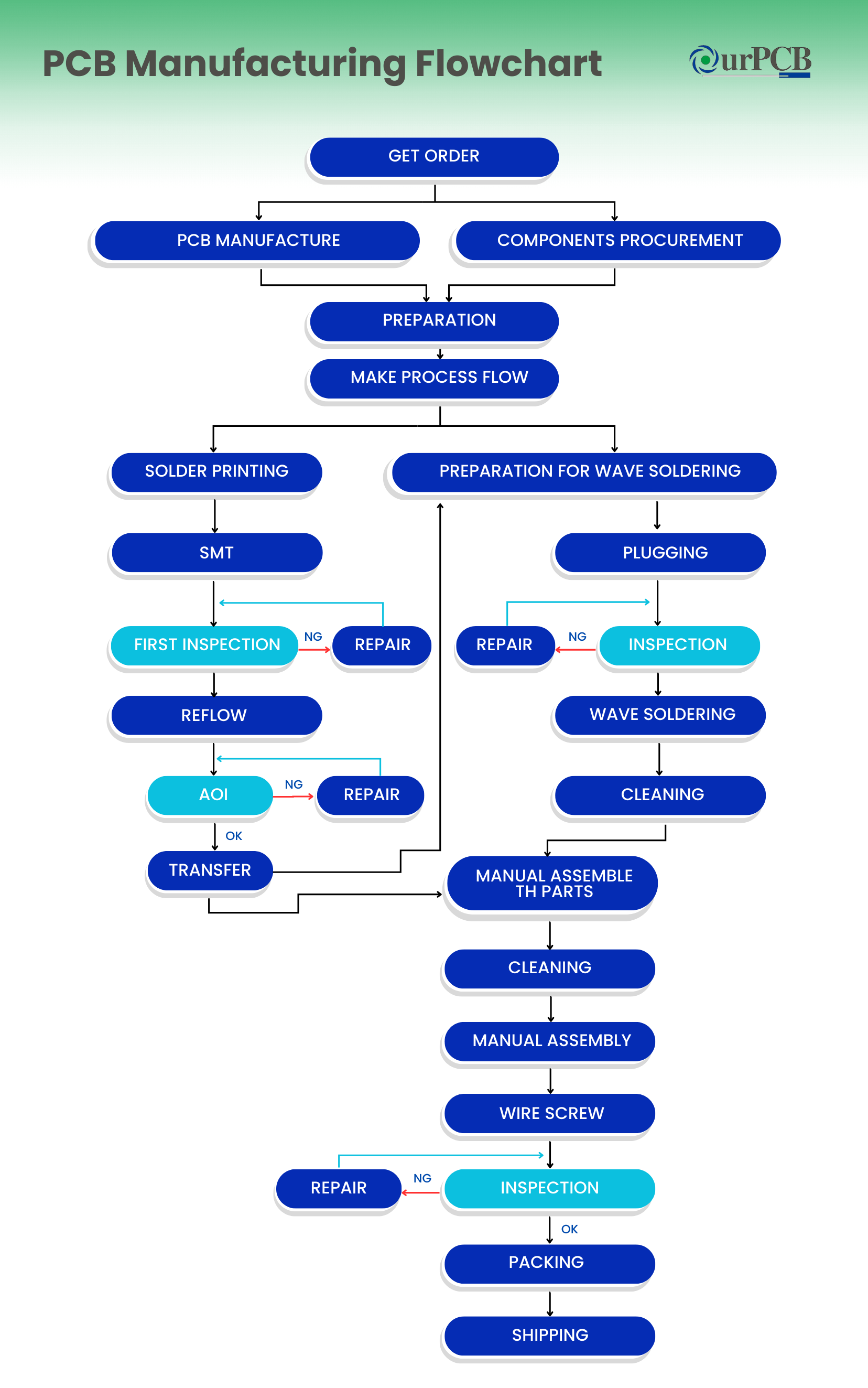

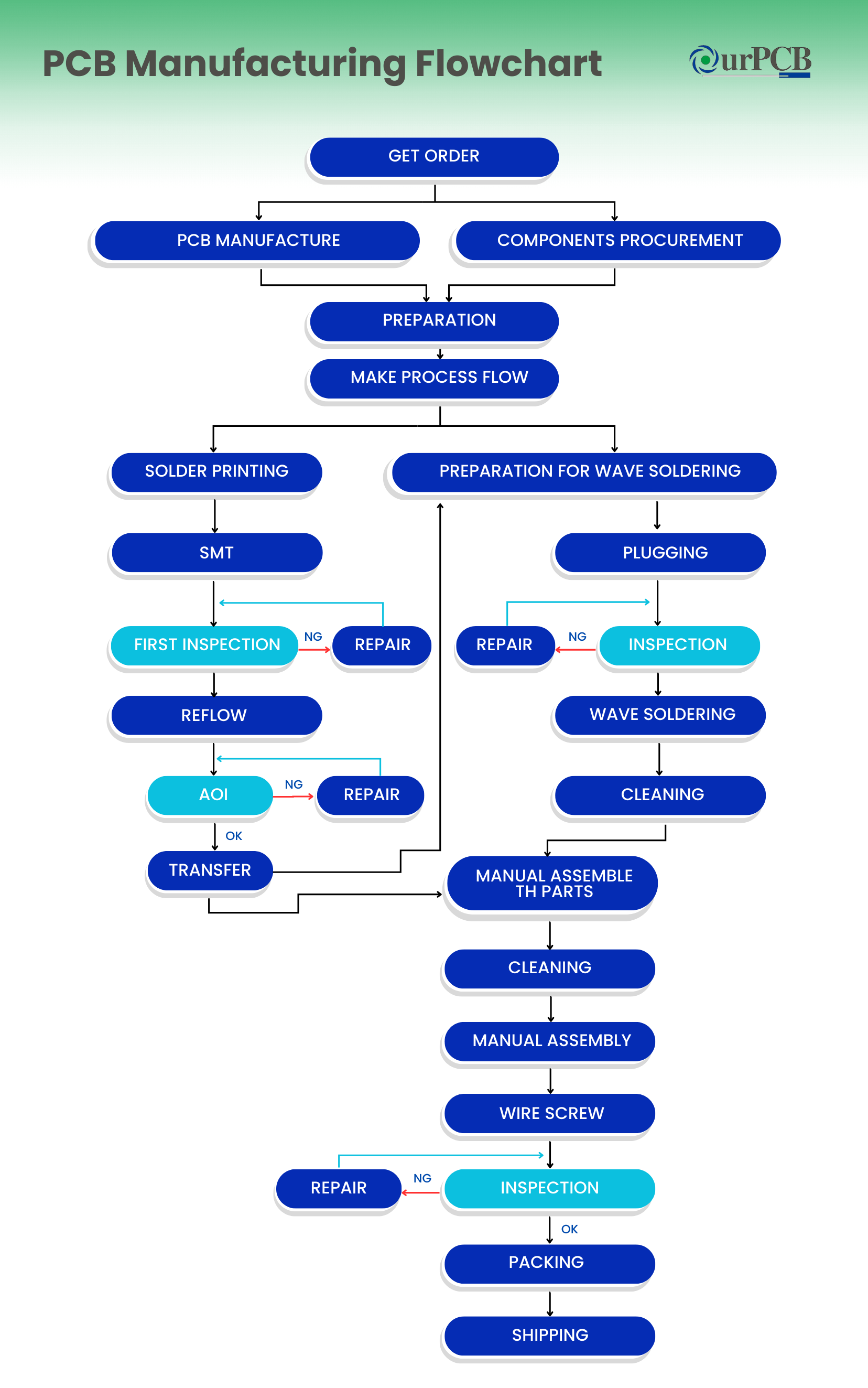

The quick-turn PCB assembly process is a streamlined manufacturing workflow that starts with design and ends with the final product’s delivery.

The key aspect of quick turn PCB assembly is time. We cover both the fabrication and assembly processes in circuit board production, so you only need to handle the design process.

Here’s a breakdown of the key steps:

Testing Methods Include:

The primary benefit of quick-turn PCB assembly is the accelerated time to market for your products. But it has some secondary benefits:

DFM is crucial before quick-turn PCB assembly, ensuring the design aligns with the manufacturer’s capabilities. This includes using cost-effective materials and reducing errors that may be expensive to fix later. DFA further lowers costs by optimizing the layout, reducing parts, and simplifying assembly.

Quick-turn PCB assembly accelerates product development by allowing multiple iterations to refine the design. This process enables quick feature enhancements, keeping your product ahead of the competition while reducing time to market.

Since the process mirrors prototyping, defects in design or manufacturing are detected early and resolved within the production timeline. Early identification prevents costly revisions and ensures a smooth, efficient assembly process.

We handle everything from parts sourcing to final assembly, providing a hassle-free experience that ensures top-quality boards every time.

Whether you need a few prototypes or large-volume batches, our flexible assembly services adapt to your project’s scope and timeline.

Stay environmentally responsible with our compliant assembly processes, offering RoHS and lead-free options for safe, reliable builds.

No matter the complexity, we can assemble boards of all configurations—single-layer, multi-layer, or a mix—to match your exact specifications.

From one-off prototypes to bulk orders, we accommodate projects of all sizes without compromising on quality or turnaround time.

Join our growing community of satisfied clients who rely on our dependable assembly expertise and dedicated customer support.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Our quick-turn PCB assembly capabilities include delivering rigid, flexible, and rigid-flex circuit boards in this short timeline. We can make these bendable boards compact and resistant to heat and vibrations as well.

Our team of expert technicians and engineers can also build quick-turn miniature circuit boards for the modern compact devices used in IoT and communications equipment.

Regardless of the size or rigidity, these boards will have a high tensile strength to maximize durability and enhanced heat dissipation to keep the components at their optimal performance range. Some of the techniques we can use to improve heat dissipation include installing heat sinks and enhancing airflow above and below the PCBA.

When choosing a quick-turn PCB assembly partner, we recommend checking these five factors:

Quick-turn PCB assembly isn’t without its challenges and limitations. Although the DFM and DFA processes help to cut costs, the expedited manufacturing, assembly, and shipping processes will increase the overall production costs.

Component availability can also be challenging due to the quick nature of this process. Consignments and partial assembly options can eliminate this issue, especially for the unique, hard-to-find parts.

Lastly, although the process includes quality control measures, they might not be as stringent as the ones implemented in regular PCB production. Fab houses have to do the tests quickly to deliver within the stipulated timelines, which can affect quality.

OurPCB is the leading electronics manufacturer in China that specializes in PCB manufacturing, assembly, quick turn PCB assembly, and electronics design. We have an extensive list of clients including Intel, Sigfox, Great Wall, and Bewatec – testaments to our abilities as a professional PCB fab house you can rely on for customized, efficient services. We’re also ISO:9001 certified, so high-quality products are guaranteed.

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree