Top 7 Truck Wiring Harness Manufacturers

Truck wiring harnesses are the electrical backbone of commercial vehicles, from long-haul trucks to construction fleets and emergency vehicles. They must withstand continuous vibration, thermal

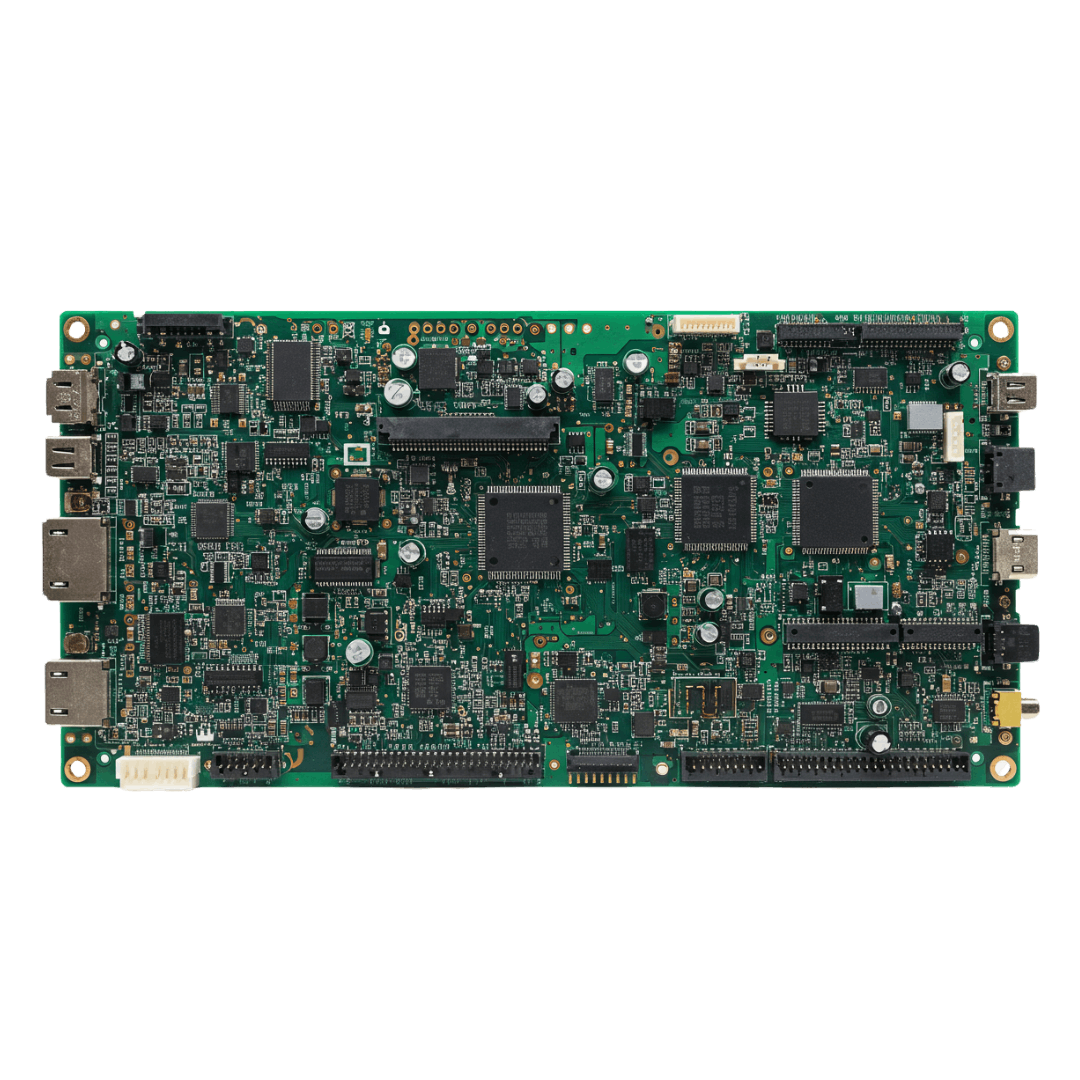

One-stop PCB assembly services provide complete circuit board production under one roof. OurPCB offers comprehensive PCB assembly solutions, from design to final testing. We handle every step of the process, ensuring quality and efficiency. Trust OurPCB for all your PCB assembly needs.

OurPCB delivers cost-effective one-stop PCB assembly without compromising quality. We optimize our processes to reduce waste and increase efficiency, passing the savings to you. Our bulk ordering and strong supplier relationships allow us to offer competitive pricing on components and materials.

Our affordable services cover the entire PCB assembly process. From PCB fabrication to component placement and testing, we handle it all in-house. This integrated approach eliminates middlemen and shipping costs between facilities, resulting in lower overall prices for our customers.

Partnering with OurPCB for wholesale one-stop PCB assembly offers numerous advantages. We provide end-to-end solutions, streamlined communication, and cost savings. Here are the key benefits:

One-stop PCB assembly services offer a simplified approach to circuit board production. They eliminate the need to coordinate with multiple vendors and streamline the entire process. Here’s why you should consider a one-stop service:

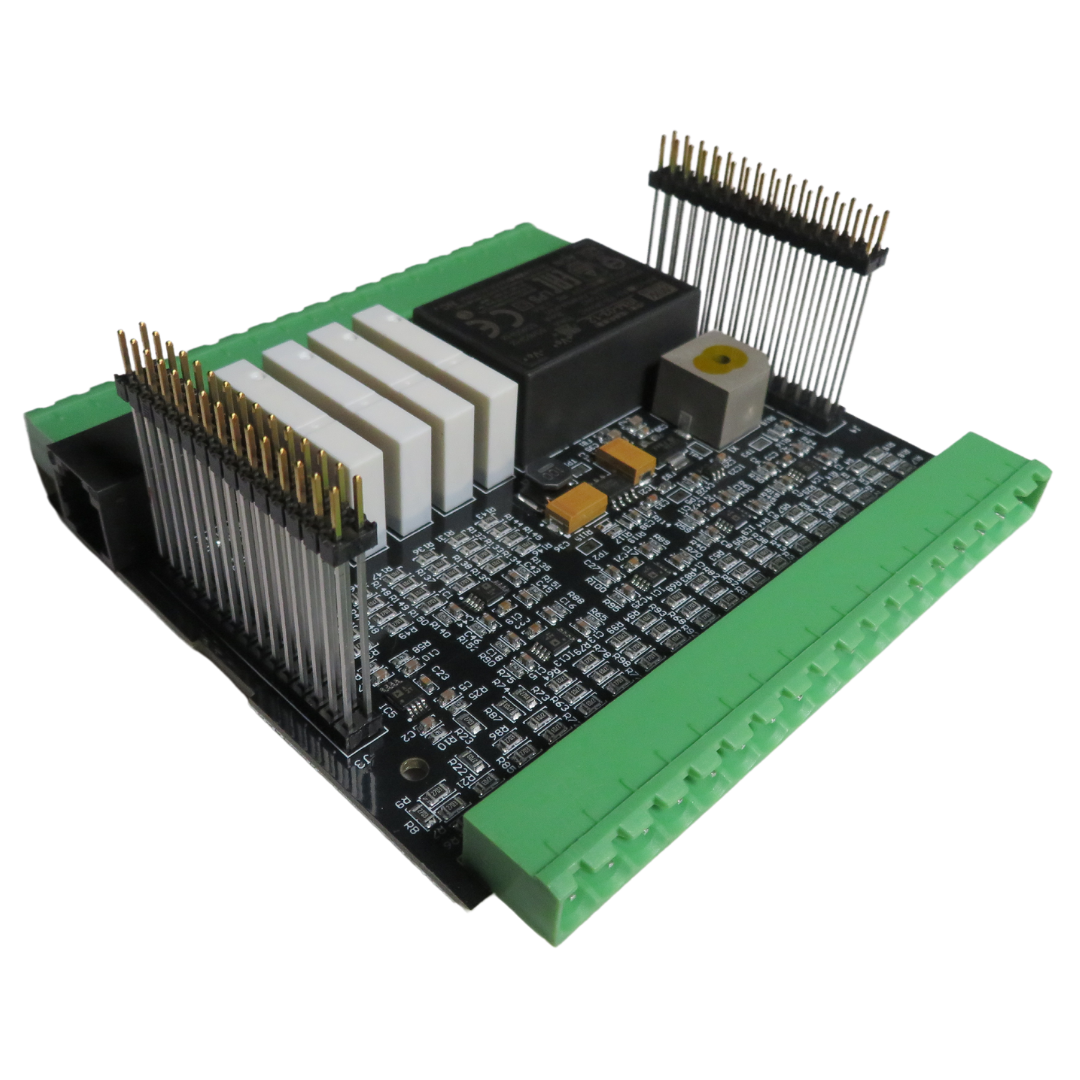

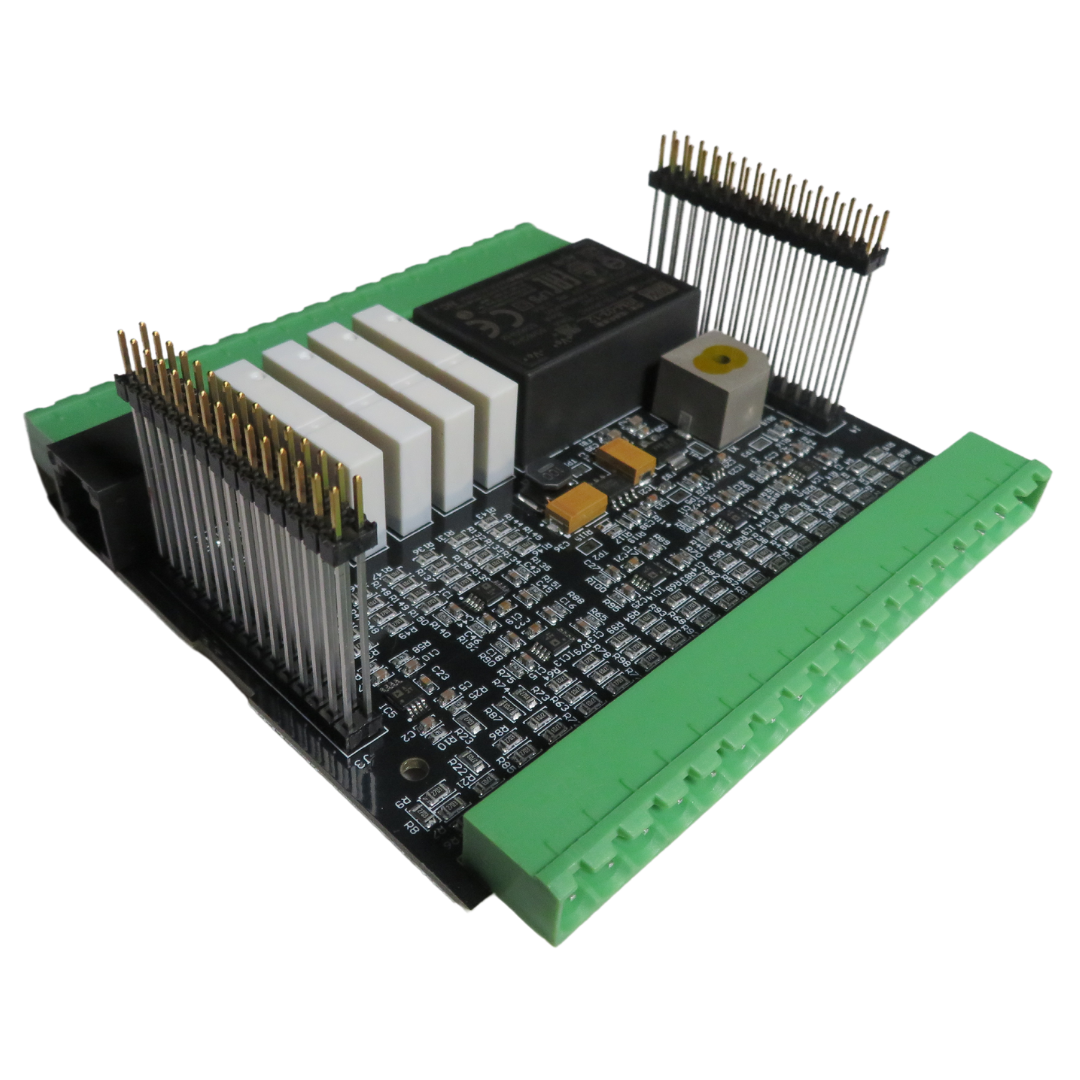

OurPCB offers a wide range of PCB assembly services to meet diverse customer needs. From standard to specialized assemblies, we have the expertise to deliver high-quality results. Our services include:

We excel in Surface Mount Technology assembly, perfect for compact and high-performance products. Our advanced equipment ensures precise component placement and reliable connections.

We offer flexible options, working with customer-supplied parts or providing full turnkey solutions. Our turnkey service covers component sourcing, assembly, and final delivery.

Our team delivers tailored PCB assembly services to match your unique project specifications. We work closely with clients to ensure their designs are accurately translated into finished products.

We provide rapid PCB assembly services without sacrificing quality. Our efficient processes and dedicated teams ensure fast turnaround times for urgent projects.

We produce PCB assemblies that meet strict IPC Class 3 standards. This high-quality service is ideal for industries with demanding requirements, such as aerospace and medical devices.

Our skilled technicians handle all types of IC package assembly. We work with BGAs, POPs, CGAs, QFNs, DFNs, CSPs, and more, ensuring reliable connections and performance.

OurPCB boasts premium equipment and skilled technicians for quality PCB assembly. We handle single-sided, double-sided, and multi-layer PCBs with precision. Our capabilities include fine-pitch component placement, BGA rework, and advanced inspection techniques. We use automated optical inspection (AOI) and X-ray systems for quality assurance. Our facilities are equipped to handle both prototype and high-volume production runs efficiently.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Yes, you can buy low- to medium-volume one-stop PCB assembly boards. This service covers PCB manufacturing, component sourcing, and solder processes in a single package. It is ideal for PCB prototype projects and ensures efficient lead time and affordable PCB assembly. Many PCB manufacturers in Shenzhen, like OurPCB, offer advanced PCB assembly, including double-sided PCB and rigid-flex options.

The disadvantages of one-stop PCB assembly services include limited flexibility and higher PCB assembly costs. Some PCB manufacturers may impose minimum order quantities, affecting affordability for smaller projects. The through-hole assembly method and through-hole technology (THT) can also increase costs and lead times. Additionally, substrate choices and DFM (Design for Manufacturing) limitations might restrict custom PCB design options.

There is no standard one-stop PCB assembly price list due to varying factors like BOM complexity. PCB assembly costs depend on laminate types, stencil requirements, and functional test procedures. Affordable PCB solutions often exclude advanced PCB assembly options, affecting customization. PCB production costs also vary based on board assembly techniques, including flexible PCB and printed circuit board assembly services.

Truck wiring harnesses are the electrical backbone of commercial vehicles, from long-haul trucks to construction fleets and emergency vehicles. They must withstand continuous vibration, thermal

Medical cable assemblies sit at the intersection of electrical safety, biocompatibility, and sterilization durability. For regulated medical devices, OEMs must work with manufacturers that understand

Robotics cable assemblies are unlike ordinary cables, they must survive continuous motion, tight bend radii, torsion, vibration, electrical noise, and often harsh industrial or outdoor

Waterproof cable assemblies have to do more than just “keep water out.” For outdoor, marine, industrial washdown, and transportation platforms, assemblies are expected to survive

Aerospace cable assembly manufacturers work under standards such as AS9100, ISO 9001, and RTCA/DO-160, and many also maintain ITAR registration to support flight-critical and space-qualified

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree