- PCB Manufacturer

- PCB Assembly

- Lead Free

Certified RoHS-Compliant Manufacturing for Lead-Free PCBs

OurPCB delivers precision lead-free PCB assembly services using SAC305 lead-free solder paste, RoHS-certified laminates, and profile-controlled reflow temperatures for electronics manufacturing.

Every lead-free PCB is built on high-temperature materials with full traceability and meets the export requirements under RoHS, WEEE, and regional compliance laws.

Finishes such as ENIG, OSP, and lead-free HASL meet thermal cycling, contact resistance, and wettability targets in fine-pitch and high-density applications.

- ✅ In-house RoHS screening, solderability testing, and ionic contamination control.

- ✅ ISO 9001, IATF 16949, and IPC-A-610 Class 2 & 3 certified.

- ✅ All materials selected for lead-free reflow with 260 °C laminate performance.

PCB Manufacturing Process

Why Choose Our Lead-Free PCB Assembly Services?

OurPCB delivers lead-free PCB assembly services using certified production systems, RoHS-compliant materials, and alloy-specific soldering controls applied throughout fabrication and assembly. All processes are documented, internally verified, and executed using dedicated tooling and inspection across IPC-A-610 Class 2 and Class 3 builds.

RoHS Job Handling from Fabrication to Final Inspection

OurPCB manages every stage of lead-free PCB manufacturing, including UL-rated laminate selection, in-house lead-free surface finish application, and component-level traceability.

No subprocesses are subcontracted, eliminating uncontrolled thermal cycles, undocumented finishes, or mixed solder contamination across lead-free PCB assemblies.

Lead-Free Tooling, Fixtures, and Profile Calibration

Dedicated SMT and PTH lines are configured for daily SAC305 and SnCuNi production. Stencils, oven rails, wave pots, and flux systems are isolated from tin-lead lines and cleaned with segregated chemistry.

Reflow profiles are tuned by board thickness, copper loading, and layout density, with 10-zone oven control and 1 to 2.5 °C/sec ramp rates per alloy.

Pre-Assembly BOM Validation for RoHS Compatibility

Each job is reviewed by engineering to verify lead-free component status and solderability.

We check BOM part numbers against plating libraries and confirm that all component finishes, matte tin, SnCu, or SnAg, are compatible with lead-free solder paste alloys.

MSL-3 and higher components are baked for 24 to 48 hours at 125 °C per J-STD-033 before placement.

Internal Control of Lead-Free Surface Finishes

We apply ENIG (2 to 5 µin Au over 120 to 240 µin Ni), lead-free HASL, OSP, and Immersion Silver in-house. Surface finishes are selected based on alloy wetting compatibility, shelf life, and pad geometry.

All finish lines are RoHS-aligned, and finish data is included with every RoHS-compliant PCB order.

Thermally Rated Stackups for 260 °C Reflow

Stocked materials include FR408HR, IS420, and G200, each rated for ≥260 °C lead-free reflow.

These laminates pass T288 delamination testing at 288 °C with hold times over 6 minutes and Td ≥340 °C.

Stackups are modeled to maintain resin-glass stability across two or more lead-free assembly cycles, preventing copper barrel fatigue or dielectric deformation.

RoHS Documentation Delivered Per Job

All assemblies are delivered with solder paste lot IDs, reflow validation charts, finish certs, and laminate origin.

This RoHS package is supplied by default with every lead free PCB assembly, eliminating the need for post-shipment document requests and accelerating downstream compliance, inspection, or integration for export-regulated applications.

How Our Consignment PCB Assembly Process Works

Each consignment PCB assembly job begins with part intake tied directly to machine setup and line scheduling.

We group kits by reel type, feeder pitch, and placement side, then assign each one to specific staging lanes with matching reflow oven configuration and solder type. Our technicians pre-scan each feeder slot against the BOM and PNP file to catch mismatches before programming.

All consigned PCB kits are assigned a unique internal tracking ID at intake. Components are unpacked, sorted by feeder compatibility (tray, tube, tape), and checked against the BOM line-by-line.

Discrepancies in part number, reel labeling, or quantity shortfall trigger a hold and customer notification before any line setup is authorized.

Moisture-sensitive components are scanned for MSL classification and timeout. Floor-exposed parts are queued for bake-out and resealing before feeder prep.

Kits are then moved into a staging buffer with recorded timestamps, ready for scheduled job release into SMT or PTH lanes within a 24-hour window to avoid MSL re-exposure.

Feeder lanes are assigned based on component pick frequency, rotation offset, and machine head type (high-speed vs. multi-function).

Job setup includes vision system calibration, feeder load sequence, and nozzle selection to match the footprint.

For cut tape or partial reels, feeder splicing or leader creation with cover tape is performed in-line.

Boards flagged for BGA, PoP, or QFN automatically route to X-ray before post-reflow AOI.

Inspection sequence follows preassigned logic: X-ray → AOI → functional test, with exception routing for manual visual review if solder bridges or lifted leads are detected.

Final pass/fail disposition is recorded against the internal build traveler before packaging.

Once released to production, boards follow the programmed sequence of stencil printing, SMT placement, and thermal profile reflow based on solder type and component density.

For double-sided builds, bottom-side SMT is supported with low-tack adhesive or pallet fixturing. If mixed with PTH, boards are transferred to selective soldering or manual insertion before final reflow or wave pass.

Our Consignment PCB Assembly Quality and Inspection Standards

Our quality control framework for consignment PCB assembly services applies traceable inspection steps, file-to-placement verification, and IPC-driven acceptance thresholds for every customer-supplied kit.

We treat PCB assemblies built from consigned parts with the same process discipline, solder acceptance logic, and visual defect grading as turnkey orders, while tailoring workflows to file sets and final test specs.

We scan all BGA, QFN, and µBGA placements using 5-axis X-ray with 12 µm scan resolution, checking for head-in-pillow, voids exceeding 30%, lifted balls, and insufficient wetting.

Components with leads or terminations visible on one or more sides are routed through AOI systems with dual 15 µm resolution optics and centroids offset detection.

Each PCB assembly service order is built to Class 2 or Class 3 requirements, depending on your application. We apply numeric solder fill targets, maximum void ratios, lead length thresholds, and wetting angles per pad type.

If your consigned job includes components that exceed those tolerances, we flag them for engineering deviation approval before line release.

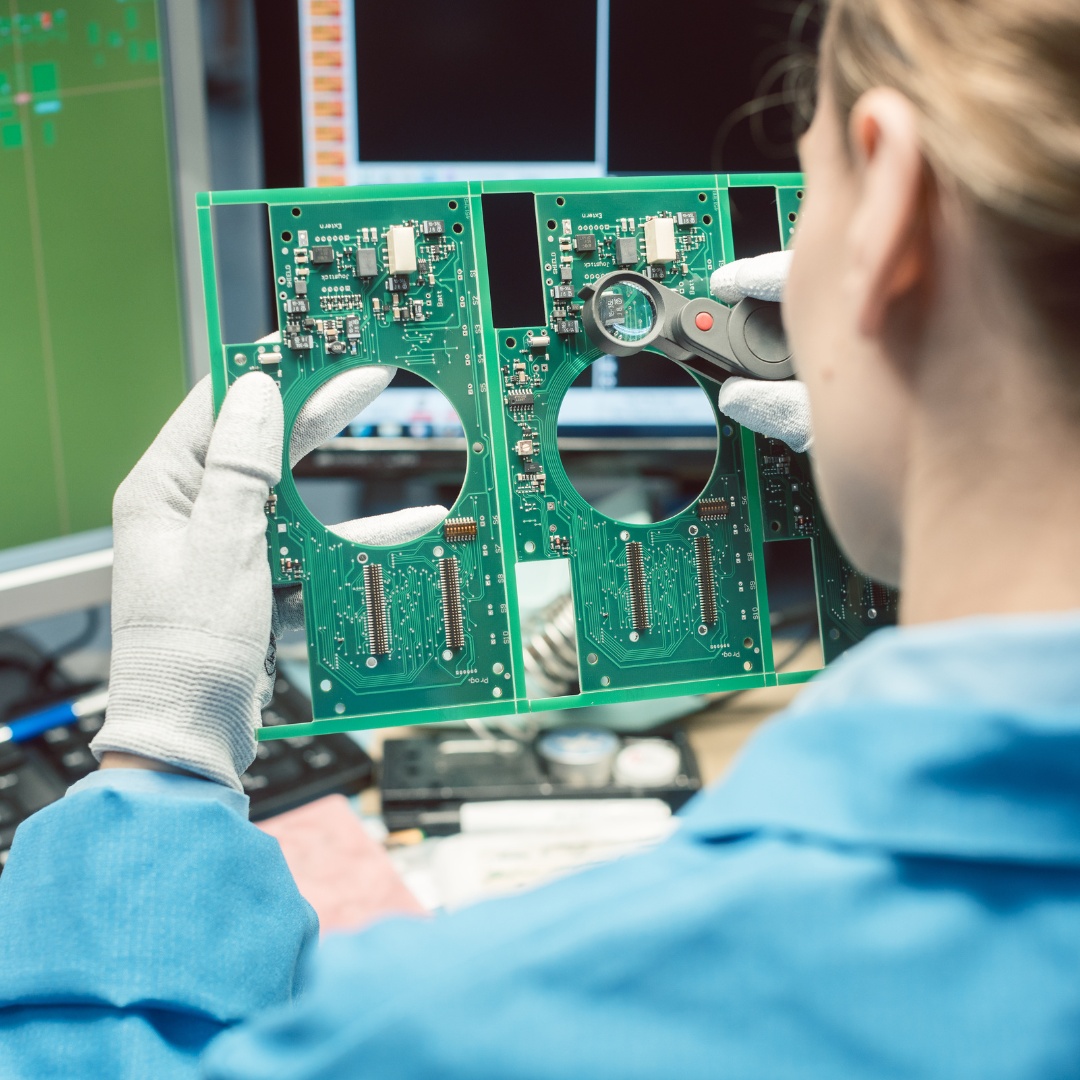

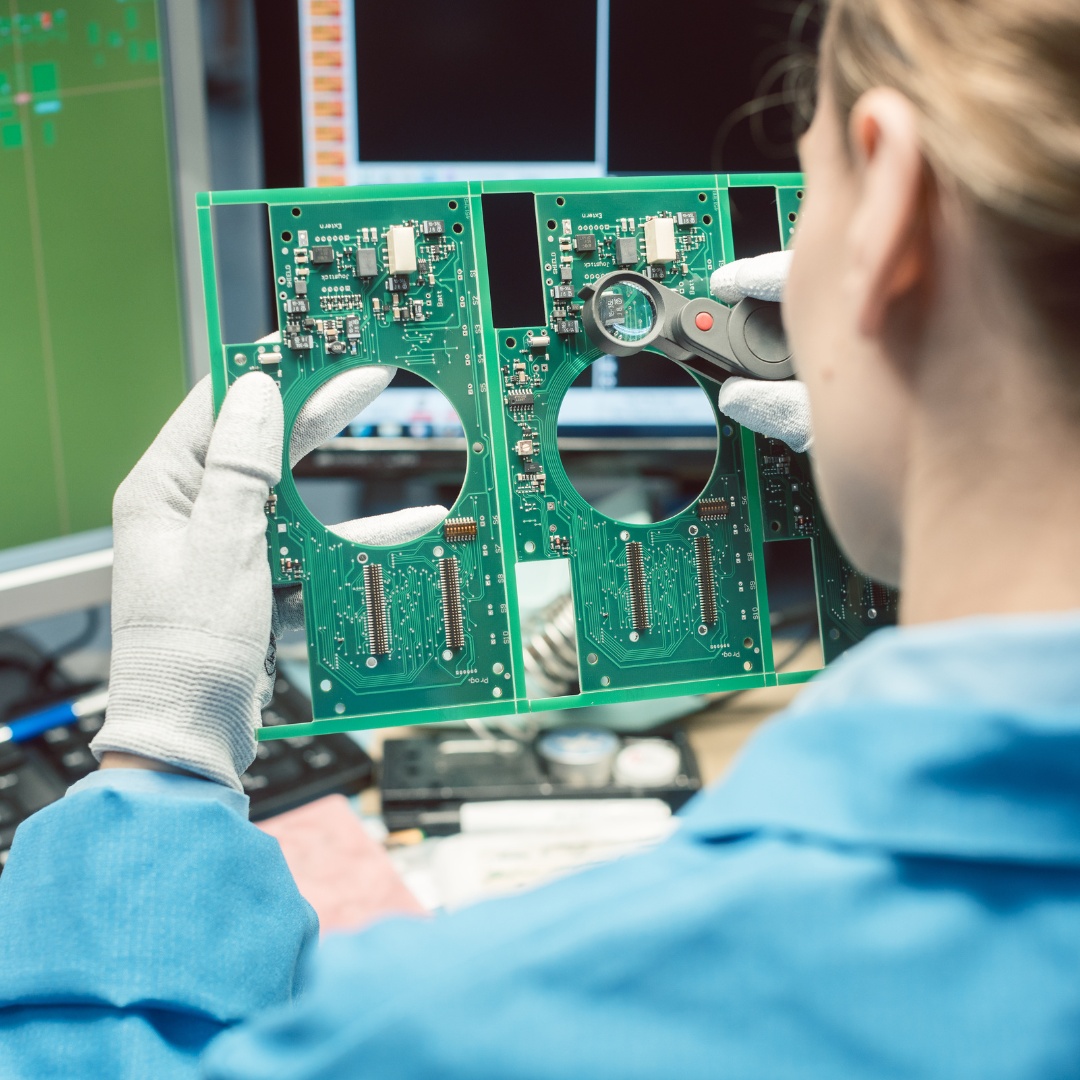

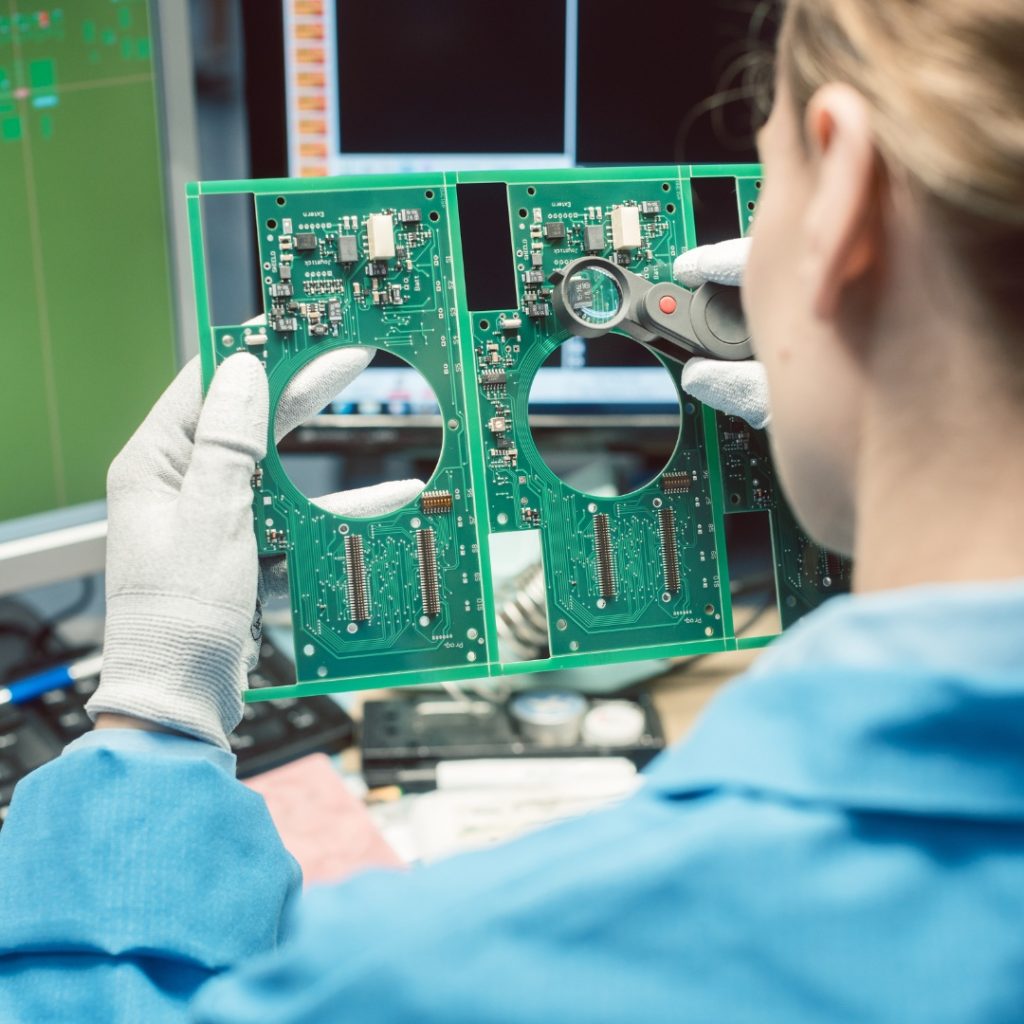

We perform first article inspection (FAI) on every consigned batch, comparing placed components against your pick-and-place file, bill of materials, and silkscreen overlay.

Our inspectors confirm polarity, part marking, footprint match, and pad alignment under magnification. Any FAI hold is escalated before continuing to production.

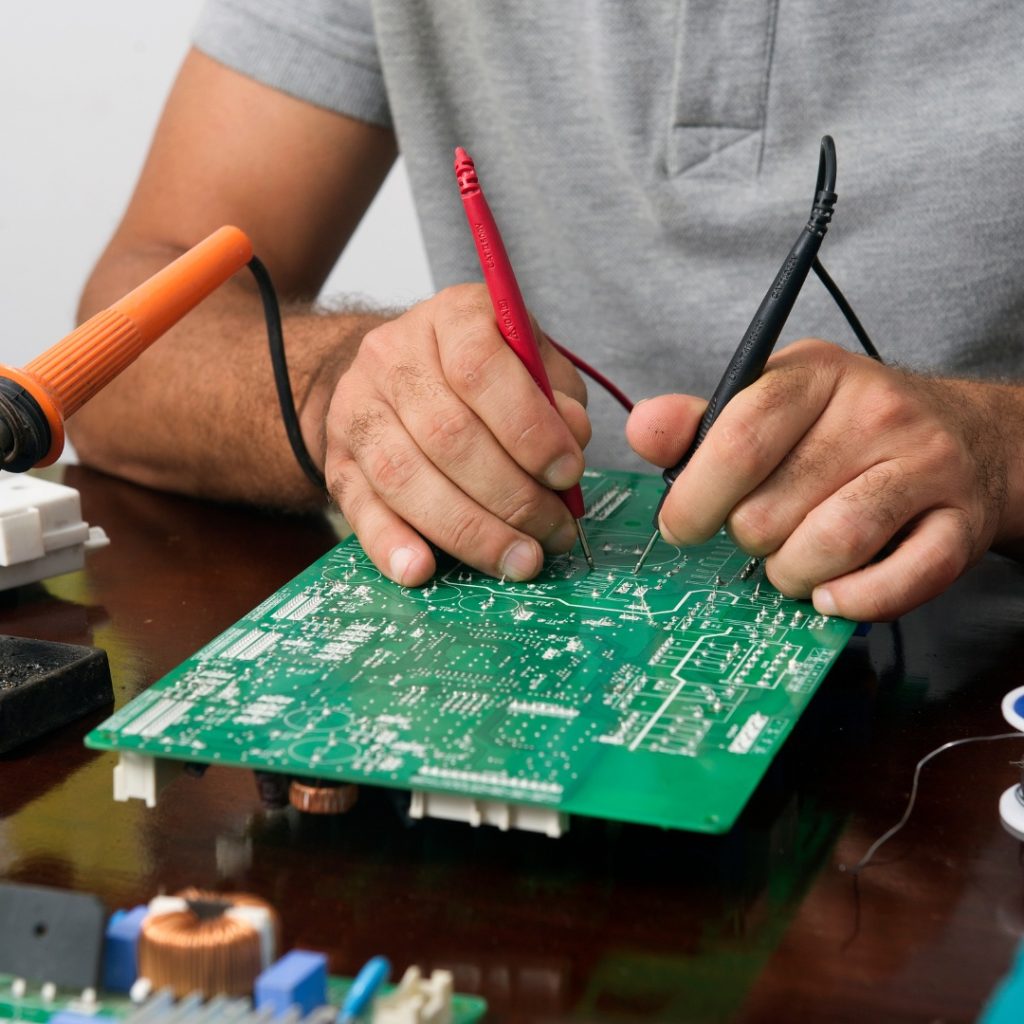

For consigned PCB assemblies that require post-assembly validation, we support customer-supplied test fixtures for in-circuit test (ICT) or functional test.

Test steps may include power-on response, signal edge timing, voltage thresholds, or I2C/SPI communication verification. Boards can be logged by serial number with the attached result files on request.

Before release, all finished PCB assemblies are checked for soldermask overflow, improper screen alignment, bent leads, and mechanical interference with standoffs or connectors. X-out boards are quarantined, and pass/fail data is recorded in our MES system.

No consignment PCB assembly shipment is approved without a supervisor-signed QA release.

Why We Remove No-Clean Flux

We remove no-clean flux residue because its remaining solids form hygroscopic films with ionic content capable of enabling leakage currents under bias. These residues often contain halide activators or rosin derivatives that, in humid environments, allow ionic mobility as low as 10⁸ Ω insulation resistance across narrow conductor spacing.

On high-density printed circuit board assemblies, especially those with ≤0.3 mm pitch, this can lead to dendritic growth, moisture-induced tracking, and eventual open or short failures. In Class 3 applications, even visually benign residues violate IPC J-STD-001 Section 8.3.1, prohibiting any visible residue under conformal coating.

Removing these residues is required to maintain dielectric performance and prevent latent field degradation.

How We Remove No-Clean Flux

Our cleaning strategy depends on the flux chemistry and board design. For fully assembled SMT boards, we use vapor degreasing with HFE-72DA or Vertrel XF, which condense at 55 °C – 65 °C onto the PCBA surface, dissolve polar and non-polar residues, and evaporate without leaving water or exposing components to immersion.

In rework areas or where selective cleaning is required, we use Decotron T383 or high-purity IPA with aerosol precision nozzles to rinse solder ball traps and low-solids residue from around pads.

The process is followed by 30 psi filtered air drying or vacuum-assisted drying to prevent water adsorption beneath packages. Surface prep is validated using surface insulation resistance (SIR) measurements, ionic testing (<1.56 µg/cm² NaCl equivalent), and UV light to detect fluorescence from missed residues.

How this Enables Coating and Inspection

Removing flux residue allows for consistent conformal coating flow and edge adhesion, especially in boards using urethane or acrylic coatings. Cleaned surfaces increase surface energy, improving film wetting and eliminating common defects like dewetting, bridging, or edge lift.

Coating adhesion strength improves from 1.2 N/mm (on flux-contaminated surfaces) to over 2.5 N/mm on properly cleaned copper and solder mask regions, reducing delamination risk during thermal cycling. In addition, a clean PCB surface ensures that automated optical inspection (AOI), UV inspection, or manual visual checks can accurately detect voids, bubbles, or skipped areas.

For applications in automotive ECUs, implantable medical devices, or high-speed digital RF systems, surface cleanliness before coating directly correlates to long-term device reliability in harsh conditions.

Why We Remove No-Clean Flux

We remove no-clean flux residue because its remaining solids form hygroscopic films with ionic content capable of enabling leakage currents under bias. These residues often contain halide activators or rosin derivatives that, in humid environments, allow ionic mobility as low as 10⁸ Ω insulation resistance across narrow conductor spacing.

On high-density printed circuit board assemblies, especially those with ≤0.3 mm pitch, this can lead to dendritic growth, moisture-induced tracking, and eventual open or short failures. In Class 3 applications, even visually benign residues violate IPC J-STD-001 Section 8.3.1, prohibiting any visible residue under conformal coating.

Removing these residues is required to maintain dielectric performance and prevent latent field degradation.

How We Remove No-Clean Flux

Our cleaning strategy depends on the flux chemistry and board design. For fully assembled SMT boards, we use vapor degreasing with HFE-72DA or Vertrel XF, which condense at 55 °C – 65 °C onto the PCBA surface, dissolve polar and non-polar residues, and evaporate without leaving water or exposing components to immersion.

In rework areas or where selective cleaning is required, we use Decotron T383 or high-purity IPA with aerosol precision nozzles to rinse solder ball traps and low-solids residue from around pads.

The process is followed by 30 psi filtered air drying or vacuum-assisted drying to prevent water adsorption beneath packages. Surface prep is validated using surface insulation resistance (SIR) measurements, ionic testing (<1.56 µg/cm² NaCl equivalent), and UV light to detect fluorescence from missed residues.

How this Enables Coating and Inspection

Removing flux residue allows for consistent conformal coating flow and edge adhesion, especially in boards using urethane or acrylic coatings. Cleaned surfaces increase surface energy, improving film wetting and eliminating common defects like dewetting, bridging, or edge lift.

Coating adhesion strength improves from 1.2 N/mm (on flux-contaminated surfaces) to over 2.5 N/mm on properly cleaned copper and solder mask regions, reducing delamination risk during thermal cycling. In addition, a clean PCB surface ensures that automated optical inspection (AOI), UV inspection, or manual visual checks can accurately detect voids, bubbles, or skipped areas.

For applications in automotive ECUs, implantable medical devices, or high-speed digital RF systems, surface cleanliness before coating directly correlates to long-term device reliability in harsh conditions.

Our Lead-Free PCB Assembly Capabilities

Lead-free PCB assembly requires process segregation, thermal resilience, and precise solder control across all board classes and build types.

OurPCB executes RoHS-compliant PCB manufacturing using dedicated lead-free PCB assembly lines, alloy-matched profiles, stocked high-Tg laminates, and in-house lead-free surface finish application—all performed under IPC-A-610 Class 2 and Class 3 guidelines (confirms solder joint geometry, wetting angle, and pad coverage with 5-axis X-ray and AOI review) with full traceability.

Our SMT and wave soldering systems are physically isolated from tin-lead lines. Stencils, solder pots, reflow ovens, conveyors, and cleaning systems are dedicated to SAC-class jobs.

This prevents cross-contamination between solder alloys and allows continuous lead-free PCB assembly without reconfiguration delays. Each line includes solder paste inspection (SPI), inline AOI, and post-reflow X-ray at 12 to 15 µm resolution.

Cleaning cycles use alloy-specific chemistry to maintain the purity of lead-free solder processes.

We manufacture lead-free PCB assemblies using high-Tg laminate systems, including FR408HR, IS420, and G200. These materials support ≥260 °C reflow cycles with Td ≥340 °C and T288 delamination times exceeding 6 minutes.

Stackups are validated for resin flow, dimensional stability, and copper-to-prepreg bonding across multiple thermal excursions to prevent pad lift, delam, or barrel deformation. All laminates are certified to meet RoHS directive 2015/863.

SAC305 and SnCu-based lead-free solder pastes are processed on nitrogen-assisted reflow ovens with 10-zone temperature control. Profiles are tuned per board design using K-type thermocouples mounted on representative assemblies.

Standard peak temperature ranges from 245 to 250 °C with 10 to 15 seconds above 217 °C to ensure full alloy wetting, grain uniformity, and low void formation under BGA or BTCs. Each lead-free PCB assembly profile is archived per job for traceability.

We apply ENIG, lead-free HASL, OSP, and Immersion Silver using internal plating and finish lines. ENIG deposits are controlled to 120 to 240 µin Ni and 2 to 5 µin Au. HASL coatings are applied using SnCu or SnNi solder and leveled for uniform pad coverage.

Finishes are selected based on lead-free solder paste alloy, shelf life, and component layout to avoid wetting imbalance or solder balling. All surface finish records are included in each RoHS-compliant PCB build file.

All BOMs are reviewed for terminal plating compatibility, alloy interaction, and moisture sensitivity classification. Matte Sn, SnCu, and SnAg finishes are accepted for SAC-class soldering.

MSL-3 and higher parts are dry-baked per J-STD-033 and assembled under moisture exposure limits. Rejected parts are quarantined and flagged before placement, preventing compliance failures or solder defects in lead-free PCB assemblies.

Each lead-free PCB assembly ships with a complete process record, including solder paste lot tracking, thermal profile log, finish certificates, and laminate batch traceability.

Documentation aligns with the RoHS directive (EU 2015/863), IPC-A-610, and J-STD-001. Certificates are delivered per job and archived internally, eliminating post-shipment delays and supporting audit or export documentation.

Millions of business and innovators use OurPCB

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- Cleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shiping

Our Technical Capabilities

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly, Single/double-sided Assembly Mixed PCB Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 64 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 1.8mil/1.8mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

How does Our Lead-Free PCB Assembly Process Work?

OurPCB executes lead-free PCB assembly through a calibrated, fully documented process built around RoHS compliance, alloy-specific soldering, and internal finish control.

All steps, from stencil printing to final inspection, are performed in-house using isolated tooling, nitrogen-assisted ovens, and standards-based validation under IPC-A-610 Class 2 or Class 3 requirements.

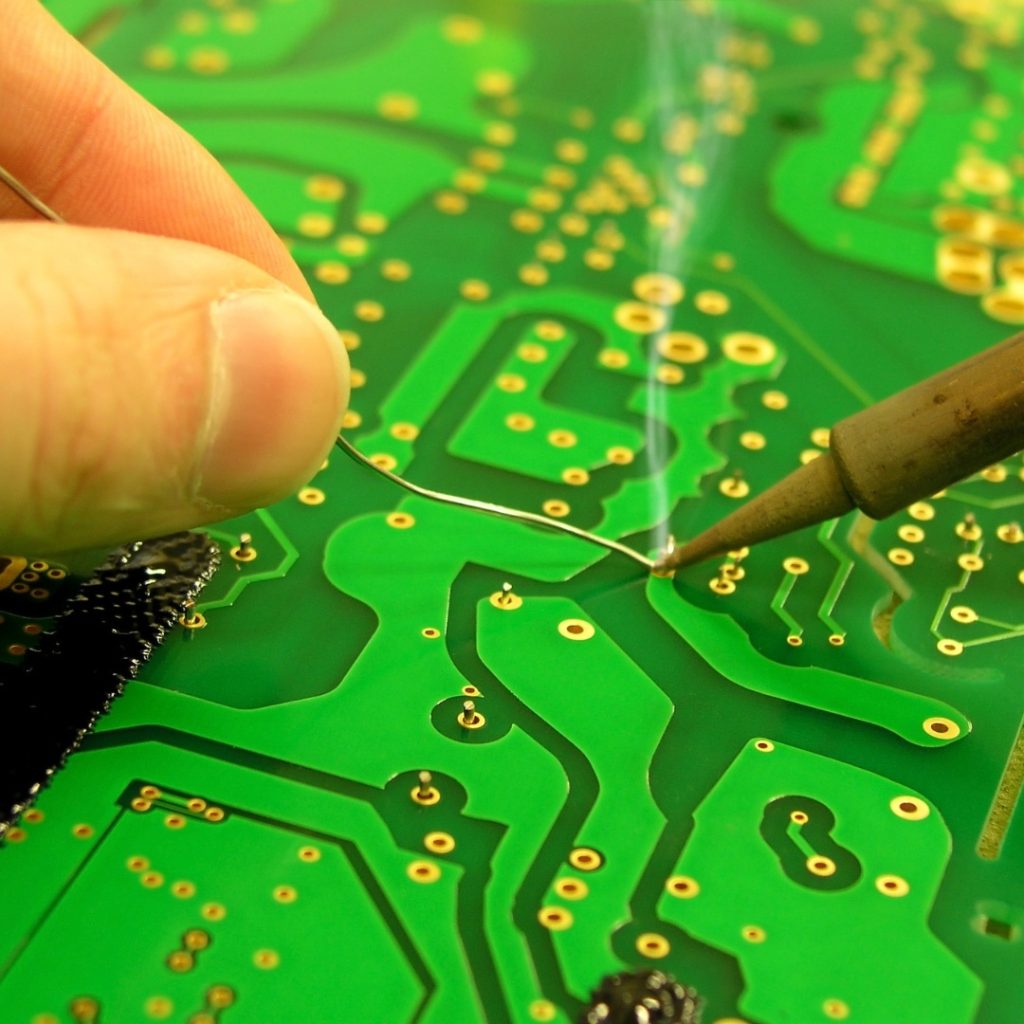

Solder Paste Printing and Inspection

Lead-free solder paste uses stainless steel stencils and precision screen printers with ±15 µm alignment accuracy.

Paste type matches surface finish, component pitch, and board layout. SPI (Solder Paste Inspection) systems verify deposit height, volume, and coverage within ±5% tolerance across critical pads.

Component Placement with Alloy-Matched Profiles

SAC305 or SnCu solder alloys are selected based on BOM compatibility and finish type.

Components use high-speed pick-and-place platforms with optical centering and down-looking vision systems. BGA, µBGA, and BTC devices are aligned within ±25 µm before reflow.

Nitrogen Reflow Soldering

Boards are reflowed on nitrogen-controlled 10-zone ovens. Thermal profiles are tuned by layer count, copper plane mass, and laminate Tg.

SAC-class pastes are processed at peak temperatures of 245 to 250 °C, with dwell times of 10 to 15 seconds above 217 °C. Profiling is verified with thermocouples and job-specific coupons.

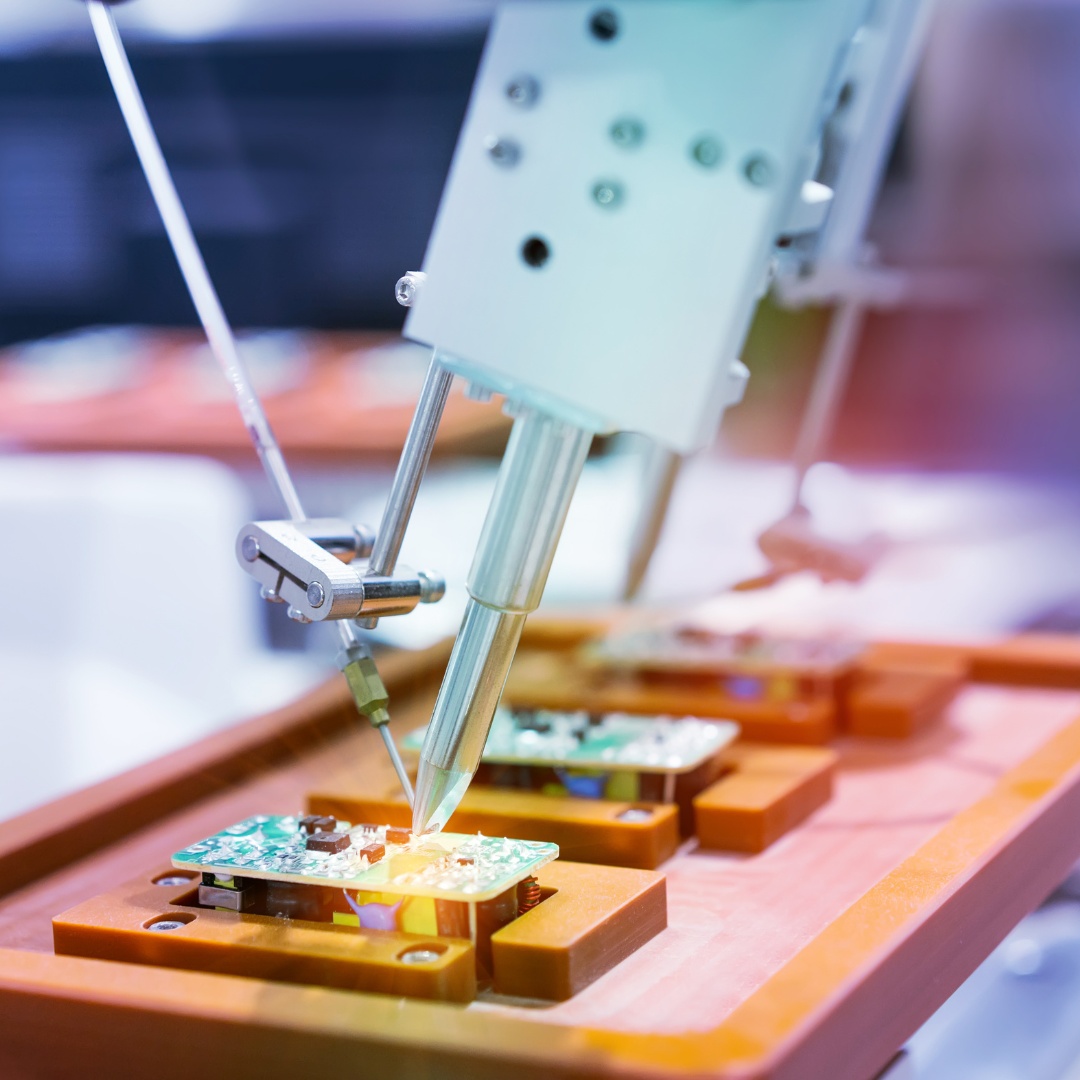

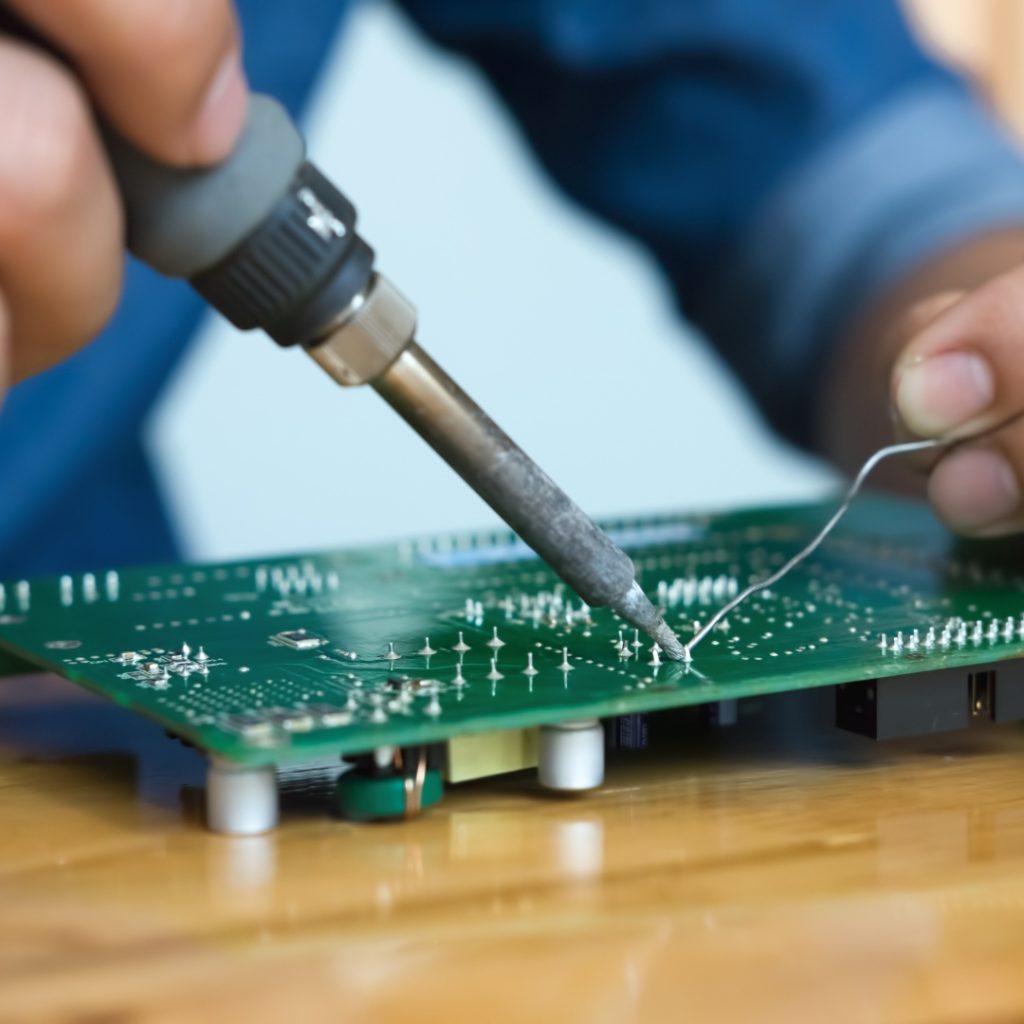

Selective Wave and Manual Soldering for PTH

For mixed-technology boards, through-hole components are soldered using lead-free wave systems with SAC305 or SnCuNi solder.

Flux application, dwell time, and conveyor speed are calibrated to board thickness and copper distribution.

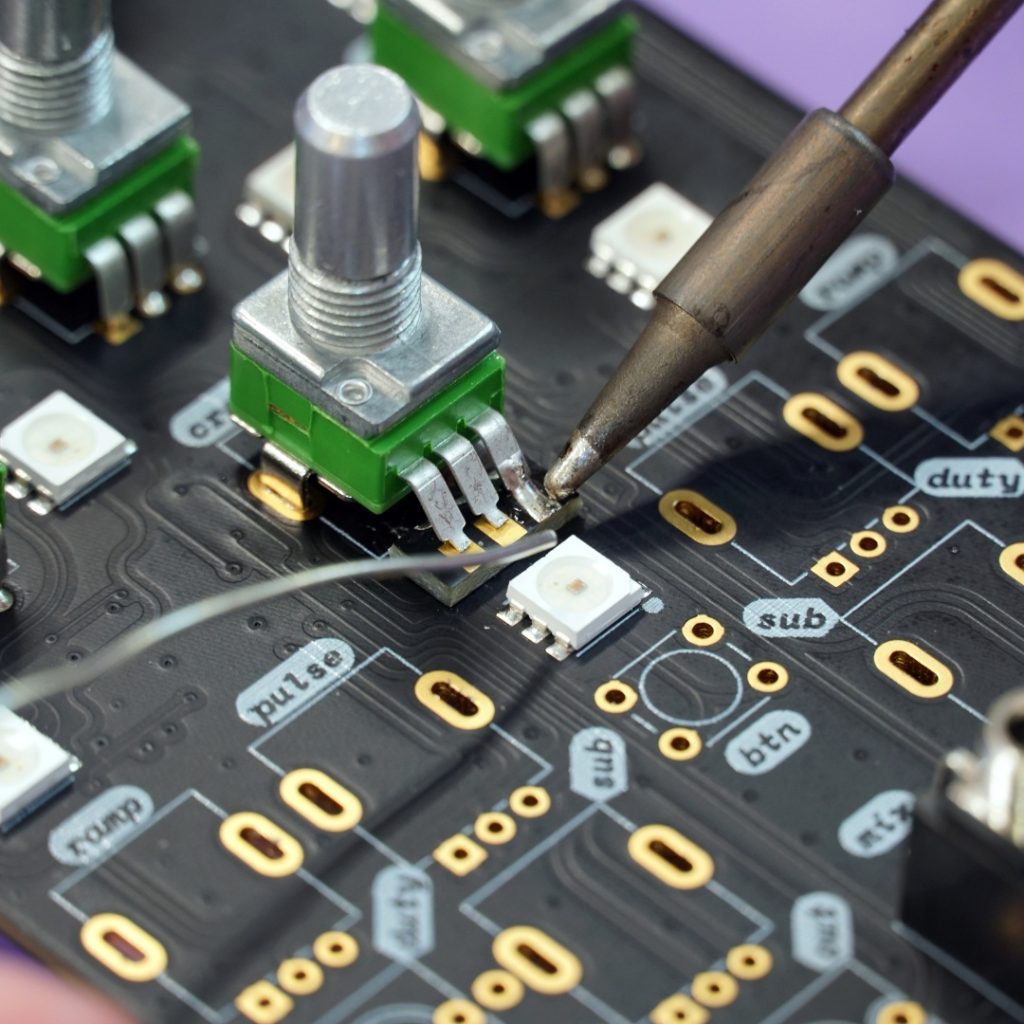

Manual soldering stations use RoHS-compliant solder wire and temperature-controlled tips under ESD protection.

Post-Reflow Cleaning and Conformal Coating

Assemblies using water-soluble or no-clean flux undergo process-specific cleaning in batch or inline systems.

Cleaning agents are RoHS-certified and alloy-compatible.

Boards requiring coating receive optional acrylic or silicone-based conformal films applied by spray, dip, or selective coating with UV inspection.

Final Inspection and Documentation

All lead-free PCB assemblies undergo 2D AOI and 5-axis X-ray (≤15 µm resolution) for BGA and BTC solder joint validation. Functional or ICT tests are applied where specified.

Reflow and inspection data are archived per job and included with the RoHS compliance package for each shipment.

What Surface Finishes are Available for Lead-Free PCB Assembly?

OurPCB offers multiple surface finish options that meet RoHS and lead-free assembly requirements, each selected based on solder paste compatibility, pad geometry, and wetting behavior under high-temperature reflow.

All finishes are applied in-house and tracked by job number, thickness, and plating date as part of our lead-free PCB assembly documentation package.

Electroless Nickel Immersion Gold (ENIG)

ENIG is applied with 120 to 240 µin of nickel and 2 to 5 µin of immersion gold, following IPC-4552A. Nickel provides diffusion resistance while gold preserves solderability under high-heat reflow.

This finish pairs well with SAC305 lead-free solder paste, offering flatness critical for lead-free PCB assembly involving BGA, QFN, or µBGA layouts. ENIG supports multiple 260 °C reflow cycles without oxidation and maintains solder joint planarity for high-density SMT.

Lead-Free Hot Air Solder Leveling (HASL)

Lead-free HASL finishes are applied with SnCu or SnNi solder at 260 to 270 °C, then leveled with high-velocity air knives. Thickness ranges from 100 to 500 µin, measured against IPC-6012 standards.

This finish supports lead-free PCB manufacturing using through-hole or mixed-technology components and is compatible with SAC-class and SnCuNi lead-free solder. It offers excellent solder wetting and mechanical robustness but is unsuitable for 0.4 mm or finer pitch components due to surface unevenness.

Organic Solderability Preservative (OSP)

OSP coatings are deposited via horizontal conveyor systems to a controlled film thickness of 0.2 to 0.5 µm. The organic layer inhibits copper oxidation before soldering and is removed during the first reflow.

OSP is RoHS compliant and optimized for single-pass lead-free reflow using SAC305 solder paste. It is commonly used in high-yield SMT lead-free PCB assembly, but not recommended for boards requiring multiple thermal cycles or extended shelf life beyond 6 months.

Immersion Silver and Immersion Tin

Immersion Silver coatings are applied to 5 to 12 µin thickness, offering low contact resistance and substantial wetting for SAC-class lead-free solder alloys. Immersion Tin creates a SnCu intermetallic directly at the copper interface, applied to a 30 to 50 µin thickness.

Both finishes are RoHS compliant and suitable for medium-volume lead-free PCB assemblies requiring flat pads and reliable first-pass yield. Silver is preferred for multiple reflow cycles; Tin is selected when oxide prevention and surface planarity are the priority.

What Materials do we use for RoHS-Compliant PCB Manufacturing?

All materials used in lead-free PCB manufacturing are certified to meet the thresholds outlined in the RoHS directive 2015/863, with no more than 0.1% by weight of restricted substances such as lead, mercury, or hexavalent chromium.

Every PCB order requiring lead-free processing is matched to compliant stackups and solder alloys to reduce the risk of failed inspection or restricted shipment due to banned lead content.

High-Tg Laminates for Lead-Free Assembly Cycles

We stock UL-certified base materials including FR408HR, IS420, and G200 for high-temperature lead-free reflow. These laminates support 260 °C peak temperature profiles and meet IPC-TM-650 Method 2.4.24.1 for delamination time (T288) exceeding 6 minutes.

Dielectric properties (Dk 4.1 to 4.3, Df ≤ 0.008) remain stable through multiple reflow cycles, and each stackup is validated for copper thickness, press-out, and expansion behavior.

These lead-free PCB designs support thermal reliability without degradation in dimensional tolerance, impedance, or resin-glass bond strength across the full assembly cycle.

Lead-Free Compatible Solder Alloys

Solder alloys used in our facility include SAC305, SnCuNi, and low-Ag high-reliability blends, selected through internal solder alloy selection guidelines.

These alloys form lead-free solder joints with controlled wetting angles, predictable intermetallic thickness (1 to 2 µm), and reduced crack propagation under strain.

Each batch is certified for <1000 ppm impurities and <100 ppm lead use. Mechanical performance under shear and vibration is validated using JEDEC JESD22-B111.

These lead-free materials are part of our lead-free solutions portfolio applied across all Class 3 PCB manufacturing and assembly jobs.

Surface Finishes Matched to Paste and Alloy

ENIG, lead-free HASL, Immersion Silver, and OSP are applied in-house. Each lead-free surface finish is selected based on compatibility with component terminations, lead-free solder paste type, and board layout.

Immersion finishes are tested for shelf life stability, oxide layer thickness, and wetting behavior under SAC-class alloys. HASL coatings are evaluated for planar uniformity and solder mask dam clearance per IPC-6012.

These materials are used across PCB fabrication and assembly jobs requiring reflow consistency, press-fit durability, or fine-pitch pad coplanarity.

RoHS-Certified Components and Termination Finishes

All BOMs, including component body materials and terminal plating, are checked for RoHS conformity.

We validate each part as compliant with lead-free and RoHS standards and confirm plating compatibility across ENIG, SnCu, and SnAg finishes.

Components used in lead-free circuit board builds are verified for moisture sensitivity (MSL) and thermal exposure limits based on JEDEC J-STD-033.

This prevents exposure to lead and ensures long-term solder joint reliability across fine-pitch ICs, BGA, and bottom-terminated devices on RoHS-compliant PCB builds.

What Testing and Certifications do Our Lead-Free PCBs Meet?

Turnkey PCB assembly is best when you want OurPCB to manage sourcing, while consignment gives you control over the components you supply. We recommend turnkey for fast lead times, stable BOMs, and minimal sourcing overhead.

Consignment PCB assembly is better when you need to protect proprietary parts, use pre-purchased inventory, or meet strict vendor requirements. Our team supports both models and helps you select the most efficient path based on supply chain control, traceability needs, and build complexity.

AOI and X-Ray Validation for Lead-Free Solder Joints

Our PCB Boards undergo 100% inspection using 12 to 15 µm automated optical inspection (AOI) and 5-axis X-ray imaging.

We identify defects, including insufficient solder, tombstoning, wetting imbalance, and head-in-pillow on BGAs or bottom-terminated components.

For X-ray-inspected assemblies, we scan for voiding <25% per IPC-7095D guidelines for lead-free solder joints, which ensures current-carrying capacity and reduces heat buildup within SAC-class intermetallic layers, and maintain image logs for all BGA nets and broadline distribution sourcing.

Solderability Testing and Ionic Contamination Control

We apply solderability tests per IPC-TM-650 Method 2.6.33 for surface finish wetting verification before placement. Ionic cleanliness is tested using resistivity of solvent extract (ROSE) to meet ≤1.56 µg NaCl/cm² for no-clean flux and ≤0.75 µg for water-soluble flux.

These procedures validate that the board is a compatible lead-free process suitable for high-density fine-pitch component mounting without surface oxidation or flux residue buildup.

Thermal Profile, Alloy Traceability, and MES Logging

Each lead-free PCB manufacturing job includes archived thermal profile logs from 10-zone nitrogen reflow ovens.

We record soak time, peak temperature, and dwell at liquidus using embedded K-type thermocouples and track solder paste lot number, alloy type, and date code per job traveler.

These controls are structured to prevent undocumented RoHS lead content or off-spec thermal excursions across long-run or repeat builds.

RoHS Compliance Certification and Product Labeling

Finished boards are labeled with RoHS compliance marks per RoHS directive 2015/863, and documentation includes full material declarations, solder alloy certification, and process conformance.

All RoHS-compliant PCB shipments include a C of C, RoHS declaration, and optional test coupon report.

Our process aligns with lead-free and RoHS standards for all regulated lead-free products, including medical, automotive, and telecom hardware, subject to global certification.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Lead Free PCB Assembly FAQs

What is Lead Free PCB Assembly?

Lead-free PCB assembly is the process of manufacturing and assembling printed circuit boards without using lead in solder, components, plating, or laminate systems.

By replacing SnPb solder with SAC305 or SnCu, and applying RoHS-certified finishes and materials, the assembly becomes fully compliant with international restrictions on lead use in electrical and electronic equipment.

At OurPCB, we apply lead-free solder paste to ENIG, OSP, or lead-free HASL finishes on high-Tg, RoHS-declared substrates.

What are the Reliability Factors in Lead-Free PCB Assembly?

Lead-free assemblies are limited by solder joint brittleness, thermal fatigue, and intermetallic growth at higher reflow temperatures. SAC305 joints form Cu₆Sn₅ or Ni₃Sn₄ intermetallic compounds (KMC), which define long-term strength and crack resistance in lead-free soldering.

To stabilize lead-free solder joints, OurPCB controls reflow profile ramp rates, matches alloys to surface finishes, and verifies wetting angle, void rate, and IMC thickness using X-ray and cross-section analysis. Boards are screened to Class 3 J-STD-001 (validates fillet height, joint continuity, and no evidence of fractured IMC layers post reflow) and IPC-7095D acceptance criteria.

How do we Handle Component and BOM Compliance?

Every BOM is screened for plating compatibility, RoHS status, and MSL classification before release. Parts with SnPb or undefined finishes are quarantined, while lead-free components are cross-checked against declared alloys like matte Sn, SnCu, or SnAg.

For MSL-3 and above, we apply JEDEC J-STD-033 bake-out protocols and log exposure time per lot. Compliance is confirmed using manufacturer declarations and test data, ensuring all materials comply with lead-free and RoHS thresholds.

What Types of PCBs and Projects do we support?

OurPCB assembles lead-free rigid, flex, and HDI boards from 2 to 40 layers for industrial, medical, telecom, and automotive applications. We support Class 3 lead-free PCB assemblies with µBGA, fine-pitch QFN, and mixed SMT/PTH using SAC305, SnCuNi, or low-Ag alloys.

Boards are built on high-Tg laminates and processed with selective wave, nitrogen reflow, and lead-free HASL or ENIG finishes. Each job is configured as a lead-free and RoHS PCB assembly, validated per IPC-6012 and delivered with full solder, laminate, and plating documentation.

How do we Perform Lead-Free PCB Rework and Repair?

Rework on lead-free PCBs is performed using high-precision thermal tools with alloy-specific profiles between 245 and 260 °C. Components are removed under nitrogen heating with pre-bake staging when required, then replaced using lead-free solder paste matched to the original finish.

We clean pads using non-abrasive wicks or copper coupon methods to avoid mask damage and control intermetallic reformation. All rework is documented per J-STD-001 Class 2 or Class 3, depending on build type.

How do we Handle Lead-Free Wave Soldering Requirements?

Lead-free wave soldering is performed using SnCuNi or SAC alloys held at 260 to 270 °C, with conveyor speeds and dwell times tuned per board thickness and copper loading.

Flux systems are selected based on alloy and lead-free process compatibility, and applied through foam, spray, or selective nozzles.

To limit voiding and bridge formation, we control preheat gradients to 1.0 to 2.0 °C/sec and maintain full pad wetting using active flux residues under nitrogen. All joints are inspected per IPC-A-610 Class 2 or Class 3 solder acceptance standards.

What Makes Tin Whiskers a Concern in Lead-Free PCB Designs?

Tin whiskers are conductive metal filaments that form due to compressive stress in electroplated tin, especially under mismatched CTE or external humidity. They can grow from pure tin finishes used in lead-free PCB designs, potentially causing shorts or latent failures. Because lead-free plating lacks alloy suppression, matte Sn or SnCu layers may release whiskers under compressive stress, thermal load, or humidity exposure.

OurPCB reduces risk by specifying lead-free HASL, ENIG, or OSP finishes, controlling electroplated grain structure, and applying conformal coatings where required.

Ready to Start Your Lead-Free PCB Assembly Project?

Request a quote and get lead-free solder pairing, finish selection, and RoHS stackup confirmation from a certified build team. We’ll confirm material compatibility and process flow for your next lead-free PCB assembly in under 24 hours.