- PCB Manufacturer

- PCB Assembly

- Consignment

Consignment PCB Assembly for Cost and Supply Chain Control

Consignment PCB assembly lets you supply the components, PCBs, or materials while OurPCB carries out the assembly process in-house using certified SMT and through-hole lines.

You can choose full consignment, where all parts are customer-provided, or partial consignment, where we source the remaining components.

This approach is ideal for protecting proprietary PCB designs, reducing sourcing costs, or using pre-purchased inventory without delaying production.

Our certified facilities support advanced assembly types including BGA, mixed technology, and high-density SMT, all built to IPC Class 2 and Class 3 standards.

✅ Support for full and partial consignment builds.

✅ In-house X-ray, AOI, and temperature-controlled storage for client-supplied components.

✅ ISO 9001, IATF 16949, and IPC-A-610 Class 2 & 3 certified.

PCB Manufacturing Process

Why Choose OurPCB for Consignment PCB Assembly?

OurPCB handles customer-supplied components through certified in-house assembly backed by full traceability and structured quality control. We support sourcing scenarios involving proprietary parts, excess inventory, or long-lead components and align them with secure storage, automated inspection, and flexible production handling.

Controlled Storage with ESD, MSL, and Lot-Level Logging

All customer-supplied parts are inspected at intake, stored in ESD-safe dry cabinets under <10% RH, and labeled by manufacturer part number, lot code, and quantity received.

Components sensitive to moisture follow JEDEC J-STD-033 bake-out and dry-pack protocols before surface mount placement.

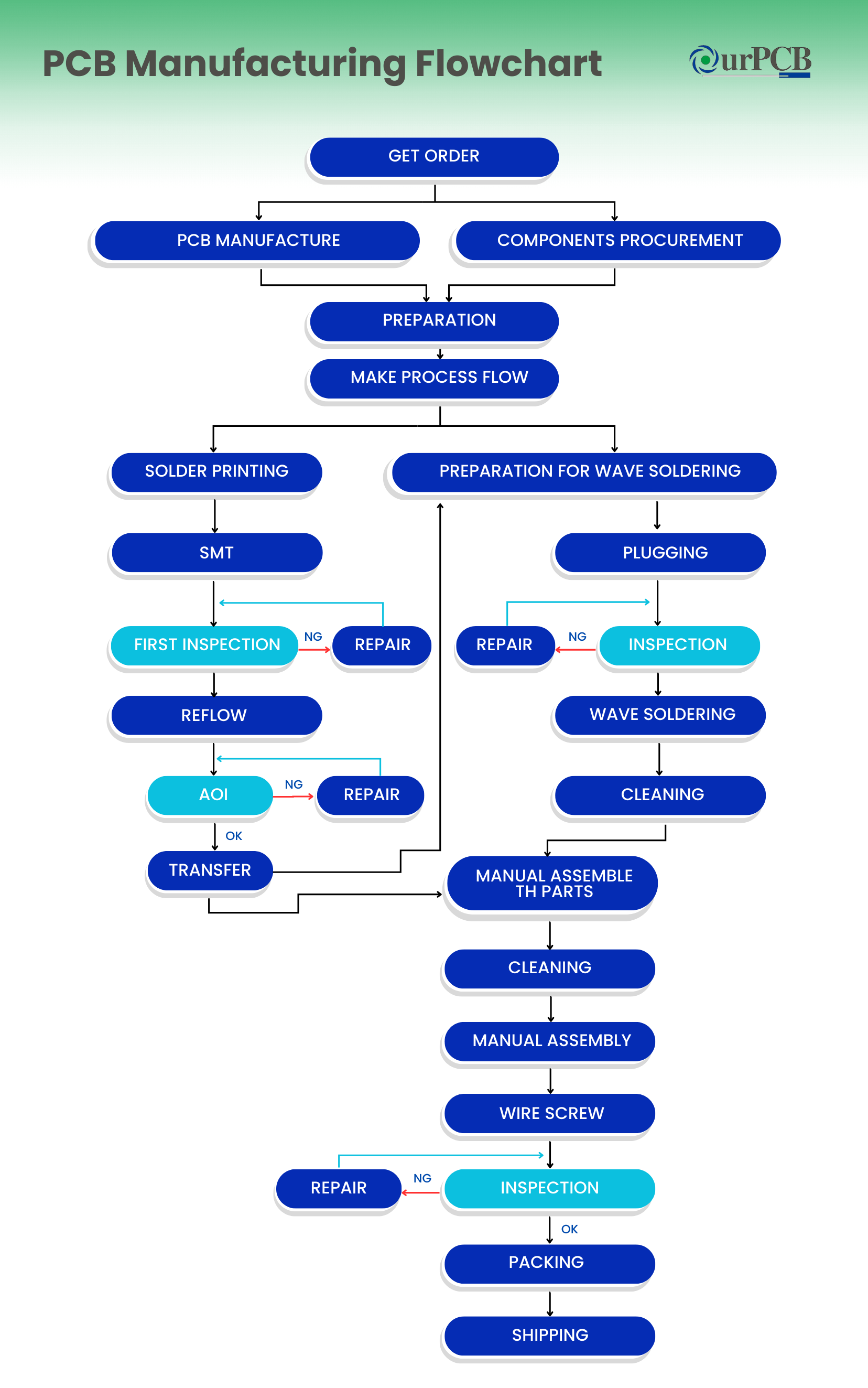

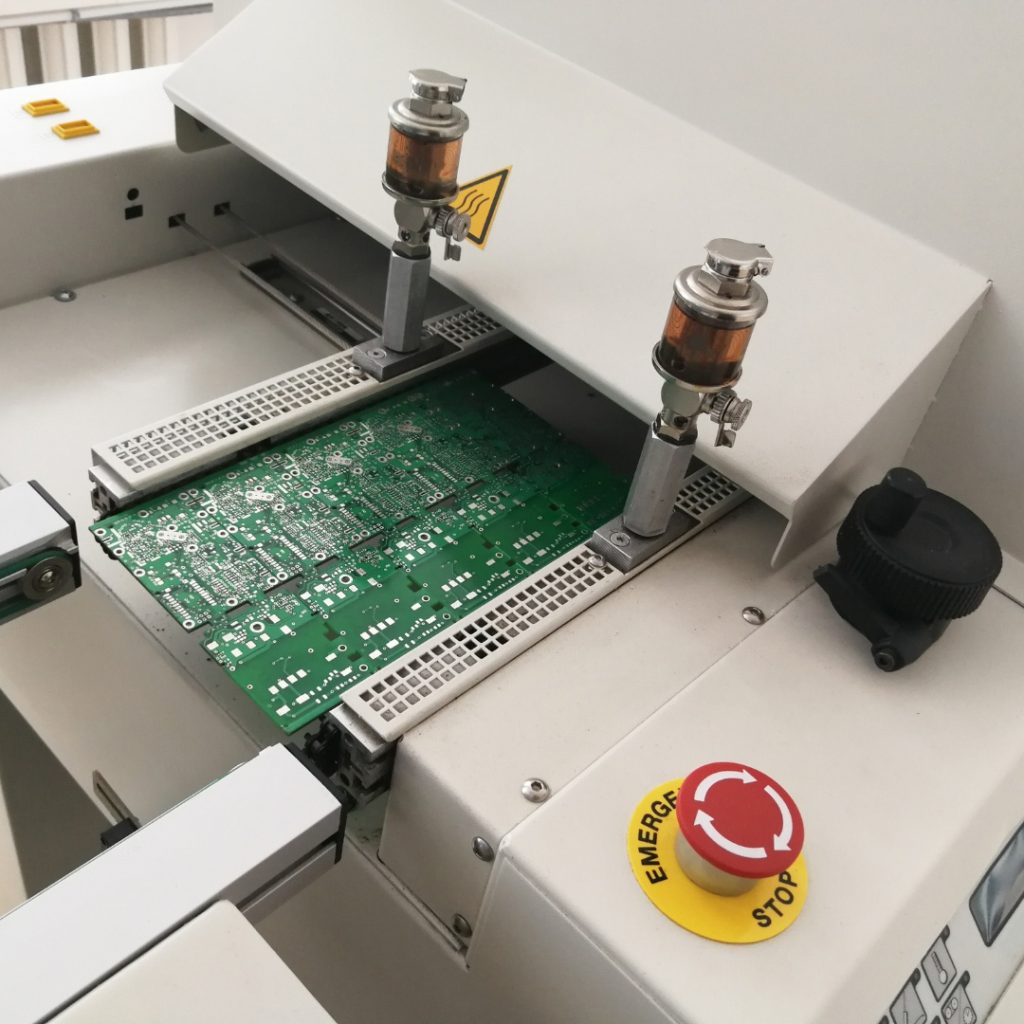

Certified SMT Lines with Mixed-Mode Assembly Options

Our SMT platforms support 0201, BGA, µBGA, CSP, QFN, and lead pitch down to 0.3 mm, placed with ±25 µm accuracy and verified by SPI.

For hybrid builds, we use selective wave soldering and manual PTH insertion with nitrogen-assisted reflow for high I/O or double-sided placement.

Clients may consign only proprietary or long-lead components. Remaining parts are sourced by OurPCB using a locked AVL and matched against your BOM, PNP, and gerber stack-up.

We conduct a first article inspection (FAI) and trace all sourced parts to authorized distribution.

Assemblies using BGA, PoP, or bottom-terminated components are scanned with 5-axis X-ray (15 µm resolution) for voids, open joints, or head-in-pillow defects.

All boards also pass automated optical inspection (AOI) with 12 to 15 µm optical resolution for lead coplanarity, polarity, and placement accuracy.

Each consignment assembly is barcoded and tracked through an MES system that logs inspection status, operator ID, soldering parameters, and equipment data.

We provide clients with build-to-order travelers documenting every step from kit release to final quality assurance (FQA).

We offer downstream assembly services including firmware flashing, box build, cable harness connection, and functional test, all executed in isolated, ESD-controlled lines.

These services ensure that consigned printed circuit board assemblies are delivered as ready-for-deployment subassemblies or complete units.

How Our Consignment PCB Assembly Process Works

Each consignment PCB assembly job begins with part intake tied directly to machine setup and line scheduling.

We group kits by reel type, feeder pitch, and placement side, then assign each one to specific staging lanes with matching reflow oven configuration and solder type. Our technicians pre-scan each feeder slot against the BOM and PNP file to catch mismatches before programming.

Kit Receipt and Verification Workflow

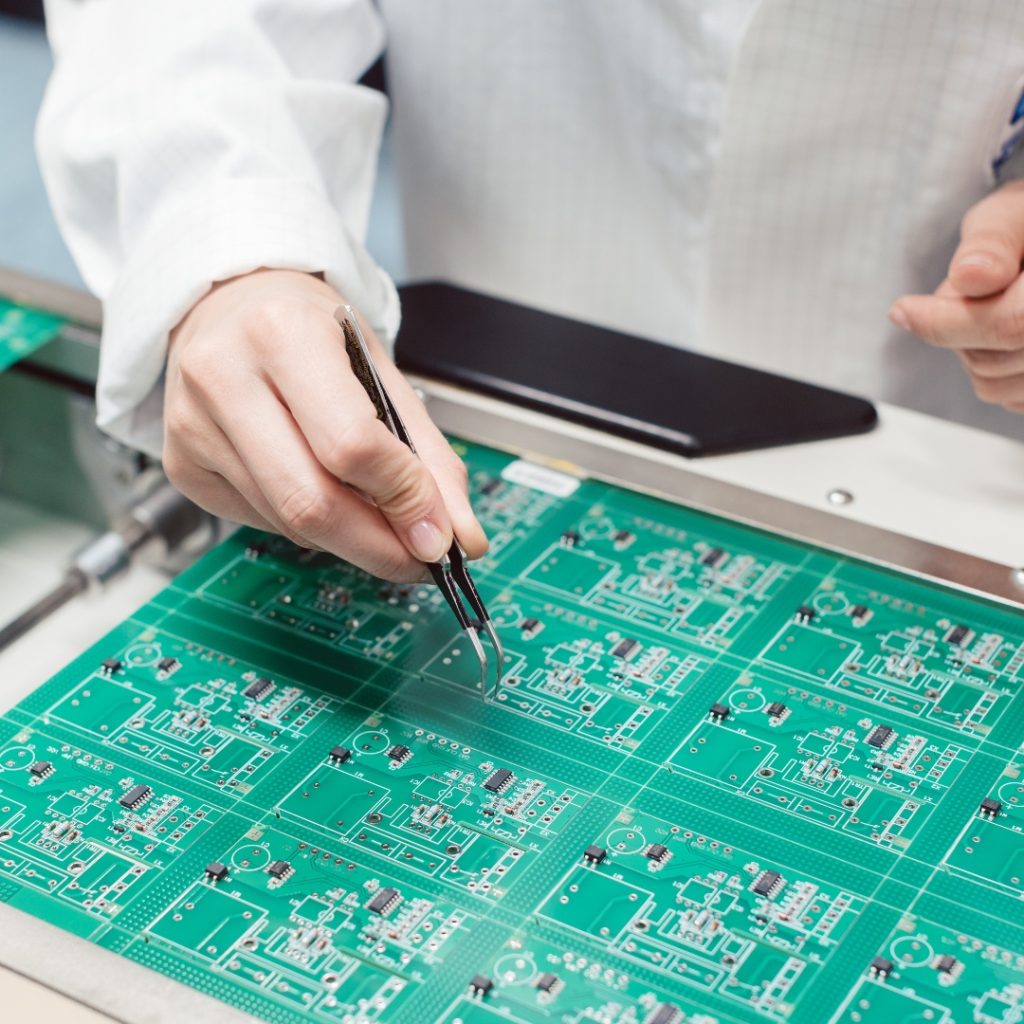

All consigned PCB kits are assigned a unique internal tracking ID at intake. Components are unpacked, sorted by feeder compatibility (tray, tube, tape), and checked against the BOM line-by-line.

Discrepancies in part number, reel labeling, or quantity shortfall trigger a hold and customer notification before any line setup is authorized.

Material Conditioning and Job Release Staging

Moisture-sensitive components are scanned for MSL classification and timeout. Floor-exposed parts are queued for bake-out and resealing before feeder prep.

Kits are then moved into a staging buffer with recorded timestamps, ready for scheduled job release into SMT or PTH lanes within a 24-hour window to avoid MSL re-exposure.

Feeder Setup and Placement Optimization

Feeder lanes are assigned based on component pick frequency, rotation offset, and machine head type (high-speed vs. multi-function).

Job setup includes vision system calibration, feeder load sequence, and nozzle selection to match the footprint.

For cut tape or partial reels, feeder splicing or leader creation with cover tape is performed in-line.

Final Inspection Sequencing and Routing

Boards flagged for BGA, PoP, or QFN automatically route to X-ray before post-reflow AOI.

Inspection sequence follows preassigned logic: X-ray → AOI → functional test, with exception routing for manual visual review if solder bridges or lifted leads are detected.

Final pass/fail disposition is recorded against the internal build traveler before packaging.

Assembly Execution and Process Sequencing

Once released to production, boards follow the programmed sequence of stencil printing, SMT placement, and thermal profile reflow based on solder type and component density.

For double-sided builds, bottom-side SMT is supported with low-tack adhesive or pallet fixturing. If mixed with PTH, boards are transferred to selective soldering or manual insertion before final reflow or wave pass.

Our Consignment PCB Assembly Quality and Inspection Standards

Our quality control framework for consignment PCB assembly services applies traceable inspection steps, file-to-placement verification, and IPC-driven acceptance thresholds for every customer-supplied kit.

We treat PCB assemblies built from consigned parts with the same process discipline, solder acceptance logic, and visual defect grading as turnkey orders, while tailoring workflows to file sets and final test specs.

Kit Receipt and Verification Workflow

All consigned PCB kits are assigned a unique internal tracking ID at intake. Components are unpacked, sorted by feeder compatibility (tray, tube, tape), and checked against the BOM line-by-line.

Discrepancies in part number, reel labeling, or quantity shortfall trigger a hold and customer notification before any line setup is authorized.

Material Conditioning and Job Release Staging

Moisture-sensitive components are scanned for MSL classification and timeout. Floor-exposed parts are queued for bake-out and resealing before feeder prep.

Kits are then moved into a staging buffer with recorded timestamps, ready for scheduled job release into SMT or PTH lanes within a 24-hour window to avoid MSL re-exposure.

Feeder Setup and Placement Optimization

Feeder lanes are assigned based on component pick frequency, rotation offset, and machine head type (high-speed vs. multi-function).

Job setup includes vision system calibration, feeder load sequence, and nozzle selection to match the footprint.

For cut tape or partial reels, feeder splicing or leader creation with cover tape is performed in-line.

Final Inspection Sequencing and Routing

Boards flagged for BGA, PoP, or QFN automatically route to X-ray before post-reflow AOI.

Inspection sequence follows preassigned logic: X-ray → AOI → functional test, with exception routing for manual visual review if solder bridges or lifted leads are detected.

Final pass/fail disposition is recorded against the internal build traveler before packaging.

Assembly Execution and Process Sequencing

Once released to production, boards follow the programmed sequence of stencil printing, SMT placement, and thermal profile reflow based on solder type and component density.

For double-sided builds, bottom-side SMT is supported with low-tack adhesive or pallet fixturing. If mixed with PTH, boards are transferred to selective soldering or manual insertion before final reflow or wave pass.

Kit Receipt and Verification Workflow

All consigned PCB kits are assigned a unique internal tracking ID at intake. Components are unpacked, sorted by feeder compatibility (tray, tube, tape), and checked against the BOM line-by-line.

Discrepancies in part number, reel labeling, or quantity shortfall trigger a hold and customer notification before any line setup is authorized.

Material Conditioning and Job Release Staging

Moisture-sensitive components are scanned for MSL classification and timeout. Floor-exposed parts are queued for bake-out and resealing before feeder prep.

Kits are then moved into a staging buffer with recorded timestamps, ready for scheduled job release into SMT or PTH lanes within a 24-hour window to avoid MSL re-exposure.

Visual Defect Inspection and Final Lot Clearance

Before release, all finished PCB assemblies are checked for soldermask overflow, improper screen alignment, bent leads, and mechanical interference with standoffs or connectors. X-out boards are quarantined, and pass/fail data is recorded in our MES system.

No consignment PCB assembly shipment is approved without a supervisor-signed QA release.

Feeder Setup and Placement Optimization

Feeder lanes are assigned based on component pick frequency, rotation offset, and machine head type (high-speed vs. multi-function).

Job setup includes vision system calibration, feeder load sequence, and nozzle selection to match the footprint.

For cut tape or partial reels, feeder splicing or leader creation with cover tape is performed in-line.

Final Inspection Sequencing and Routing

Boards flagged for BGA, PoP, or QFN automatically route to X-ray before post-reflow AOI.

Inspection sequence follows preassigned logic: X-ray → AOI → functional test, with exception routing for manual visual review if solder bridges or lifted leads are detected.

Final pass/fail disposition is recorded against the internal build traveler before packaging.

Assembly Execution and Process Sequencing

Once released to production, boards follow the programmed sequence of stencil printing, SMT placement, and thermal profile reflow based on solder type and component density.

For double-sided builds, bottom-side SMT is supported with low-tack adhesive or pallet fixturing. If mixed with PTH, boards are transferred to selective soldering or manual insertion before final reflow or wave pass.

Kit Receipt and Verification Workflow

All consigned PCB kits are assigned a unique internal tracking ID at intake. Components are unpacked, sorted by feeder compatibility (tray, tube, tape), and checked against the BOM line-by-line.

Discrepancies in part number, reel labeling, or quantity shortfall trigger a hold and customer notification before any line setup is authorized.

Material Conditioning and Job Release Staging

Moisture-sensitive components are scanned for MSL classification and timeout. Floor-exposed parts are queued for bake-out and resealing before feeder prep.

Kits are then moved into a staging buffer with recorded timestamps, ready for scheduled job release into SMT or PTH lanes within a 24-hour window to avoid MSL re-exposure.

Feeder Setup and Placement Optimization

Feeder lanes are assigned based on component pick frequency, rotation offset, and machine head type (high-speed vs. multi-function).

Job setup includes vision system calibration, feeder load sequence, and nozzle selection to match the footprint.

For cut tape or partial reels, feeder splicing or leader creation with cover tape is performed in-line.

Final Inspection Sequencing and Routing

Boards flagged for BGA, PoP, or QFN automatically route to X-ray before post-reflow AOI.

Inspection sequence follows preassigned logic: X-ray → AOI → functional test, with exception routing for manual visual review if solder bridges or lifted leads are detected.

Final pass/fail disposition is recorded against the internal build traveler before packaging.

Assembly Execution and Process Sequencing

Once released to production, boards follow the programmed sequence of stencil printing, SMT placement, and thermal profile reflow based on solder type and component density.

For double-sided builds, bottom-side SMT is supported with low-tack adhesive or pallet fixturing. If mixed with PTH, boards are transferred to selective soldering or manual insertion before final reflow or wave pass.

Our Fine Pitch PCB Assembly Capabilities

OurPCB provides fine pitch PCB assembly services for advanced electronic systems requiring component pitches down to 8 mil. Every fine-pitch circuit board is evaluated against strict PCB fabrication tolerances, with DFM input provided before production to reduce defects and improve yield.

We manufacture fine-pitch PCB assembly for components with center-to-center spacing as low as 0.3 mm (12 mil) and down to 8 mil for reviewed designs.

Our pick and place machines operate at ±25 µm placement tolerance with real-time optical correction, supporting the exacting alignment needed for fine-pitch parts like BGA, CSP, and chip-scale packages. Fiducials and board-level tooling holes are verified for every job to maintain positional accuracy during stencil registration and component placement.

We assemble fine-pitch ICs, package-on-package (PoP) devices, QFN, QFP, µBGA, and 0201 passives across multilayer printed circuit board designs.

Our systems accommodate thousands of electronic components per unit square area, with verified solderability on exposed pads, no-lead devices, and high pin count interconnects. For aluminum PCB and hybrid designs, our team analyzes thermal mass and planarity before first-run assembly.

Our SMT assembly process uses laser-cut, electro-polished stainless steel stencils with aperture tolerances of ±10 µm. We select Type 4 or Type 5 solder paste based on aperture aspect ratio, stencil thickness, and pad geometry.

Paste is applied using squeegees with constant pressure control to prevent voids, bridging, or solder beading under fine-pitch components. Stencil thickness ranges from 100 µm for 0.5 mm pitch to 80 µm for 0.3 mm and below.

We configure custom reflow soldering profiles using board-mounted thermocouples and zone profiling to manage wetting for dense fine-pitch PCB assembly. Nitrogen-assisted convection is used to reduce oxidation and improve joint formation, particularly for BGA PCB packages and dual-row QFNs.

Our thermal profiles maintain ramp rates under 3 °C/sec and peak reflow between 235 °C and 245 °C, minimizing warpage or tombstoning in high-density layouts.

Our engineering team evaluates PCB fabrication and assembly readiness by validating trace widths, pad clearances, and PCB manufacturing capabilities against stackup tolerances.

Designs with via-in-pad, HDI PCB layers, or ultra-thin cores are reviewed for warpage risk, copper balance, and press cycle integrity. We also support impedance control and reference plane continuity essential for fine-pitch circuit routing.

Millions of business and innovators use OurPCB

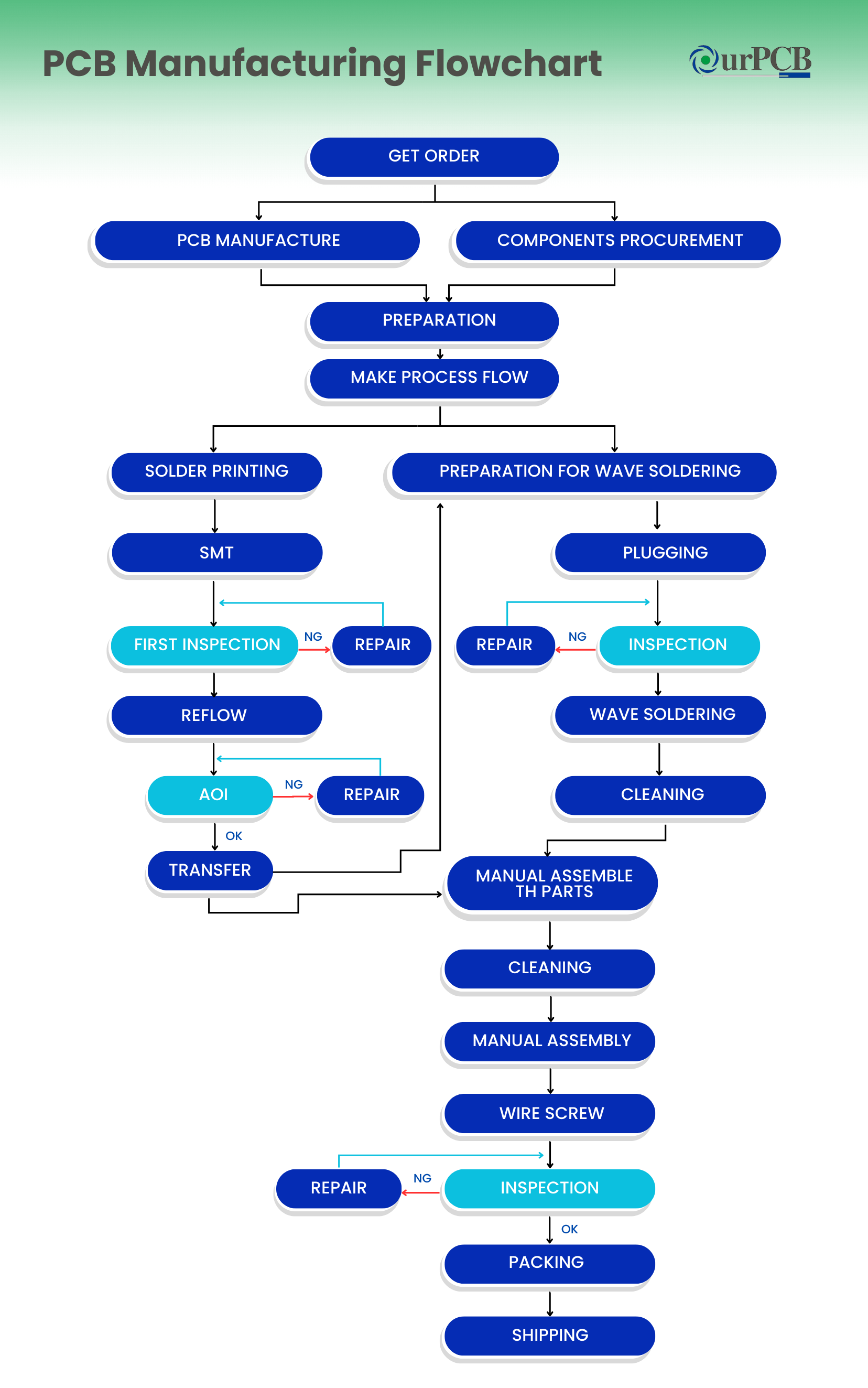

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- Cleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shiping

Our Technical Capabilities

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly, Single/double-sided Assembly Mixed PCB Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 64 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 1.8mil/1.8mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Industries That Use Consignment PCB Assembly

Certain industries depend on consignment PCB assembly services due to sourcing restrictions, compliance mandates, proprietary part constraints, or long lead times.

OurPCB supports these sectors by integrating partial consignment PCB assembly into controlled workflows while preserving traceability, handling compliance-critical materials, and avoiding sourcing conflicts with client-approved vendor lists.

Medical Devices and Diagnostic Platforms

OEMs in the medical sector often provide hard-to-find components like imaging ASICs, Class III-rated modules, or components with validated shelf lives.

We assemble these using ESD-safe handling and Class 3 solder standards, while maintaining serial traceability for UDI compliance and post-market surveillance.

Aerospace and Defense Systems

Defense integrators use consignment PCB workflows to control export-restricted or ITAR-classified components.

We stage these parts under secured, access-controlled areas and validate each line item against the project BOM before SMT release.

Our builds follow IPC-A-610 Class 3, with optional conformal coating and serialization.

Telecom and Network Infrastructure

High-speed backplanes and switch modules often require components with fixed vendor sourcing to ensure consistency across thousands of deployed nodes.

Clients consign memory buffers, transceivers, and custom magnetics that we integrate into custom PCB assembly builds with impedance-controlled routing and X-ray-inspected BGA layouts.

Industrial Automation and Control Systems

Legacy systems and low-volume automation boards often use obsolete or client-held ICs that require PCB consignment to avoid costly redesign.

We support these cases with hand-insertion, selective wave soldering, and integration of customer-stocked parts alongside standard passives from our sourcing library.

EV and Automotive Electronics

Tier 1 and Tier 2 suppliers use partial consignment PCB assembly to control supply chain risks for microcontrollers, power FETs, and AEC-Q200-certified passives.

Our assembly lines maintain temperature and humidity profiles suited for high-reliability automotive builds, with end-of-line functional testing and barcoded tracking for trace recall.

When Should You Choose Turnkey vs. Consignment PCB Assembly?

Turnkey PCB assembly is best when you want OurPCB to manage sourcing, while consignment gives you control over the components you supply. We recommend turnkey for fast lead times, stable BOMs, and minimal sourcing overhead.

Consignment PCB assembly is better when you need to protect proprietary parts, use pre-purchased inventory, or meet strict vendor requirements. Our team supports both models and helps you select the most efficient path based on supply chain control, traceability needs, and build complexity.

Choose Turnkey for Full Procurement and Line Scheduling

Our turnkey PCB assembly services cover component sourcing, BOM validation, reel formatting, kitting, and feeder setup under one MES-controlled workflow.

This option reduces vendor coordination and consolidates liability for sourcing errors, mismatched part numbers, or shelf-life violations.

Ideal for prototype PCB builds or scaled production with common-value passives and broadline distribution sourcing.

Use Full Consignment for Proprietary and Controlled Components

Full consignment PCB assembly is used when your design includes ITAR-classified ICs, expired-lot inventory, or components with restricted supply chains.

You supply reels, trays, or tubes; we handle ESD-safe storage, dry cabinet staging (≤10% RH), and slot programming based on your pick and place file.

Recommended for aerospace, medical, and encryption-enabled PCBs where in-house sourcing is prohibited.

Choose Partial Consignment for Critical Item Control

Partial consignment PCB assembly lets you consign FPGAs, PMICs, or automotive-rated semiconductors while OurPCB sources the balance.

We separate sourcing responsibilities by line item, with full AVL traceability, and route the job through split-kit integration during feeder loading.

Best for builds affected by allocation, MOQ lockouts, or vendor qualification loops.

Use Consignment to Preserve BOM Integrity Across Batches

PCB consignment builds maintain exact-match sourcing across revisions, serial lots, or customer-specific product variants.

You define the vendor, lot number, and reel ID; we track placement accuracy through AOI, X-ray, and final test logging.

This is critical for projects requiring component sourcing and assembly verification for audit, trace recall, or FDA/automotive documentation.

Use Turnkey for Speed, Cost, and Short-Run Validation

For projects with tight delivery schedules or cost pressure, turnkey assembly enables rapid cycle time through inline BOM quoting, multivendor sourcing, and auto-matched substitution logic.

We manage feeder setup, solder profile tuning, and overage planning to compress assembly and testing into a single run. Recommended for prototype PCB launches or pre-pilot low-volume builds.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Consignment PCB Assembly FAQs

What’s the difference between full and partial consignment PCB assembly?

In full consignment PCB assembly, you supply 100% of the materials, including PCBs, components, and documentation. In partial consignment, you provide critical or hard-to-source parts, while OurPCB handles component sourcing for the rest.

Both models are tracked under a single internal job ID with distinct traceability for each material origin.

What files do I need to submit for a consignment PCB assembly order?

We require a validated bill of materials (BOM), pick-and-place (PNP) file, Gerber files, and optional test specs or mechanical drawings.

BOMs must list part number, quantity, manufacturer, and footprint match. PNP files must define X/Y, rotation, polarity, and top/bottom layer. Gerbers must include copper, soldermask, paste, and silkscreen layers.

Can you use partial reels or cut tape in my consignment kit?

Yes, partial reels and cut tape under 150 mm must be pre-approved. OurPCB can splice, re-reel, or repackage components to make them compatible with automated feeders. Loose or bulk components must be bagged and labeled by MPN to avoid misload during feeder setup.

What happens if parts are missing or mismatched in my consigned kit?

We check every PBC consignment against the BOM and flag any quantity mismatch, expired shelf life, or part number error before line release. If your kit is incomplete, you can ship the missing items separately or authorize OurPCB to source the components under your approval.

Can you store unused inventory from my consignment kit for future builds?

Yes. Our warehouse offers secure, humidity-controlled inventory retention for surplus components linked to future production runs. You can reference the same job ID to trigger material reuse, saving time and eliminating reshipment for ongoing or revision-stable builds.

What happens if a consigned component fails inspection?

If a component in your PCB consignment arrives oxidized, mislabeled, expired, or visibly damaged, we place it in quarantine and report the issue before line release.

You may replace the part, request OurPCB to source an alternative, or authorize exclusion depending on the impact. No build proceeds without your written disposition for non-conforming items.

Can you update your BOM after submitting the consigned kit?

Yes, you may submit BOM updates or footprint changes after kit delivery, but any revision must be confirmed by OurPCB before feeder setup begins.

We version-control all consignment PCB assembly documentation, and new files are applied only if parts have not yet been programmed or loaded to feeders.

Do you accept customer-supplied PCBs as part of the consignment?

Yes, in full consignment PCB assembly, we can receive and assemble your bare boards alongside the components. Each panel is checked for soldermask integrity, surface finish, dimensional tolerance, and warpage before assembly.

Our lines support panel sizes up to 520 mm × 400 mm and board thicknesses from 0.6 mm to 3.2 mm.

What is the lead time for a consignment PCB assembly job?

OurPCB does not publish fixed lead times for consignment PCB assembly, as turnaround depends on part verification, stencil readiness, board complexity, and whether testing is required.

For most jobs, assembly is completed within 5 to 12 working days after kit approval. Longer lead times may apply to high-layer boards, partial kits, or orders requiring functional test or custom fixture integration.

Ready to Start Your Consignment PCB Assembly Project?

Send us your BOM, PNP file, and list of consigned materials to get started. Our quoting team will review your documentation and respond within 2 working days with build feasibility, lead time options, and format compatibility guidance.

We support split-kit scheduling, consigned PCBs, and hybrid sourcing workflows. Whether launching a new design or managing an existing supply chain, OurPCB is ready to help.