Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables. This makes sure that there is a clear connection between your circuit boards and interconnect systems.

OurPCB mixes PCB fabrication skills with cable assembly prototyping for quick design validation. This mixed way of going about it gets rid of compatibility problems between PCBs and their prototype cables. It does this while ensuring both components meet the same exact quality standards and regulatory compliance.

Contents

- Key Takeaways

- What are Prototype Cable Assemblies?

- Why do Prototype Cable Assemblies Matter?

- Load and Environmental Considerations

- How do IPC Standards Define Quality Requirements?

- Product Classification System

- Workmanship Standards Coverage

- What Technical Specifications Ensure Assembly Reliability?

- MIL-DTL-38999 Connector Performance

- Environmental Protection Materials

- How does OurPCB's Integrated PCB-Cable Process Work?

- Design and Engineering Phase

- Manufacturing and Validation

- What Testing Protocols Validate Performance?

- Electrical Validation Testing

- Custom Test Equipment Design

- Environmental and Mechanical Testing

- Why Choose PCB-Integrated Cable Assembly Solutions?

- Design for Manufacturing Excellence

- Risk Mitigation Through Early Validation

- Component Selection and Sourcing

- Accelerate Your Development With Expert Cable Assembly Solutions

- Prototype Cable Assemblies for PCBs FAQs

- What reverse engineering services do you provide for obsolete cable assemblies?

- How does 3D printing enhance prototype cable assembly development?

- What custom test equipment capabilities support specialized validation requirements?

Key Takeaways

- PC/WHMA-A-620 Revision E compliance ensures 388 pages of documented quality standards with 700+ technical illustrations

- Class 1, 2, and 3 product classifications support applications from consumer electronics to aerospace and medical devices

- MIL-DTL-38999 connector compatibility provides -65 °C to +200 °C operating range with 500 mating cycle durability

- 3D printing and reverse engineering capabilities speed up prototype development and legacy system upgrades

- Custom test equipment design validates performance beyond standard continuity testing for enhanced reliability

What are Prototype Cable Assemblies?

Prototype cable assemblies are pre-production wire harness solutions that validate electrical connectivity, mechanical fit, and environmental performance before mass production. These assemblies transmit electrical signals or power through bound cables using durable materials like rubber, vinyl, electrical tape, or conduit between PCBs and system components. Cable assemblies serve as the communication backbone for Electronic Control Units (ECUs) connecting central processing units to motors, valves, displays, and actuators across every cable application.

According to Bishop & Associates, Inc, the global cable assembly market is expected to grow by 6.3% each year from 2023 to 2028. This is in spite of problems like inflation, high interest rates, and geopolitical instability.

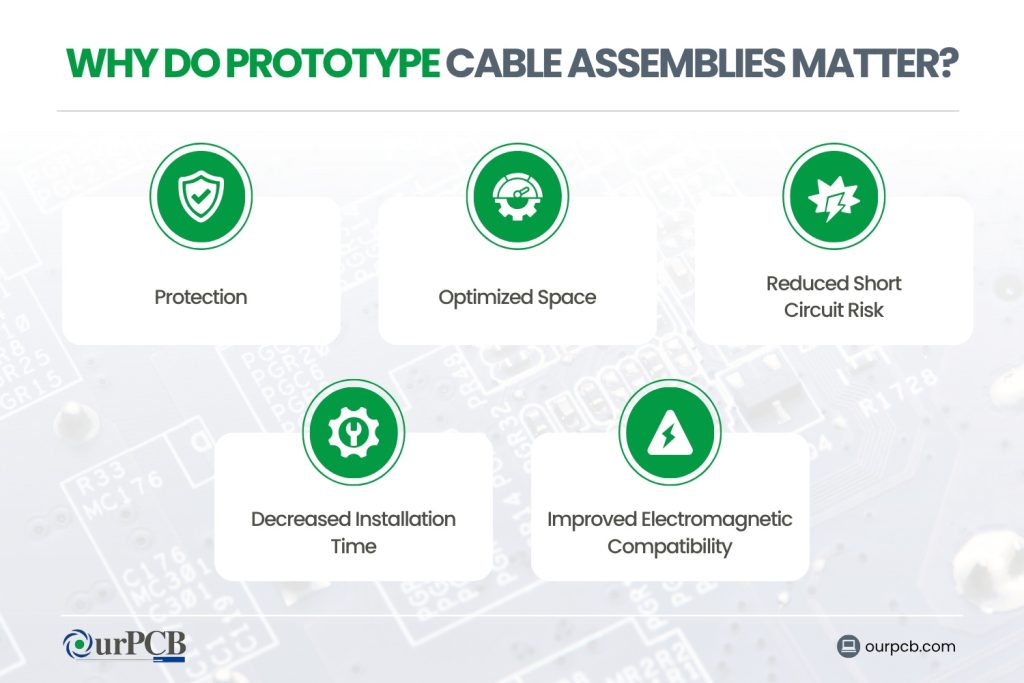

Why do Prototype Cable Assemblies Matter?

Wire harness assemblies provide essential benefits over loose discrete wire configurations and off-the-shelf solutions:

- Protection against vibrations, abrasions, and moisture exposure through specialized shield materials

- Optimized space usage in complex electronic assemblies with proper cable management

- Reduced short circuit risk through organized routing and assembly manufacturing techniques

- Decreased installation time during manufacturing and field service operations

- Enhanced electromagnetic compatibility through proper shielding and integration methods

Load and Environmental Considerations

Cable prototyping enables objective performance measurement against stated design objectives, particularly for mechanical assemblies supporting loads and motion control. Load requirements determine wire gauge selection, insulation thickness, and overall structural design parameters for various length specifications. Installation constraints influence connector selection, routing options, and accessibility considerations for maintenance procedures in real-world conditions.

How do IPC Standards Define Quality Requirements?

IPC/WHMA-A-620 Revision E represents the only industry-recognized specification for wire assembly workmanship expectations with 388 pages of detailed requirements released in October 2022. This standard sets mandatory requirements for quality and workmanship that prototyping services and customers must follow. The comprehensive documentation includes 19 chapters covering assembly criteria with over 700 full-color pictures and illustrations supporting RoHS and UL compliance.

Product Classification System

| Class | Application | Performance Requirements | Typical Industries |

|---|---|---|---|

| Class 1 | General Products | Basic functionality | Consumer appliances, refrigerators |

| Class 2 | Dedicated Services | Extended life performance | Televisions, gaming systems, cellular devices |

| Class 3 | High Performance | Critical-use applications | Military, aerospace, medical devices |

Workmanship Standards Coverage

The specification encompasses comprehensive assembly requirements for custom cable assemblies:

- Cable and wire preparation with precise stripping specifications for discrete cable assemblies

- Discrete wire termination using approved crimping techniques and state-of-the-art tool requirements

- Soldering procedures for terminal connections and splicing operations

- Mechanical interconnections including insulation displacement connectors and micro-fit applications

- Ultrasonic welding quality standards and acceptance criteria for durability enhancement

- Molding, potting, and environmental protection requirements for cutting-edge applications

Special Offer: Get $100 off your order!

Email [email protected] to get started!

What Technical Specifications Ensure Assembly Reliability?

Wire gauge specifications range from 4 AWG to 38 AWG depending on current carrying capacity, voltage drop limitations, and mechanical strength requirements for cable needs. Conductor materials primarily utilize copper due to excellent electrical conductivity and mechanical flexibility when drawn into wire form. The copper transformation process involves mining, smelting, refining, and drawing to create electrical wire suitable for complex routing applications and variety of cable lengths.

MIL-DTL-38999 Connector Performance

| Series | Coupling Type | Mating Cycles | Bend Moment | Application |

|---|---|---|---|---|

| Series I | Bayonet | 500 cycles | 650 lbs-in | High-vibration environments |

| Series II | Bayonet | 250 cycles | 150 lbs-in | Weight/space limitations |

| Series III | Quick Screw Tri-start | 500 cycles | 1000 lbs-in | Normal mating applications |

| Series IV | Breech-Lok | 500 cycles | 1000 lbs-in | Blind mating requirements |

Environmental Protection Materials

Protective materials selection considers specific environmental challenges during the design phase:

- Corrugated tubes for mechanical protection and functionality enhancement

- Braided sleeves providing electromagnetic shielding effectiveness

- Silica sleeves for high-temperature applications up to 200 °C

- Flame retardant binding materials reducing electrical fire risk

- Chemical-resistant jacketing for harsh industrial environments and global production standards

How does OurPCB's Integrated PCB-Cable Process Work?

OurPCB's integrated approach combines PCB fabrication with custom cable prototyping to ensure perfect compatibility between circuit boards and their interconnecting harnesses. The process begins with technological interviews determining bundle types, current and voltage parameters, wiring topology, interfaces, working environment, EMC requirements, and harness classification for agile development cycles.

Design and Engineering Phase

The design process transforms customer requirements into manufacturable specifications through systematic analysis and CAD modeling. Our team of engineers collaborates with customers to refine design requirements and optimize performance before moving to prototype design stages.

Requirements Analysis

Basic customer expectations include performance requirements, usage location, installation method, and operational environment specifications. Working environment analysis influences material selection, protective measures, and performance specifications for temperature ranges, humidity exposure, and chemical contact factors that could send projects back to the drawing board.

3D CAD Modeling and Interference Checking

Specialized CAD software enables 3D harness modeling within target devices for accurate fit verification and cable design optimization. Virtual modeling identifies potential interference issues before physical prototyping while ensuring harness routing compatibility within complex assemblies. Software tools generate wiring topology drawings, 2D harness drawings, and connection diagrams with broad offering of Molex connectors and other industry-standard components.

Manufacturing and Validation

Manufacturing services transform validated designs into physical prototypes through advanced production techniques and quality control processes. Assemblies are manufactured using state-of-the-art equipment to ensure consistent quality and performance validation.

3D Printing for Rapid Prototyping

Advanced 3D printing capabilities accelerate prototype development through rapid connector housing fabrication and custom bracket production. This technology enables design iterations without tooling delays while supporting unique geometries impossible with traditional manufacturing methods for quick-turn cable assemblies and first article production.

Reverse Engineering Services

Legacy system upgrades benefit from reverse engineering capabilities that recreate obsolete assemblies from existing samples. This service includes connector identification, wire specification analysis, and performance characteristic documentation for modernization projects, helping customers customize solutions without multiple suppliers.

What Testing Protocols Validate Performance?

UL certification ensures detailed traceability of individual components including cables, plugs, and sleeves through documented quality control procedures. Testing protocols verify electrical performance, mechanical integrity, and environmental resistance according to IPC/WHMA-A-620 acceptance criteria to optimize reliability before volume production.

Electrical Validation Testing

Standard electrical testing includes comprehensive validation for cable assemblies and wire systems:

- Continuity and polarity verification for all connections in cable and wire assemblies

- Insulation resistance testing at specified voltage levels

- EMC compliance validation preventing electromagnetic interference

- Signal integrity analysis for high-frequency applications and overmolded connections

- Power delivery capability verification under load conditions for various cable lengths

Custom Test Equipment Design

OurPCB designs and builds custom cable testing equipment tailored to specific assembly requirements. These testing systems validate performance characteristics beyond standard continuity testing including:

- Wire-to-board connection integrity under thermal cycling conditions

- Flex cable bend radius testing for repeated motion applications

- Environmental stress testing simulating real-world conditions

- Automated testing protocols reducing human error and improving repeatability for manufacturing services

Environmental and Mechanical Testing

Comprehensive validation includes temperature cycling from -65 °C to +200 °C for military applications, humidity exposure testing, chemical resistance validation, and mechanical stress testing. Vibration testing confirms assembly integrity under transportation and operational stresses while tensile strength verification ensures connector retention under specified loads for enhanced durability.

Why Choose PCB-Integrated Cable Assembly Solutions?

OurPCB's unique position as both PCB manufacturer and cable assembly provider eliminates compatibility issues between circuit boards and their interconnecting harnesses. This integrated approach ensures identical quality standards, testing protocols, and documentation requirements across both PCB and cable components for streamlined design and production workflows.

Design for Manufacturing Excellence

Technical expertise in PCB design enables optimized cable routing and connector placement during board layout phases. Understanding PCB manufacturing constraints allows cable assembly designs that complement circuit board geometries and component placement requirements. Form, fit, and functionality optimization occurs through collaborative design processes addressing both electrical and mechanical requirements for quick turn cable solutions.

Risk Mitigation Through Early Validation

Prototype development identifies potential design flaws before full production commitment and helps assemblies help customers avoid costly redesign cycles. Early validation prevents expensive revisions while ensuring performance meets specification requirements. Design confirmation through prototype testing validates electrical connectivity, mechanical fit, and environmental resistance under realistic operating conditions, allowing teams to test and refine designs efficiently.

Component Selection and Sourcing

Access to over 5,000 unique components, connectors, and specialized materials enables precise customization for specific application requirements. Established relationships with major manufacturers including Amphenol, TE Connectivity, Glenair, Souriau, Conesys, ITT Cannon, and Eaton ensure component availability and quality consistency for cable assemblies for end products across diverse industries.

Accelerate Your Development With Expert Cable Assembly Solutions

OurPCB's integrated PCB and cable assembly capabilities provide the technical expertise and manufacturing quality your projects demand. Our IPC/WHMA-A-620 certified processes, 3D printing capabilities, and custom test equipment design ensure reliable prototypes that transition seamlessly to full production volumes while supporting cable development from concept through deployment.

Get your prototype quote today and experience the advantage of unified PCB-cable solutions that eliminate compatibility issues and accelerate your time-to-market through advanced prototyping technologies and comprehensive cable solutions.

Prototype Cable Assemblies for PCBs FAQs

What reverse engineering services do you provide for obsolete cable assemblies?

OurPCB reverse engineers obsolete cable assemblies by analyzing existing samples to recreate exact specifications including conductor materials, connector types, and assembly techniques. We document wire gauge specifications, insulation materials, and connector pin configurations while ensuring modern manufacturing compliance with current IPC standards for legacy system upgrades and replacement part production without requiring customers to build cable assemblies for end applications from scratch.

How does 3D printing enhance prototype cable assembly development?

3D printing accelerates prototype development through rapid connector housing fabrication, custom bracket production, and strain relief component creation within 24-48 hours. This technology enables complex geometries impossible with traditional manufacturing while supporting design iterations without tooling delays, particularly beneficial for unique form factors and specialized mounting requirements in quick-turn cable assembly applications.

What custom test equipment capabilities support specialized validation requirements?

OurPCB designs and manufactures custom cable testing equipment tailored to specific assembly requirements including automated continuity testers, environmental stress testing chambers, and high-frequency signal integrity analyzers. Custom testers validate performance characteristics beyond standard testing including flex cycle testing, thermal shock validation, and application-specific electrical parameter verification for specialized industries requiring comprehensive cable development validation.

Back to Top: Prototype Cable Assemblies

Special Offer: Get $100 off your order!

Email [email protected] to get started!