Who are the Top 6 Data Cable Manufacturers in China?

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

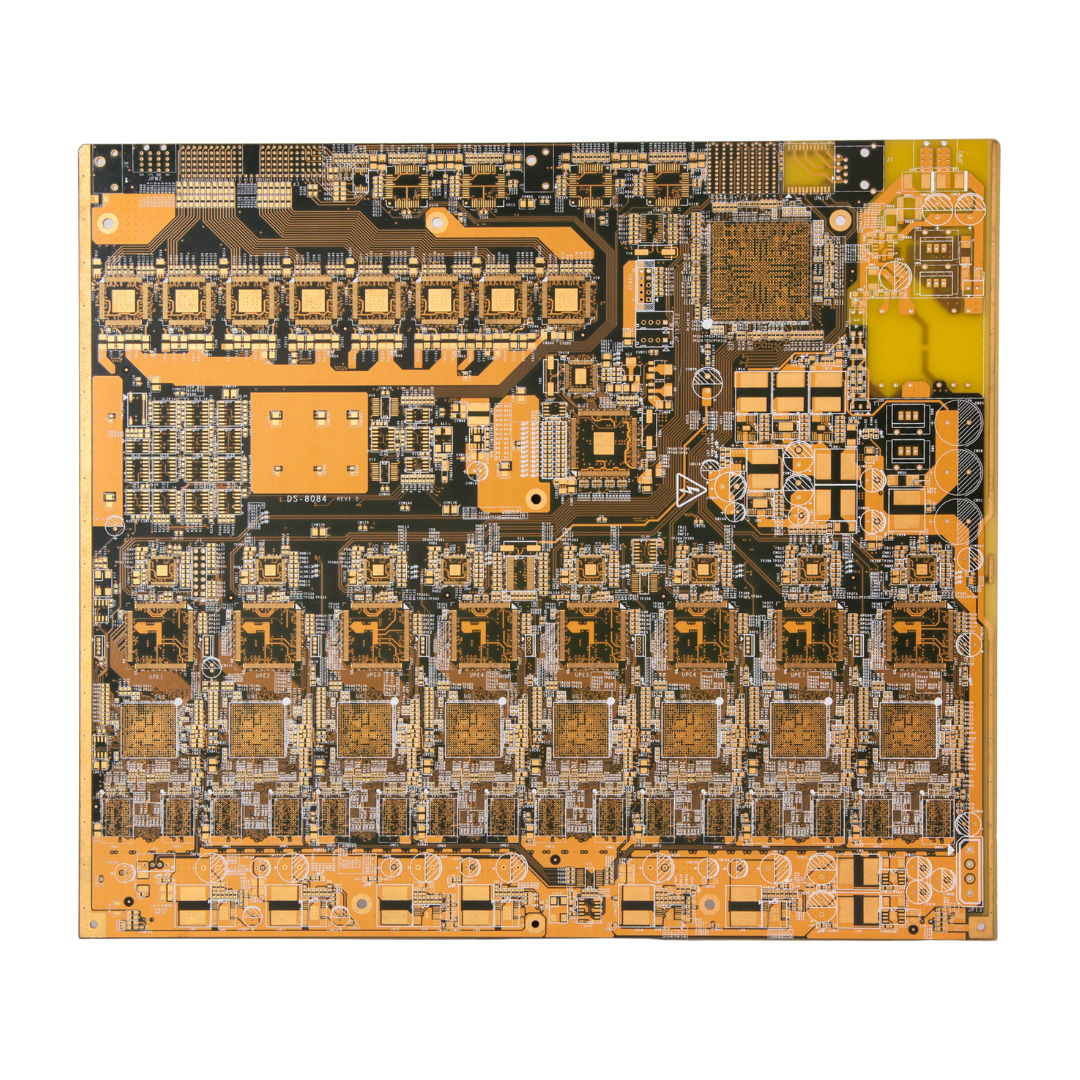

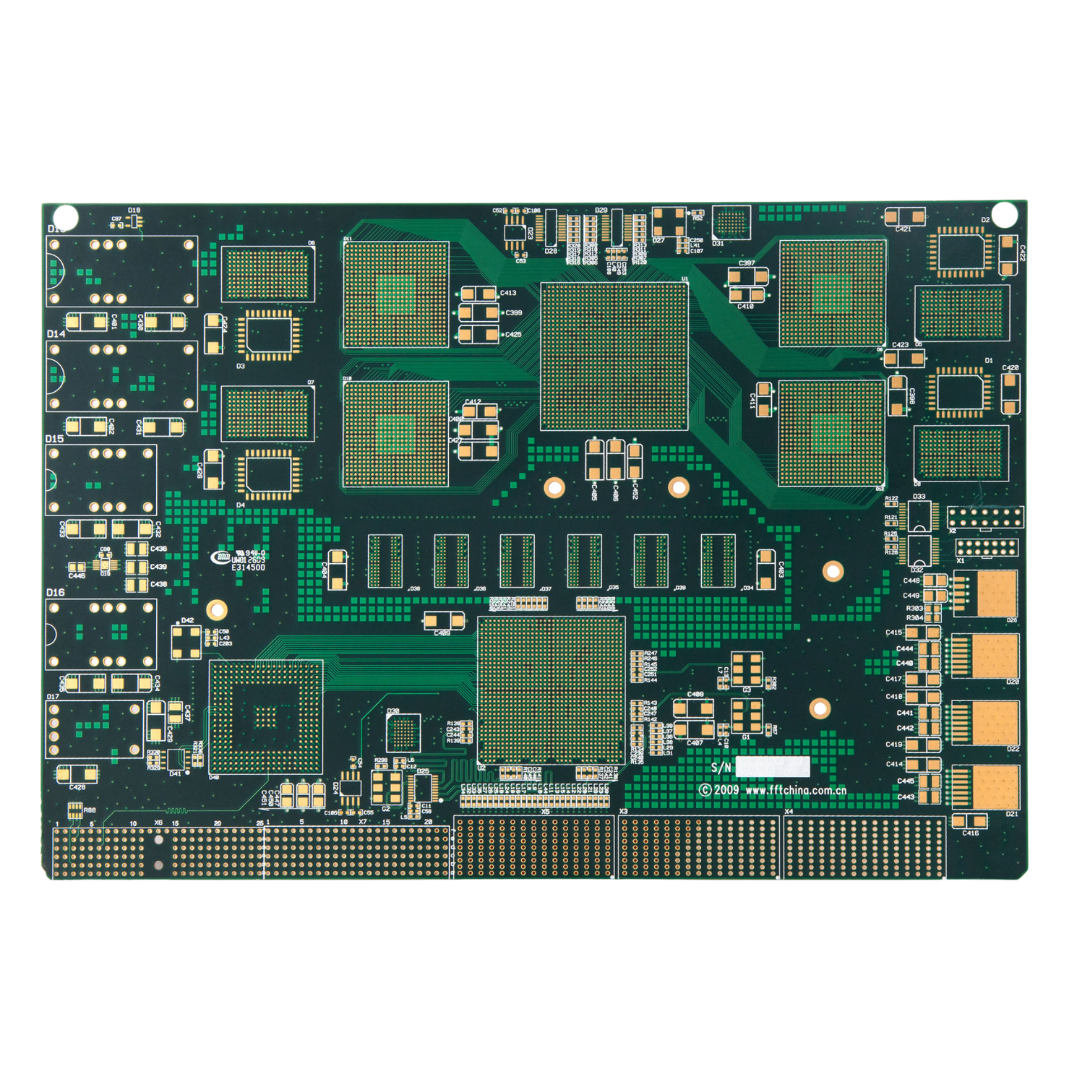

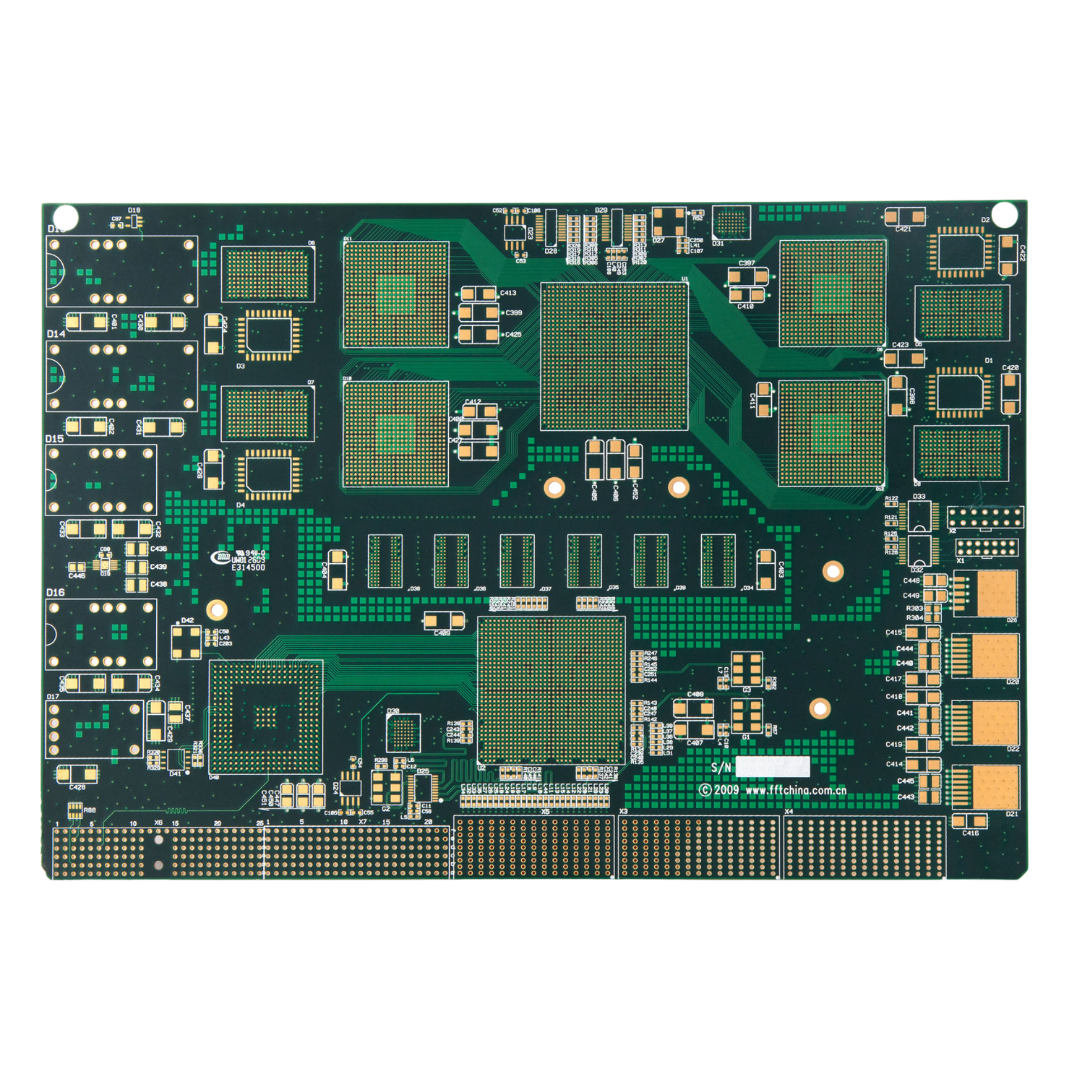

Industrial PCB assembly is the process of attaching electronic components to printed circuit boards for industrial applications. It involves soldering parts onto PCBs to create functional electronic devices. OurPCB offers top-quality industrial PCB assembly services tailored to meet diverse industry needs. We combine advanced technology with expert craftsmanship to deliver reliable, high-performance PCBs.

Industrial PCB assembly services focus on creating robust circuit boards for demanding industrial environments. These services include component placement, soldering, and testing to ensure PCBs can withstand harsh conditions. Our assembly process uses premium equipment to achieve precise component placement and secure connections.

We offer a range of assembly options to suit different industrial needs. From simple single-layer boards to complex multilayer designs, our team has the skills to handle various PCB types. We also provide both through-hole and surface mount assembly techniques, allowing us to work with a wide array of components and board designs.

Choosing OurPCB as your industrial PCB assembly partner offers numerous advantages. We combine technical expertise, quality assurance, and customer-focused service to deliver superior results. Here are the key benefits of working with us:

Selecting an industrial PCB assembly factory offers significant benefits for companies needing reliable circuit boards. These specialized facilities have the tools and expertise to produce high-quality PCBs efficiently. Here’s why partnering with an industrial PCB assembly factory is advantageous:

Our PCB assembly services cover a wide range of needs, from prototype development to large-scale production. We offer flexible solutions to meet diverse client requirements. Our services include:

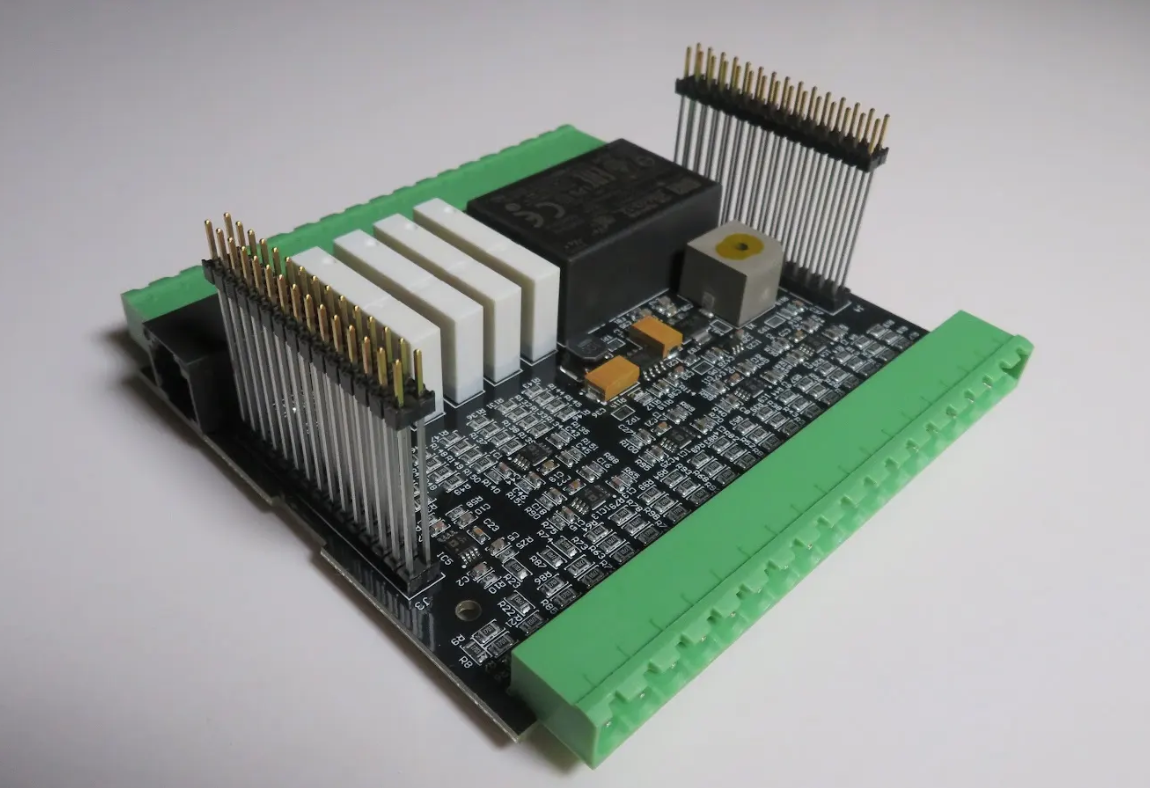

We excel in Surface Mount Technology assembly, ideal for compact and high-performance products. Our SMT process ensures accurate placement of tiny components on PCBs.

We offer flexibility in component sourcing. Clients can provide their own parts or opt for our turnkey solutions, where we handle everything from sourcing to final delivery.

Our team creates tailored PCB assemblies to match specific project needs. We work closely with clients to understand and implement their unique design requirements.

We provide fast, high-quality PCB assembly with short lead times. Our efficient processes ensure quick turnaround without compromising on quality.

We produce PCB assemblies that meet strict IPC Class 3 standards. This makes our boards suitable for critical applications in aerospace and healthcare industries.

We assemble all types of IC packages, including BGAs, POPs, CGAs, QFNs, DFNs, and CSPs. Our team ensures reliable connections for these complex components.

Our technical capabilities span a wide range of PCB assembly techniques and technologies. We can handle single-sided, double-sided, and multilayer boards with ease. Our equipment allows for precise component placement, including fine-pitch and leadless parts. We offer both leaded and lead-free soldering options to meet different regulatory requirements. Our expertise extends to flex and rigid-flex PCBs, enabling us to tackle complex three-dimensional designs. We also provide advanced testing services, including AOI, X-ray inspection, and ICT, to ensure the highest quality standards.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Yes, you can buy low- to medium-volume industrial PCBs assemblies with OurPCB. We offer PCB fabrication, PCB design, and printed circuit board assembly for various needs. Our PCB manufacturing ensures quality while meeting specific industrial requirements. For inquiries, contact us to discuss your project specifications.

To order industrial control PCB assembly, provide a BOM and adhere to our design services guidelines. We begin with a PCB prototype before full PCBA production. Our PCB assembly process follows a strict manufacturing process to guarantee reliability. High-quality double-sided PCB production and pick-and-place technology ensure efficiency.

Extra industrial controller PCB assembly costs can provide long-term savings in performance and reliability. Higher initial investment in PCB fabrication and PCB manufacturing reduces maintenance costs. Optimized PCB design and a well-structured PCB assembly process improve efficiency. Without these, you might pay more for replacements and repairs.

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree