Who are the Top 6 Data Cable Manufacturers in China?

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

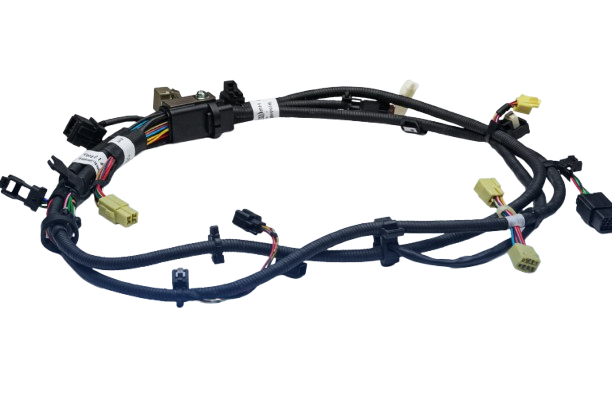

As a leading custom wiring harness manufacturer, OurPCB makes OEM wiring harnesses that meet incredibly strict automotive and aerospace standards. Our IATF 16949-certified factory creates custom wire harness assemblies rated from 12V to 800V systems. This supports vehicle applications, like traditional automotive and high-voltage electric systems.

We blend advanced automated assembly with full testing protocols. OurPCB does this to make sure that there is zero-defect shipping for your important applications.

OEM wiring harnesses are precisely engineered groupings of wires, cables, connector assemblies, and protective materials. They are made to reach the original equipment manufacturer’s specifications. These fully assembled electrical systems send out power and data signals throughout vehicle networks, machinery, and electronic systems. It does this while handling environmental threats. These can be vibration, temperature extremes, abrasion, and so much more.

Modern OEM harness assemblies serve critical functions in automotive engine management, infotainment systems, safety networks, and high-voltage battery connections in electric vehicles. Leading automotive wiring harness manufacturers ensure these systems meet stringent industry standards. Aerospace applications require AS50881-compliant harnesses with enhanced fire resistance and reduced weight for aircraft electrical systems. Industrial machinery depends on specialized harnesses rated for continuous operation in harsh manufacturing environments where original equipment reliability is essential.

| Material Type | Applications | Temperature Range | Key Benefits |

|---|---|---|---|

| Cross-linked Polyethylene | High-temp engines | -55 °C to 150 °C | Superior thermal stability |

| Teflon® Insulation | Aerospace/Military | -70 °C to 260 °C | Chemical resistance |

| Aluminum Conductors | Weight reduction | -40 °C to 125 °C | 40% weight savings |

| PVC Insulation | General automotive | -40 °C to 105 °C | Cost-effective protection |

OEM wiring harness manufacturing delivers superior reliability, performance, and compliance through precision engineering and certified quality processes that eliminate the need for aftermarket replacement parts.

test

OurPCB combines advanced manufacturing capabilities with comprehensive certifications to deliver superior OEM harness solutions for demanding applications across automotive, aerospace, and industrial sectors.

![]()

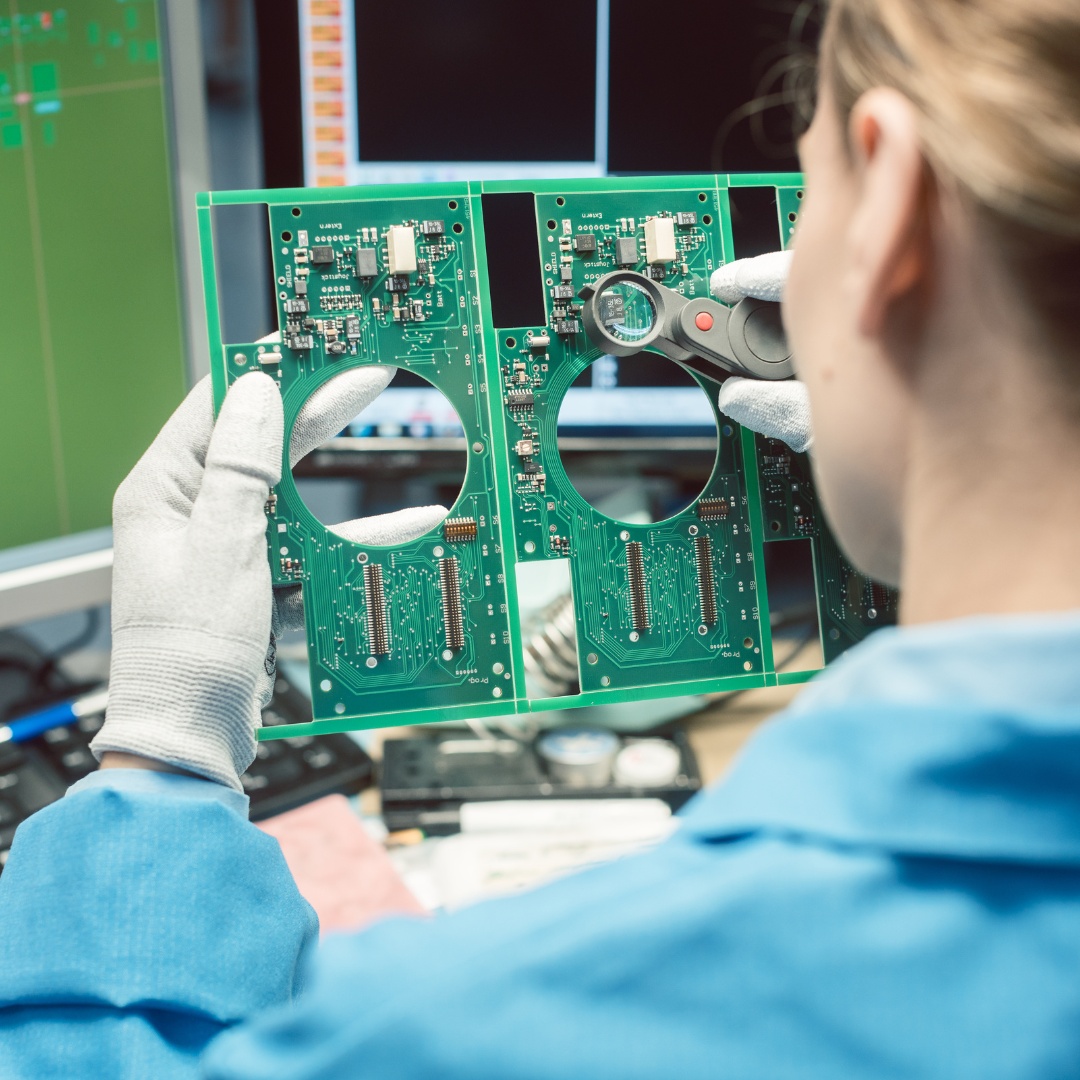

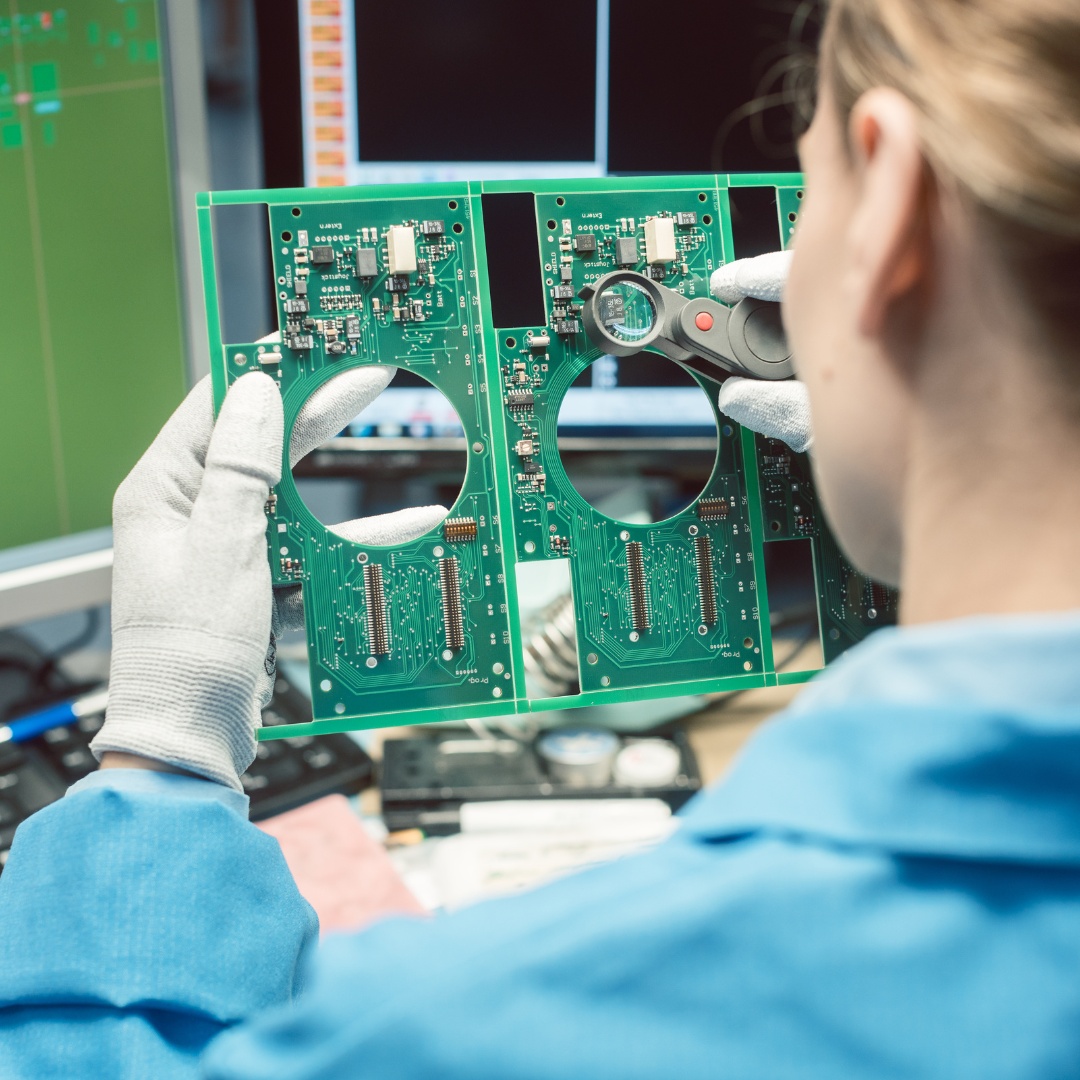

Our dual 10,000 m² PCB assembly houses in Shenzhen and Shijiazhuang are equipped with high-speed SMT assembly lines capable of placing fine-pitch parts with ±25 µm tolerance.

Each line includes temperature- and humidity-controlled environments, active anti-static systems, and vacuum transport for handling thin or flex printed circuits.

![]()

We are fully certified to ISO 9001, IATF 16949, and IPC-A-610 Class 2 & 3, supporting applications where fine-pitch PCB assembly must meet elevated acceptance criteria for solder joint geometry, lead coplanarity, and component body clearance.

Our QA workflows are built to handle fine-pitch PCBs requiring zero solder bridging and uniform joint fillets across dense arrays.

All assemblies involving ball pitch under 0.5 mm, QFN, or PoP packages undergo X-ray inspection, SPI, and AOI with 15 µm resolution optics.

We detect voids, open leads, insufficient solder, lifted terminations, and hidden shorts. This inspection process is a requirement for successful assembly when working with components that provide no visible solder access.

Every fine-pitch electronic assembly receives a DFM and DFA review focused on stencil coverage, aperture tuning, pcb design limitations, and routing near fine-pitch ICs.

We assist in verifying pad design, thermal pad exposure, and via escape planning, important for high I/O packages like BGA and chip scale layouts where misalignment or solder blockage can compromise yield.

We offer full assembly component sourcing through partners like Digi-Key, Mouser, and WPG, including traceable lots for hard-to-find or moisture-sensitive electronic components.

Components are stored under MSL-compliant conditions, with drying cabinets and vacuum packaging for all incoming fine-pitch parts.

Technical standards and certifications govern every aspect of OEM wiring harness manufacturing from design through final test validation. These industry requirements ensure that harnesses are manufactured to meet the demanding performance, safety, and reliability standards required for automotive, aerospace, and industrial applications.

IATF 16949 automotive quality management certification ensures consistent manufacturing processes with full traceability from raw materials through final assembly and test procedures. This standard mandates statistical process control, continuous improvement protocols, and comprehensive documentation systems that meet automotive industry audit requirements. Our certified processes address the demanding requirements of modern vehicles where electrical system failures can impact safety and performance.

IPC/WHMA-A-620 Class 3 certification establishes the highest reliability standards for wire harness assembly, particularly critical for aerospace and military applications where failure is not acceptable. AS50881 Enhanced Electrical Wiring Interconnection Systems (EWIS) standards govern aerospace applications, specifying fire-resistant materials, reduced weight requirements, and enhanced durability under extreme environmental conditions with complete socket and plug reliability.

ISO 9001:2015 quality management certification provides the foundation for consistent manufacturing excellence across all product lines. RoHS compliance ensures environmental responsibility through elimination of hazardous substances, while UL and CSA certifications validate safety performance for North American market applications including car or truck installations.

OurPCB offers advanced manufacturing services that distinguish our OEM wire solutions from standard assembly providers through specialized techniques and custom engineering approaches. Wire marking and identification systems provide clear component labeling for maintenance and troubleshooting applications. Custom covering options include split-loom tubing, braided sleeving, tape wrapping, and heat-shrink protection tailored to specific environmental requirements.

Our engineering team develops custom fixtures and tooling for complex harness configurations that require precise routing and connector positioning for optimal vehicle installation. Splicing services accommodate field modifications and repair applications while maintaining original electrical specifications. CAN bus integration expertise ensure optimal data transmission performance with minimal wire count requirements for modern wiring systems.

OurPCB operates advanced manufacturing equipment configured for precision OEM cable and wire harness production with complete quality control throughout the process. Automated wire cutting and stripping systems maintain ±0.2 mm dimensional tolerance, while pick-and-place automation incorporates vision verification for accurate component placement. Temperature-controlled soldering stations ensure consistent joint quality, and automated testing stations perform comprehensive electrical validation including continuity, insulation resistance, and HiPot testing protocols.

Environmental testing capabilities include thermal chambers for temperature cycling validation, vibration tables for frequency response testing, and IP rating validation chambers for dust and water ingress testing. Quality documentation systems provide complete traceability with statistical process control monitoring that ensures consistent manufacturing performance across all production runs.

OurPCB delivers the technical expertise, certified quality processes, and advanced manufacturing capabilities required for mission-critical OEM electrical applications. Our comprehensive certifications and smart harness technologies provide the reliability and innovation your projects demand without requiring aftermarket parts or replacement components.

Contact our engineering team today to discuss your OEM wire harness requirements and discover how our turnkey manufacturing solutions can streamline your production while delivering superior quality and reliability.

Custom Wire/Cable Service:

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Our manufacturing capabilities support voltage ratings from 12V traditional automotive systems up to 800V high-voltage electric vehicle applications, with current capacity ranging from 0.5A for signal circuits to 300A for high-power battery interconnections. We use appropriate wire gauges, insulation materials, and connector specifications to ensure safe operation across this complete range, with proper derating factors applied for temperature and environmental conditions.

We maintain IATF 16949 automotive certification and IPC/WHMA-A-620 Class 3 certification through continuous training, regular audits, and strict adherence to documented procedures that govern every aspect of manufacturing from incoming inspection through final testing. Our quality management system includes statistical process control, corrective action protocols, and comprehensive documentation that provides full traceability and meets automotive industry audit requirements.

Our unique capabilities include smart harness technology with embedded sensors for real-time condition monitoring, lightweight solutions using aluminum conductors that reduce weight by 40%, and multi-material construction integrating copper, aluminum, and fiber optic technologies. We also provide wire marking systems, custom covering options, splicing services, chassis mounting solutions, and blueprint-based reproduction wiring harnesses that competitors typically don’t offer as integrated services.

Request a quote and get a custom testing plan tailored to your design, BOM, and inspection needs. We provide PCB testing services with full traceability, calibrated measurement systems, and certified workflows for Class II and Class III assemblies.

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree