Dash Wiring Harness Manufacturer

Think of your vehicle’s dashboard as a body — all those gauges, displays, and controls need a nervous system to function properly. That’s exactly what our custom dash wiring harnesses provide. At OurPCB, we don’t just make wire bundles — we craft the critical connections that bring your entire dashboard to life.

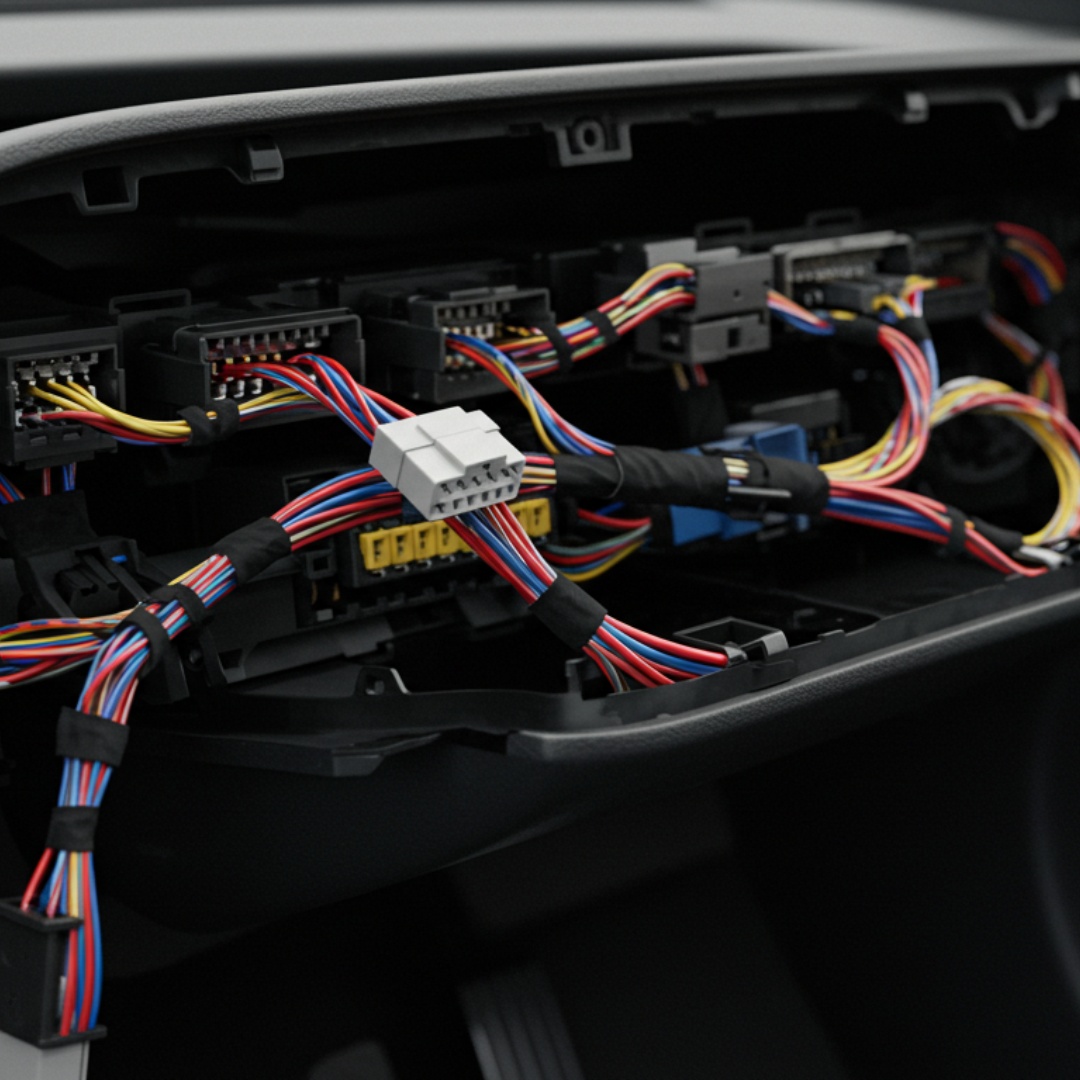

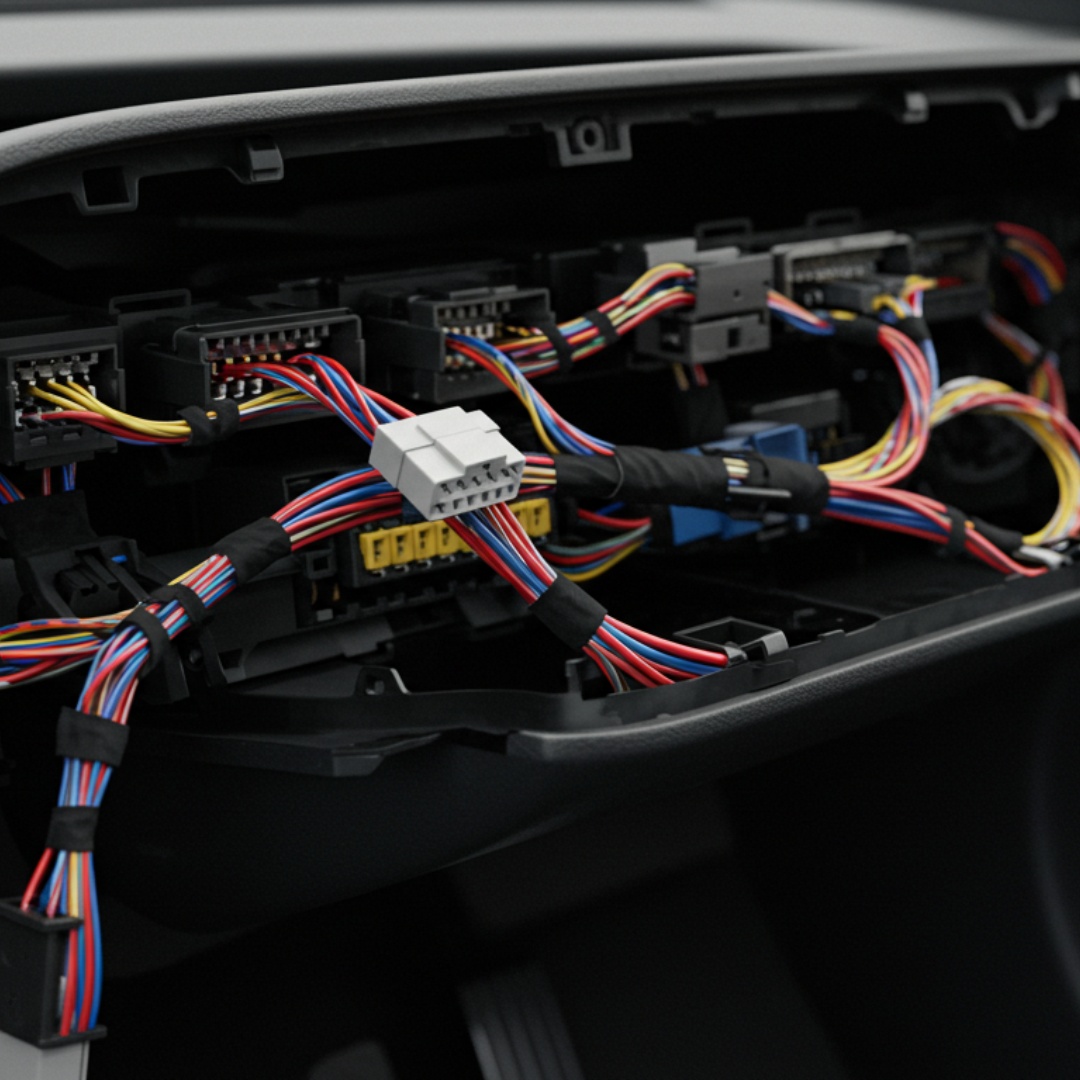

Our premium dash harnesses ensure everything from your basic warning lights to that fancy infotainment system gets reliable power and clear signals exactly when needed. Modern vehicles have gotten ridiculously complex, with electronics stuffed into every available space. A properly designed dash harness is absolutely essential for performance.

Our team combines old-school attention to detail with cutting-edge engineering to deliver dash harnesses that actually exceed what you’d expect. When that dashboard lights up perfectly every time you turn the key, that’s the difference quality wiring makes.

What is a Dash Wiring Harness?

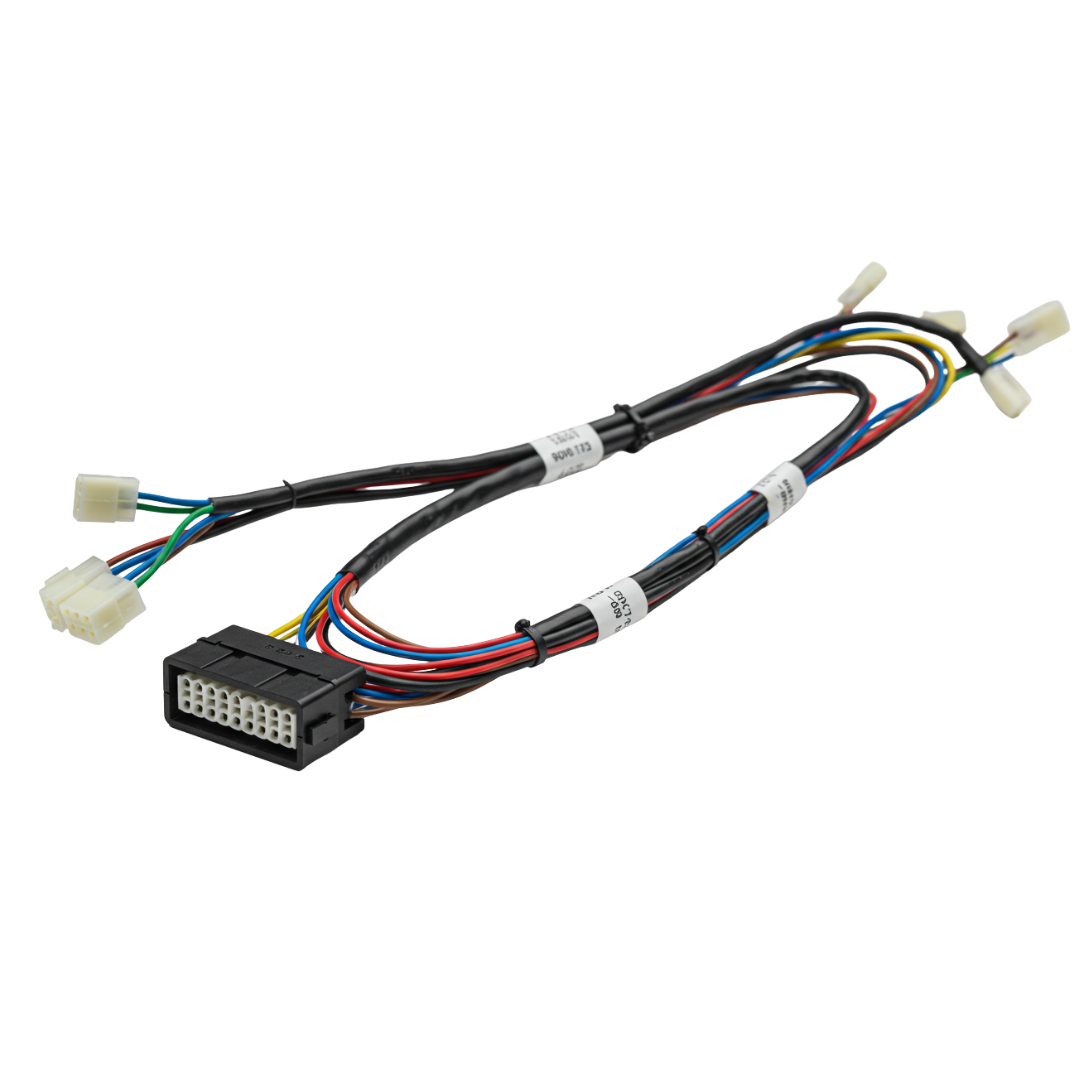

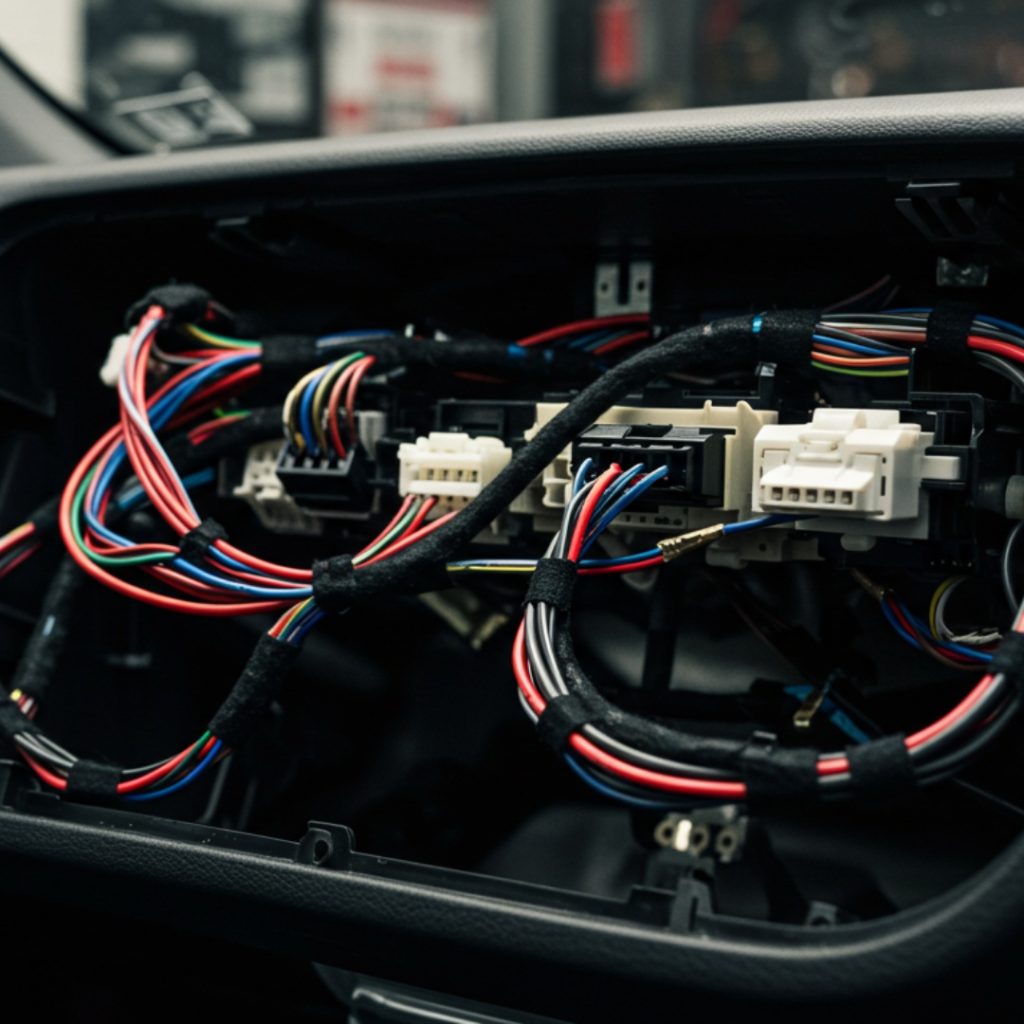

Think of a dash wiring harness as the central nervous system for your vehicle’s dashboard. It’s a carefully engineered collection of wires, connectors, terminals, and protective elements that bring your entire dashboard to life. Unlike basic wire setups you might find elsewhere, dashboard harnesses have to deal with serious challenges.

These custom-designed wire assemblies act like highways, directing power and data to everything from your basic instrument gauges to that fancy touchscreen infotainment system. They create an organized electrical network that makes installation straightforward and maintenance actually possible when problems arise.

A well-built dash harness cuts down assembly time during manufacturing and makes your entire vehicle more reliable. When you don’t have to worry about your dash lights randomly flickering or your radio cutting out, that’s the difference quality wiring makes.

What are the Benefits of Custom Dash Wiring Harnesses?

The benefits of custom dash wiring harnesses are their enhanced dashboard reliability, compliance with automotive standards, and a more reliable dashboard. Our precision-engineered dash side harness solutions deliver multiple advantages that enhance vehicle performance, safety, and maintenance efficiency.

- Each harness undergoes rigorous electrical testing to ensure consistent performance in all operating conditions.

- Our precision manufacturing eliminates common failure points like loose connections that cause dashboard malfunctions.

- Custom-designed harnesses include clear labelling for straightforward dashboard integration.

- Modular connector design allows for easier troubleshooting without requiring complete harness removal.

- Our engineering team creates compact, efficiently routed dashboard harness designs that maximize available space.

- We offer lightweight wire options that reduce vehicle weight while maintaining performance standards.

- All dash wiring harnesses meet ISO 6722, IATF 16949, and IPC/WHMA-A-620 standards.

- Our quality management system ensures complete traceability for safety-critical applications.

Superior Field Reliability

- IP67-rated connectors resist complete dust ingress and withstand water immersion up to 1 m for 30 minutes.

- Marine-grade insulation materials provide chemical resistance against fertilizers, pesticides, and fuel exposure.

Extended Equipment Lifespan

- Temperature-resistant components function reliably from -40 °C to 105 °C, preventing heat damage in engine compartments.

- Reinforced strain relief and secure terminal connections prevent failures from constant diesel engine vibration.

Simplified Troubleshooting

- Color-coded wiring with clear detail reduces diagnostic time by up to 60%.

- Comprehensive documentation includes wiring diagram specifications specific to your tractor model.

Customization Options

- Exact-fit design ensures perfect compatibility with your specific Farmall or Cub Cadet restoration.

- Additional capacity options accommodate future implements or aftermarket electrical accessories you may add later.

Why Choose OurPCB for Dash Wiring Harness Manufacturing

OurPCB combines automotive expertise, quality manufacturing processes, and responsive customer service to deliver superior dash harness solutions for your specific needs.

- Our engineering team specializes in dashboard electrical systems for modern vehicles.

- We’ve produced custom dash harness assemblies for various vehicle types, from passenger cars to commercial trucks.

- We work directly from your specifications or collaborate to develop optimized solutions.

- Our design process includes 3D modeling to ensure perfect fit within complex dashboard configurations.

- Every dash wiring harness undergoes multi-stage inspection and electrical testing.

- Our facility maintains IATF 16949 certification, ensuring adherence to strict automotive standards.

- We accommodate both prototype development and high-volume production runs.

- Our manufacturing facility can scale to meet your timeline without compromising quality.

Our Custom Wiring Harness Features

ROHS-Compliant Materials

Safe, approved, and eco-friendly materials

Custom Materials to Suit the Environment

Customized materials for abrasion-, oil-, heat-, or water-resistance

Your Choice of Coverings

Choose from PVC, nylon, XLPE, rubber, braided sleeving, heat shrink tubing, and more!

Variable Wire Options

We offer various wire thicknesses and lengths to meet your exact needs

Across Many Industries

We serve almost every industry you can think of! Contact us today.

Millions of business and innovators use OurPCB

Our Custom Wiring Harness Process

Fast, free, and includes a production timeline

Our engineers create your design schematic and select the right materials

We’ll manufacture a high-quality prototype within 7 days

The prototype goes through various functionality and stress tests

Cutting, stripping, and assembly to the highest standard

After final testing and packaging, your custom wiring harnesses are delivered

Technical Capabilities

Our manufacturing capabilities include wire gauges from 0.5 to 1.5 AWG with various insulation options including PVC, XLPE, and Teflon. Our facility features advanced wire processing equipment for precise cutting, stripping, and crimping operations.

We maintain tight tolerances on all terminations and use automated testing equipment to verify electrical performance. Our dash wiring harness products accommodate standard automotive voltage ratings up to 60V, with specialized options for EV dashboard applications requiring higher voltage handling.

Capabilities & Services

- Wire Gauge: 40AWG-120mm²

- Production Capacity: 10,000 pieces/hour

- Wire Cutting Service

- Wire Stripping Service

- Wire Marking Service

- Label Types

- Wire Ends Treatment

Custom Wire/Cable Service:

- Wire/Cable types

- Wire gauge

- Wire/Cable length

- Insulation/Jacket color

- Core numbers etc.

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

- Electrical cable assembly

- Coaxial cable assembly

- Multi-core cable assembly

- Connector to board cable assembly

- Automobile communication cable assembly

- Power transmission cable assembly

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Dash Wiring Harness Manufacturer FAQs

What materials are used in your dash wiring harnesses?

Our harnesses use automotive-grade copper or aluminum conductors with high-performance insulation materials like PVC, XLPE, or Teflon. We select connectors that offer excellent conductivity and corrosion resistance for dashboard environments.

How do you ensure the reliability of dash wiring harnesses?

We implement a multi-stage quality process including material inspection, in-process checks, and comprehensive electrical testing. Every harness undergoes continuity testing, insulation resistance verification, and visual inspection.

Can you create custom dash wiring harnesses for specific vehicle models?

Yes, we specialize in custom solutions tailored to specific vehicle makes and models. Our design team works with your specifications to create harnesses that perfectly match your dashboard architecture and electrical systems.