Who are the Top 6 Data Cable Manufacturers in China?

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

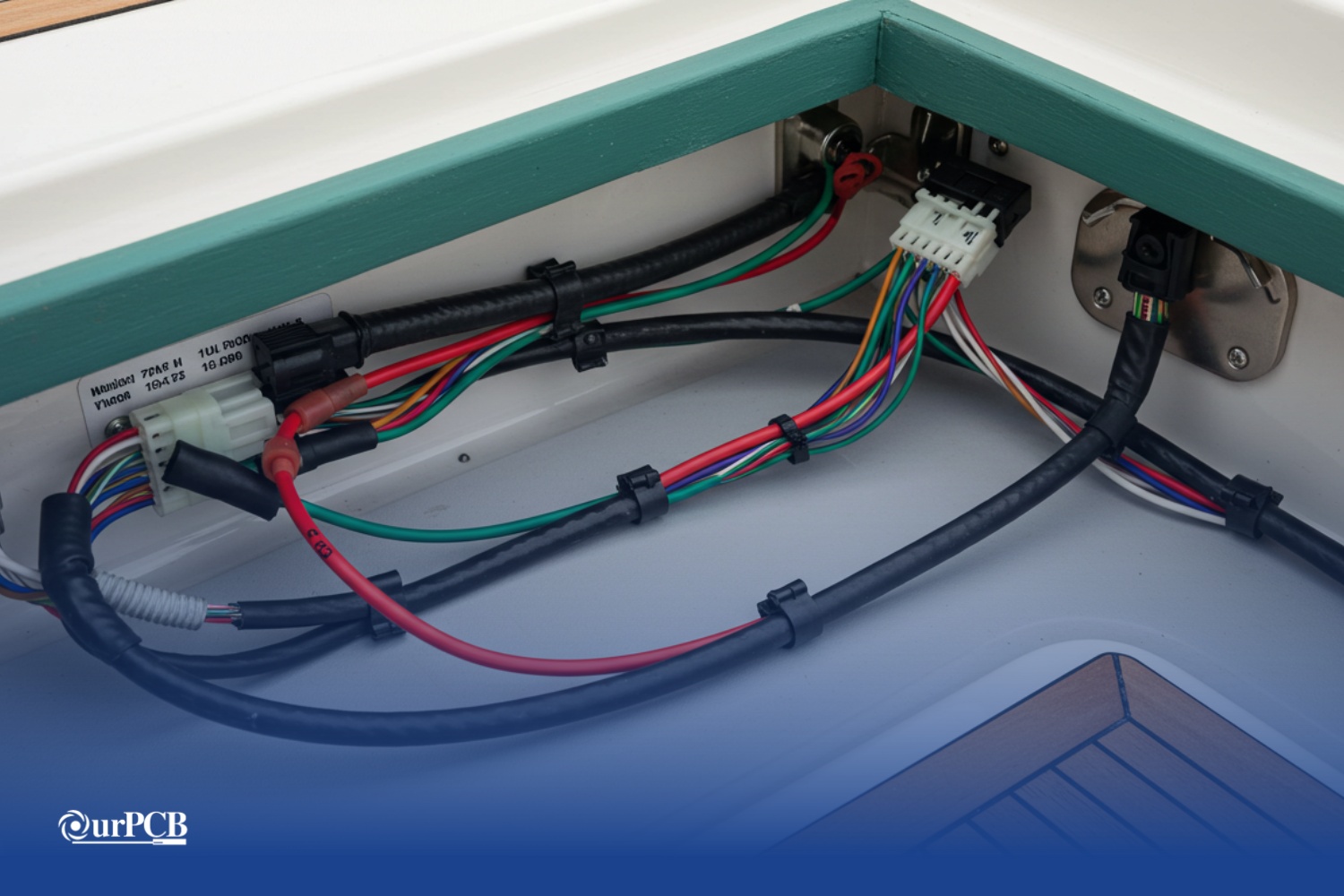

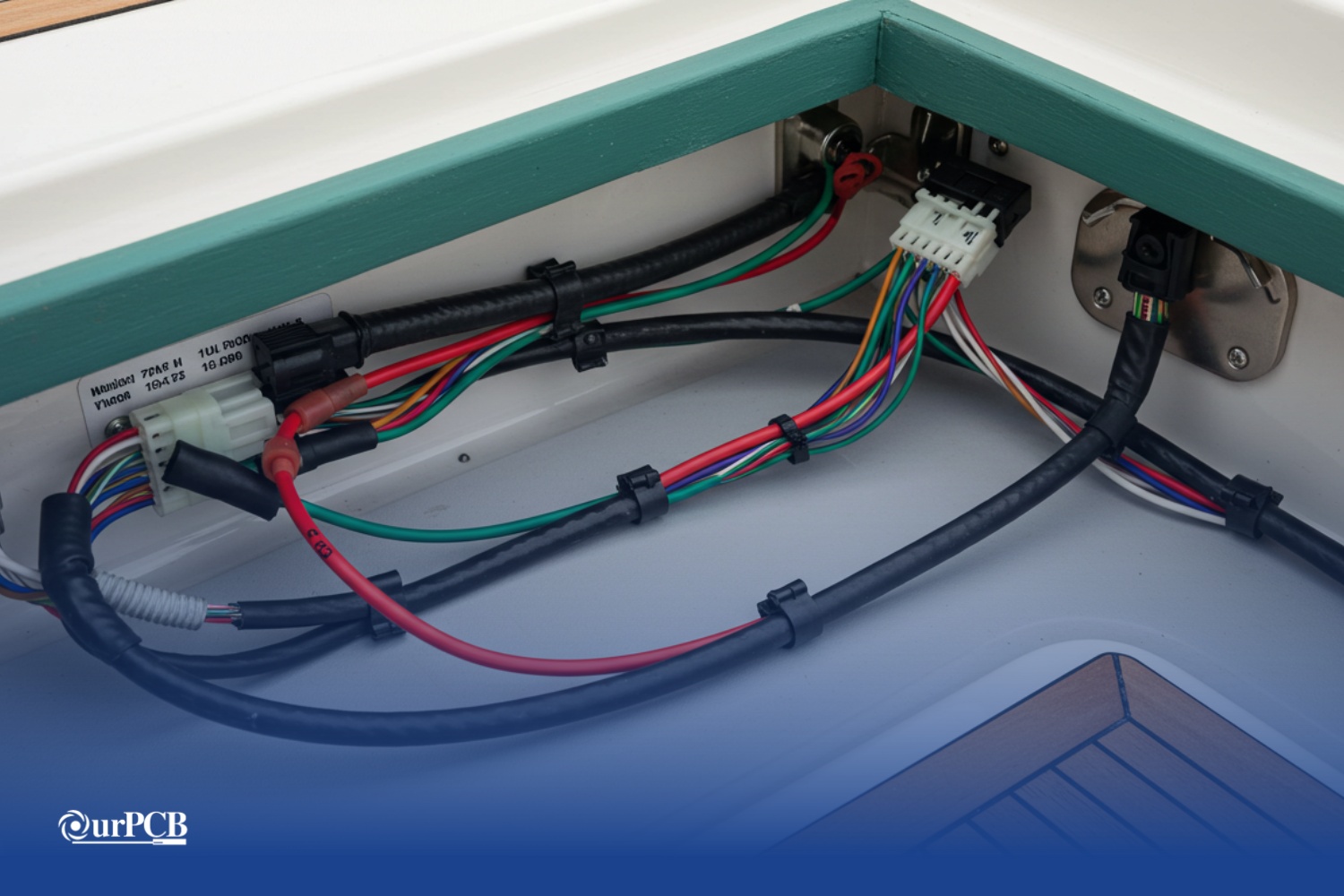

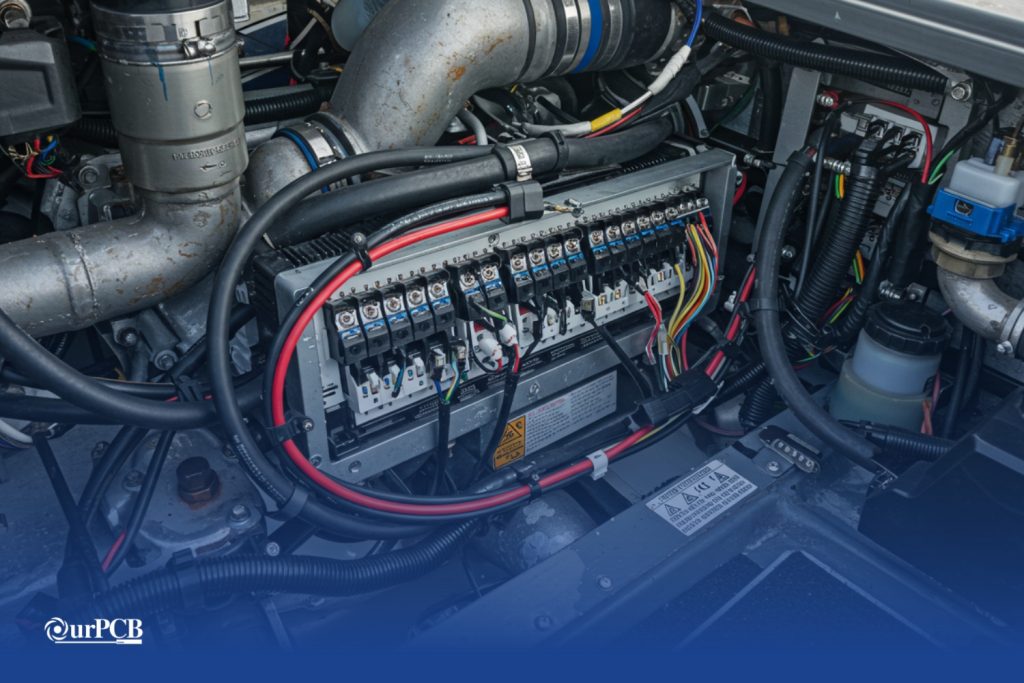

Among specialized wiring harness suppliers, OurPCB is a premier marine wire harness manufacturer. OurPCB makes full assemblies that work extraordinarily well with marine electronics because we meet ABYC standards and CFR Title 33 regulations for saltwater spaces. Marine electrical failures cause major safety issues and really expensive repairs.

On the other side of things, standard automotive harnesses give up pretty quickly from saltwater corrosion and vibration. We keep assembly standards with resilient materials like tinned copper conductors to stop electrical failures from happening.

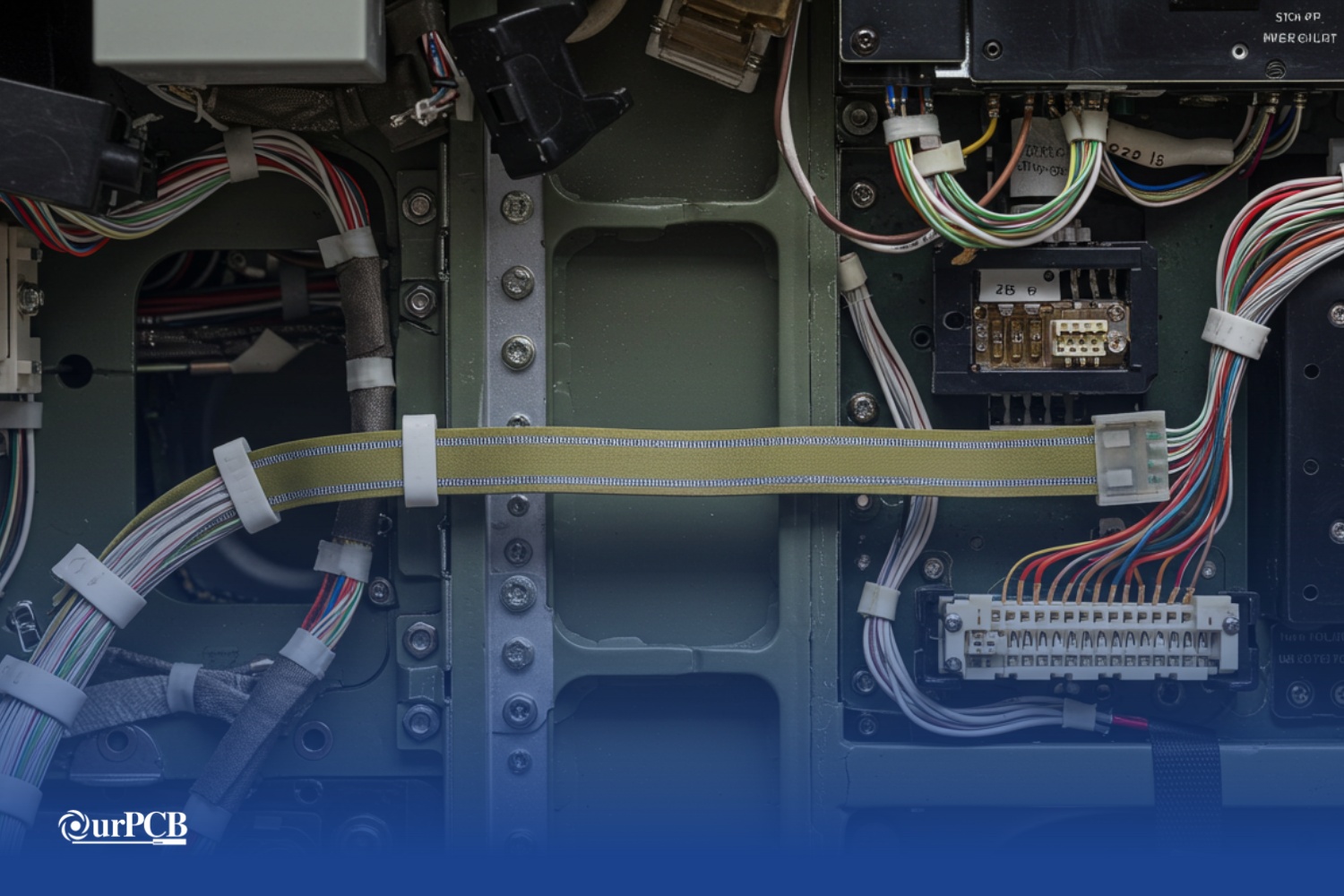

Marine wire harness manufacturing is the production of wire harnesses that are made to handle saltwater, vibration, and intense temperature changes around boats. They package a bunch of different electrical wires with protective materials. These can be corrugated tubes, braided sleeves, and more. A wiring harness for boat applications sends electrical signals and power throughout vessel systems. It does this while protecting connections from corrosion, moisture ingress, and stress.

Marine wire harness designs need a minimum of 16 AWG tinned copper conductors with stranded construction for flexibility and corrosion resistance. All wires must meet a 50V DC minimum rating with a standard 600V voltage rating and 105 °C insulation for continuous operation. Engine compartment applications require 75 °C minimum temperature rating with oil resistance and flame-retardant properties meeting marine fire safety specifications.

Professional wire harness manufacturing follows IPC-620WHMA assembly standards, ensuring consistent quality and reliability. Assemblies must comply with ABYC standards and mandatory CFR Title 33 regulations, including proper wire identification through color coding and voltage drop limitations of 3% for essential circuits and 10% for general purpose applications.

Marine wire harness manufacturing delivers critical advantages for vessel electrical systems by providing superior environmental protection, regulatory compliance, installation efficiency, and long-term reliability.

OurPCB combines advanced PCB manufacturing expertise with specialized marine wire harness capability delivering fully integrated electrical solutions. Our ISO 9001-certified facility maintains stringent quality control processes and employs marine-specific testing equipment, including hydrostatic chambers and megger insulation testers.

| Specification | Standard Requirement | Engine Compartment |

|---|---|---|

| Wire Gauge | Minimum 16 AWG | Minimum 16 AWG |

| Voltage Rating | 600V standard | 600V standard |

| Temperature Rating | 105 °C continuous | 75 °C minimum |

| Insulation Type | UV-resistant thermoplastic | Oil-resistant compound |

| Conductor Type | Tinned copper stranded | Tinned copper stranded |

| Voltage Drop | 10% general / 3% essential | 3% essential circuits |

High-quality wire harnesses utilize specialized materials including corrugated tubes for abrasion protection, braided sleeves for electromagnetic shielding, and silica sleeves for high-temperature applications. Twisted pair construction maintains signal integrity for communication systems while duplex and triplex cables with outer jackets provide additional protection.

Advanced manufacturing techniques include molding processes for custom connector solutions and multi-conductor cable assemblies for complex marine electrical systems.

Each final product receives comprehensive testing including electrical continuity verification, insulation resistance measurement, and environmental exposure validation. Documentation packages include assembly drawings, parts lists, wiring diagrams, test certificates, and certificates of conformance meeting IPC-620WHMA professional standards for top-quality marine applications.

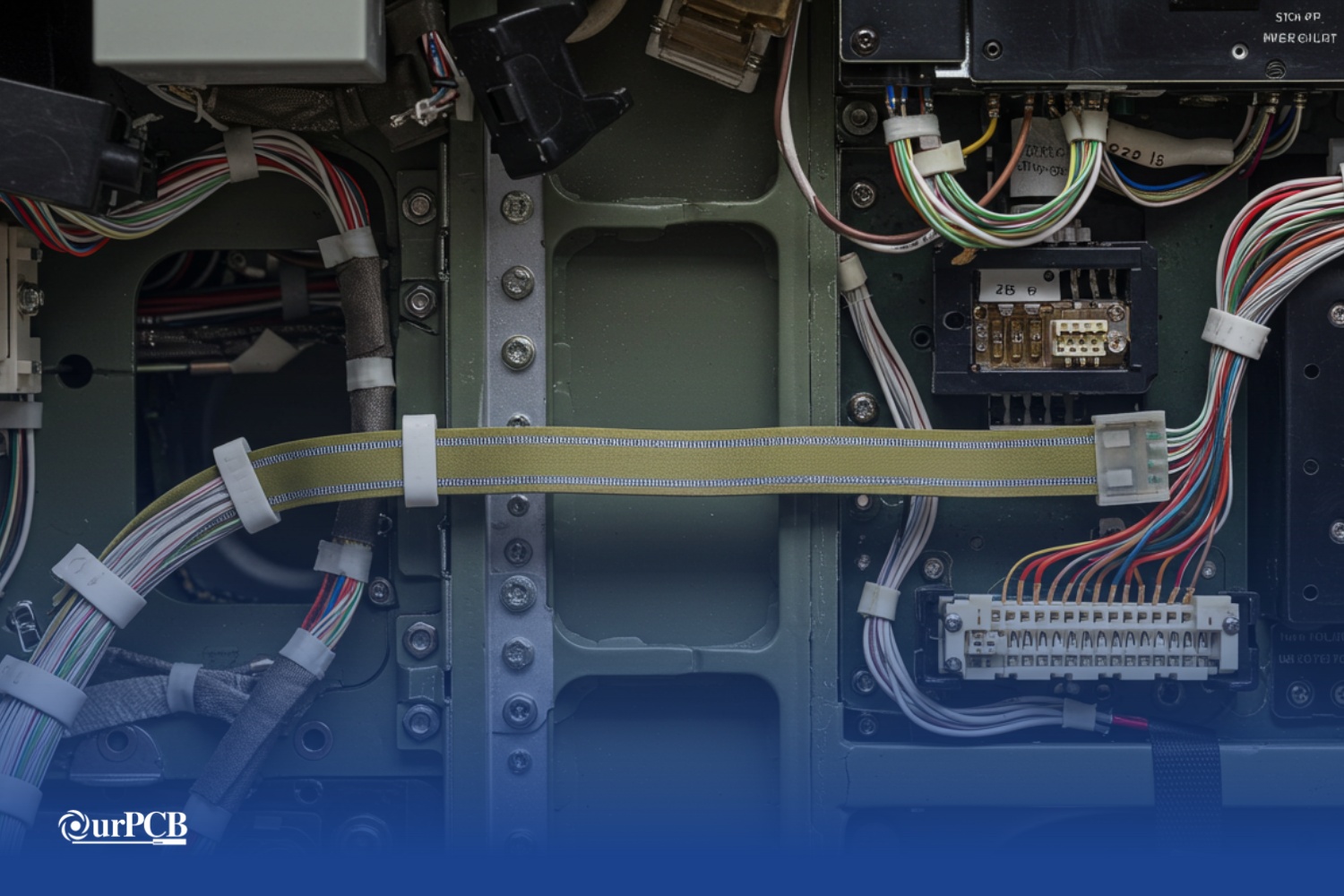

OurPCB specializes in marine wire harness solutions for defense industry applications including naval vessels, submarines, and military marine equipment. Submarine applications require extreme pressure resistance with specialized materials and super-absorbent polymers for pressure control in deep-water environments. Our harnesses meet stringent military specifications for vibration resistance, electromagnetic compatibility, and performance in combat conditions.

Marine electronics integration requires specialized knowledge of NMEA 2000 networks, CANbus protocols, and marine-specific signal requirements. Wire harness assembly accommodates differential signaling for GPS navigation systems, radar displays, and fish finder equipment while maintaining proper impedance control. Marine communication systems including VHF radios and satellite communication require shielded cables with proper grounding to prevent interference.

OurPCB’s marine wire harness manufacturing facility features specialized equipment including hydrostatic test chambers rated to 200 PSI, automated wire cutting and stripping systems with 0.1mm precision, and ultrasonic welding equipment for marine connector assembly. Our quality control laboratory maintains calibrated megger testers, salt spray chambers, and vibration test equipment meeting ASTM standards for marine applications serving various industries including defense, commercial, and recreational boating.

Custom Wire/Cable Service:

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

OurPCB delivers industry-leading marine wire harness manufacturing solutions combining specialized marine expertise with comprehensive PCB assembly capabilities. Our ABYC-compliant high-quality wire harnesses ensure your vessel meets all safety regulations while providing superior reliability in harsh marine environments with competitive pricing and exceptional customer service.

Get in touch with our marine electronics specialists today to discuss your custom wire harness requirements and receive a detailed quote for your marine project. We’re ready to deliver the precision-engineered electrical solutions your marine application demands.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Our marine wire harness solutions exceed ABYC standards by incorporating SAE automotive standards adapted for marine use, UL marine component certifications, and ISO 9001 quality management compliance. We follow IPC-620WHMA professional assembly standards and provide comprehensive documentation including hydrostatic test certificates and megger insulation verification meeting Coast Guard equipment approval requirements for OEM and aftermarket applications.

We manufacture custom marine connector solutions including molded cable assemblies, bulkhead penetrators, and underwater-rated connectors using specialized elastomers and marine-grade materials. Our custom connector capabilities include IP68 sealing, pressure ratings up to 100 PSI, and compatibility with NMEA 2000 networks, radar systems, and marine communication equipment requiring specialized interface solutions for boater applications.

Complex marine wire harness projects typically require 3-4 weeks including custom design, prototype development, and comprehensive testing phases with an additional 1-2 weeks for high volumes production runs. Rush orders can be accommodated in 10-14 days for critical marine applications, and we maintain expedited processes for emergency vessel repairs and seasonal marine industry requirements through our streamlined manufacturing process.

Request a quote and get a custom testing plan tailored to your design, BOM, and inspection needs. We provide PCB testing services with full traceability, calibrated measurement systems, and certified workflows for Class II and Class III assemblies.

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree