Who are the Top 6 Data Cable Manufacturers in China?

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

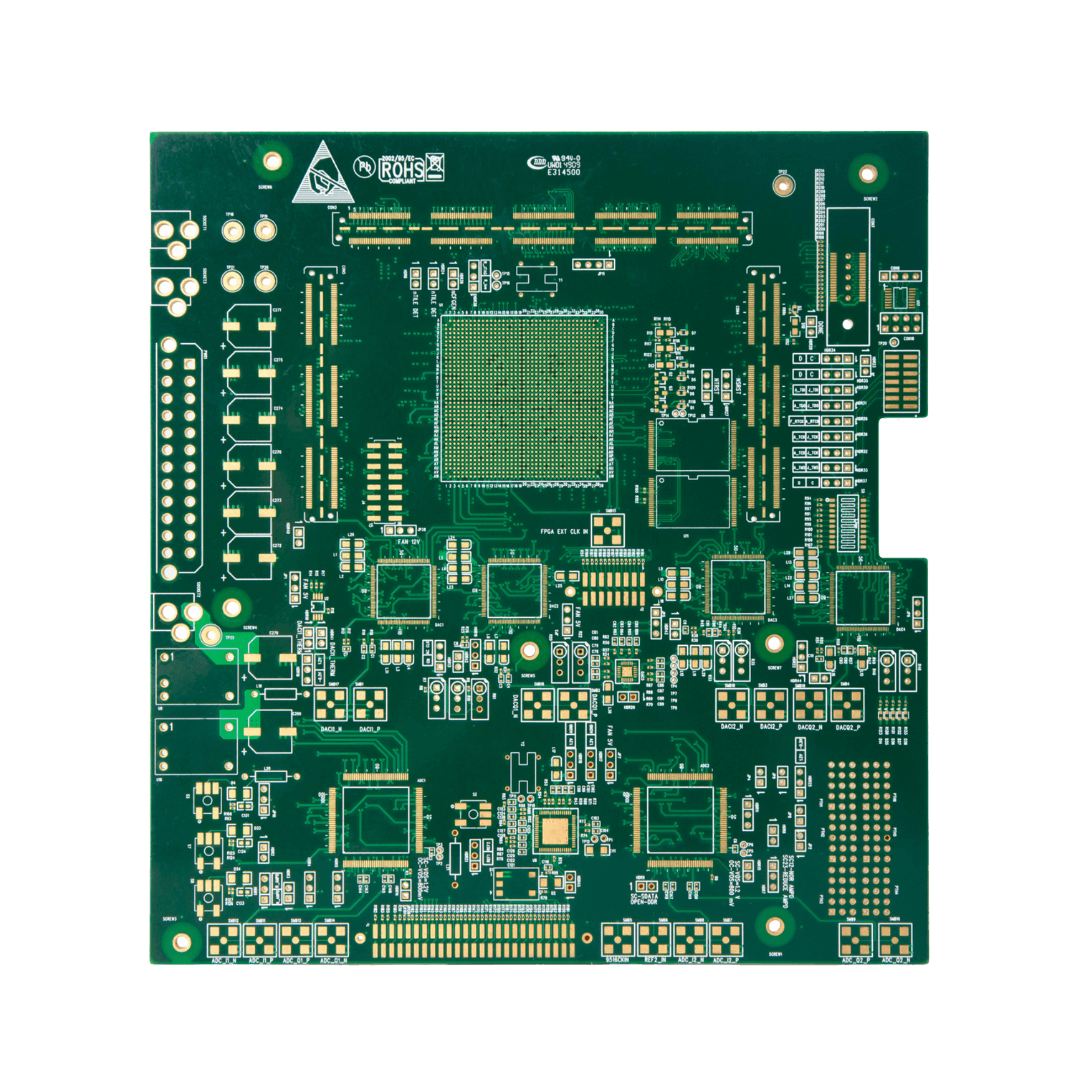

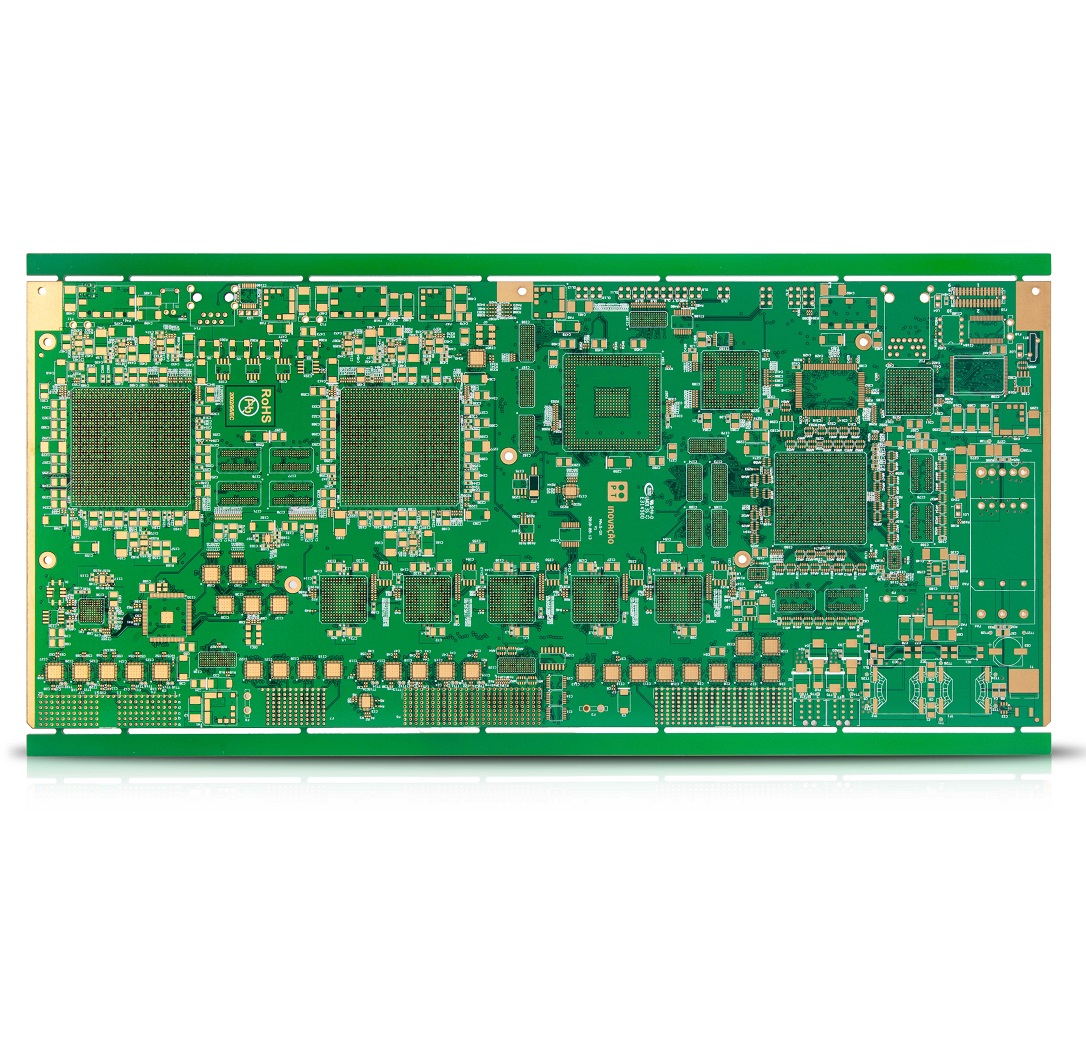

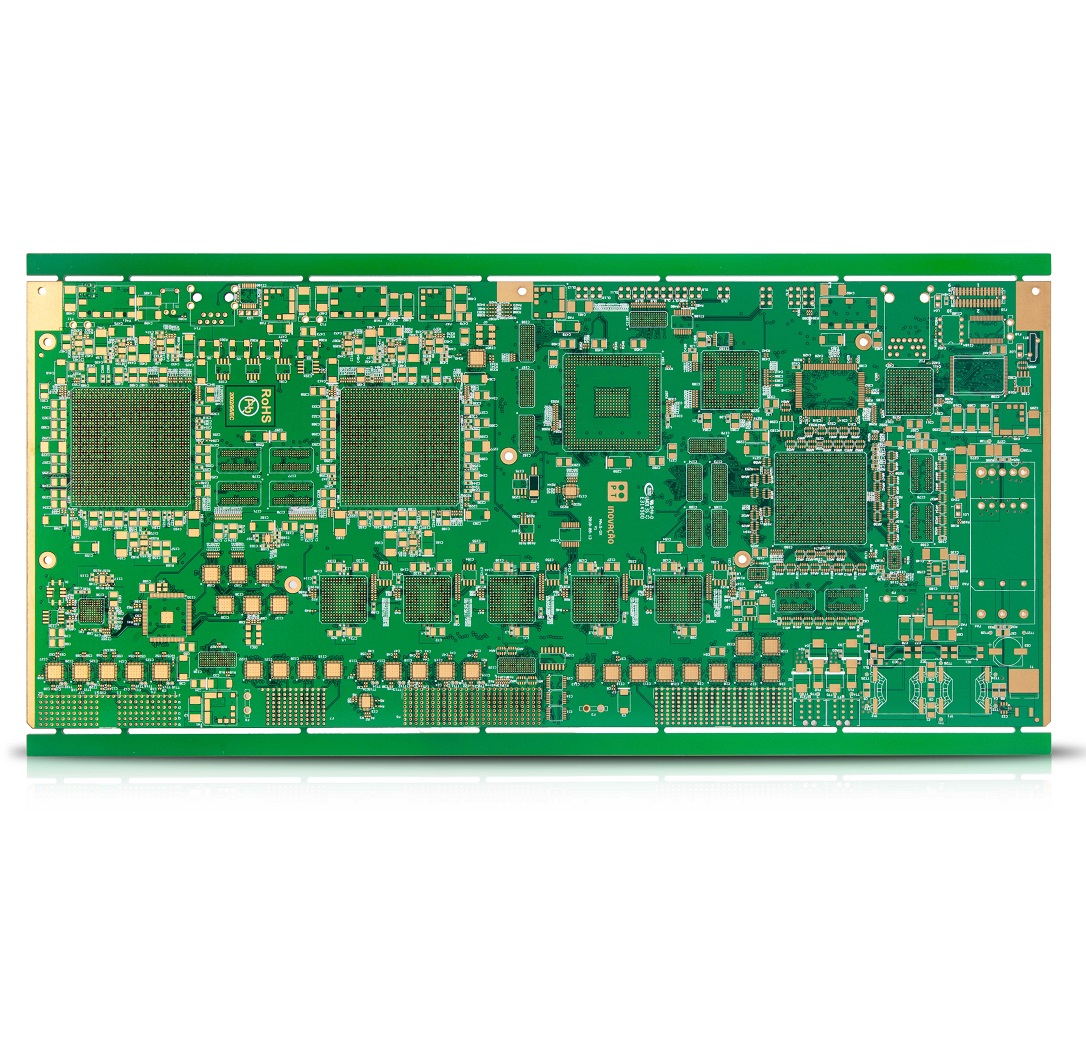

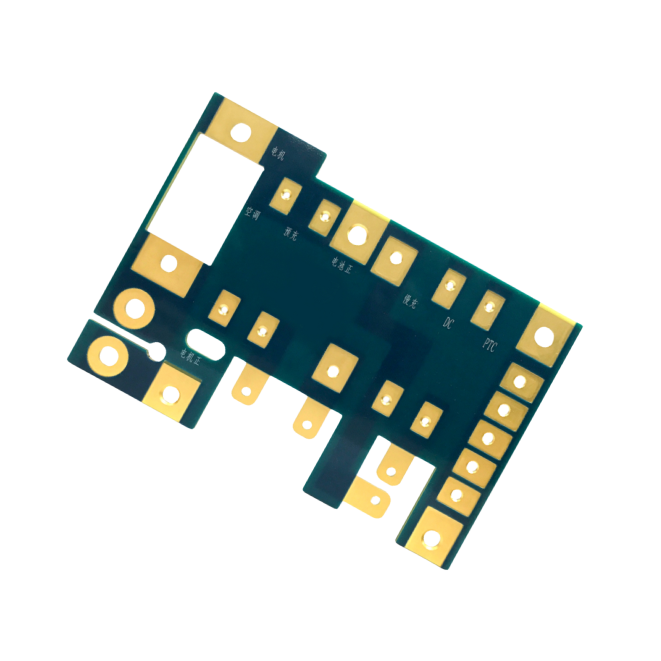

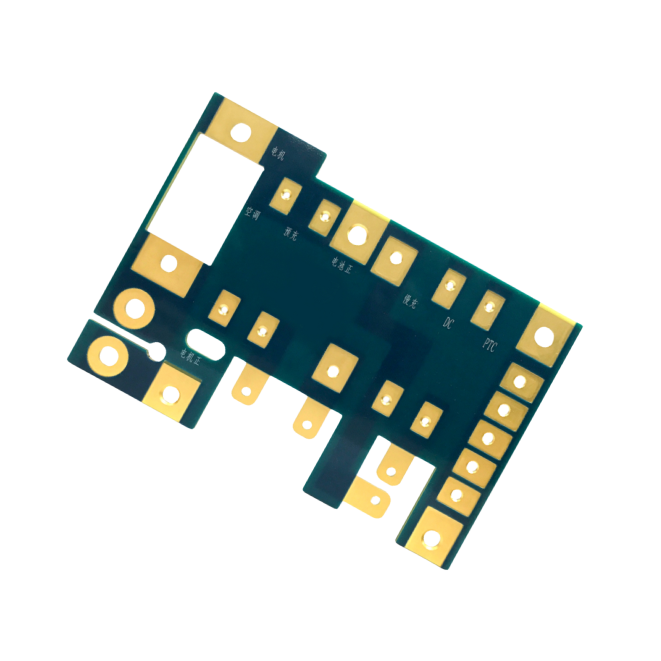

As a trusted 10-layer PCB manufacturer, we design and produce multilayer circuit boards for high-speed signal transmission and space-saving layouts. Some of our clients’ applications include aerospace systems, medical equipment, and advanced telecommunications, where performance and reliability are non-negotiable.

OurPCB manufactures high-performance 10-layer printed circuit boards with fast prototype turnaround, precise specifications, tighter tolerances, and reliable performance for RF and high-frequency applications. Our specialized manufacturing processes ensure optimal results for your most complex electronic designs.

OurPCB manufactures high-performance 10-layer printed circuit boards with precise specifications, tighter tolerances, and reliable performance. This enables us to cater to complex electronic designs such as RF and high-frequency applications. HDI PCB design and manufacturing provide optimized solutions for intricate layer stacking and advanced interconnects.

For a deeper understanding of PCB manufacturing and its various challenges, we offer a comprehensive guide to PCBs, which is ideal for those new to PCB design or looking to expand their knowledge.

High-Density Fabrication for these PCBs involves fine trace capabilities and advanced interconnect options, ensuring that your design not only meets but exceeds performance standards.

We combine advanced technical expertise in PCB fabrication with superior materials and comprehensive quality assurance. For demanding applications, our PCB assembly services include design assistance, advanced production, and thorough testing. Our team works closely with you, ensuring that your design specifications are met with precision.

For anyone looking to avoid common PCB issues like tombstoning or to better understand how schematic diagrams work, we can provide insights into the design and assembly processes.

OurPCB uses innovative PCB manufacturing and assembly techniques, including precise registration systems, advanced lamination processes, and multi-stage quality control to ensure consistent performance in all 10-layer PCB stack-ups.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Lead times for 10-layer PCBs depend on the processing area: 8 days for areas <1m², 14 days for 1m² to 3m², 20 days for 3m² to 30m², and 25 days for areas >30m².

For RF (radio frequency) and high-temperature applications in 10-layer PCBs, the most effective materials include Rogers high-frequency laminates (e.g., RO4003C, RO4350B), Teflon/PTFE-based substrates (e.g., Taconic, Arlon), high TG FR-4 (e.g., TG170 or higher), and polyimide.

Yes, we offer comprehensive prototyping services for 10-layer PCBs with expedited timelines and complete testing to validate your design before volume production.

Yes, we provide complete assembly services, including component sourcing, placement, various soldering techniques, and comprehensive testing for fully functional 10-layer PCBAs.

Our 10-layer PCBs comply with ISO 9001:2015, ISO 13485:2016, ISO 14001:2015, IATF 16949:2016, and IPC-A-610 Class 2 & 3 standards, ensuring consistent quality and reliability for demanding applications.

When designing a 10-layer PCB, it’s important to pay attention to controlled impedance and effective thermal management. Implementing ICT (In-Circuit Testing) during the production phase is one way to enhance PCB production and ensure that your board will meet all necessary requirements.

10-layer PCBs offer high performance but come with some drawbacks. They are more expensive to manufacture due to added materials, complex lamination, and tighter tolerances. Design changes are harder to implement once the layout is finalized. Repairs and rework are also difficult because of the dense internal layers. Lastly, lead times are longer compared to simpler boards, especially when custom stack-ups or advanced materials are used.

The primary distinction between PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) is that a PCB is just the bare board, whereas PCBA refers to the entire process where electronic components are mounted, soldered, and tested on the PCB.

For a more in-depth comparison, we’ve provided a detailed breakdown of PCBA vs PCB: Key Differences, so you can understand the nuances between them, especially when dealing with advanced applications like 10-layer designs.

Absolutely! 10-layer PCBs can be used in more complex applications, including 10-minute countdown timer circuits, where precise time-keeping and signal integrity are crucial. These designs often require careful layout and controlled impedance to ensure the circuit performs reliably.

Our advanced manufacturing capabilities allow us to create precise, functional designs for all your timing needs. For a deeper understanding of how such circuits are designed, feel free to explore our resources on circuit assembly and related design challenges.

OurPCB adheres to ISO certified circuit card assembly standards, ensuring that each board meets the highest levels of quality, reliability, and consistency. Whether you’re looking for high-frequency applications or custom-built designs, our certifications like ISO 9001 and ISO 13485 reflect our commitment to excellence in PCB manufacturing.

For those who want to understand how industry standards affect the manufacturing process, we invite you to dive into Exploring IPC Standards for PCBs, where we break down the key guidelines that govern PCB production and assembly.

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree