When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in ranks as the Silicon Valley of data cable manufacturing. Don’t believe us? A significant share of global demand is produced and consumed by China.

An abundance of data cable manufacturers means that picking the right one can be tricky. Luckily, our team at OurPCB has written this guide to help you along the path of choosing the cardinal data cable manufacturer. We also inform you about what data cables are, why they matter, and explain why they choose to source from China.

Contents

- Key Takeaways

- What is the Difference Between Data Cables & Cable Assemblies?

- What are the Elements & Materials in a Data Cable?

- The Top 6 Data Cable Manufacturers in China

- 1. OurPCB – Integrated PCB & Wire Harness Solutions

- 2. ECOCABLES

- 3. Romtronic

- 4. WIRINGO

- 5. Kaifa Connector

- 6. Yingkou Abe Harness Co., Ltd

- What are the Key Standards & Certifications You Should Check?

- How do Chinese Manufacturers Control Quality?

- Process Discipline & Testing

- Detailed Engineering Documentation

- Controlled Production Steps

- In-Process Inspections

- 100% Electrical Testing

- Final QA & Traceability

- Reviewing a Manufacturer’s QC Flow

- FAQs on Cable Manufacturers in China

- How long do data cable orders from China usually take?

- What is the typical minimum order quantity (MOQ) for data cables?

Key Takeaways

- Chinese data cable manufacturers offer much necessary support for all stages of the manufacturing process — design, prototyping, testing, and clear documentation all the way through.

- Don’t let price be your only evaluation criterion for a Chinese data cable manufacturer — relevant certifications like ISO 9001, IATF 16949 or ISO 13485, UL/CSA, and IPC/WHMA-A-620 are more important.

- OurPCB combines PCB assembly, data cable assemblies, and box-build, and can simplify your supply chain and reduce integration and signal integrity issues.

What Is a Data Cable Anyway?

A data cable is basically a specially designed cable that sends and receives digital signals between devices like computers. It’s become a core communication lifeline for many products that enables the transfer of data, so different components can “speak” to each other — neat, right?

What is the Difference Between Data Cables & Cable Assemblies?

A data cable, just by itself, is the core medium that carries signals. These are usually made up of one or more conductors, shielding, insulation, and an outer jacket.

A cable assembly, on the other hand, is a completely finished, ready-to-use product that incorporates one or more data cables with connectors, strain relief, labeling, and sometimes additional protection such as overmolding or braided sleeving.

Why Do So Many Brands Use Data Cable Manufacturers in China?

Brands pick Chinese data cable manufacturers because they have built one of the most complete electrical and electronics supply chains in the world. Sourcing from China means way more cost advantages thanks to its competitive labor and low overhead costs. You also have your pick of dense local supplier networks for conductors, insulation materials, connectors, and packaging.

China also benefits from highly mature manufacturing ecosystems. A significant portion of data cable factories sit close to connector makers, PCB assemblers, and injection molders, which makes logistics between them incredibly easy.

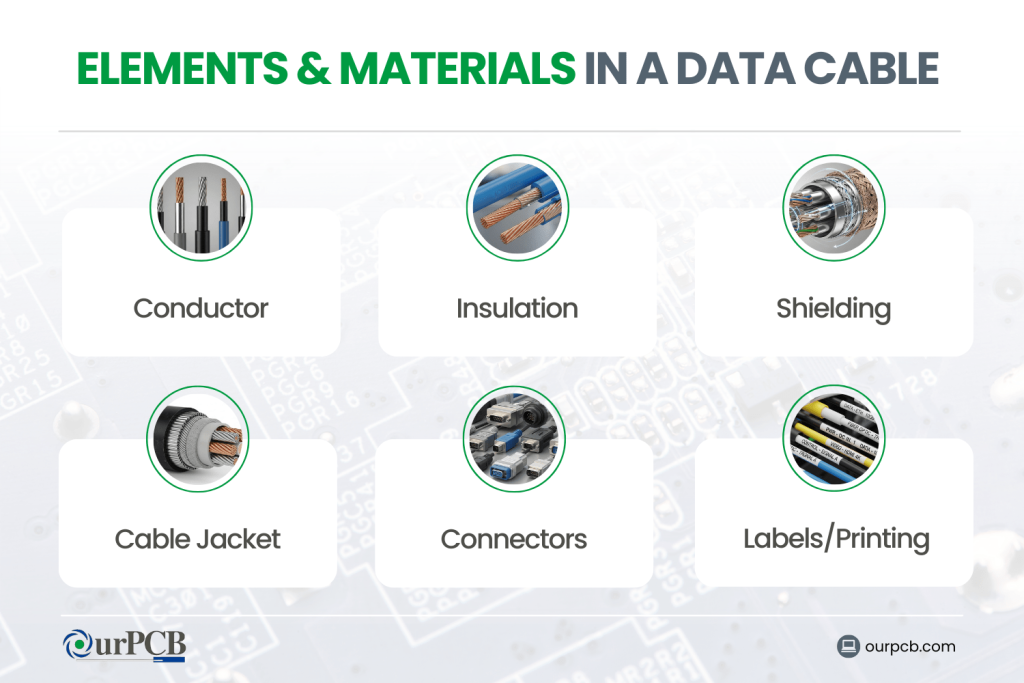

What are the Elements & Materials in a Data Cable?

The main elements of a data cable are the conductor, insulation, shielding, cable jacket, etc. High-quality data cables use materials matched to your environment, data rate, and safety/EMC requirements. We’ve created the following table to help you understand a data cable’s main components, their function, and common material options:

| Component | Function | Typical Material Options |

|---|---|---|

| Conductor | Carries data signals | Bare copper, tinned copper, copper alloys, CCA, various AWG sizes |

| Insulation | Separates conductors, controls impedance | PVC, PE, PP, XLPE, FEP, PTFE, halogen-free compounds |

| Shielding | Reduces EMI/RFI and crosstalk | Aluminum foil, braided copper, foil + braid combinations |

| Cable Jacket | Overall mechanical & environmental protection | PVC, PUR, TPU, LSZH |

| Connectors | Plug-and-play interface to devices/modules | USB, HDMI, DisplayPort, RJ45, custom I/O; gold-plated contacts; PA/PBT housings; metal shells |

| Labels/Printing | Identification & traceability | Heat-shrink markers, printed sleeves, jacket printing, wrap labels |

Special Offer: Get $100 off your order!

Email [email protected] to get started!

The Top 6 Data Cable Manufacturers in China

Below are examples of established wire harness manufacturers in China. Keep in mind that this is not an objective ranking, but merely a starting point for your supplier shortlist. You should contact and enquire quotes from each of the following manufacturers in order to ensure the highest quality results.

1. OurPCB – Integrated PCB & Wire Harness Solutions

OurPCB combines PCB manufacturing and assembly with custom data cable and cable assembly production, giving customers a true one-stop solution for complete electronic systems.

Location & footprint

- Manufacturing bases in Shijiazhuang and Shenzhen

- Data cable/cable assembly facility integrated with PCB/PCBA capabilities

Core offerings

- Custom data cables and cable assemblies for automotive, industrial, and electronics

- PCB fabrication & assembly, box-build, and sub-assembly services

Strengths

- Easier integration between boards, data cables, and enclosures

- OEM/ODM support from prototype through to volume production

- Consistent matching of PCB layout, connector selection, and data cable design for better signal integrity

This integrated approach is especially useful if you want a single supplier for PCBs and data cables, instead of coordinating multiple factories for each part of your system.

2. ECOCABLES

ECOCABLES is a dedicated data cable and cable assembly manufacturer with over 20 years of experience in custom solutions. What’s more, they offer a large range of connector types like Molex, JST, Tyco, and AMP. They tend to specialize in custom data cables for the automotive industry and appliances.

If necessary, they can build data cables based on your drawings or co-develop with you. This priority on customisation makes ECOCABLES a versatile partner that creates higher quality products compared to off-the-shelf data cables.

3. Romtronic

Romtronic was founded in 1997 and operates out of Dongguan, Guangdong, as a data cable manufacturer for OEMs. Since their inception, they’ve grown to be a global provider, offering data cable shipping to over 80 countries in the EU, USA, and Japan.

The ability to ship all over the world makes them a popular contender for manufacturing data cables, especially in the medical and automotive industry. Their experience means better certifications, higher-quality products, and consistency - the most underrated aspect.

4. WIRINGO

WIRINGO focuses heavily on custom data cable and cable assembly solutions for global customers. They work closely with customers to optimize routing, shielding, strain relief, and connector choices for each project. From there, they provide design reviews and DFM recommendations for both data cables and complete assemblies.

They also handle prototyping for validation and testing, then ramp to full-scale production for automotive, industrial, and electronics applications.

5. Kaifa Connector

Kaifa, more formally as Yueqing Kaifa Electronics Co., Ltd., positions itself as a custom automotive cable and connector assembly manufacturer in China. They also boast 15 years of experience, with a few unique applications of data cables and wire harnesses — like LED lighting, industrial automation, and communication.

Kaifa focuses on data cables and assemblies for automotive applications, from traditional vehicles to EVs. That includes in-vehicle networking, sensor, and control cables where connector reliability really matters. They build custom assemblies to match your drawings, specific vehicle requirements, and target performance levels.

Kaifa is pretty valuable if you need vehicle-grade data cables with consistent quality, traceability, and compatibility with existing automotive connector ecosystems.

6. Yingkou Abe Harness Co., Ltd

Yingkou Abe Harness Co., Ltd. is a Chinese company with long-standing ties to automotive wiring and data cable manufacturing. They serve both domestic and international customers — providing years of experience within the industry.

Yingkou Abe Harness Co., Ltd. was founded in the 1990s. They supply data and control cables for airbags, seat-belt control, and other safety-critical systems. This experience makes it a useful benchmark when comparing automotive-focused data cable suppliers in China and indicates deep familiarity with strict quality, reliability, and testing requirements.

If your project involves safety or mission-critical automotive electronics, Yingkou Abe Harness Co. can help ensure your data cables meet the high and drastic expectations of the industry.

What are the Key Standards & Certifications You Should Check?

| ISO 9001 | General quality management; should be the baseline for almost any supplier and shows they have structured processes. |

| IATF 16949 | Essential if your harness will be used in vehicles; indicates compliance with global automotive quality requirements. |

| ISO 13485 | Important for medical or lab equipment harnesses, where traceability, documentation, and process control are critical. |

| UL / CSA approvals | Demonstrate that wires, cables, and assemblies meet North American safety and performance standards. |

| IPC/WHMA-A-620 | Industry standard for cable and wire harness assembly workmanship; many professional factories train staff to this guideline. |

How do Chinese Manufacturers Control Quality?

Choosing a data cable manufacturer in China isn’t just about price; it’s about how reliably they can deliver the same cable performance, batch after batch. The best factories follow strict, documented quality-control processes at every stage, from design to final inspection.

Process Discipline & Testing

Top data cable manufacturers in China use a combination of structured processes and rigorous testing to keep defect rates low and ensure consistent electrical and mechanical performance.

Detailed Engineering Documentation

They start with clear, detailed engineering documents, including:

- Cable structure drawings (conductor size, insulation, shielding, jacket)

- Pinout charts and connector specs

- Impedance, capacitance, and signal integrity requirements

Revision control and formal engineering change notices (ECNs) are used, so every design update is tracked, approved, and implemented correctly.

Controlled Production Steps

On the production line, conductors are drawn, stranded, insulated, twisted, shielded, and jacketed using automated equipment to maintain consistent geometry and dimensions. For assemblies, cutting, stripping, crimping, and soldering are also automated where possible.

In-Process Inspections

During cabling and assembly, operators and inspectors perform visual and dimensional checks to catch issues early, such as jacket or insulation defects (nicks, bubbles, discoloration), poor shielding coverage or braid density, incorrect connector orientation or incomplete terminations. First-article inspections are carried out for new or revised part numbers to validate the setup before full production runs.

100% Electrical Testing

Most reputable factories perform 100% electrical testing on finished data cables and assemblies. This typically includes continuity testing, insulation resistance / Hi-Pot testing for high-voltage or safety-related applications, and impedance and signal integrity checks. For critical applications, additional tests such as bending/flex tests, insertion/withdrawal cycles, and environmental aging may be performed.

Final QA & Traceability

At the end of the process, final quality assurance links each batch to specific lot numbers and material batches, process parameters and machine IDs, test results and inspection records. This traceability allows any field issue to be tracked back to the exact materials, tools, and conditions used for that cable batch.

Reviewing a Manufacturer’s QC Flow

When you shortlist data cable manufacturers in China, ask each one to walk you through this quality-control flow step by step so you can see how they protect your product’s reliability.

FAQs on Cable Manufacturers in China

How long do data cable orders from China usually take?

Prototypes or samples from Chinese data cable manufacturers usually take around 1 to 3 weeks after final confirmation. If you intend to mass produce, you’ll find it typically takes about 3 to 6 weeks, depending on cable complexity, custom tooling, and material availability. Lead times vary by factory and project, so always confirm timing directly with each supplier for every new order.

What is the typical minimum order quantity (MOQ) for data cables?

There’s not a specific or regulated minimum MOQ for data cables, as many Chinese data cable manufacturers are fairly flexible. Some manufacturers will accept lower MOQ requirements (for example, 10–100 pieces) for custom assemblies. However, for high-volume sectors like automotive, networking, or consumer electronics, MOQs are often higher to keep pricing competitive.

Back to Top: Who are the Top 6 Data Cable Manufacturers in China?

Special Offer: Get $100 off your order!

Email [email protected] to get started!