Who are the Top 6 Data Cable Manufacturers in China?

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

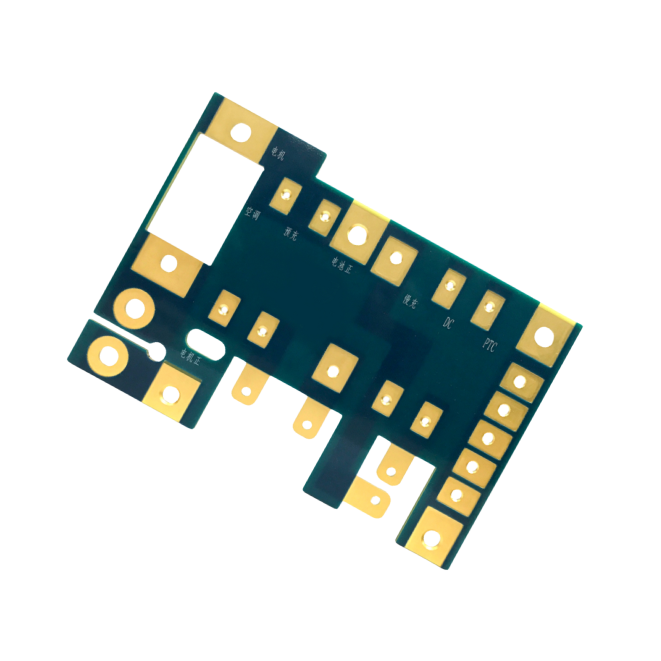

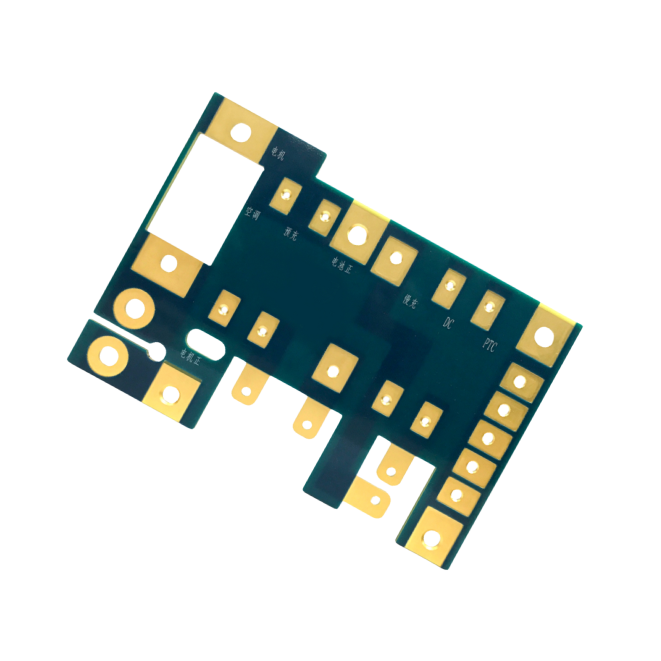

Looking for dependable circuit card assembly manufacturers for automotive systems, industrial automation, or aerospace electronics? OurPCB delivers high-precision CCA solutions backed by 15+ years of experience, top-tier certifications, and faster-than-average lead times for prototypes and full production.

OurPCB delivers comprehensive circuit card assembly solutions with industry-leading quality standards and efficient turnaround times. Our state-of-the-art facilities in China support diverse manufacturing needs, from turnkey prototypes to high-volume production.

| Specification | PCBA Capability |

|---|---|

| Placer speed | 60,000 chips/hour |

| Lead Time | 25+ Days (To Be confirmed) |

| SMT | SMT, Through Hole Assembly Single/Double-Side SMT, Single/Double-Sides Mixture Assembly |

| PCB Size | 50mm×50mm ~610mm×508mm |

| PCB Thickness | 0.5mm~4.5mm |

| Min. diameter /space of BGA | 0.2mm/0.35mm |

| Qualifications | ISO 9001:2015 |

| Accuracy | <±30µm, under the condition of 3σ,CPK≥1 |

| Minimum width/space of QFP | 0.15mm/0.25mm |

| Minimum Diameter /Space of BGA | 0.2mm/0.35mm |

| Reliability Test | Flying Probe Test/Fixture test, Impedance Test, Solderability Test, Thermal Shock Test, Hole Resistance Test, and Micor Metallographic Section Analysis, etc. |

With over 18 years of experience and two fully equipped CCA manufacturing facilities covering 20,000+ square meters, OurPCB offers complete circuit card assembly services backed by strict quality control and international certifications. We review every design for manufacturability (DFM) to reduce defects, streamline production, and avoid costly revisions.

OurPCB combines printed circuit board expertise, over a decade of manufacturing experience, premium materials, and comprehensive services to deliver exceptional value to over 3,000 satisfied customers worldwide.

sssss

OurPCB leverages advanced manufacturing processes and equipment, including pick-and-place machines, SPI inspection, AOI machines, X-ray inspection, and automated testing systems to ensure consistent quality across all products.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

We require Gerber files (RS274-X format), BOM (Bill of Materials), component coordinate files, and any testing instructions if testing is required.

Both refer to assembled circuit boards, but PCBA is used in general electronics, while CCA is more common in military and regulated sectors. The difference is mostly in naming conventions, not the physical product.

OurPCB manufactures single-sided, double-sided, multilayer, rigid, flex, and rigid-flex PCBs to meet various application requirements. We also use surface mount (SMT), through-hole (THT), and mixed assembly technologies.

We offer green, yellow, orange, black, blue, red, white, matte green, matte black, matte blue, purple, and gray solder mask colors.

We adhere to GB/T19001-2016/ISO 9001:2015, IPC-A-610H Class I/II/III, GB/T42061-2022/ISO 13485:2016, and IATF 16949:2016 standards. These allow us to provide the highest quality printed circuit board manufacturing services possible for reliable operation in automotive, aerospace, medical, and other industries.

Lead times range from 4 days for simple designs (2 layers, <1m²) to 25 days for complex boards (12 layers, >30m²). Note that lead times vary based on complexity and size.

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree