Aerospace cable assembly manufacturers work under standards such as AS9100, ISO 9001, and RTCA/DO-160, and many also maintain ITAR registration to support flight-critical and space-qualified systems. These requirements ensure every conductor, connector, termination and jacket can survive vibration, altitude, temperature extremes, EMI and other harsh conditions found in aircraft, spacecraft and ground-support equipment.

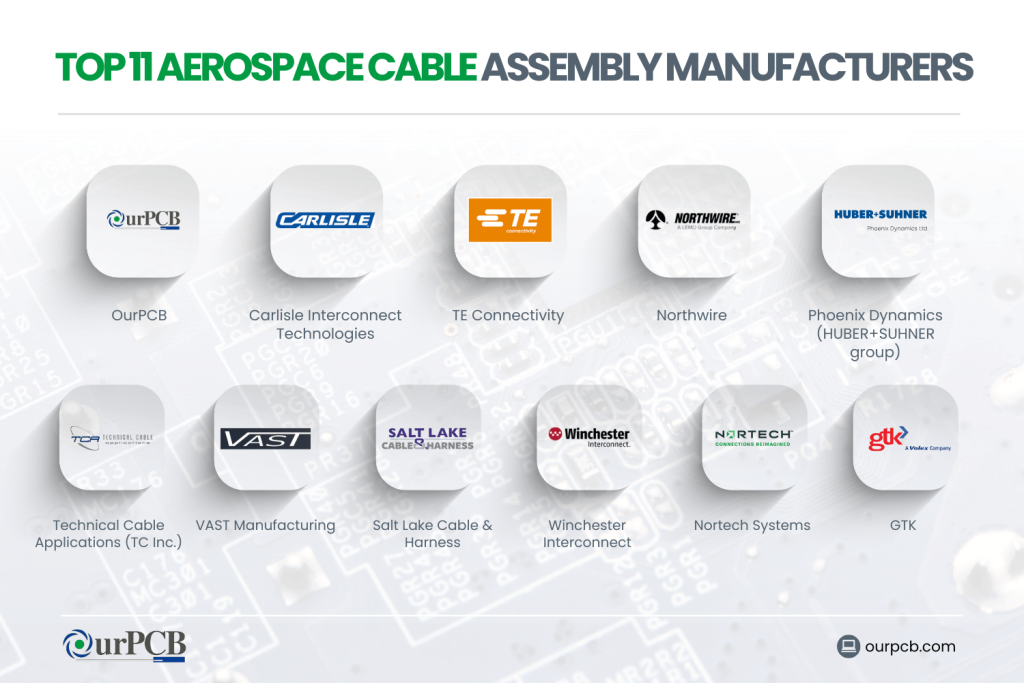

Commercial aviation, defense aviation and space programs all depend on partners that can deliver highly controlled, traceable builds that perform reliably throughout an aircraft’s service life. With so many suppliers available, choosing the right one can feel complex, so this guide provides an in-depth comparison of 11 leading aerospace cable assembly manufacturers. Our goal is to help you navigate this complex landscape and make an informed decision based on engineering depth, proven performance, and certification compliance.

Contents

- Aerospace Cable Assembly Manufacturer Comparison Table

- 11 Aerospace Cable Assembly Manufacturers | In-Depth Analysis

- OurPCB

- Carlisle Interconnect Technologies

- TE Connectivity

- Northwire

- Phoenix Dynamics (HUBER+SUHNER Group)

- Technical Cable Applications (TC Inc.)

- VAST Manufacturing

- Salt Lake Cable & Harness

- Winchester Interconnect

- Nortech Systems

- GTK

- How to Choose an Aerospace Cable Assembly Manufacturer

- Service Capabilities

- Industry Experience

- Standards & Compliance

- Supply Chain for Aerospace-Grade Components

- Testing and Qualification

- Certifications & Audits

- Customization Options

- Order Quantities & Scalability

- Customer Support & Engineering Access

- Aerospace Cable Assembly Manufacturers FAQs

- What certifications should an aerospace cable assembly manufacturer have?

- How long does it take to manufacture custom aerospace cable assemblies?

- How are aerospace cable assemblies different from commercial/industrial ones?

- Can aerospace cable assemblies be used in space applications?

- OurPCB | Select the Right Manufacturer for Your Program

Aerospace Cable Assembly Manufacturer Comparison Table

| Manufacturer | Founded | Certifications (selected) | Specialty |

|---|---|---|---|

| OurPCB | 2007 | ISO 9001, ISO 13485, IATF 16949, IPC/WHMA-A-620, ITAR Registered | Aerospace wire harness and cable assemblies with integrated PCB/PCBA manufacturing and full traceability for avionics and mission systems |

| Carlisle Interconnect Technologies | 1940 | AS9100D, ISO 9001 | High-performance wire, cable, complex harnesses and RF assemblies for commercial and military aircraft |

| TE Connectivity | 2007 (roots back to AMP 1941) | AS9100 (multiple sites), ISO 9001 | Connectors, contacts and cable systems for avionics, engines and cabin systems |

| Northwire | 1972 | AS9100 aviation/space/defense, ISO 9001 | Custom cables and assemblies for extreme-environment aerospace and defense uses |

| Phoenix Dynamics (HUBER+SUHNER group) | 1994 | AS9100, ISO 9001, IPC/WHMA-A-620 | High-precision wiring harnesses and aerospace cable assemblies including UAVs |

| Technical Cable Applications (TC Inc.) | 2000s | AS9100D, ISO 9001 | Custom aerospace cable and harness builds including coax, RF and data bus |

| VAST Manufacturing | 1980s | AS9100 (Class III cable assembly) | Class III cable and harness assemblies for flight systems and defense programs |

| Salt Lake Cable & Harness | 1985 | AS9100D, ISO 9001, ITAR, IPC-A-620 Class 3 Capable | Aerospace wiring harnesses and custom Make-to-Print assemblies |

| Winchester Interconnect | 1941 | Meets various MIL-SPEC and aerospace standards | RF, hermetic and fiber-optic cable assemblies for harsh aerospace and defense environments |

| Nortech Systems | 1990 | AS9100, ISO 9001, ITAR | Ruggedized cable assemblies and PCBA solutions for aerospace and defense systems |

| GTK | 1990s | AS9100D, ISO 9001, ISO 14001, UL | Defence and aerospace cable assemblies from UK and EU manufacturing sites |

Special Offer: Get $100 off your order!

Email [email protected] to get started!

11 Aerospace Cable Assembly Manufacturers | In-Depth Analysis

Here, we present eleven aerospace cable assembly manufacturers with strong experience in flight-critical environments, complex harnessing and compliance with sector-specific standards.

OurPCB

Founded: 2007

Headquarters: Hebei, China with additional manufacturing in Asia-Pacific and global sales/support offices

Company Overview

OurPCB is an integrated PCB, PCBA, cable assembly and wire harness manufacturer that also offers dedicated aerospace wire harness manufacturing and assembly services.

For aerospace and defense customers, OurPCB emphasizes:

- ISO 9001-certified quality management across PCB and harness operations

- Additional certifications including ISO 13485 and IATF 16949 that support high-reliability, regulated applications

- IPC/WHMA-A-620 workmanship practices specifically for cable and wire harness manufacturing

- ITAR-registered aerospace harness operations with DFARS-compliant processes for defense programs

OurPCB’s aerospace wire-harness offering includes:

- Make-to-Print and co-engineered wire harnesses for avionics, communication systems and mission equipment

- 100% electrical testing (continuity, insulation resistance, dielectric strength where applicable) and pull testing on terminations

- Comprehensive material and process traceability from incoming components to final assembly, documented to support airworthiness and regulatory audits

Because OurPCB also manufactures PCBs and PCBA, programs can source both the electronic assemblies and the associated aerospace harnessing from a single supplier, simplifying configuration control and reducing integration risk.

Carlisle Interconnect Technologies

Founded: 1940 (as Tensolite)

Headquarters: USA (operations serving global aerospace markets)

Company Overview

Carlisle Interconnect Technologies (CarlisleIT) is a vertically integrated manufacturer of high-performance wire, cable, harnesses and RF products. Their offerings include:

- Primary and secondary aircraft wiring

- High-speed data and Ethernet cabling

- RF/microwave assemblies for radar and SATCOM

- Complete, certified cable harnesses and installation kits for airframes

The company’s AS9100D and ISO 9001:2015 certification, along with additional environmental and medical standards, underpin their role as a preferred supplier for major commercial and defense OEMs.

TE Connectivity

Founded: 2007 (roots back to AMP, founded 1941)

Headquarters: Galway, Ireland (domicile) / Berwyn, Pennsylvania, USA (executive)

Company Overview

TE Connectivity designs and manufactures a broad portfolio of connectors, cable assemblies and sensors used in avionics, engines, interiors and landing-gear systems. For aerospace users, TE provides:

- High-reliability connectors and contacts

- Wire and cable systems optimized for weight and routing constraints

- Harness components engineered for EMI control and high-temperature operation

Their aerospace offerings are backed by AS9100-certified plants and a global engineering team that supports certification and documentation needs for FAA, EASA and military authorities.

Northwire

Founded: 1972

Headquarters: Osceola, Wisconsin, USA

Company Overview

Northwire specializes in custom cable and cable assemblies for demanding environments, with AS9100 certification specifically covering aviation, space and defense.

Their aerospace and defense portfolio emphasizes:

- High-flex cables for moving axes (galleys, seats, mechanisms)

- RFI/EMI-shielded constructions

- Composite and hybrid designs (power + data + control)

- Rugged coax and RF microwave cables for radar and communications

Northwire’s engineering team collaborates early with OEMs to tune materials and constructions for temperature, chemical resistance and mechanical robustness, reducing risk later in DO-160 or MIL-STD-810 test programs.

Phoenix Dynamics (HUBER+SUHNER Group)

Founded: 1994

Headquarters: UK

Company Overview

Phoenix Dynamics is an AS9100-certified specialist in high-performance cable assemblies and wiring harnesses for challenging environments, including civil and military aerospace.

Key capabilities include:

- Harsh-environment harnesses optimized for weight and packaging

- RF, fiber-optic and power cables

- Electro-mechanical assemblies such as control panels and distribution boxes

They are particularly active in UAVs and next-generation aircraft, where weight, data-rate and lead-time pressures are most acute.

Technical Cable Applications (TC Inc.)

Founded: Early 2000s (TC Inc. within the Volex group)

Headquarters: North America (with AS9100D-certified operations in Canada)

Company Overview

Technical Cable Applications focuses on custom aerospace wire, cable and harness solutions, with AS9100D and ISO 9001 certification to support aviation and defense projects.

Their capabilities cover:

- RF and coaxial assemblies for aircraft communications

- Engine and nacelle harnesses designed for heat and vibration

- Complex mixed-signal harnesses combining power, data and control

TC Inc’s participation in Canada’s Controlled Goods Program (similar in intent to ITAR) helps support secure defense and aerospace programs in North America.

VAST Manufacturing

Founded: 1980s (commercial records cite 1984–1987)

Headquarters: USA (operations supporting aerospace and defense programs)

Company Overview

VAST Manufacturing is an AS9100-registered contract manufacturer specializing in Class III cable assemblies and wire harnesses for aerospace, defense and robotics.

For aerospace customers, VAST focuses on:

- Flight-system harnesses (avionics, controls, sensors)

- Prototype-to-production transitions

- Assemblies built to IPC/WHMA-A-620 Class III workmanship

Class III covers applications where failure “cannot be tolerated” and environments are unusually harsh, exactly the conditions encountered in many flight-critical systems.

Salt Lake Cable & Harness

Founded: 1985

Headquarters: North Salt Lake, Utah, USA

Company Overview

Salt Lake Cable & Harness is an AS9100-certified, ITAR-registered custom manufacturer of cable assemblies and wiring harnesses, with Spec 3 IPC build capability for high-reliability aerospace and defense applications.

Their aerospace work includes:

- Aircraft wiring harnesses and molded cable assemblies

- Avionics, engine and cabin harnesses

- Box builds and control panels tied into harness production

Decades of experience with low-to-medium volume, high-mix production makes them well-suited to retrofit programs and specialized platforms.

Winchester Interconnect

Founded: 1941

Headquarters: Connecticut, USA

Company Overview

Winchester Interconnect provides connectors, RF/microwave solutions and cable assemblies for harsh environments, including aerospace, defense and space.

For aerospace users, their portfolio features:

- Semi-rigid and flexible RF cable assemblies for radar, EW and SATCOM

- Hermetic feedthroughs and sealed interconnects for pressurized or space applications

- High-reliability harness assemblies and coil cords for moving mechanisms

Winchester’s solutions are engineered to cope with shock, vibration, pressure and moisture in mission-critical environments.

Nortech Systems

Founded: 1990

Headquarters: Maple Grove, Minnesota, USA

Company Overview

Nortech Systems is an AS9100- and ISO 9001-certified, ITAR-compliant provider of cable assemblies, PCBA solutions and electromechanical builds for aerospace and defense.

Within aerospace and defense, Nortech focuses on:

- Ruggedized cable assemblies and custom bulk cables

- Integration of fiber-optic interconnects (including Expanded Beam Xtreme™ technology) into complex harnesses

- Turnkey system-level assemblies and final test

GTK

Founded: 1990s (over 30 years of operations)

Headquarters: United Kingdom (manufacturing also in Romania)

Company Overview

GTK is a UK-based provider of custom defence and aerospace cable assemblies with AS9100D-certified manufacturing and additional ISO 9001 and ISO 14001 approvals.

Typical aerospace work includes:

- Lightweight, high-performance mil-spec harnesses

- RF cable assemblies and connectors for high-speed links

- Ruggedized and miniaturised assemblies for space-constrained systems

GTK’s combination of UK engineering and European manufacturing capacity makes them attractive for EMEA-based programs needing AS9100D quality with competitive lead times.

How to Choose an Aerospace Cable Assembly Manufacturer

When selecting a partner for aerospace cable and harness work, consider the following factors.

Service Capabilities

Look for manufacturers that can provide:

- Custom cable and harness design support

- Prototyping and rapid engineering changes

- Assembly, testing and packaging under one quality system

Suppliers with in-house design and test capability are better positioned to navigate DO-160, MIL-STD-810 and similar environmental test requirements without excessive back-and-forth.

Industry Experience

Aerospace programs involve long lifecycles, controlled configuration baselines and intensive audits. Prioritize partners that:

- Have multi-year or multi-platform aerospace references

- Understand FAA/EASA certification implications

- Are comfortable with documentation and traceability expectations

Standards & Compliance

For aerospace, key indicators include:

- AS9100 (aerospace quality management)

- ISO 9001 (general quality management)

- ITAR / Controlled Goods / export-control frameworks for defense work

- Workmanship standards such as IPC/WHMA-A-620 Class 3

These standards collectively help ensure that design, production and change management meet aviation-specific expectations.

Supply Chain for Aerospace-Grade Components

A good aerospace harness partner has proven relationships with connector and cable OEMs (e.g., Amphenol, TE Connectivity, CarlisleIT) and maintains controlled processes for:

- Lot traceability and material certification

- Counterfeit-parts avoidance

- Long-term availability planning for platform life

Market reports consistently show that these OEMs dominate the aircraft wire and cable market, making aligned supply chains a key advantage.

Testing and Qualification

Check that the manufacturer can perform or coordinate:

- Electrical testing (continuity, hipot, insulation resistance)

- Environmental testing to RTCA/DO-160 or MIL-STD-810, as applicable

- RF performance tests for coax and microwave assemblies

Many new or custom test profiles take weeks to design and validate, so clarify capability and timelines early in your planning.

Certifications & Audits

In addition to AS9100 and ISO 9001, consider whether your application needs:

- NADCAP or equivalent for special processes (e.g., soldering, heat-treat)

- Customer-specific approvals (airframe OEM approved-supplier lists)

Customization Options

Aerospace installations often require unique routing, connector mixes and serviceability features. Look for partners that can support:

- Tailored harness breakouts and labeling schemes

- Mixed copper/fiber architectures

- Design for weight, maintainability and future upgrades

Order Quantities & Scalability

Confirm that your supplier can handle:

- Small prototype runs and engineering development units

- Transition to low-rate initial production

- Eventual full-rate production or long-term spares demand

Customer Support & Engineering Access

A responsive engineering contact is crucial when requirements change mid-program. Ask about:

- Standard response times for drawing updates

- Access to design reviews and DFM feedback

- Post-delivery support for investigations and failure analysis

Aerospace Cable Assembly Manufacturers FAQs

What certifications should an aerospace cable assembly manufacturer have?

At minimum, look for AS9100 for aerospace quality management and ISO 9001 for general quality systems. Defense-related programs usually require ITAR (or equivalent export-control) registration and evidence of compliance with workmanship standards such as IPC/WHMA-A-620. Site-specific approvals from major OEMs can be an additional advantage.

How long does it take to manufacture custom aerospace cable assemblies?

Manufacturing lead times for custom aerospace cable assemblies vary by project stage. Prototypes typically take around 2 to 4 weeks once drawings and materials are finalized. Initial production lots usually require 4 to 8 weeks, largely depending on connector availability. Repeat orders are often faster when materials and tooling are already in place. Suppliers with strong aerospace-grade supply chains and in-house testing capabilities can often reduce these timelines compared to manufacturers that outsource critical steps.

How are aerospace cable assemblies different from commercial/industrial ones?

Aerospace cable assemblies differ from their commercial/industrial counterparts in four critical areas:

Materials: They use specialized, qualified materials designed for extreme temperature ranges, low outgassing (for space), and resistance to aviation fluids.

Construction & Shielding: They feature more robust construction and advanced EMI/RFI shielding to ensure signal integrity in electrically noisy aircraft environments.

Testing & Qualification: They undergo rigorous environmental testing to standards like RTCA/DO-160 or MIL-STD-810, far exceeding typical commercial requirements.

Traceability & Documentation: They demand full lot traceability for every component and tightly documented configuration control to support airworthiness certification and long-term service.

Can aerospace cable assemblies be used in space applications?

Many aerospace-grade designs can be adapted for space applications. However, true space-qualified assemblies must address additional constraints such as vacuum outgassing, radiation, and atomic oxygen exposure. Several of the manufacturers mentioned above support both aviation and space programs. They use specialized materials and test regimes to qualify assemblies for orbital environments.

OurPCB | Select the Right Manufacturer for Your Program

Stop risking schedule slips and rework with unproven suppliers. Manufacturers like OurPCB maintain AS9100 aviation/space/defense certification and specialize in custom cables and assemblies tuned for extreme environments, helping to compress design cycles and reduce qualification risk.

When your aerospace or space program depends on fast, compliant builds, shortlist a few of the manufacturers above, map their capabilities against your platform’s requirements, and engage early with their engineering teams to secure cable assemblies built for reliability, speed and mission-ready performance.

Back to Top: Top 11 Aerospace Cable Assembly Manufacturers

Special Offer: Get $100 off your order!

Email [email protected] to get started!