Truck wiring harnesses are the electrical backbone of commercial vehicles, from long-haul trucks to construction fleets and emergency vehicles. They must withstand continuous vibration, thermal shock, and exposure to oil, grease, salt spray, and other chemicals. Harnesses also need resistance to dust, water intrusion, abrasion, and high electrical loads over long service life.

Modern trucks add further complexity with CAN and LIN communications, which can be sensitive to electrical noise and grounding issues. Because harnesses support safety systems, emissions controls, telematics, ADAS, lighting, power distribution, and electrification, the design requirements are increasingly demanding. Choosing the right supplier helps ensure reliable operation, long service life, and smooth OEM integration, and the following guide highlights seven trusted manufacturers with proven heavy-duty capability.

Contents

- Truck Wiring Harness Manufacturers | Quick Comparison

- An In-Depth Look at 7 Reputable Truck Harness Manufacturers

- 1. OurPCB

- Company Overview

- Strengths in Truck Applications

- Why They Stand Out

- 2. Lear Corporation

- Company Overview

- Strengths in Truck Applications

- Why They Stand Out

- 3. Yazaki

- Company Overview

- Strengths in Truck Applications

- Why They Stand Out

- 4. Sumitomo Wiring Systems

- Company Overview

- Strengths in Truck Applications

- Why They Stand Out

- 5. Delphi Technologies (BorgWarner)

- Company Overview

- Strengths in Truck Applications

- Why They Stand Out

- 6. Motherson Wiring Systems

- Company Overview

- Strengths in Truck Applications

- Why They Stand Out

- 7. PKC Group (Motherson Group)

- Company Overview

- Strengths in Truck Applications

- Why They Stand Out

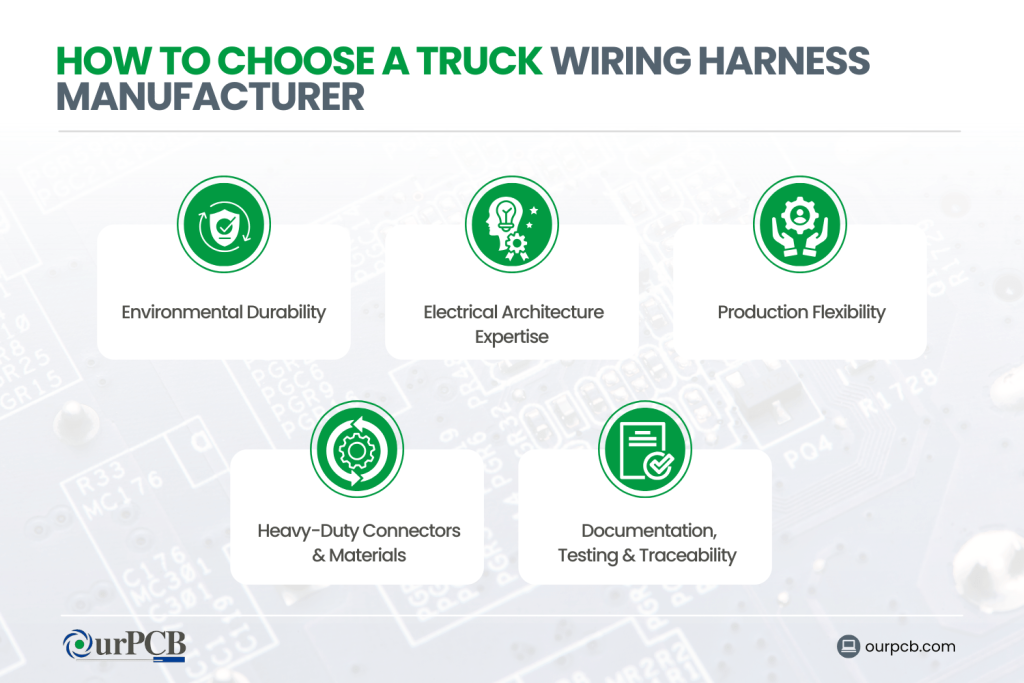

- How to Choose a Truck Wiring Harness Manufacturer

- 1. Environmental Durability

- 2. Electrical Architecture Expertise

- 3. Production Flexibility

- 4. Heavy-Duty Connectors & Materials

- 5. Documentation, Testing & Traceability

- Truck Wiring Harness Manufacturers FAQs

- What certifications should truck harness manufacturers have?

- How long does it take to produce custom truck wiring harnesses?

- What’s the difference between truck wiring harnesses and automotive harnesses?

- Your Next Step: Get a Quote Tailored to Your Truck

Truck Wiring Harness Manufacturers | Quick Comparison

| Manufacturer | Founded | Certifications | Specialization |

|---|---|---|---|

| OurPCB | 2007 | ISO 9001, IATF 16949-capable, IPC/WHMA-A-620 | Custom truck wiring harnesses, high-current power harnesses, CAN/LIN harnesses, chassis & cabin looms |

| Lear Corporation | 1917 | IATF 16949, ISO 14001, ISO 9001 | OEM automotive & heavy-duty wiring harnesses, electronic distribution systems |

| Yazaki | 1941 | IATF 16949, ISO 14001 | High-volume automotive & commercial vehicle harnesses, connectors and PDU integration |

| Sumitomo Wiring Systems | 1919 | IATF 16949, ISO 9001 | Heavy-duty vehicle harnessing, powertrain looms, ADAS and EV truck interconnects |

| Delphi Technologies (BorgWarner) | 1994 (Delphi legacy, 1880s) | IATF 16949, ISO 9001 | High-reliability truck wiring, diesel/emissions systems, high-temperature engine-bay harnesses |

| Motherson Wiring Systems | 1986 | IATF 16949, ISO 9001 | Full-vehicle wire harnessing for commercial trucks, buses and agricultural vehicles |

| PKC Group (Motherson Group) | 1969 | IATF 16949, ISO 14001, ISO 9001 | Heavy-duty and off-highway harnesses, modular power distribution, EV truck platforms |

An In-Depth Look at 7 Reputable Truck Harness Manufacturers

1. OurPCB

Founded: 2007

Headquarters: China with global engineering support

Company Overview

OurPCB builds custom truck wiring harnesses and cable assemblies for heavy-duty vehicles, utility trucks, construction machinery, and transport fleets. They specialize in low-to-medium volume OEM builds where customization, robustness and fast turnaround are essential.

Strengths in Truck Applications

- Engine-bay harnesses designed for heat, oil and vibration

- Chassis harnesses for lighting, brakes, ABS, sensors and communication loops

- Cabin & dashboard harnesses with precise routing, labeling and connector integration

- CAN, LIN, J1939 and telematics harnesses for modern smart trucks

- High-current power harnesses for battery, alternator, starter and auxiliary systems

- Sealed connectors (Deutsch/TE/AMP) and overmolded strain relief for durability

Why They Stand Out

OurPCB is ideal for OEMs and upfitters who need flexible production, customization, and the ability to adapt quickly to new truck models or system upgrades, especially when integrating custom electronics, lighting, tracking systems and aftermarket gear.

2. Lear Corporation

Founded: 1917

Headquarters: Southfield, Michigan, USA

Company Overview

Lear is a tier-one automotive supplier producing wiring harnesses for the world’s largest automakers and truck manufacturers. Their heavy-duty harness production focuses on vehicles with complex electrical architectures and safety systems.

Strengths in Truck Applications

- Full-vehicle wiring systems for commercial trucks, buses and specialty vehicles

- High-voltage harnesses for hybrid and electric trucks

- Modular power distribution centers and smart fuse boxes

- Thermally robust engine-bay harnesses tested for harsh duty cycles

- Precision fit for OEM production lines and complex vehicle platforms

Why They Stand Out

With massive global capacity, Lear is ideal for high-volume production, long-term programs and truck OEMs requiring tightly controlled just-in-time manufacturing.

3. Yazaki

Founded: 1941

Headquarters: Tokyo, Japan

Company Overview

Yazaki is one of the largest global producers of automotive and commercial vehicle wiring harnesses. They supply major truck OEMs in North America, Europe and Asia.

Strengths in Truck Applications

- High-volume harness manufacturing with global redundancy

- Commercial-grade connectors, terminals and sealing systems

- CAN, LIN and Ethernet harnesses for modern truck networks

- Durable chassis looms optimized for vibration and moisture

- Integrated harness design with Yazaki’s own connector ecosystems

Why They Stand Out

Yazaki is best for OEMs requiring scalable global manufacturing, consistent quality across regions, and deep expertise in vehicle network architecture.

4. Sumitomo Wiring Systems

Founded: 1919

Headquarters: Yokkaichi, Japan

Company Overview

Sumitomo Wiring Systems (SWS) is a major supplier to automotive and heavy-duty truck manufacturers. They’re known for high-reliability harnessing and advanced connectors built for extreme environments.

Strengths in Truck Applications

- High-temperature engine-bay harnesses with heat-resistant insulation

- Powertrain and transmission looms for diesel and hybrid trucks

- ADAS & sensor harnesses (radar, cameras, ultrasonic)

- EV & hybrid truck harnesses, including high-voltage routing solutions

- Robust wiring for mining, agricultural and construction vehicles

Why They Stand Out

SWS excels in mission-critical reliability, making them ideal for trucks operating in mining, construction and extreme climates.

5. Delphi Technologies (BorgWarner)

Founded: As Delphi in 1994 (legacy roots back to 1880s), acquired by BorgWarner

Headquarters: Auburn Hills, Michigan, USA

Company Overview

Delphi Technologies, now part of BorgWarner, specializes in high-performance wiring harnesses for engine management, emissions systems and power distribution — all essential for modern heavy-duty trucks.

Strengths in Truck Applications

- Engine management harnesses for diesel engines

- Aftertreatment / emissions system harnesses (DEF, SCR, NOx sensors)

- High-temperature automotive-grade materials

- High-speed data harnesses for truck ECUs and smart modules

- Solutions supporting Euro VI & EPA emission requirements

Why They Stand Out

Delphi is a strong fit for OEMs needing engine-related harnesses, diesel system wiring, and ruggedized electrical distribution for Class 5–8 trucks.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

6. Motherson Wiring Systems

Founded: 1986

Headquarters: Part of Samvardhana Motherson Group, India

Company Overview

Motherson is one of the world’s largest wiring harness manufacturers and heavily serves the commercial vehicle and truck sector. They offer end-to-end harness production from design to assembly.

Strengths in Truck Applications

- Chassis and cabin wiring looms for medium and heavy-duty vehicles

- Harnesses for agricultural, off-highway and municipal fleet vehicles

- Sealed and compact harnesses for vibration-heavy environments

- Integrated electrical distribution systems and fuse modules

- Large global footprint with regional manufacturing

Why They Stand Out

Motherson is ideal for OEMs seeking cost-effective, large-scale production with access to global engineering and supply chains.

7. PKC Group (Motherson Group)

Founded: 1969

Headquarters: Finland (global facilities under Motherson Group)

Company Overview

PKC Group focuses specifically on heavy-duty trucks, off-highway vehicles and specialty commercial fleets. Their modular harnessing solutions are widely used in North America and Europe.

Strengths in Truck Applications

- Full electrical distribution systems including power, control and communication

- Heavy-duty harnesses for Class 8 trucks, construction and forestry machinery

- Battery and power harnesses including EV truck platforms

- Modular system design for easier assembly and serviceability

- Expertise in long harness runs and chassis routing

Why They Stand Out

PKC is an excellent choice for OEMs wanting complete truck electrical system integration, especially in off-highway or high-load applications.

How to Choose a Truck Wiring Harness Manufacturer

Selecting the right partner for heavy-duty vehicle wiring depends on durability needs, production volume and integration complexity. Key factors include:

1. Environmental Durability

Truck harnesses must handle:

- High vibration

- Abrasive routing paths

- Engine heat + cold starts

- Oil, coolant, DEF, and salt spray

- Water intrusion

Look for suppliers experienced with:

- Sealed connectors (Deutsch/TE/AMP)

- Cross-linked polyethylene (XLPE), TPE or high-temp PVC insulation

- Overmolded joints and abrasion-resistant loom coverings

2. Electrical Architecture Expertise

Modern trucks use complex communication systems:

- CAN / CAN FD

- LIN

- J1939

- Ethernet (for ADAS and telematics)

- Smart-sensor loops

Suppliers must understand EMI shielding, impedance control and proper grounding practices.

3. Production Flexibility

Depending on the operation, you may need:

- High-volume OEM harnessing

- Medium-scale fleet builds

- Low-volume specialty or upfitter harnesses

- Rapid prototyping for new vehicle models

OurPCB is strong for custom and low-to-mid volume, while Yazaki, Lear and Sumitomo excel in high-volume programs.

4. Heavy-Duty Connectors & Materials

For trucks, connector choices matter:

- Deutsch DT, DTM, DTP

- AMP Superseal

- Metri-Pack / Weather-Pack

- IP67+ sealing requirements

Ensure the supplier has certified crimping processes and test data for these systems.

5. Documentation, Testing & Traceability

A qualified truck-harness manufacturer should provide:

- Electrical testing (continuity, hipot, insulation resistance)

- Connector pull-force validation

- Environmental testing where required (salt-spray, thermal cycling)

- Full traceability from raw materials to final harness

Truck Wiring Harness Manufacturers FAQs

What certifications should truck harness manufacturers have?

Truck wiring harness manufacturers should ideally hold IATF 16949 to meet automotive-grade quality requirements and vehicle OEM expectations. ISO 9001 is also important as a baseline quality management system supporting consistent processes, documentation, and corrective actions.

ISO 14001 is often required by global OEMs to demonstrate environmental management and compliance across manufacturing operations. They should also follow IPC/WHMA-A-620 workmanship requirements to ensure consistent build quality, inspection criteria, and assembly methods.

How long does it take to produce custom truck wiring harnesses?

Custom truck wiring harness lead times depend on design maturity and component availability throughout the supply chain. Prototype harnesses typically take about two to six weeks, especially if connectors and terminals are standard parts. Pilot builds often require six to twelve weeks because they include process tuning, documentation, and first-article inspections.

Production orders commonly run six to ten weeks or longer, driven mainly by connector and raw-material lead times. Manufacturers with strong supply chains and in-house testing can often shorten timelines by reducing outsourced steps.

What’s the difference between truck wiring harnesses and automotive harnesses?

Truck wiring harnesses differ from automotive harnesses because they use heavier-gauge conductors and are designed for significantly higher electrical loads. They are engineered to resist continuous vibration, harsh chemicals, and wider thermal extremes common in commercial vehicle environments.

Truck harnesses are typically routed over much longer distances along the chassis, increasing mechanical and environmental stress exposure. They also support heavy-duty accessories, power distribution systems, and auxiliary equipment that exceed typical passenger vehicle requirements.

Your Next Step: Get a Quote Tailored to Your Truck

Choosing the right partner isn't just about comparing spec sheets; it's about finding a manufacturer who understands your specific operational demands. Whether you're designing a new fleet vehicle, upfitting a truck with specialized equipment, or needing a reliable replacement harness, the right build quality makes all the difference.

If your project requires customized, robust harnesses in low-to-medium volumes with expert engineering support, OurPCB is ready to help.

Back to Top: Top 7 Truck Wiring Harness Manufacturers

Special Offer: Get $100 off your order!

Email [email protected] to get started!