Waterproof cable assemblies have to do more than just “keep water out.” For outdoor, marine, industrial washdown, and transportation platforms, assemblies are expected to survive repeated flexing, UV exposure, chemicals, and pressure spray while still maintaining electrical integrity. That usually means meeting IP67, IP68 or even IP69K ingress protection levels under IEC 60529, along with application-specific vibration and salt-spray tests.

Because sealing is typically achieved with overmolding, potting, gaskets, or compression glands, choosing the right manufacturing partner is critical. The best waterproof cable assembly manufacturers combine robust design support, carefully controlled materials, and verified testing protocols so every connector and termination survives real-world conditions — not just a one-time dip test.

Below are 9 established manufacturers known for waterproof and overmolded cable assemblies, along with a quick comparison to help you shortlist suppliers.

Contents

- Top 8 Waterproof Cable Assembly Manufacturers | Comparison Table

- 8 Reputable Waterproof Cable Assembly Manufacturers

- 1. OurPCB

- 2. Cypress Industries

- 3. GTK (UK)

- 4. FLECONN

- 5. YCABLE Electronics

- 6. Totek (TOTEK Cable)

- 7. TechWare Group

- 8. Switchcraft / Conxall

- How to Choose a Waterproof Cable Assembly Manufacturer

- Service Capabilities

- Industry Experience

- IP & Environmental Ratings

- Component Sourcing & Supply Chain

- Testing & Validation

- Certifications

- Customizations

- Order Quantities and Lead Times

- Engineering Support & Customer Service

- Waterproof Cable Assembly Manufacturers FAQs

- What certifications should a waterproof cable assembly manufacturer have?

- How long does it take to manufacture custom waterproof cable assemblies?

- Can waterproof cable assemblies be used for permanent submersion?

- OurPCB | Select the Right Waterproof Cable Assembly Partner for Your Program

Top 8 Waterproof Cable Assembly Manufacturers | Comparison Table

| Manufacturer | Founded | Certifications / Key Standards* | Waterproof / Environmental Specialty |

|---|---|---|---|

| OurPCB (China) | 2007 | ISO 9001, IPC/WHMA-A-620 Compliant | IP67, IP68, IP69K waterproof cable assemblies and wire harnesses for industrial, marine, solar, transportation and outdoor electronics |

| Cypress Industries (USA / Global) | 2001 | ISO 9001:2015, ISO 14001, OHSAS 18001, UL, IPC-A-610 / IPC-A-620 | Custom cable assemblies up to IP68 for industrial, rugged and automotive use |

| GTK (UK) | 1989–1990 | ISO 9001:2015, ISO 14001:2015, UL Wiring Harness Traceability | Overmoulded and waterproof cable assemblies for industrial, defence and medical markets |

| FLECONN (China) | 2013 | ISO 9001, RoHS, CE | IP66–IP68 M5/M8/M12 waterproof connectors and custom cable assemblies |

| YCABLE Electronics (China) | 2012 | ISO 9001, IATF/TS 16949 (automotive) | IP67 / IP68 waterproof RF and coaxial cable assemblies for automotive and communications |

| Totek (TOTEK Cable) (China) | 2005 | In-house IP67 testing, IP67/IP68 Testing Capability | IP67 / IP68 cable assemblies including USB, circular and M12 solutions |

| TechWare Group (Singapore / Global) | 2008 | Advanced manufacturing group, automotive / industrial quality systems | Overmolded cable assemblies achieving IP67, IP68, IP69K for high-reliability equipment |

| Switchcraft / Conxall (USA) | 1946 | UL, CSA, RoHS | Sealed IP67–IP68 harsh-environment molded cable assemblies (EN2, Con-X, Multi-Con-X) |

*Certifications summarized from publicly available company and product documentation; always request up-to-date certificates during supplier qualification.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

8 Reputable Waterproof Cable Assembly Manufacturers

1. OurPCB

Founded: 2007

Headquarters: China, with global support (e.g., Australia, USA)

Company Overview

OurPCB is best known for PCB fabrication and assembly, but it also manufactures custom cable assemblies and wire harnesses, including robust waterproof solutions for harsh industrial and outdoor environments. This makes OurPCB a strong choice when you want one partner to integrate sealed harnesses with electronics builds.

Waterproof Harness Capabilities Include:

- IP67, IP68 and IP69K rated harnesses using overmolded junctions, grommeted entry points and sealed housings

- Waterproof assemblies engineered for industrial machinery, marine systems, solar installations, outdoor lighting and heavy equipment

- Custom cable sets that combine power, signal and data in a single rugged assembly

- Options for PUR / TPE jackets designed for UV, chemical and abrasion resistance in aggressive environments

- Fast-turn prototyping and small-to-mid volume production backed by established PCB and electronics manufacturing infrastructure

Whether you’re building outdoor telecom gear, marine electronics, EV charging systems or rugged industrial controls, OurPCB’s ability to deliver both sealed harnesses and supporting electronics simplifies your supply chain and speeds up development.

2. Cypress Industries

Founded: 2001

Headquarters: Texas, USA (operations in the USA, Mexico, India, China)

Company Overview

Cypress Industries is a vertically integrated contract manufacturer delivering custom cable assemblies, wire harnesses, control panels and precision machined parts. Their cable operations are certified to ISO 9001, ISO 14001 and OHSAS 18001, and they hold UL listing plus IPC-A-610 / IPC-A-620 workmanship certifications.

For waterproof assemblies, Cypress supports:

- Custom premolding, potting and braiding to achieve IP68-rated cable assemblies

- Rugged solutions for oil & gas, solar, industrial automation and automotive platforms

- Global production with mirrored processes in North America and Asia for flexible volume and cost structures

3. GTK (UK)

Founded: 1989 (operating for 30+ years)

Headquarters: Basingstoke, UK, with manufacturing in UK, Romania and Far East

Company Overview

GTK is a UK-based manufacturer of custom cable assemblies, connectors and display solutions, with a strong focus on OEM cable and harness builds. They offer dedicated “Waterproof Cable Assemblies” and “Overmoulded Cable Assemblies” lines targeted at harsh-environment electronics.

Key points:

- ISO 9001:2015 cable assembly facilities in the UK and Romania; also ISO 14001:2015 and UL Wiring Harness Traceability program participation

- Overmoulded assemblies and custom connector interfaces designed to meet IP67 / IP68 ratings

- Experience across defence & aerospace, high-end industrial, automotive/EV and medical equipment

GTK is a good fit when you want UK / EU-centric engineering support with offshore cost options.

4. FLECONN

Founded: 2013

Headquarters: Shenzhen, China (with origins in Hong Kong)

Company Overview

FLECONN specializes in circular waterproof connectors and cordsets, especially M5, M8 and M12 solutions. Their portfolio includes IP65–IP68-rated molded cables and sensor cordsets used in industrial automation, robotics, outdoor LED lighting and automotive applications.

Highlights:

- Custom IP66–IP68 waterproof cables including outdoor LED and industrial sensor leads

- ISO 9001-aligned quality and RoHS/CE-compliant production noted on product lines

- Engineering support for connector selection, cable jacket choices (PVC, PUR) and overmolding geometry

If your design uses M-series circular connectors or compact sensor cables, FLECONN is particularly strong.

5. YCABLE Electronics

Founded: 2012

Headquarters: Jiaxing and Dongguan, China

Company Overview

YCABLE Electronics is an OEM cable and wire assembly manufacturer that increasingly focuses on automotive and RF applications. Their waterproof cable assembly range centers on coaxial and RF cables using sealed bulkhead and in-line connectors.

Capabilities:

- Waterproof coaxial cable assemblies with internal seals and O-rings for IP67 and IP68 protection, designed to prevent moisture ingress at the contact and panel interface

- ISO 9001 and TS/IATF 16949-certified automotive factory for quality-critical builds

- OEM experience with automotive cable assemblies and wire harnesses for high-reliability use cases

YCABLE is suited to RF, antenna and automotive telematics applications that demand both RF performance and environmental sealing.

6. Totek (TOTEK Cable)

Founded: 2005

Headquarters: China

Company Overview

Totek is a cable assembly manufacturer with a broad product range, including energy storage cables, industrial harnesses and waterproof interfaces. Their IP67/IP68 product line includes USB, circular and M12 assemblies targeted at outdoor and industrial equipment.

Key offerings:

- IP67 / IP68 cable assemblies such as panel-mount USB Type-C, circular power connectors and M12 sensor cables

- Manufacturing infrastructure with IP67 test equipment and automated molding machinery for volume production

Totek works well for cost-sensitive programs that still require properly tested, sealed interconnects.

7. TechWare Group

Founded: 2008 (Techware Corporation (S) Pte. Ltd.)

Headquarters: Singapore, with operations across Asia, Europe and the US

Company Overview

TechWare is a precision manufacturing group providing advanced mechanical and electrical assemblies, including cable assemblies and harnesses. Their overmolded cable capability specifically targets high-reliability applications requiring IP67, IP68 and IP69K performance.

Waterproof strengths:

- Overmolded cables designed for IP67, IP68 and IP69K, providing weathertight seals around connectors and transitions

- Integrated mechanical + electrical engineering for complex assemblies and equipment harnesses

They’re a good fit when you need a turnkey precision-machined enclosure or subassembly with sealed cable integration.

8. Switchcraft / Conxall

Founded: 1946 (Switchcraft; Conxall acquired 1999)

Headquarters: Chicago, Illinois, USA

Company Overview

Switchcraft and its Conxall brand are well-known for sealed harsh-environment connectors and molded cable assemblies. Product families such as Con-X, Multi-Con-X, Maxi-Con-X and EN2 offer IP67-sealed circular interconnects and factory overmolded cables.

Waterproof portfolio:

- Custom factory-molded cables with watertight terminations, often rated NEMA 6P / IEC IP67 and higher

- UV-resistant, UL-recognized and CSA-certified assemblies designed for outdoor and industrial use

Switchcraft is a strong option when you want long-established, catalog-driven harsh-environment connector systems plus custom cable molding.

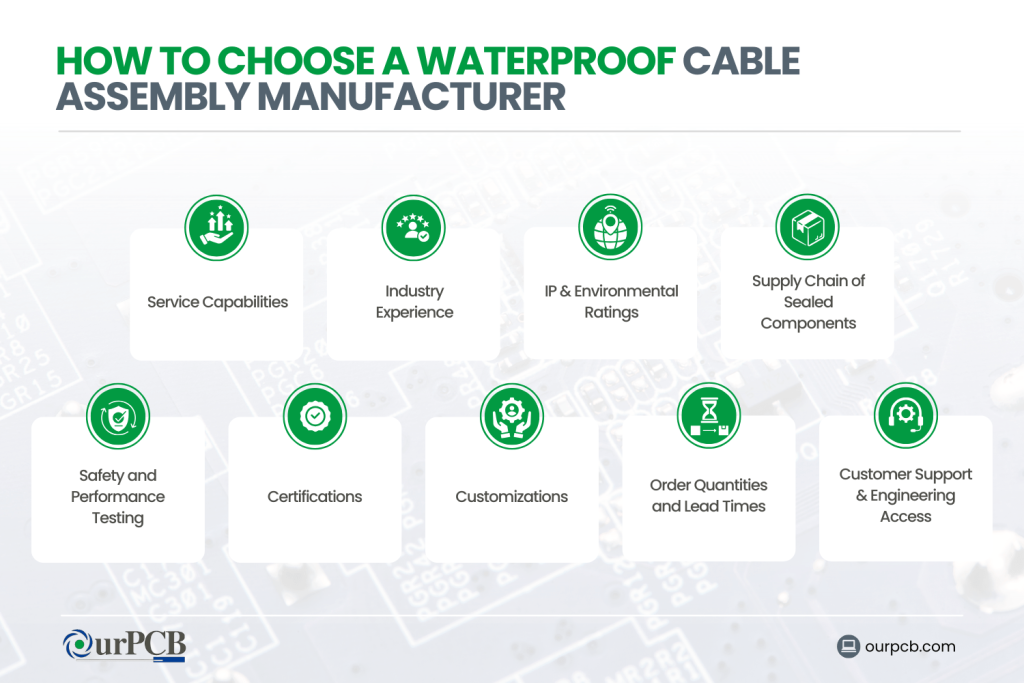

How to Choose a Waterproof Cable Assembly Manufacturer

When you’re selecting a waterproof cable assembly partner, the decision is less about a catalog part and more about whether they can deliver repeatable sealing performance at your required volumes and timelines.

Service Capabilities

- Prefer manufacturers who can design, overmold, pot, test, and package in-house — each extra handoff is a new leak-path risk.

Ask whether they support:

- Custom connector overmolding

- Potting and encapsulation

- IP-rating validation (IP67, IP68, IP69K)

- Washdown and salt-spray resistant materials

Industry Experience

Look for a track record in your specific environment: marine, food & beverage washdown, off-highway vehicles, outdoor telecom, etc.

- Many of the companies above explicitly target sectors like industrial automation, marine, solar energy, and automotive — use that as a filter when shortlisting.

IP & Environmental Ratings

Waterproof performance is codified under IEC 60529, which defines IP67 (temporary immersion) and IP68/IP69K (prolonged immersion or high-pressure cleaning). Confirm that the manufacturer has:

- Your Target IP rating (IP67 vs IP68 vs IP69K)

- Depth / duration of immersion or pressure levels tested

- Whether tests are done on finished assemblies, not just connectors

Component Sourcing & Supply Chain

Ask how they source connectors, glands, jackets and sealing compounds:

- Do they rely on major connector brands (Amphenol, Phoenix Contact, etc.) or house designs?

- Do they maintain buffer stock of key IP-rated connectors to protect your lead times?

Testing & Validation

- Waterproof cables should be qualified through:

- IP ingress tests (e.g., IP67 immersion / IP69K spray)

- Thermal cycling and vibration for mobile equipment

- Salt-spray tests for marine exposure

- Many vendors note in their literature that new or custom test profiles can take weeks to define, so bake this into your prototype planning.

Certifications

For critical applications, look for:

- ISO 9001 (quality management) and, where applicable, ISO 14001 (environmental) and ISO 13485 / IATF 16949 for medical or automotive.

- UL / CSA recognition for cable assemblies and components.

- Workmanship standards like IPC-A-620 / IPC-WHMA-A-620 for wire harnesses.

Customizations

- Waterproof assemblies often require:

- Non-standard cable jackets (PUR, TPE) for flexibility and chemical resistance

- Unique overmold geometry to fit housings or strain-relief channels

- Mixed power + signal in a single multi-pin connector

Ensure the supplier can help with DFM (design for manufacturability) and has tooling capacity for new molds if needed.

Order Quantities and Lead Times

- Discuss prototype vs mass-production timelines:

- Many shops quote 10–14 days for simple waterproof harness prototypes; complex overmolds or new test profiles can take longer.

- Clarify minimum order quantities for custom overmolds — some vendors allow low-volume pilot runs using modular tooling.

Engineering Support & Customer Service

- Prioritize suppliers who can:

- Provide prompt engineering feedback on drawings (48 hours is a common target)

- Suggest alternative connectors or IP strategies when supply constraints appear

- Offer clear documentation packages (test reports, IP certification, PPAP for automotive, etc.)

Waterproof Cable Assembly Manufacturers FAQs

What certifications should a waterproof cable assembly manufacturer have?

While an IP rating is essential, the best manufacturers back it up with key certifications that prove their quality process. Look for:

Specific IP Test Reports: Don't just accept an "IP68" claim. Ask for the actual test report that defines the test's depth and duration to ensure it matches your application's needs.

ISO 9001: Ensures consistent manufacturing processes, which is critical for repeatable sealing and overmolding.

IPC/WHMA-A-620: Guarantees reliable internal electrical connections before they are permanently sealed.

UL Recognition / CSA Certification: Verifies safety and component traceability, especially for the North American market.

How long does it take to manufacture custom waterproof cable assemblies?

Manufacturing timelines for custom waterproof cable assemblies depend on complexity and tooling. Simple prototype harnesses can often be completed in about 2–3 weeks when standard IP-rated connectors and existing overmold tools are used. Production runs typically take 4–8 weeks, based on connector lead times, custom molding, and testing requirements. Projects that require new tooling or bespoke IP test profiles, such as custom IP68 pressure testing or IP69K spray setups, may add several additional weeks beyond standard production schedules.

Can waterproof cable assemblies be used for permanent submersion?

Waterproof cable assemblies can be used for permanent submersion depending on their IP rating and how that rating is tested. IP67 covers only temporary immersion, typically up to 1 metre for 30 minutes. IP68 allows for continuous immersion, but only to the depth and duration defined by the manufacturer. IP69K is designed for resistance to high-pressure, high-temperature spray rather than submersion.

For true permanent underwater use, such as subsea systems or underwater lighting, it is essential to confirm the specific IP68 test parameters, the cable jacket’s water absorption properties, and the assembly’s long-term sealing performance.

OurPCB | Select the Right Waterproof Cable Assembly Partner for Your Program

If your application lives outdoors, in a washdown bay, under the hood or near the waterline, the cable assembly is often the first point of failure, or the quiet hero when designed correctly. OurPCB offers reliable waterproof cable assembly manufacturing for your assembly needs.

Use the quick comparison above to pick 3–4 candidates whose sector experience and certifications line up with your needs. Then, send them the same set of drawings and IP requirements so you can compare not just price, but also their design feedback and test approach.

Back to Top: Top 8 Waterproof Cable Assembly Manufacturers

Special Offer: Get $100 off your order!

Email [email protected] to get started!