Robotics cable assemblies are unlike ordinary cables, they must survive continuous motion, tight bend radii, torsion, vibration, electrical noise, and often harsh industrial or outdoor environments. Whether the robot is a 6-axis industrial arm, surgical robot, autonomous mobile robot (AMR), cobot, or agricultural rover, its cables must withstand millions of flex cycles while maintaining signal integrity and safety.

Leading robotics manufacturers typically choose partners with strong high-flex and continuous-motion cable expertise, including custom torsion-resistant constructions for rotating joints. These partners also offer EMI- and EMC-optimized cable geometries for sensors, encoders, servo motors, and high-speed communication. Appropriate quality and sector-specific certifications are important, such as ISO 9001, IATF 16949, or ISO 13485, depending on the application.

To help you navigate this specialized field, this guide provides an in-depth comparison of the top robotics cable assembly manufacturers, focusing on their technical capabilities, high-flex engineering, and proven reliability across key robotics platforms.

Contents

- Top 10 Robotics Cable Assembly Manufacturer Comparison

- 10 Reputable Robotics Cable Assembly Manufacturers

- 1. OurPCB

- Company Overview

- Robotics Applications

- 2. igus® – chainflex® & readycable®

- Company Overview

- Robotics Specialization

- 3. LAPP Group

- Company Overview

- Robotics Strengths

- 4. HELUKABEL

- Company Overview

- Key Capabilities

- 5. Molex (Robotics / Industrial Automation Division)

- Company Overview

- Robotics Specialties

- 6. TE Connectivity

- Company Overview

- Robotics Capabilities

- 7. Carlisle Interconnect Technologies

- Company Overview

- Notable Strengths

- 8. Alpha Wire

- Company Overview

- Robotics Uses

- 9. Nexans

- Company Overview

- Strengths

- 10. TPC Wire & Cable

- Company Overview

- Robotics Focus

- How to Choose a Robotics Cable Assembly Manufacturer

- 1. Look for High-Flex and Torsion Expertise

- 2. Evaluate Motion Requirements (Flex vs. Torsion vs. Hybrid)

- 3. Communication and Control Signal Integrity

- 4. Cable Material & Environmental Requirements

- 5. Assembly, Strain-Relief and Overmolding Quality

- 6. Scalability from Prototype to Production

- Robotics Cable Assembly Manufacturers FAQs

- What certifications should a robotics cable manufacturer have?

- How long do robotic cable assemblies last?

- What makes robotic cables different from standard industrial cables?

- OurPCB | Select the Right Robotics Cable Manufacturer for Your Applications

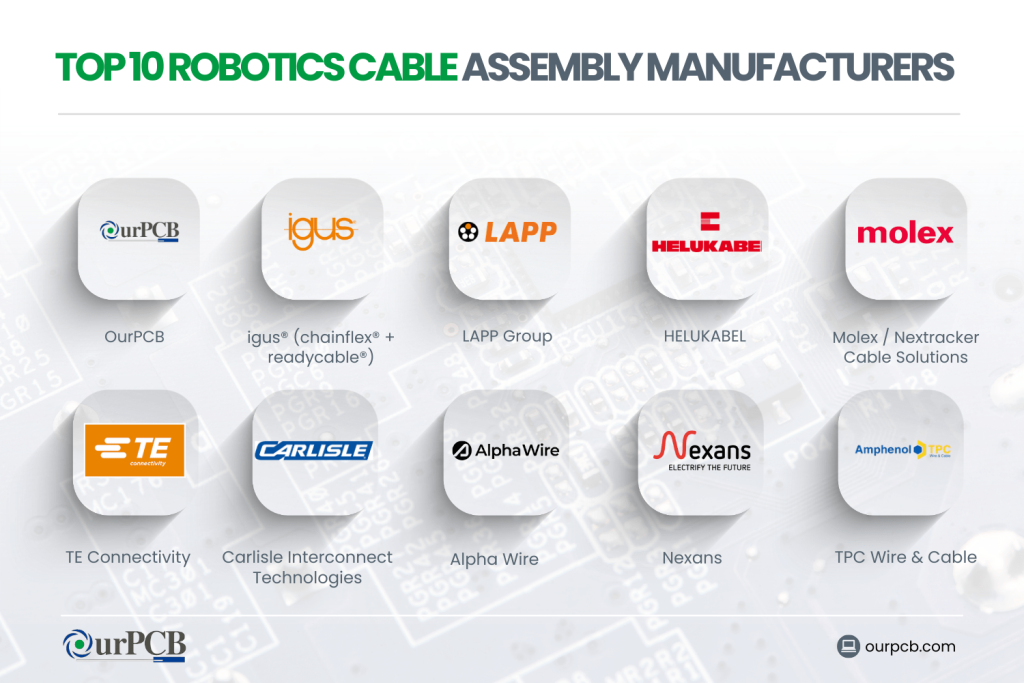

Top 10 Robotics Cable Assembly Manufacturer Comparison

| Manufacturer | Founded | Certifications* | Robotics Specialization |

|---|---|---|---|

| OurPCB | 2007 | ISO 9001, IATF 16949-capable, IPC/WHMA-A-620 | High-flex robotic cable assemblies, automation harnesses, AMR wiring, gimbal/actuator cables |

| igus® (chainflex® + readycable®) | 1964 | ISO 9001, ISO 14001 | High-flex robotic/drag-chain cables, torsion cables, pre-assembled servo/encoder chains |

| LAPP Group | 1957 | ISO 9001, UL, CSA, CE | High-motion robotic cables (ÖLFLEX® ROBOT), servo & motor cables, industrial automation |

| HELUKABEL | 1978 | ISO 9001, UL, CE | Robotic flex/ torsion cables, servo drives, drag-chain systems |

| Molex / Nextracker Cable Solutions | 1938 | ISO 9001, IATF 16949 | High-density connectors & robotic cable assemblies for harsh industrial use |

| TE Connectivity | 2007 (roots to 1941 AMP) | ISO 9001, UL | Robotic interconnects, servo-motor cabling, ruggedized signal assemblies |

| Carlisle Interconnect Technologies | 1940s | AS9100, ISO 9001, ISO 13485 | High-reliability robotic cables for aerospace, defense & surgical robotics |

| Alpha Wire | 1922 | ISO 9001 | High-flex robotic & automation cables (Xtra-Guard®, EcoFlex®) |

| Nexans | 1900 | ISO 9001, ISO 14001 | Industrial robotic cables for automation lines, robotics OEMs and power motion |

| TPC Wire & Cable | 1979 | ISO 9001 | Heavy-duty robotic cables for harsh industrial and welding environments |

| Epec Engineered Technologies | 1952 | ISO 9001, IPC/WHMA-A-620 | Custom robotic cable assemblies for industrial automation and motion systems |

*Certifications summarized based on publicly available data. Always verify current certificates during qualification.

10 Reputable Robotics Cable Assembly Manufacturers

1. OurPCB

Founded: 2007

Headquarters: China with global engineering support

Company Overview

OurPCB is a global electronics and cable assembly manufacturer with expanding capability in robotics cable assemblies, specializing in high-flex, torsion-resistant, and custom-length harnesses used in both industrial and mobile robotic systems.

Their engineering team focuses on:

- Continuous-motion cable assemblies designed for millions of cycles

- Torsion-stable cables for multi-axis robots, gimbals and joints

- Robot-ready harnesses for motors, encoders, sensors and communication loops

- Compact harnessing solutions for AMRs, AGVs, UAVs and small mechatronic assemblies

- IPC/WHMA-A-620 quality for wire harness production

- IATF 16949-capable processes for robotics and automation suppliers serving automotive customers

OurPCB's key differentiator is its ability to provide fully integrated electromechanical modules. For a robotics OEM, sourcing both the control PCBs and the custom high-flex cable assemblies from a single, qualified partner streamlines development, simplifies the supply chain, and ensures seamless integration between electronics and motion systems.

Robotics Applications

- Industrial robotics & cobots

- Autonomous mobile robots (logistics & warehouse AMRs)

- Robotic end-effectors & grippers

- Gimbal and actuator cables

- 3D printers, pick-and-place systems and CNC automation

- Medical and lab automation robots

2. igus® – chainflex® & readycable®

Founded: 1964

Headquarters: Cologne, Germany

Company Overview

igus is the gold standard for high-flex robotic and drag-chain cables, with the chainflex® series tested for tens of millions of cycles. Their readycable® line offers fully assembled servo, encoder and sensor cables built to OEM specifications.

Robotics Specialization

- Cables engineered for continuous motion, torsion and bending

- Pre-assembled harnesses for KUKA, FANUC, ABB and other robot brands

- High-speed feedback and servo motor cable solutions

- Extensive in-house robotic test labs simulating years of flexing

3. LAPP Group

Founded: 1957

Headquarters: Stuttgart, Germany

Company Overview

LAPP is known for its ÖLFLEX® ROBOT and ÖLFLEX® SERVO cable lines, engineered for rapid acceleration, continuous bending and multi-axis torsion.

Robotics Strengths

- Robotic motion cables validated for >10 million flex cycles

- Shielded communication cables (EtherCAT, Profinet, CAN, DeviceNet)

- Servo, encoder, motor and hybrid power/signal cables

- Custom assemblies with overmolding, labeling and strain relief

4. HELUKABEL

Founded: 1978

Headquarters: Hemmingen, Germany

Company Overview

HELUKABEL produces a wide range of robotic flex cables with special torsion-optimized jacket materials to handle ±360°/m torsion movement in multi-axis robotic arms.

Key Capabilities

- High-flex robotic servo cables

- Drag-chain and torsion cables

- Power, data, feedback & hybrid cable combinations

- Large catalog + custom builds for OEMs

5. Molex (Robotics / Industrial Automation Division)

Founded: 1938

Headquarters: Lisle, Illinois, USA

Company Overview

Molex provides high-density connectors and robotic cable assemblies for industrial controls, servos and motion systems. Their emphasis on electrical integrity makes them suitable for robots requiring precise sensing or control.

Robotics Specialties

- Servo feedback, encoder & sensor assemblies

- Compact harnessing for embedded robotics electronics

- Ruggedized connectors for vibration and shock

- Solutions for industrial robots, medical robotics and automated equipment

6. TE Connectivity

Founded: 2007 (AMP roots to 1941)

Headquarters: Switzerland / USA

Company Overview

TE develops highly reliable connector systems and robotic cable assemblies for industrial machinery, servos, actuators and advanced sensing.

Robotics Capabilities

- Servo motor cable assemblies

- High-speed signal and communication cabling

- Ruggedized connectors for harsh robotics environments

- Solutions for cobots, AMRs, SCARA systems and precision automation

7. Carlisle Interconnect Technologies

Founded: 1940s

Headquarters: USA

Company Overview

Carlisle specializes in mission-critical robotic cable assemblies, including aerospace robotics, medical robotics, and defense-grade manipulators.

Notable Strengths

- High-precision robotic cable assemblies

- Hybrid power + fiber + signal harnesses

- ISO 13485 and AS9100-certified facilities

- Excellent for surgical robots, UAV systems and robotic labs

Special Offer: Get $100 off your order!

Email [email protected] to get started!

8. Alpha Wire

Founded: 1922

Headquarters: USA

Company Overview

Alpha Wire offers cable families optimized for flex, chemical resistance and EMI stability, such as Xtra-Guard® and EcoFlex®.

Robotics Uses

- Industrial robot flex cabling

- Sensor, encoder and actuator cabling

- Harsh-environment and oil-resistant jackets

- Small robotic assemblies needing high reliability

9. Nexans

Founded: 1900

Headquarters: Paris, France

Company Overview

Nexans supplies advanced cable solutions for industrial robotics and automation lines worldwide.

Strengths

- Servo/motor cables for high-speed robots

- Data communication cables for factory systems

- Drag-chain optimized cabling

- Broad distribution and supply-chain depth

10. TPC Wire & Cable

Founded: 1979

Headquarters: Macedonia, Ohio, USA

Company Overview

TPC is known for extremely rugged cables, ideal for industrial robots operating in welding, metalworking, chemical exposure or heavy manufacturing.

Robotics Focus

- High-durability flex cables

- Cables for welding robots and harsh industrial settings

- High-temperature and abrasion-resistant designs

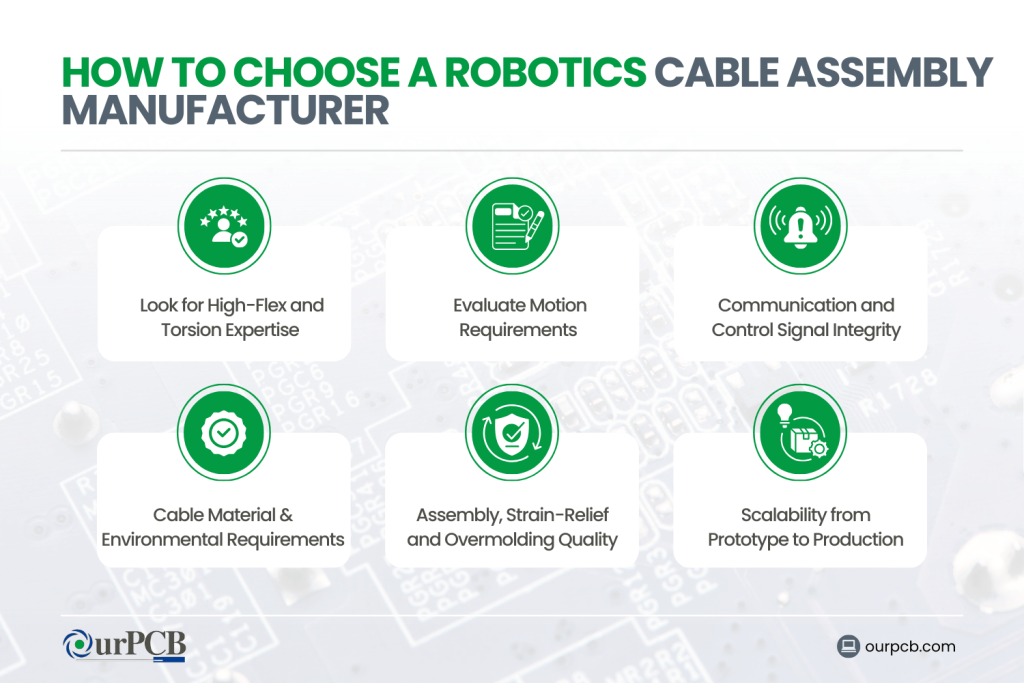

How to Choose a Robotics Cable Assembly Manufacturer

Selecting the right manufacturer for robotic cable assemblies depends on performance requirements, the type of robot, environmental conditions, and production scale.

1. Look for High-Flex and Torsion Expertise

Robotic cables fail primarily from:

- Repeated bending

- Torsional loading

- High accelerations

- Vibration

Choose manufacturers with:

- Millions-of-cycle flex testing data

- Validated torsion test results (e.g., ±360°/m)

- In-house drag-chain or robotic test labs

- Specific continuous-motion cable designs

Manufacturers like igus®, LAPP, and HELUKABEL are known for their extensive catalogs, while custom manufacturers like OurPCB provide specialized engineering for unique high-flex and torsion requirements.

2. Evaluate Motion Requirements (Flex vs. Torsion vs. Hybrid)

Robots use different cable motions:

- Axis 1–6 industrial arms → torsion + flex

- Gimbals / pan-tilt units → tight bending & rotation

- AGVs & AMRs → vibration + flex + abrasion

- Surgical robotics → micro-cables, EMI stability, sterilization

Choose a supplier with the motion profile expertise relevant to your system.

3. Communication and Control Signal Integrity

Robotics relies on:

- EtherCAT / PROFINET / CAN

- High-speed encoders

- Servo feedback loops

- Low-noise sensor signals

PVC cables won’t cut it — you need:

- Precise shielding & grounding

- Twisted-pair geometry

- Controlled impedance

- EMI-resistant materials

Component giants like Molex and TE Connectivity offer proven connectors, while assembly specialists like OurPCB and Carlisle excel at integrating these components into EMI-optimized, high-reliability harnesses.

4. Cable Material & Environmental Requirements

Consider:

- Oil resistance

- Chemical exposure

- Washdown-ready or IP-rated designs

- UV and outdoor durability

- High-temperature resistance

Your supplier should recommend jacket types such as PUR, TPE, FEP or robot-grade PVC.

5. Assembly, Strain-Relief and Overmolding Quality

The assembly itself is as important as the cable:

- Overmolded strain relief

- Reinforced entry points

- Correct crimp & solder standards (IPC/WHMA-A-620)

- Cable routing and bend-limiter design

Manufacturers like OurPCB, Epec and TPC excel at robust assembly.

6. Scalability from Prototype to Production

Ensure your partner can handle:

- Small prototype batches

- Pilot runs for validation

- High-volume production

- Custom labeling and documentation

- Stable supply chain for long-life robotics product lines

Robotics Cable Assembly Manufacturers FAQs

What certifications should a robotics cable manufacturer have?

A robotics cable manufacturer should hold ISO 9001 for overall quality management. They should also have relevant sector-specific standards, such as IATF 16949 for automotive robotics or ISO 13485 for medical and surgical robotics. UL and CE approvals for cables and assemblies are also important. In addition, the manufacturer should demonstrate adherence to IPC/WHMA-A-620 workmanship standards for cable and wire harness assembly.

How long do robotic cable assemblies last?

The service life of robotic cable assemblies varies by design and application. High-quality assemblies commonly achieve 5 to 10 million or more bending cycles and around 3 to 5 million torsion cycles. Even longer lifetimes are possible when materials are optimized and routing is well-designed. In practice, actual longevity depends on factors such as bend radius, operating environment, mechanical load, jacket material, and motion frequency.

What makes robotic cables different from standard industrial cables?

Robotic cables differ from standard industrial cables in that they use fine-stranded conductors, torsion-optimized constructions, multi-layer shielding, high-flex insulation materials, and abrasion-resistant jackets, all of which are specifically engineered to withstand continuous motion rather than stationary routing.

OurPCB | Select the Right Robotics Cable Manufacturer for Your Applications

Selecting the right robotics cable manufacturer is critical to ensuring long-term reliability, maximum uptime, and consistent performance, and the ideal partner should be chosen based on your specific robot type. OurPCB provides the required motion profile (bending, torsion, or hybrid movement), environmental operating conditions, and applicable certification requirements including ISO 9001, ISO 13485, or IATF standards.

Back to Top: Top 10 Robotics Cable Assembly Manufacturers

Special Offer: Get $100 off your order!

Email [email protected] to get started!