Leaded solder has been the preferred material applied in the PCB manufacturing world for many years. But in the recent past, there has been a heightened concern about the health and environmental effects of leaded products to consumers.

For these reasons, The European Union’s Restriction of Hazardous Substances in Electrical and Electronic Equipment (RoHS) regulated the use of leaded electronic products in July 2006.

Like the United States of America, some countries have not put up laws illegalizing the application of lead in consumer products.

Nevertheless, some businesses are demanding the use of lead solder on the electronic products they order. So, which solder is the best to use in the electronic world?

What is the difference between leaded solder and lead-free solder? This article answers these questions in detail and offers more insights about leaded solder and lead-free solder.

Contents

- 1. What is Lead vs. Lead-Free Solder?

- 1.1 Lead Solder

- 1.2 Lead-Free Solder

- 2. Comparing the Properties of Lead vs. Lead-Free Solder

- 2.1 Lead-free Solder Has Higher Melting Point than Lead Solder

- 2.2.Eutectic or Not

- 2.3 Health Concerns

- 2.4 Cost

- 2.5 Lead-free Solder has Poor Wettability than Leaded Solder

- 2.6 Comparing the Physical Features of Lead-free Solder and Lead Solder

- 3. The Switch to Lead-Free Solder

- 3.1 Growing of Metal Dendrite

- 3.2 Tin Whisker Growing

- 3.3 Creation of CAF

- 3.4 Tin Pest

- 4. Which Solder is Better for Use Between Lead vs. Lead-Free Solder?

- 5. Disadvantages of Lead-Free Solder

- High Melting Point

- Low Wettability

- Deposit Formation

- Tin Whisker Formation

- Metal Dendrite Formation

- High Cost

- 6. Effects of Lead vs. Lead-Free Solder on Different Types of Soldering

- 7. What Happens if You Mix Lead and Lead-Free Solder?

- Conclusion

1. What is Lead vs. Lead-Free Solder?

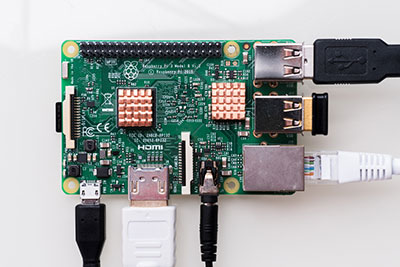

Most electronic manufacturers use solder to stick components to PCBs. Whether it is a lead-free or a leaded solder, they all serve the same function.

Nevertheless, various devices and use cases utilize different soldering techniques.

1.1 Lead Solder

Generally, leaded solder is composed of tin and lead. The advantage of using leaded solder is its adequate flowing capacity. It has a lower melting point than lead-free solder, hence presenting less thermal effects to components.

Besides, when the solder cools down, it assumes a brighter appearance than lead-free solder, making it easy for you to detect issues like oxidation. Furthermore, lead solder is cheaper and easier to use than lead-free solder.

1.2 Lead-Free Solder

The main reason why manufacturers are shifting to the use of lead-free solder is to eradicate lead from electronic production and waste recycling processes.

In the past two decades, the electronic manufacturing world has experienced a dynamic development of alternative soldering materials centered on tin metal.

This alternative approach uses materials with properties that are distinct from the lead and tin eutectic composition.

Since soldiers are effective at 80% of their melting point, they call for performances similar to the jet engine superalloys.

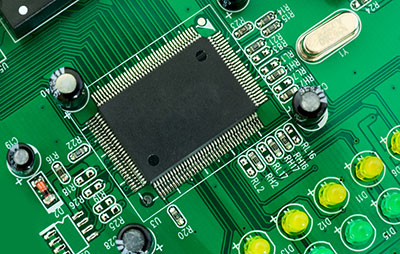

However, solder joints requirements are continually increasing because of the rising density and stress properties from miniaturization.

Therefore, lead-free solders need a PCB design that accommodates the high melting point and anisotropic properties.

2. Comparing the Properties of Lead vs. Lead-Free Solder

The use of high quantities of lead in consumer products over an extended period causes harmful effects on the environment and people.

Currently, companies have shifted to lead-free soldering to support their social responsibility efforts of protecting the environment.

Thus, it is crucial to learn how lead-free solder compares with leaded solder and examine the better option for use.

2.1 Lead-free Solder Has Higher Melting Point than Lead Solder

Lead solder has a melting point of 1830C, while lead-free solder has a melting point of 2170C. Now, these are the effects of the higher melting point of lead-free solder:

- The higher temperature of lead-free soldering oxidizes the solder quickly compared to the lower temperature of lead soldering.

- Like those containing plastic packages and electronic capacitors, some components are negatively affected by the high soldering temperature of lead-free solder.

- The high temperature of lead-free solder comes with significant component stress; therefore, low-dielectric components are more vulnerable to failures.

- Lead-free solder components have several soldering surfaces. Companies often use tin on such surfaces because it is cost-effective. However, the tin generates a small oxidation coat on the outside that can lead to electroplating.

2.2.Eutectic or Not

Manufacturers valued the use of tin and lead because it formed a eutectic mixture. In other words, the lead and tin composition have a lower temperature than the individual metals' temperatures.

Although the electronic manufacturing world has not managed to discover another eutectic metal combination, it has invented a lead-free soldering technique that works well.

2.3 Health Concerns

Companies sensitive to environmental conservation state the poisonous nature of lead as their main reason for embracing lead-free soldering.

Lead can indeed accumulate in the human body, even from small prolonged exposures.

Furthermore, lead can quickly enter your body through the skin, mouth, or nose.

The paint and gasoline sectors have all gone lead-free. However, solder is among the remaining products that still use it.

In an industry experiencing high lead emissions, workers are more vulnerable to the dangers of lead as they can quickly inhale it or get it by touching contaminated surfaces.

Remember, lead is more dangerous to children. Therefore, take these health concerns seriously wherever you are using lead solder.

2.4 Cost

Leaded solder is more cost-effective than lead-free solders. This is because lead is barely a tenth of the tin price, making lead solder easily affordable.

Furthermore, some manufacturers replace tin with silver in lead-free solders, making them even more expensive.

2.5 Lead-free Solder has Poor Wettability than Leaded Solder

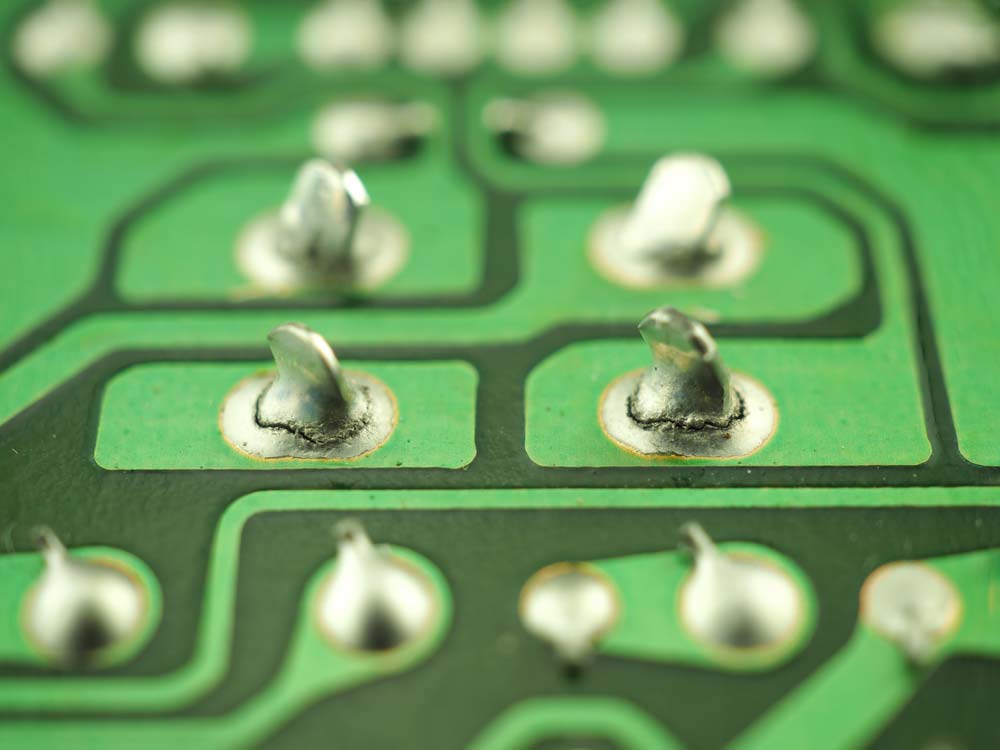

Low wettability makes the solder joint function ineffectively in meeting the demands of self-regulation ability, tensile power, and shear capacity.

Consequently, low wettability causes a high rejection rate of solder joints, especially when you fail to conduct adjustments to cater to this shortcoming.

2.6 Comparing the Physical Features of Lead-free Solder and Lead Solder

Lead-free solder has a negative joint reliability impact. From a mechanical influence point of view, lead-free solder is stronger than leaded solder.

Furthermore, lead-free solder forms surface oxides, flux impurities, and alloy deposits that can cause poor contact resistance performance.

Therefore, the shift from lead to lead-free electronic production is not a total replacement in electrical and mechanical features due to these reasons:

- The lead is comparatively soft. You will realize that lead-free production solder joints are harder than lead manufacturing solder joints. This causes heightened intensity and minor modifications, which result in high reliability.

- Lead-free soldering causes low wettability, igniting more problems, such as vacancy and tomb standing.

3. The Switch to Lead-Free Solder

When considering the type of solder to use between leaded and lead-free solder, it is essential to realize that the primary difference is the high tin levels.

Therefore, you should weigh the following concerns in your selection process.

3.1 Growing of Metal Dendrite

It is important to note that metal dendrite and tin whisker have different growth procedures.

Metal dendrite is a product of ionic electro-transfer in electrochemistry.

On the other hand, tin whisker forms shortcuts that further lead to circuit failure.

3.2 Tin Whisker Growing

Tin whisker develops from vulnerable parts of tin oxide coating as monocrystal tin, acting in columnar nature or cylindrical filament.

The whisker can result in shortcuts between adjacent pins. Additionally, it can generate a bad influence on high-frequency components.

Tin soldering coats contain pressure stress, which is one of the main factors that create tin whiskers.

For instance, when too much Cu6Sn5 metallic alloy occurs, it causes several faults, like pressure stress build-up on the tin coat, pin distortion, and CTE mismatching, further creating a tin whisker.

High quantities of tin alloy also cause tin whisker, which is more pronounced in pure tin. Luckily, several metal alloys, such as PB and Bi, can prevent tin whisker growth.

3.3 Creation of CAF

Electrochemical processes also cause another failure known as a conductive anodic filament (CAF).

Anode conductive filament bearing some copper growth from the positive electrode to the negative electrode triggers CAF formation. The process occurs within the circuit board.

Typically, CAF grows when the positive and negative electrodes are linked using short circuits.

This leads to a catastrophic tragedy for highly-compacted PCB manufacturing. The high melting point of lead-free solder accelerates CAF formation.

3.4 Tin Pest

Impulsive polymorphism phase modification causes tin pests. Usually, when the temperature is less than 130C, uncontaminated tin will change from white to grey.

Ideally, tin pests cause potential reliability threats. However, you will rarely notice it as the contamination combines with iron.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

4. Which Solder is Better for Use Between Lead vs. Lead-Free Solder?

Contrary to the health and environmental information on lead electronics, the Aerospace Corporation carried out a study on the application of lead in consumer electronics.

The study found that there is little evidence supporting the argument that the lead applied in electronic gadgets causes severe harm to the environment and people.

The truth is that when we refer to electronic rework, the number of lead manufacturers used is insignificant to be harmful to animals.

Use lead solder if it is available in your nearby markets. This is because it is easier to use, has a lower melting point, and causes fewer quality problems with the joints.

The primary reason you should opt for lead-free solder is if your government prohibits lead use.

Besides, you can also consider it if you plan to sell your products to European countries.

Remember, the amount of lead on solder is insignificant to cause some severe health complications.

Generally, it is more economical and effective to use lead solder because of its unique properties and benefits.

5. Disadvantages of Lead-Free Solder

Lead-free solder might be safer for the environment, but it has its downsides.

High Melting Point

Lead-free solder has a high Tin content to replace Lead metal, but this composition increases its melting point.

And remember, you have to melt the solder to wet the pads to bond the components to the board.

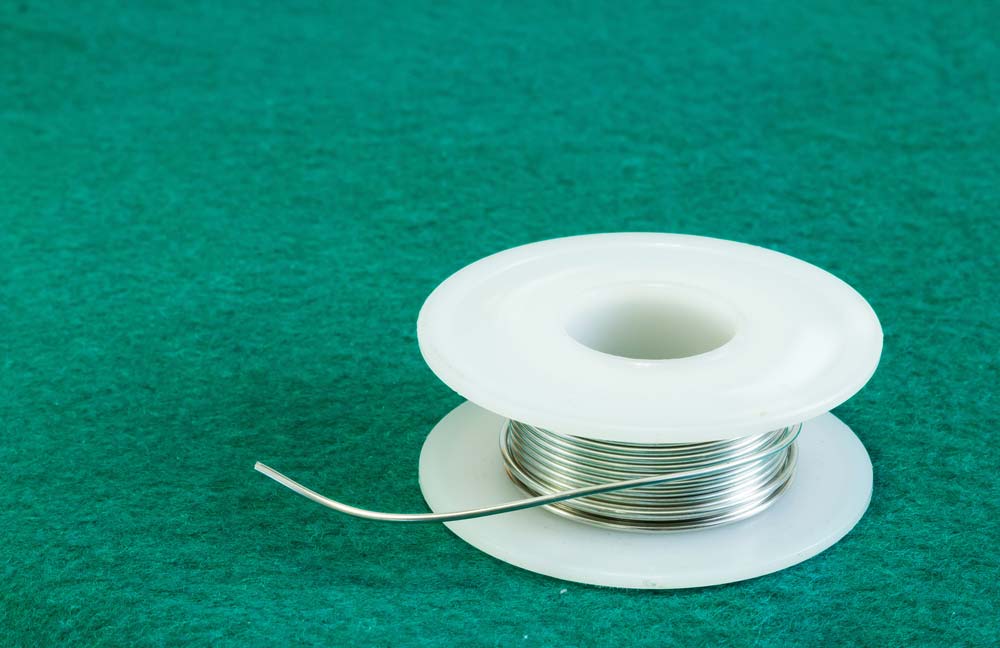

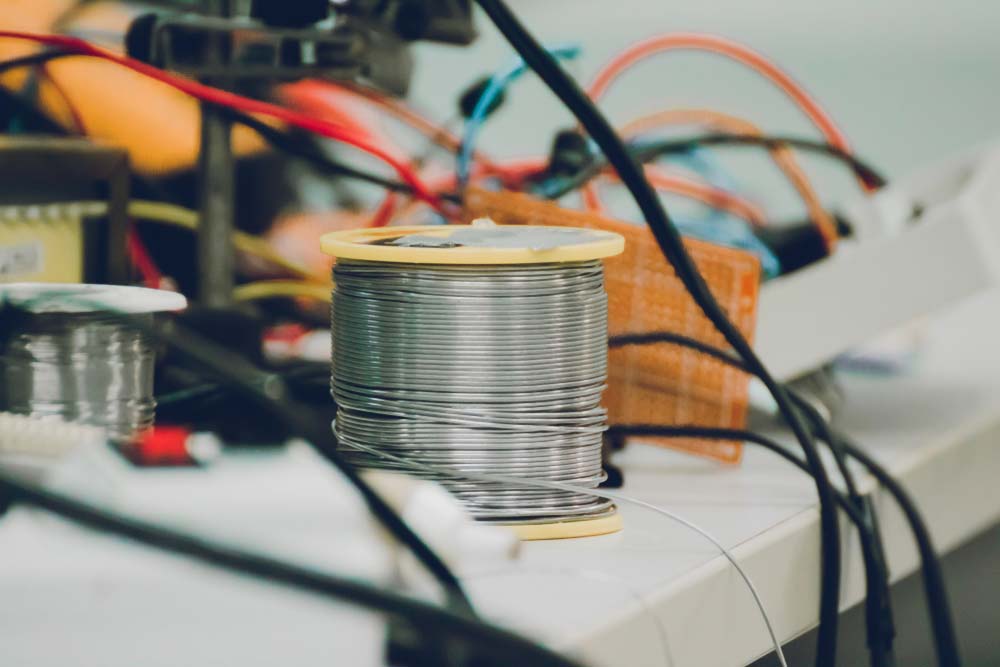

A roll of Lead-free solder wire

Soldering

at these high temperatures stresses all electronic components but can damage those with plastic packages, electrolytic capacitors, and parts with low dielectric constants.

The high heat can also damage the circuit board by peeling signal track pads from the dielectric surface.

Low Wettability

does not flow as freely on the PCB contact pads and bonds to them more easily than Lead-based solder. Therefore, the solder joints can have low tensile strength, self-regulation, and shear capacity.

Cracked solder joints

Deposit Formation

Lead-free solder naturally forms alloy deposits, flux impurities, and surface oxides, all of which can affect the solder joint by creating a weak electrical connection. This weak electrical connection affects component performance in the circuit.

Tin Whisker Formation

The high Tin content in Lead-free solder can form Tin whiskers as the molten metal cools and solidifies. These conductive structures can connect adjacent pins or pads, short-circuiting the circuit board.

Metal Dendrite Formation

Metal dendrites are unwanted conductive structures that can short-circuit the circuit board by creating electrical contact between pads or pins. But their structure resembles snowflakes or trees.

High Cost

Tin is safer for the environment than Lead but costs more, making Lead-free solder more expensive. Some Lead-free solder varieties even contain silver metal, which is costlier than Tin.

6. Effects of Lead vs. Lead-Free Solder on Different Types of Soldering

Although using Lead-free solder can lead to quality issues, your PCB manufacturer can control these effects by adjusting the soldering parameters.

For instance, the selected Lead-free solder for wave soldering to attach through-hole components should match the design parameters. It should also match the usage demands of the assembled board.

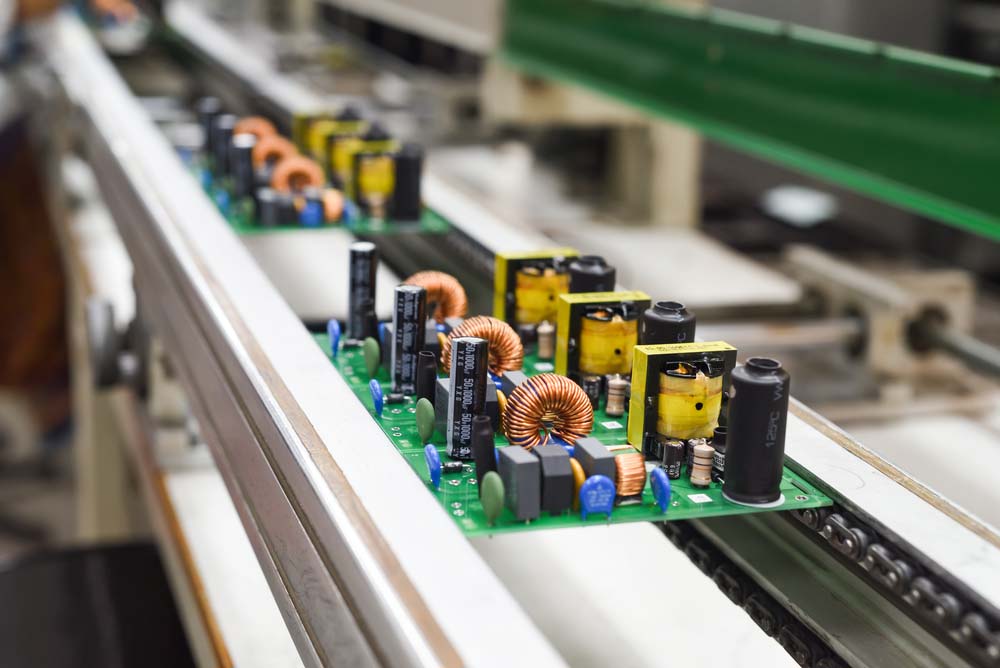

Manual component insertion along a conveyor belt before wave soldering

When attaching surface-mount components, the PCB layout and component selection matter. Reflow soldering exposes the board to high temperatures for longer, which can damage sensitive electronic components and decompose metal.

Therefore, the board layout and component selection should match the solder type.

Your PCB manufacturer should implement these parameters to ensure the solder joint quality matches that of Lead-based solder.

A reflow oven

7. What Happens if You Mix Lead and Lead-Free Solder?

Environmentally and legally, mixing the two causes a contamination issue.

Therefore, you can’t sell the board or final product in jurisdictions that don’t allow electronics with Lead.

And on the integrity of the solder joint, Leaded and Lead-free solder do not mix evenly when hot.

This mix creates different alloys on the solder joint, resulting in residual stress when the metal cools.

A roll of Lead-based solder wire

Also, you’ll have to heat the Lead-based solder to temperatures above the optimal melting level to liquefy the Lead-free solder. These high temperatures can quickly vaporize the flux in the Lead-based solder, creating voids in the joints.

Conclusion

Leaded solder comes with numerous benefits for electronic manufacturing, but the tides of change are raging. All sectors that use solder in large quantities are likely to shift to lead-free soldering soon if they have not done so yet. Besides, there may be insufficient solder in the market for hobbyists as various governments set up eco-friendly measures.

Just like with any change, some individuals resist the use of lead-free solder. However, the shift to a safer method is necessary and undoubtedly inevitable regarding human health and safety.

We acknowledge that various projects demand different soldering approaches. That is why we provide both lead and lead-free soldering for PCB assembly. If you require any of these soldering techniques, we are available to offer you customized services! Contact us today for a free PCB assembly quote.

Special Offer: Get $100 off your order!

Email [email protected] to get started!