Who are the Top 6 Data Cable Manufacturers in China?

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

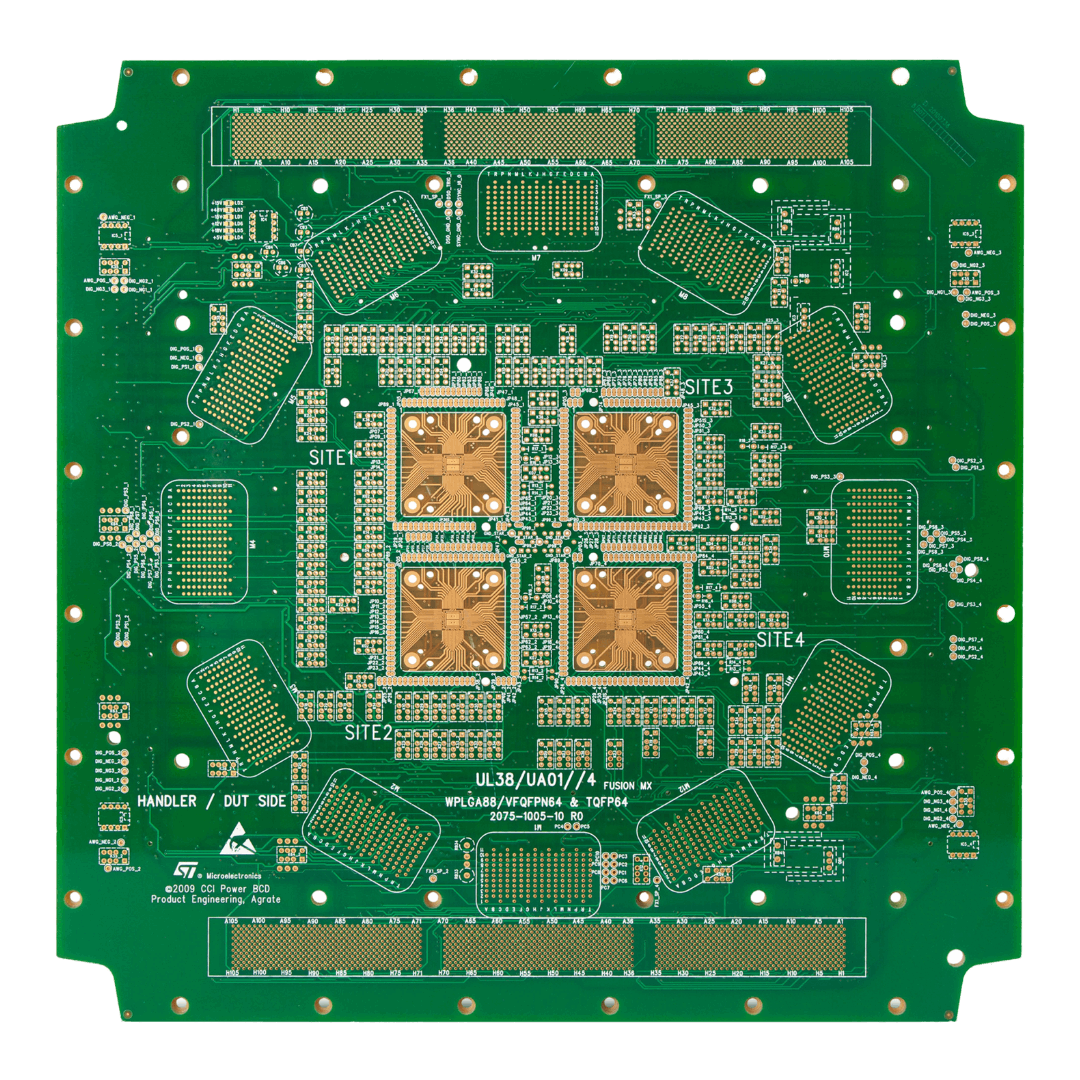

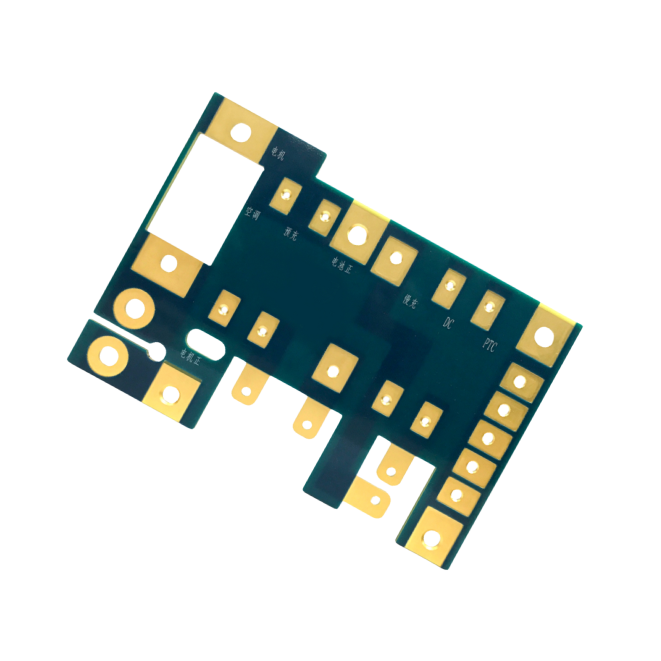

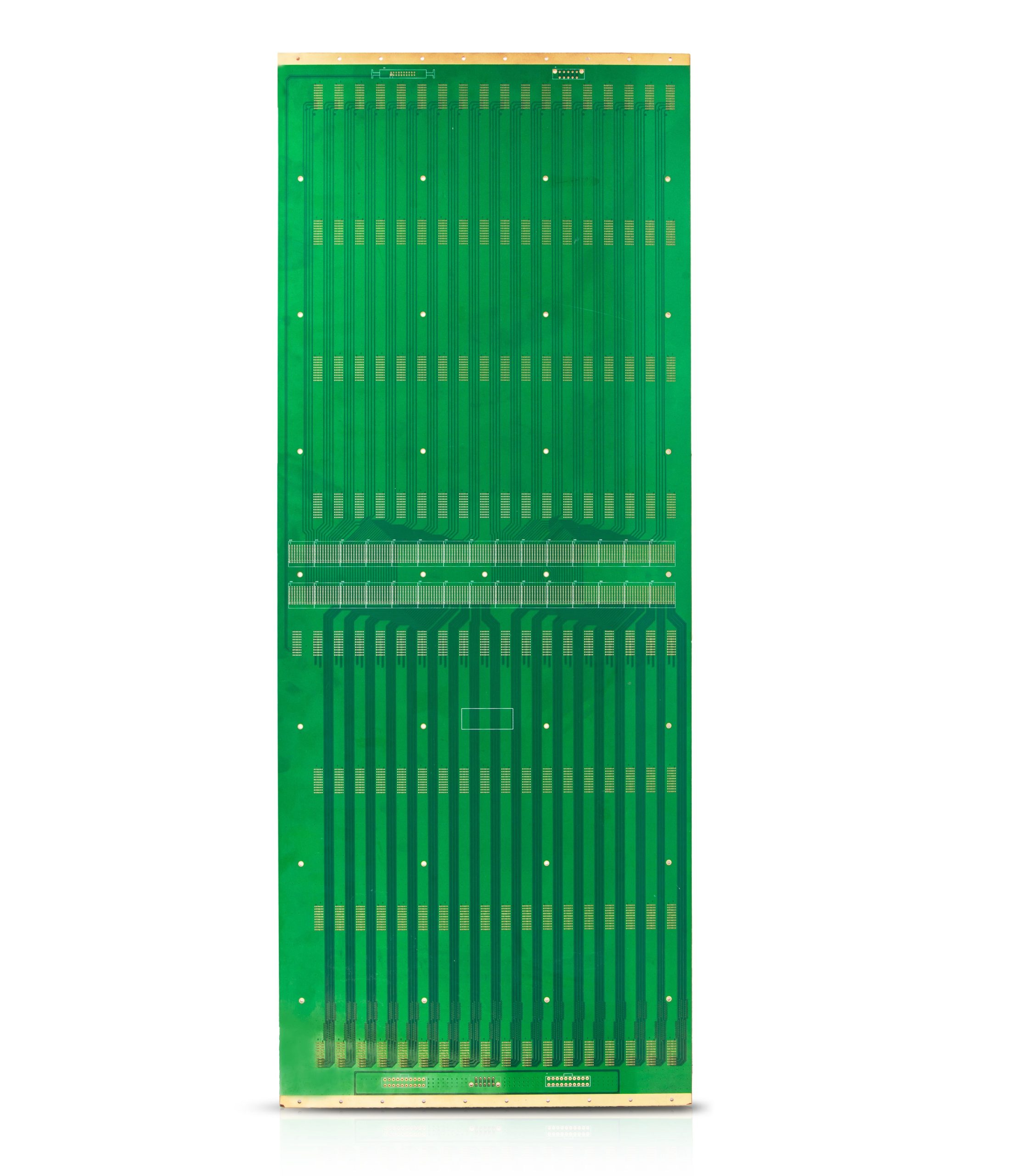

As a 16-layer PCB manufacturer, we build advanced circuit boards made of 16 stacked conductive layers, allowing for complex routing and high signal integrity. We serve industries like aerospace, telecommunications, medical devices, and high-end computing that require dense, multi-functional designs.

OurPCB delivers highly specialized 16-layer PCB manufacturing services for the most sophisticated electronic applications. Our expert approach ensures your complex high-density printed circuit board designs receive the specialized engineering attention and manufacturing precision they demand.

For advanced 16-layer PCB stack-ups, OurPCB provides specialized PCB consultation and custom manufacturing solutions. While our standard capabilities chart details up to 12 layers, we can accommodate sophisticated 16-layer designs with our technologically advanced manufacturing processes and extensive multilayer manufacturing expertise.

| Specification | PCB Capability |

|---|---|

| Layer Counts | 1-64 layers |

| Lead Time | Normal: 5-6 Days Expedited: 24-48Hours |

| Materials | FR4, Metal Core, Arlon, Taconic, Nelco, Isola, Halogen Free, Rogers, PTFE, PI,etc. |

| Max. Copper | 1000um |

| Finished Board Thickness | 0.1 – 12 mm |

| Size of Finished Products(Max) | 22.5 * 47.2 inch |

| Size of Finished Products(Min) | 2 * 5mm |

| Min. Line/Track Width&Space of Inner Layer | 1.8/1.8 mil |

| Min. Line/Track Width&Space of Outer Layer | 2/2 mil |

| Buried / Blind Via (Non-cross) | 0.1 mil |

| Aspect ratio | 40 : 1 |

| Min. Drilling Size(Mechanical) | 0.1 mm |

| Surface Treatment | HASL, Lead free HASL, ENIG(+ G/F), Immersion silver/Tin, OSP, ENEPIG, bare copper. |

| Wrap and Twist | ≤0.5% |

| Tolerance PTH/ Pressing fit hole /NPTH | ±0.0762 mm /±0.05mm /±0.05mm |

| Drill tolerance | ±2mil |

| BGA pitch | 8mil |

| Layer to layer registration | ±3mil |

| Advanced Via & Hole Structures | Blind/Buried Vias, Via-in-Via, Mechanically Crossed Blind Vias, Stacked Vias, Via-in-Pad |

| Impedance Control | ±5Ω (<50Ω), ±10% (≥50Ω) |

| HDI | 18L any layer HDI (8+N+8 structure) |

| Qualifications | ISO14001:2015, ISO9001:2015, ISO 13485:2016, IATF16949: 2016, Certified |

OurPCB combines extensive multilayer circuit board expertise with advanced PCB fabrication and PCB assembly capabilities to deliver exceptional 16-layer solutions for your most demanding electronic applications.

OurPCB leverages decades of multilayer PCB expertise to accommodate highly specialized 16-layer projects. These advanced designs extend beyond our standard catalog capabilities and receive custom attention and specialized manufacturing processes tailored to your specific requirements.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

The custom quote process for 16-layer PCBs is the same as for other types of PCBs. Please submit your design files for review, and our team will contact you to discuss your specific requirements and provide a custom quote within 12 hours.

Common configurations include alternating signal and plane layers, with power and ground layers placed symmetrically. We offer stack-up engineering support to match your electrical and mechanical requirements.

For 16-layer PCBs, we recommend specialized high TG FR-4 materials engineered for complex multilayer applications. Our materials experts will consult with you to select the optimal substrate based on your specific electrical, thermal, and mechanical requirements.

Our custom quoting process will determine lead times for 16-layer PCBs. After reviewing your design specifications, our project management team will develop a tailored production schedule based on design complexity, material requirements, and current production capacity.

We use automated optical inspection (AOI), X-ray verification, electrical testing, and multi-stage QC protocols to check internal layer alignment, solderability, and electrical performance throughout production.

Board thickness depends on your material selection and copper weight. We support a range of thicknesses, usually from 0.3 mm up to 10 mm, and can advise based on your specific application.

Yes, we support blind, buried, microvia, and via-in-pad structures for high-density interconnects. These features require advanced lamination and drilling steps — both are part of our 16-layer PCB fabrication capabilities.

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree