In recent years, Flex PCB Prototype is in high demand in the market. As a PCB small buyer or distributor, it is essential to know some necessary information about these products and their suppliers to avoid losing money, time, resources, and energy. This article aims to allow you to grasp the importance of knowing the flex PCB suppliers and the services they can render.

Below is a list of the basic things you need to know about your flex PCB supplier to ensure quality products upon delivery:

(Flexible road pavement in blue plastic film)

Contents

- 1. Understand the Qualifications of Flex PCB Suppliers.

- 2. Production Equipment that Flexes PCB Suppliers Can Provide.

- 3. The Flex PCB Supplier Can Provide Materials, Usually.

- 4. Understand the Flexible PCB Manufacturing Process.

- 5. Send your Flexible PCB Prototype to the Supplier.

- 6.Variety of Flexible Circuits, Standard Supply.

- Single-side flexible circuit.

- Double-side flexible circuit.

- Multilayer flexible circuit.

- 7. Understand Inspection Standards.

- 8.The Capable, Flexible PCB Production Team.

- Conclusion

1. Understand the Qualifications of Flex PCB Suppliers.

Before you contract your PCB prototype to any supplier, it is essential to know their qualifications. There are different flex PCBs, and some suppliers have more skill sets and experience than their counterparts. Contracting your PCB prototype to the wrong supplier can cause getting poorly manufactured flex printed circuit boards. Ensure to ask as many questions as possible such as

How many times will your PCB flex?

How thin or thick will the overall PCB be?

The answers your flex PCB prototype suppliers give to your questions will enable you to know if they can handle the project or not. Work closely with your supplier, and if you need any change in the design, you will effect changes in due time. Know your flex PCB suppliers and their capabilities. You don’t want to end up with a prototype that you cannot manufacture. Since prototyping is more like trial and error, pay attention to your flex PCB supplier's strengths and weaknesses, and know the areas that need improvement.

(Circuit Board Technology Information Pattern Concept Vector Background)

2. Production Equipment that Flexes PCB Suppliers Can Provide.

Before the PCB manufacturing process begins, ensure that your flex PCB supplier has the manufacturing and assembly processes' equipment. To produce a high flexible PCB prototype, your supplier will need to have some stuff. Some of them include:

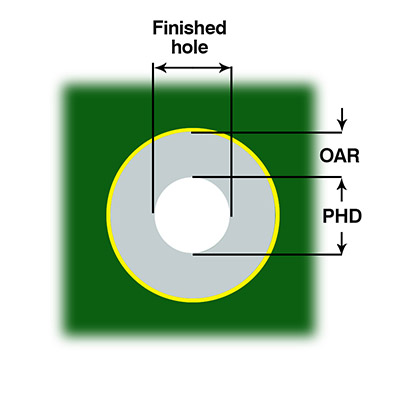

- Drill: in the manufacturing process of the PCB prototype, you can use the exercise to make holes for double-sided or multi-layer flex printed circuit boards. The training can either be CNC drill I or laser drill.

- Exposure machine: during the manufacturing process of flexible circuit boards (FCBs) prototypes, you can use the exposure machine to make the photo imaginable film's circuit. This is the roll to roll process.

- Gold plating machine: you can use it for the surface treatment of the FCB prototypes for better solderability or prevent discoloring.

- Bare board tester: this is the instrument you can use to check flexible circuit board prototypes' electrical performance.

The flex PCB supplier must invest in quality manufacturing equipment to increase efficiency and provide you with quality flex PCB prototypes.

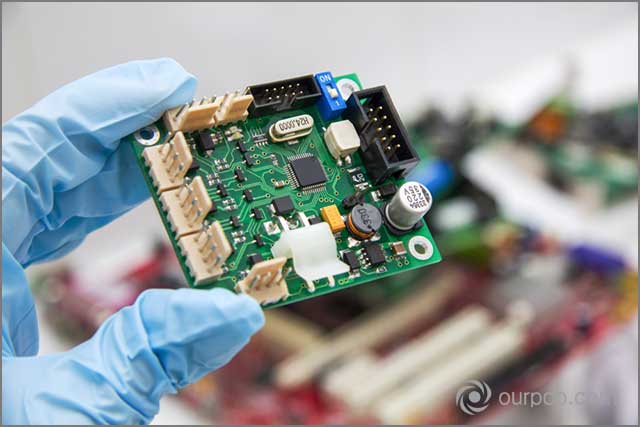

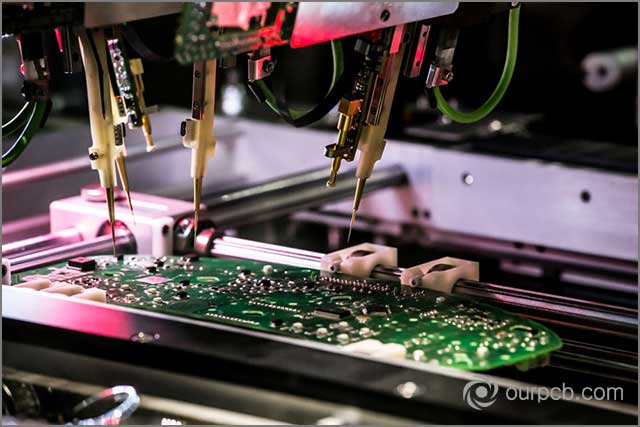

(Hand in a blue glove holds PCB chip assembly on PCB background on the production of printed circuit boards)

3. The Flex PCB Supplier Can Provide Materials, Usually.

With the increasing demand for portable electronics in recent years, your PCB suppliers need to make provision for the right material for the production of flex PCB prototypes because you can shape FCBs into various designs. Using the right materials for the production of flex PCBs will ensure the retention of precision, and the packaging of the finished products will be more comfortable.

One advantage of your flex PCB supplier providing the right materials is that there will be a limitation to any technical issues. This will lead to a reduction in the trial-and-error processes and cost, time, and resources wastage.

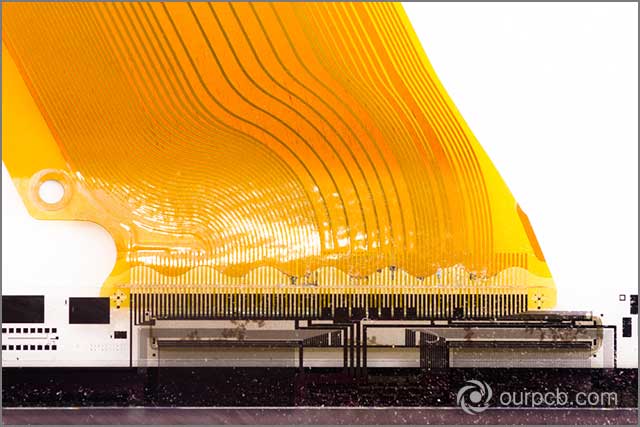

(Flexible Printed Circuit and electronic part on circuit PCB)

Special Offer: Get $100 off your order!

Email [email protected] to get started!

4. Understand the Flexible PCB Manufacturing Process.

Your flex PCB supplier must have adequate knowledge of the flexible manufacturing process. Over the years, flex PCBs have become popular because of the many advantages. Flex PCBs are lightweight, have a tiny volume, and good quality. Because of their ability to extend to three-dimensional space, there is an improvement in the freedom of circuit design and the mechanical structure design.

Your flex PCB supplier must understand that different flex PCBs have different manufacturing processes. For instance, the manufacturing of the double-side flex PCB differs from that of single-side flex PCB. Also, flex PCBs can withstand extreme temperatures, which is why you can use them in the oil and gas industries.

Flex PCBs are usually small devices that you can use in industrial environments. By ensuring that your flex PCB suppliers know the manufacturing process, you will save cost, energy, time, and resources.

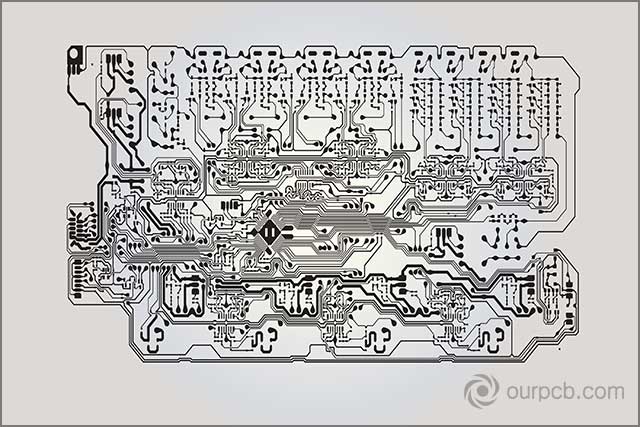

(Circuit Board of Technology Information Pattern Concept Vector Background. Black Colour Abstract PCB Trace Data Infographic Design Illustration)

5. Send your Flexible PCB Prototype to the Supplier.

To ensure that your PCB suppliers make the right selection of materials and equipment, send your flex prototypes to them. Conclusion: there are several flex PCB companies globally, but choosing the best one will save you a lot of time and resources. By sending out your prototype to them, you will know if they have what it takes to deliver the best to you. Choose a supplier that has a good reputation and experience in flex PCB.

The provision of flex PCB prototypes reduces the time and the cost you will spend during the production process. The prototypes are the sample boards you can use to test your designs and fix any mechanical problems. By sending your prototype to your flex PCB suppliers, you will give room for improvement, and this will ensure that the finished goods are error-free.

Send a file to the supplier and let the supplier tell you if they can make it and how to make it. Ensure to contract the job to a competent supplier to ensure quality PCB products. Let the supplier review and analyze the files to know the design and make the corrections before the production process starts. By doing this, you will know the design-related errors and correct them before the beginning of the production process. It will prevent delays and help save costs, time, and resources.

(Circuit Board of Technology Information Pattern Concept Vector Background. Abstract black and white PCB Trace Infographic Design Illustration)

6.Variety of Flexible Circuits, Standard Supply.

Your flex PCB supplier must understand the variety of flexible circuit boards. By equipping themselves with the right information, they will know the materials to buy for the design process of your flex PCB prototype. Since flex PCBs' design rules are like traditional ones, the supplier should not have much difficulty while getting the materials.

Some types of flexible circuit boards designs include:

-

Single-side flexible circuit.

This flex PCB contains a single conductor layer, a metal or conductive metal-filled polymer that you will mount on a flexible dielectric film. The assembly is only available on one side of the board. You can make a single-sided flexible PCB with or without a protective layer, but you need to use a flexible PCB for the best protection.

-

Double-side flexible circuit.

This flex PCB contains two conductor layers. You can fabricate this flex PCB with or without plated through holes, but it is often common to drill plated holes in the boards.

-

Multilayer flexible circuit.

This flex PCB contains over two conductor layers, and you can interconnect them by plated through holes.

With the knowledge of the different flex PCBs, your supplier will choose the materials that suit your prototype's design and provide the regular supply that is cost-effective.

(Detail of flexed printed circuit board (FPC) connected to LCD isolated on white)

7. Understand Inspection Standards.

Your flex PCB supplier must understand the inspection standards that apply to the flex PCB products. There are different inspection standards, such as the flex PCB standards of each country, the industrial standard for each country, the technical requirements on the PCB design drawings, and each country's military rules.

Also, there are different inspection methods that you can use to assess the quality and reliability of your flex PCBs. They include the Automatic/Automated Optical Inspection (AOI) method and the X-ray inspection method.

An in-depth understanding of the inspection standards and practices will ensure that the flex PCB supplier provides the right materials to aid a successful production of your flex PCBs.

(Vision measuring instrument inspecting PCB circuit board)

8.The Capable, Flexible PCB Production Team.

The success of the design of your flex PCB prototype depends on the production team. Ensure that you choose a flex PCB company or supplier that is effective and reliable. You don’t want to end up with a prototype design that you cannot manufacture as it will lead to wastage of money and resources. Ask for the flex PCB manufacturability and product performance before contracting the project to any supplier.

(Multi-purpose flying probe system for the broadest range of test requirements)

Conclusion

With the right information about your rigid flex PCB suppliers and their capabilities, you will know the best option to choose from the many suppliers in the world. Choosing a supplier who has a capable PCB production team will save you cost and time. Your prototype will be error-free, and you can move on to the fabrication process with no worries.

Are you looking for the best flex PCB supplier around you? OurPCB is the right option for you. At OurPCB, we have a capable flex PCB production team with experience and skillsets to make your prototypes error-free as much as possible. Contact us today to get the worth of your money.

Special Offer: Get $100 off your order!

Email [email protected] to get started!