As electronics advance and components get smaller, they need cutting-edge equipment for accurate assembly. SMT lines are some of the most vital production lines in the PCB assembly process, and they contain several sophisticated machines for mounting devices on the surface. We have looked at the SMT line below, including the processes, types, and machines. PCB fabricators play a critical role in ensuring these lines operate efficiently and produce high-quality assemblies. Read on to learn more!

Contents

- What is the SMT Line?

- Why Do We Use SMT Lines?

- Safe

- Save Costs

- Produce High-Quality Circuits

- Improve Customer Satisfaction

- Main SMT Line Fields

- Semiconductor Industry

- LED Industry (Lighting)

- Automotive Electronics Industry

- Smart Industry for Home and Work

- Electronic Consumer Goods (Appliances) Production Industry

- Process of SMT Manufacturing

- Material Preparation and Examination

- Stencil Preparation

- Solder Paste Printing

- SMC Placement

- Reflow Soldering

- Cleaning and Inspection

- Main SMT Line Machine

- Pick and Place Machine

- Solder Paste Mixer

- Oven

- SMT Loader

- Solder Paste Printing Machine

- Solder Paste Inspection (SPI) Machine

- Reflow Machine

- AOI

- Docking Station

- SMT Unloader

- Types of SMT Production Line Layout

- SMT Line Cost

- SMT Line Development Trends

- CIMS Application

- Efficiency Improvement

- Environmental Protection

- Flexible Information Integration Production Environment

- Summary

What is the SMT Line?

SMT is an abbreviation of the word Surface Mount Technology. On the other hand, the line refers to the production process used to mount electronic components directly onto a circuit board. It primarily consists of SMT machines, and these are the assembly line equipment needed to produce complete PCBs.

Why Do We Use SMT Lines?

We use SMT lines because they:

Safe

Using SMT production line equipment reduces the risk of injury because it makes the workers work less directly with the machine.

Save Costs

A complete SMT production line helps save on costs by:

- Reducing the need for manual labor

Automated PCB manufacturing

- Enhancing production efficiency and shortening the production cycle

- Eliminating the need to store semi-finished components in the production process, which requires more space, hence more rent costs

Produce High-Quality Circuits

In addition to enhancing the production efficiency, SMT lines lower the defect rate because machines are more precise. The result is high-quality PCB production.

Improve Customer Satisfaction

Since the SMT production line improves quality and shortens the production cycle, it will lead to faster delivery of high-grade circuit boards. Such a production process will improve customer satisfaction.

Main SMT Line Fields

Semiconductor Industry

SMT and Semiconductor production is traditionally independent. However, integrating the two is a common practice nowadays due to the advancement in packaging technology.

Semiconductor packaging companies use SMT mounters to fit passive electronic components. Also, they employ semiconductor die bonders to connect die (chips), completing the SIP manufacturing.

There are several applications of the flip-chip or die bonder. Since chips are the main products of semiconductor manufacturing, there are different needs for chip accuracy.

Therefore, most chip manufacturers are acquiring (and merging) die bonder plants to streamline the SMT line.

LED Industry (Lighting)

LEDs are becoming the lighting standard due to their efficiency and durability. The LED industry also uses the SMT line to reap the benefits discussed earlier.

Automotive Electronics Industry

Cars are getting more intelligent because they use electronic systems to manage all their parts. Automotive manufacturing facilities began using SMT lines to fill in the demand required to mass-produce these modern cars.

Smart Industry for Home and Work

Combined with EMS, ERP, and MES systems, SMT lines can assist with order arrangement, production plan arrangement, material arrangement, etc. This combination can reduce production and warehousing costs by about 50% when dealing with products like:

- Electric curtain control

- Burglar alarms

- Intelligent lighting

- Gas leakage detectors and more

Electronic Consumer Goods (Appliances) Production Industry

SMT line also comes in handy when mass producing electronic consumer goods’ components. Think of TVs, sound systems, video game consoles, washing machines, etc.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Process of SMT Manufacturing

The process of SMT manufacturing includes the following steps.

Material Preparation and Examination

This step involves preparing the SMT components and PCBs while examining them for any flaws. At this stage, the PCB should be flat with solder pads (silver, tin-lead, or gold-plated copper pads with no holes).

Stencil Preparation

Stencils give fixed positions for solder paste printing. They should be in perfect alignment with solder pads on the PCB.

Solder Paste Printing

Solder paste is the material used to connect the SMT components to the solder pads. A solder paste printer applies it to the stencil above the PCB using a squeegee at a 45°-60° angle.

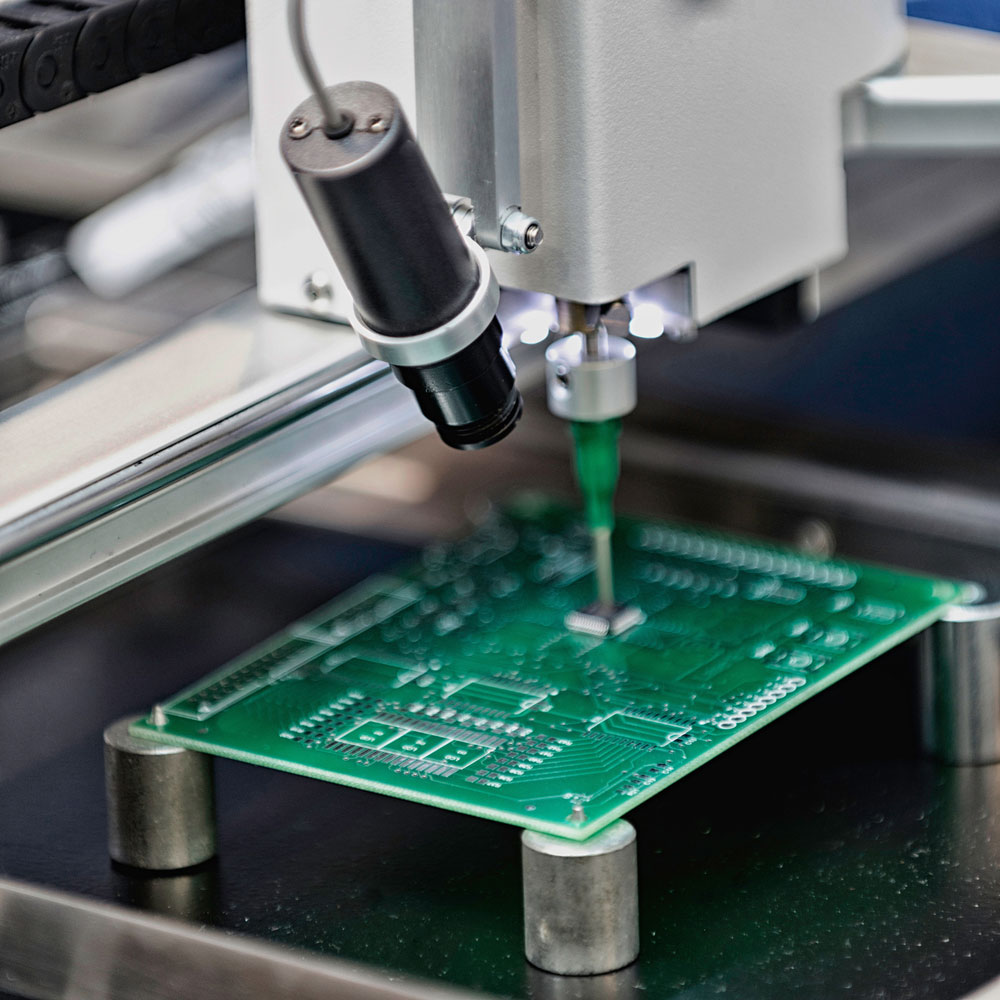

SMC Placement

The solder-printed PCB then heads to the pick & place machine, where the surface mount devices get placed on board. Some placement machines can position as many as 136,000 components per hour.

An automatic pick & place machine

Reflow Soldering

Reflow soldering involves four steps. After going into the reflow soldering oven,

Step 1: The boards stay in the preheat zone where the SMD and PCB temperature gets elevated gradually. Reflow ovens ramp up the temperature by about 1-2°C each second until it gets to 140-160°C.

A reflow oven

Step 2: Boards then go into the soaking zone where the temperature remains at 140-160°C for about 90 seconds.

Step 3: Next, the PCBs head into the reflow zone. Here, temperatures rise about 1-2°C each second up to the peak of 210-230°C. Heat melts tin in the solder paste, bonding each SMD to the solder pads. The molten solder surface tension keeps the components in alignment with solder pads.

Step 4: Lastly, the PCB assembly heads to a cooling zone to freeze the weld and avoid welding defects.

The printing, placement, and reflow process can get redone using glue or solder paste to hold the electronic components in place when dealing with double-sided PCBs.

Cleaning and Inspection

The last step in SMT manufacturing is cleaning and inspection. The process involves automated optical inspection, x-ray machines, visual inspection, etc., then repairs follow if there are any defects.

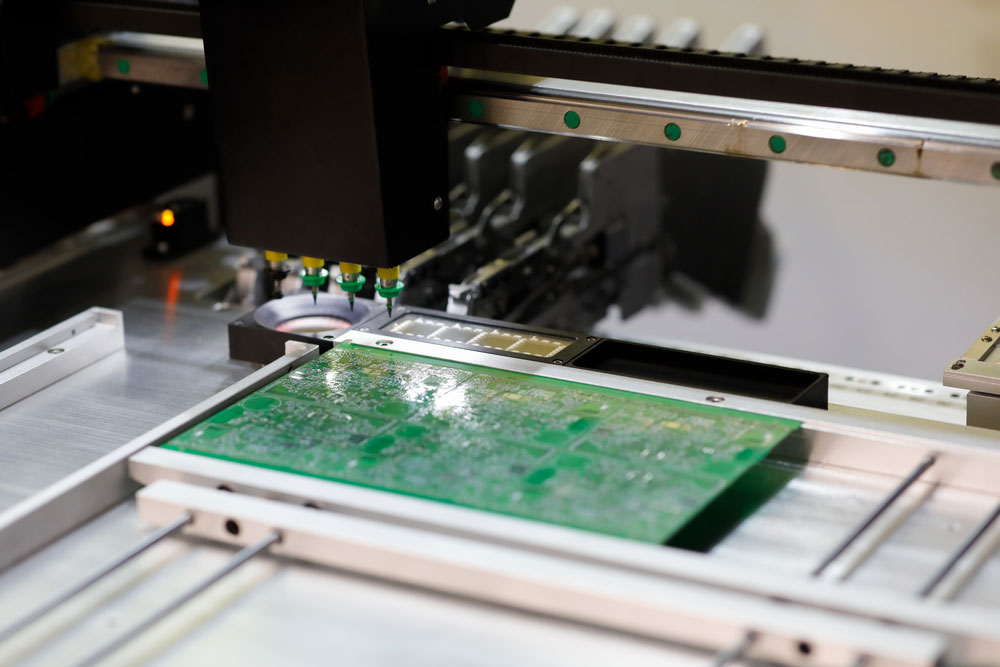

Main SMT Line Machine

The PCB assembly equipment in the main SMT production lines includes the following:

Pick and Place Machine

This machine places surface mount components accurately on the PCB by moving the placement head to the right spot. The surface tension of the molten solder pulls the SMD into alignment automatically later on in the reflow soldering process to correct minor errors in component placement.

Solder Paste Mixer

A solder paste mixer mixes the solder paste and powder evenly and efficiently. It helps perfect the printing and reflow processes, standardize operations, and reduce manual labor requirements.

Oven

Ovens are different from reflow machines. They bake the circuit boards to eliminate any moisture and are usually last in the SMT line.

SMT Loader

This machine places PCBs into solder printing machine racks automatically.

Solder Paste Printing Machine

A solder paste printing machine prints the solder paste to empty circuit boards. It is usually ahead of the pick & place machine in the SMT line.

Solder Paste Inspection (SPI) Machine

SPI machines check the solder paste's area, thickness, and volume distribution on the circuit board after solder paste printing.

Reflow Machine

A reflow machine sits after the pick & place machine. It melts the solder between the PCB and SMT components to weld them, then cools the material to solidify the bond.

AOI

AOI machines sit before and after the reflow machines. They detect component placement failures before soldering (pre-solder inspection) and check for soldering failures (post-solder inspection).

Docking Station

Docking stations are intermediary stops between different machines in the SMT line.

SMT Unloader

An SMT unloader does the opposite of an SMT loader. It receives and stores the assembled circuit boards after reflow soldering.

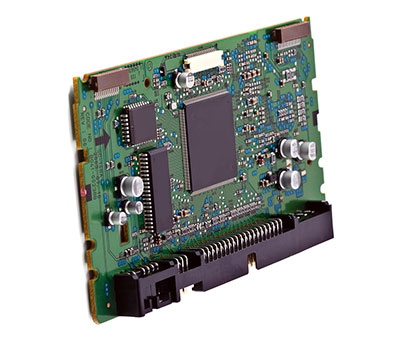

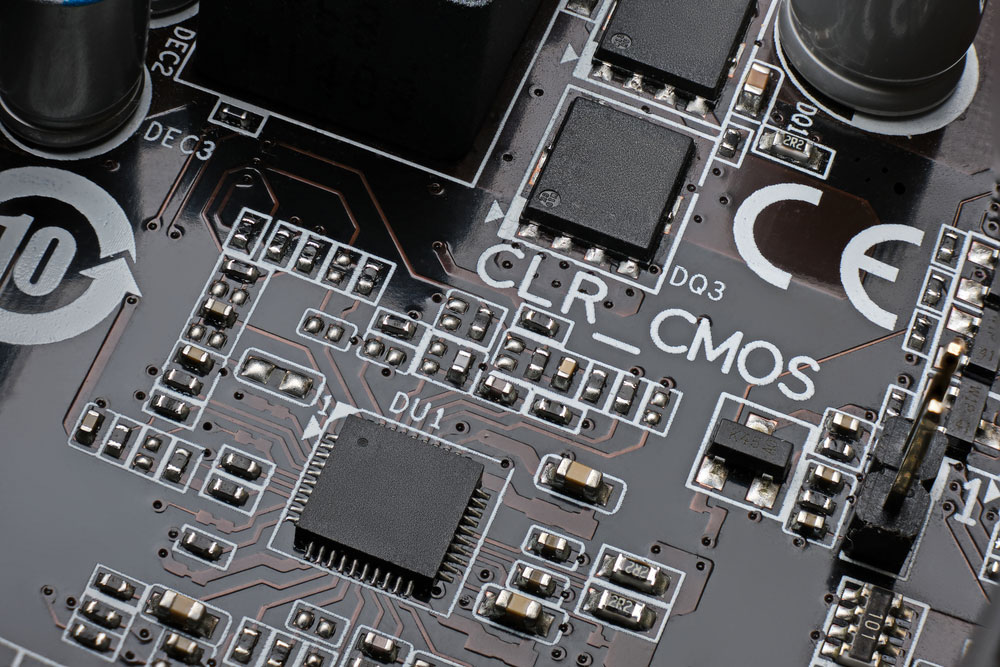

An assembled PCB with SMD components

Types of SMT Production Line Layout

SMT production line layout types include the following:

- One line a single-rail pick and place machine layout

- Two-to-one line a single-rail or dual-rail pick and place machine layout

- Two-to-one dual-rail pick and place machine high-speed layout

- Three-to-one line a single-rail pick and place machine layout

- Multiple line combination layout

SMT Line Cost

Pick & place machines are about 60-70% of the entire SMT line. Large P & P machines with a capacity of about 100.000+ CPH can cost $700,000. However, the middle capacity machines (12,000-35,000 CPH) can cost $100,000 to $200,000.

Considering the complete SMT line, most brands cost about $8,000,000 per line. Damn expensive, right?

However, OurPCB has introduced advanced and complete SMT lines that cost a fraction of that price. These provide high-quality PCB assembly service while keeping your setup costs low.

SMT Line Development Trends

SMT lines have the following development trends.

CIMS Application

Computer Integrated Manufacturing Systems link the design and production processes to reduce the time taken for SMT production preparation.

Efficiency Improvement

Efficiency leads to higher output, and SMT lines are increasingly eliminating the human element. Another strategy is implementing centralized online management control systems for the entire SMT line.

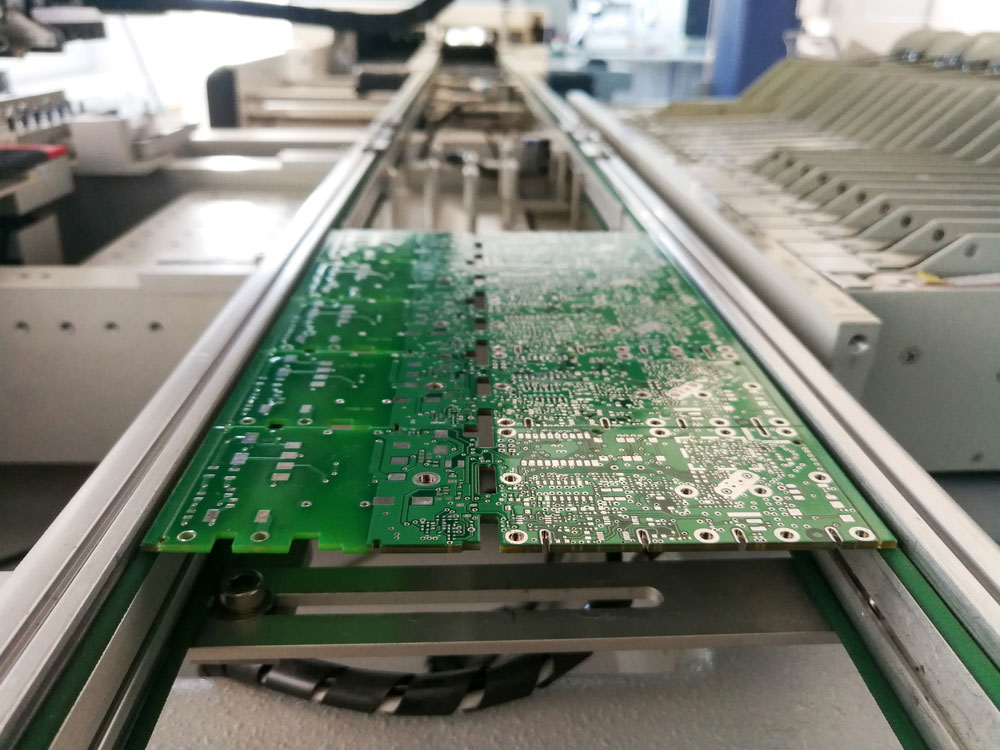

SMT production line

Environmental Protection

Packaging materials, flux, solder paste, glue, and other items used in the SMT process can cause environmental pollution. However, PCB manufacturers and assemblers are increasingly adopting eco-friendly methods in this process. They analyze the pollution sources and the degree to which they appear in the assembly process, then minimize their impact on the environment as much as possible.

Flexible Information Integration Production Environment

Grid information technology and internet development provide process information control and product data management for improving SMT production lines. Also, they enhance maintenance management and will eventually create a flexible information integration production environment for SMT lines.

Summary

In conclusion, SMT lines are critical in the PCB assembly process, and they include several machines for different functions. We hope that this article has been insightful, and if you have any questions or comments, don't hesitate to reach out.

Special Offer: Get $100 off your order!

Email [email protected] to get started!