During the manufacturing processes of the PCBs, some copper is left on the surface. Besides, once you leave the copper with no protection, the copper oxidizes, which makes the circuit board not fit for use. Therefore, PCB manufacturers use the ENIPIG process to prevent corrosion risk, improving copper solderability contact and plated through-holes. Hence, in this article, we will learn what ENIPIG is, why it’s the most preferred by fabricators, and much more.

Contents

What is ENIPIG PCB?

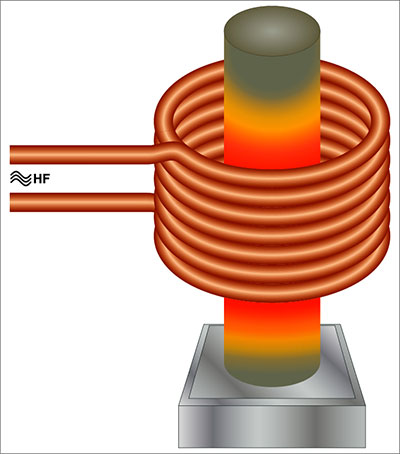

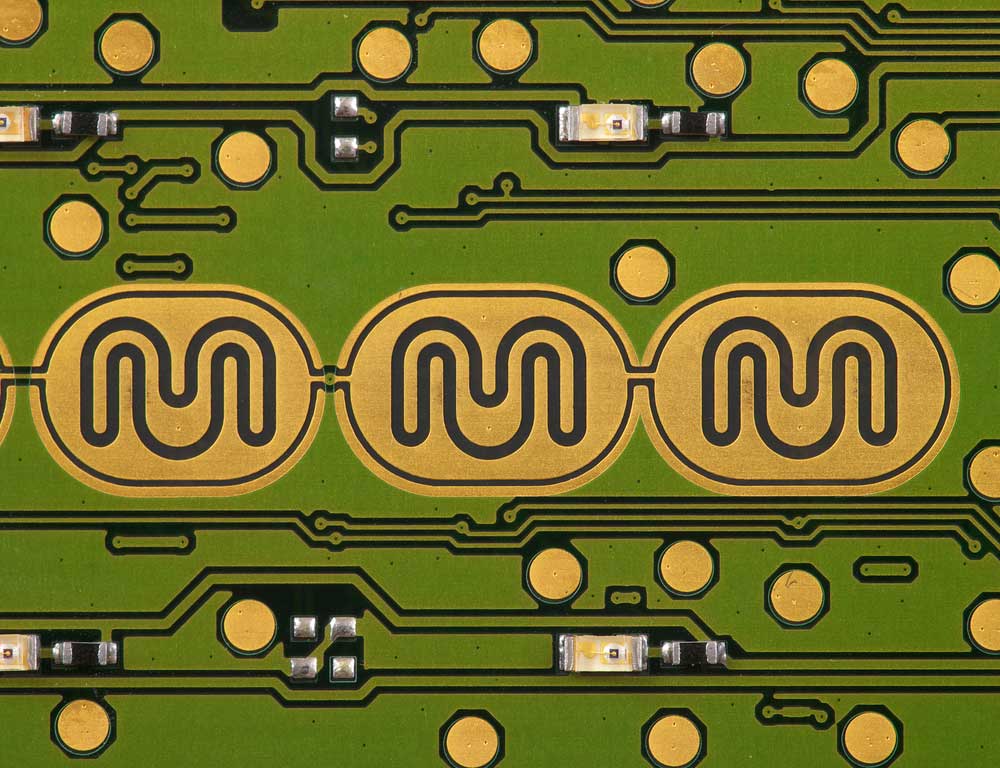

Electroless Nickel Immersion Palladium Immersion Gold is a coating process known as “universal finish.” Again, the reason for the name is that you can wire bond it or solder it with a similar coating. Besides, it provides a barricade amongst the immersion gold and electroless nickel plating, thus preventing the dread “black pad” or excessive nickel corrosion after assembly solderability. Basically, the process adds a thin electroless palladium layer for resistance above the nickel surface. Furthermore, like the ENIG process, ENIPIG intends to replace bad solder masks such as HASL/HAL (hot air solder leveling).

Printed circuit board PCB for manufacturing

ENIPIG is One PCB Surface Finish

There are many types of surface finishes in pcb manufacturing. Meanwhile, the major ones used in PCB assembly cycles; are ENIPIG, OSP, ENIG, Immersion Silver, Immersion Tin, lead-free and HASL-lead. Moreover, developers and builders work with most of these to satisfy clients’ requests. In addition, there are those, which are the most available surface finishes, which are;

- EDL – Electroless Discharge Lamp

- NNO –Nickel Oxide

- ELS – Electroless Solution

- NCG – Nickel-Copper and Gold

- NIPDAU - Nickel Palladium-Gold

- NIMH – Nickel Metal Hydride

- EBT – Electroless Bath Treatment

- ELS – Electroless Solution

- NBR – Nickel BR

- DIG – Direct Immersion Gold

- ENP – Electroless Nickel Plating

- Ni-nio – Nickel-Nickel Monoxide

- Ni-au – Nickel-Gold

- ENEP – Electroless Nickel Electroless Palladium

- ENIG – Electroless Nickel Immersion Gold

- Ni-pd – Nickel-Palladium

- Enbo – Electroless Nickel-Boron

- ENEPIG – Electroless Nickel Electroless Palladium Immersion Gold

- EN – Electrolytic Nickel

- NCGI – Nickel-Copper and Gold Interests

- ELD – Electroless Deposition

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Surface Finish Selection Considerations

ENIG, ENEPIG, Immersion Gold, Immersion Tin, OSP (Organic soldering preservatives), and HASL (hot air solder leveling) is the most prevailing surface finishes. Besides, regardless of the type of PCB finish product and the requirement you need to meet, you need to consider your choice of surface finish options. Hence, the major considerations should be:

- Thermal resistance

- Excellent shelf life

- RF applications (high-frequency probability)

- Fine pitch modules

- Application environment for end products

- Cost

- Shock and drop electrical resistance

- Volume

- Throughput

- Lead or lead-free

Stacked circuit boards

Meanwhile, those are the major areas to consider when deciding which kind of surface finish you will choose for your PCBs.

Advantages of ENIPIG PCB Surface Process

- Highly compatible with Sn-Ag-Cu excellent solder

- Extremely dependable wire connection capability

- Black pad free

- Ability to guarantee excellent solderability

- Exceptionally assorted solder joints

- Next, it features a surface as the main contact corrosion resistance

Lastly, it is available for numerous packages, mainly for PCBs with various package types

ENIG, ENIPIG and ENEPIG

ENIG is the former version of ENIPIG. Eventually, the high demand for advanced finer lines and miniaturization vias in the PCB development made fabricators begin using ENIG as a surface finish replacement. In addition, the other reasons are the distended drawbacks of OSP (including instability eradication) and HASL (including flatness issues).

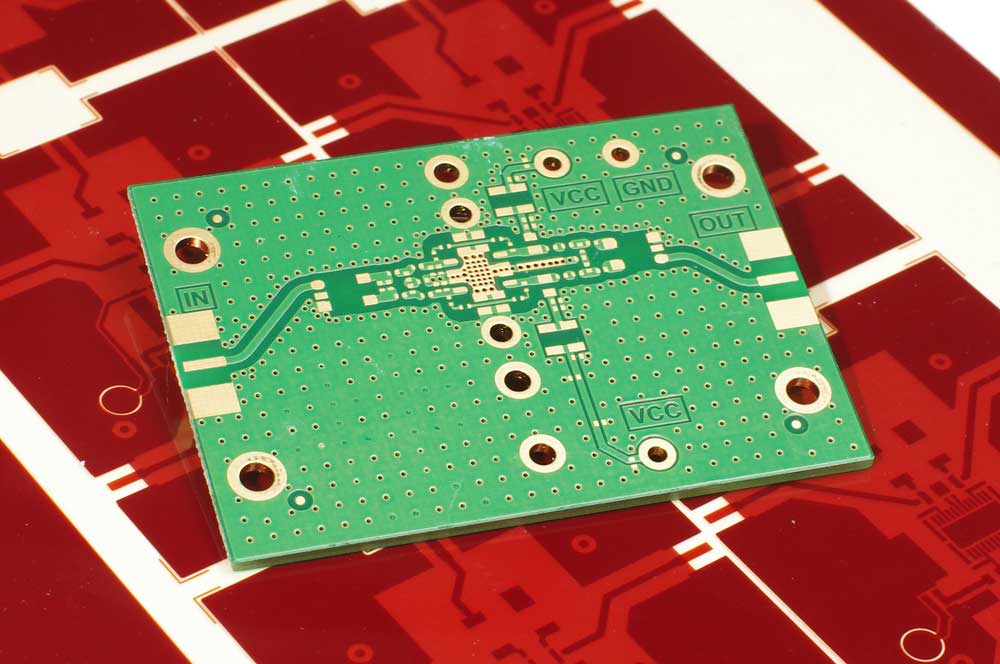

Gold-plated contact pads.

Like ENIPIG, ENEPIG is also the upgraded module of ENIG, which happens to cover its major weaknesses. Besides, ENEPIG has electroplating palladium added within the immersion gold and electroless nickel. As a result, it makes it have a thin layer for resistance with its width ranging from 0.05μm to 0.1μm. Furthermore, the palladium coating helps prevent immersion gold from putrefying the nickel layer, hence overpowering the obscure pad imperfection detained by ENIG. In addition, ENEPIG has exceptional flow soldering capability and extremely dependable wire attachment capability hence meeting stringent requirements of PCBs. Besides, it meets its requirements, including simultaneous surface packaging and peak compactness.

Transparent flexible circuit board

Summary

The highly evolving corporation demands high steadfastness, ease of use, and miniaturization for any electrical device. Therefore, it pushes the PCB fabricators towards getting a surface finish with advanced thickness, high diffusion indication swiftness, and lightweight. Besides, regarding dependability and steadiness, the surface finishes must embrace such issues to be well-matched with growth requirements. Moreover, ENIPIG comes in handy with its extremely high electrical performance, adequate electrical performance, and straightforward process technique. As such, if you have some questions about the PCB surface finish, contact us today for more information.

Special Offer: Get $100 off your order!

Email [email protected] to get started!