Contents

- What is Corrosion?

- Does Corrosion Ruin Electronics?

- Distinct Types of Corrosion

- How to Remove Corrosion from an Electrical Panel?

- How to Clean a Circuit Board of Corrosion

- How to Clean Battery Corrosion Off Electronics?

- Steps for Removing Spots of Rust in Electronic Batteries

- How to Remove Corrosion From Electronic Contacts

- Step 1: Remove the Batteries

- Step 2: Use Vinegar

- Step 3: Wipe the Corrosion

- Step 4: Apply the Paste

- Step 5: Spray

- How to Prevent Corrosion on PCB

- Summary

What is Corrosion?

Corrosion is the steady substance breakdown, especially metal, through a chemical reaction. Mainly, corrosion occurs after combining metal with oxygen and water, forming rust (iron oxide). Usually, the formation happens after combining these components for a lengthy period.

Old rusty electric transformer box with wires

Does Corrosion Ruin Electronics?

Corrosion in electronic devices can be highly detrimental. First, it interrupts electrical connection within the connectors and partner pairs, causing malfunction.

The electronic device will start to erode shortly after aquatic damage occurs. Besides, corrosion happens once water damage occurs. However, the corrosion process has no precise timespan. Few days can pass and not show signs of deleteriousness.

The rapidity of exactly how quick corrosion happens depends on several things; device design, the period of time the gadget was in the water, the harshness of aquatic deterioration, and moisture intensities. Furthermore, each one of the factors affects the duration period significantly when it comes to water damaging the device. However, the water can’t affect the device even after exposing it to water if it’s made with a barrier preventing additional water damage.

At OurPCB, as a leading printed circuit board manufacturer from China, we prioritize using protective coatings and advanced manufacturing techniques to minimize the risk of corrosion in electronic devices.

Corroded Spark Plugs

Distinct Types of Corrosion

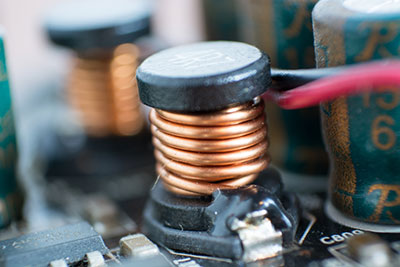

Your circuit boards' metal corrodes for several reasons, including:

- Electrolytic: This particular kind of metal deterioration happens once dendrite forms dendrites on bordering lines. Besides, it occurs because ionic contamination in the moisture contaminates the electrical voltage between the traces, producing metal slivers leading to a short circuit.

- Galvanic: Different metal types come into contact with an electrolyte with galvanic corrosion. As a result, the extra resilient metal rusts quicker than the counterpart base metal.

- Fretting: With fretting rust, the closing act of silver-plated shifts forms a smearing act of removing the oxide surface layer. Therefore, it permits the coat underneath to corrode. Ultimately, the extra rust accumulates hence hindering the switch from activating.

- Atmospheric: Atmospheric is the regularly known type of oxidation. Once you expose the metal to moisture containing oxygen for a longer time frame, it causes a reaction. Note that copper will quickly form corrosion. Nevertheless, corrosion in copper isn’t the issue when it comes to plumbing since it still preserves its mechanical attributes. Nonetheless, it won’t maintain its electrical conductivity, which is a huge concern when working with circuit board components.

Corrosion of electronic circuits

Special Offer: Get $100 off your order!

Email [email protected] to get started!

How to Remove Corrosion from an Electrical Panel?

It's always better to prevent corrosion from taking place. Hence, if your electrical panels aren’t showing any sign of corrosion, it is better to scrape off the rust and then repaint the panels. Besides, ensure you use the specific paint designed for the particular metal when repainting the panel. Additionally, don’t let the paint get to the bus bars, the wiring, etc., as it could cause overheating.

Initially, most homeowners know how to remove corrosion from an electrical panel on their own. Nevertheless, severe corrosion will require close examination by a trained inspector. Nonetheless, you must adhere to regular cleaning and maintenance to be sure the electrical network remains in perfect condition.

Rust removal on car removal

Once a panel corrodes severely, the rust eats the metal, making it corrode entirely. In such instances, all you can do is replace the irreparable part of the electrical panel. Nevertheless, if you don’t have the expertise to identify the extent of the corrosion, you can get the help of a professional electrician.

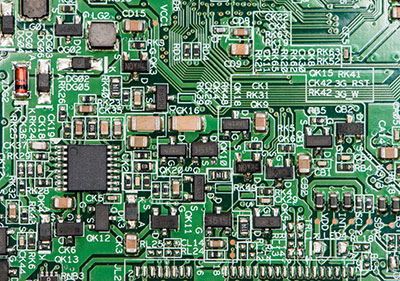

How to Clean a Circuit Board of Corrosion

Washing a corroded PCB will repair it to its original form. Besides, during the cleaning process, you need to be careful not to damage the components since the process will require you to disassemble the board. Equally important, when separating the PCB from the electronics, ensure you aren’t near water.

Printed Circuit Board of Corrosion

There are specific items you should use if you want to eradicate the corrosion successfully, including;

- Deionized Water: Pure water that contains no contaminants is a perfect item you can use to clean your PCB. Furthermore, this deionized water can’t cause any harm to the PCB since water contains no ions or impurities.

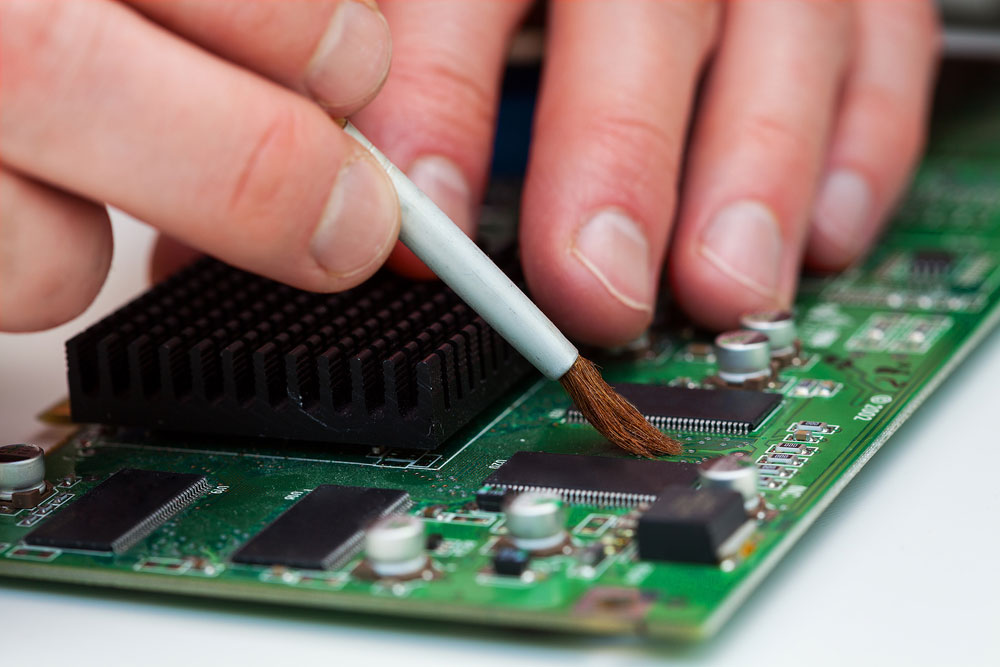

- Baking Soda: You can perfectly clean corrosion from circuit boards with baking soda. In addition, its abrasive qualities and alkalinity properties help neutralize and clear every rusty part without causing permanent damage.

- Soft-bristle brush: A soft-bristled brush that won’t scrape the delicate parts of your PCB can work effectively. Also, you can use a paintbrush, toothbrush, or any other soft brush if you don’t have any other PCB specialized cleaner tool.

Brush for rust removal

- Household Cleaner: If you have a cleaner in your home that contains no phosphate, you can use it to eliminate corrosion and remove dirt. Besides, phosphate minimizes water pollution, along with protecting PCBs from rusting.

- Oven: The oven will thoroughly dry your PCB when used in indirect heat.

- Lint-free towel: Any lint-free fabrics or clean microfiber cloth will help dry the circuit board entirely and won’t leave any particles behind.

How to Clean Battery Corrosion Off Electronics?

Once you notice corrosion in your batteries, it doesn’t automatically indicate that your devices have failed. Your gadget ought to function just as it did when new after careful cleaning. But how do you remove corrosion from electronics? An acid and a base can do a perfect job. Some other items you will need include:

- Protective gloves

- Baking soda

- Lemon juice or white vinegar

- Lint-free cloth

- Cotton swabs

Corroded Battery

Steps for Removing Spots of Rust in Electronic Batteries

Liquefy the Discharge

Based on the pH scale, battery rust is the base for using acid to neutralize it. Some of the perfect preferences are vinegar and lemon juice. First, wear the shielding gauntlet, remove the batteries, and put them separately. Afterward, apply your choice of acid to the cotton wipe and smear it on your electrical devices' corroded battery terminals. Meanwhile, the residue should start to dissolve right away.

Use the Baking Soda to Scrub

As already mentioned, baking soda contains abrasive properties that help to clean electronic products, including batteries. Therefore, apply the affected parts by rubbing them to the specific stubborn parts. After cleaning your device and eliminating all the rust, allow it to desiccate before you install the new batteries. Besides, if you want to hasten the drying procedure, use a dry lint-free cloth to eliminate excess water.

Baking Soda

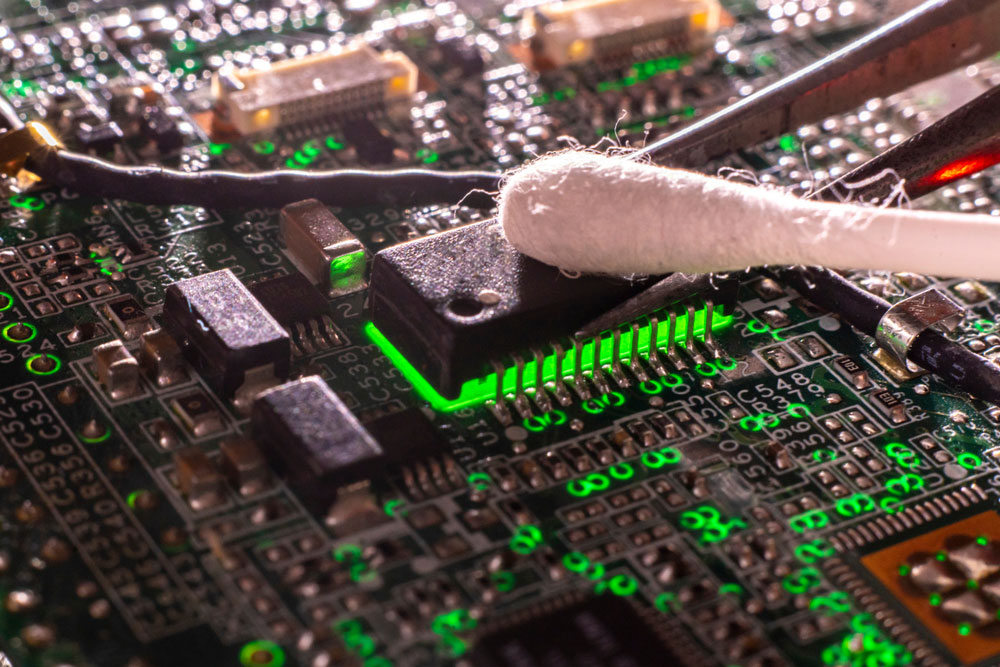

How to Remove Corrosion From Electronic Contacts

Corrosion on the electronic contacts may have a significant and negative influence on device performance. Besides, the gadget may become useless if the corrosion clogs the power connections to the point where it interrupts the electrical circuit board connections.

Rust spray

It is possible to get rid of corrosion on contacts by using home remedies that are not too costly.

Step 1: Remove the Batteries

First, remove batteries if you want to get rid of rust on the battery compartment. Besides, to avoid short circuits, ensure you disconnect power from the device before you begin cleaning the electronic contacts. Afterward, use a clean cloth to wipe away the accumulated rust.

Step 2: Use Vinegar

Vinegar is a mild acid that can dissolve and release corrosion. Therefore, take a cotton swab and soak it in white vinegar. Afterward, apply the vinegar solution to corroded parts by brushing it onto the contacts.

Step 3: Wipe the Corrosion

Remove the dissolved rust with a wipe. Before replacing the batteries, make sure the contacts are totally dry.

Step 4: Apply the Paste

Make a paste by mixing water and baking soda. Afterward, use a cotton swab to apply the baking soda paste to the contacts in a circular motion. Finally, leave the cleaning paste to dry.

cleaning or rust remove process

Step 5: Spray

Remove the paste with a wipe. To remove any leftover rust from the contacts, spray them with compressed air.

Applying a stream of compressed air to the contacts will help remove any leftover corrosion. Again, be sure to remove any traces of the paste. Finally, use a paper towel to dry out the contact area.

How to Prevent Corrosion on PCB

While you can’t prevent PCB corrosion forever, you can avoid it even beyond its expected life. Here are the steps for preventative steps you can take.

First, avoiding ionic contamination is the first step toward preventing PCB corrosion. Exposing it to contaminated ionic moisture is the leading cause of corrosion to the PCB. Therefore, you always keep it and its components in a dry and clean area.

Clean dirty electric circuit

Secondly, fabricators should also maintain the same priority when manufacturing printed boards. Therefore, battery manufacturers should avoid getting liquid and fingerprints on the boards. In addition, designers shouldn’t expose them to humid temperatures.

If designing the PCB for applications with the possibility of exposure to acidic liquid contaminants, protect them from environmental hazards. Besides, it’s not hard to prevent corrosion. Therefore, you only need to pay extra attention, such as keeping them dry and clean when manufacturing. Taking such preventive measures will significantly reduce the possibility of corrosion.

Summary

Corrosion can damage your electronics. Therefore, you must keep electronics safe from constituents that can cause them to rust. Nevertheless, if they get rusty, you can give them a thorough cleaning and secure their functional back again.

Special Offer: Get $100 off your order!

Email [email protected] to get started!