We can deduce that those adding to the surface finishes play an essential part in the PCB assembly among the various technologies applied in the printed circuit board fabrication process.

So, are you on a low budget? Not sure of how to go about the whole thing? Alternatively, are you need something with a better offer for your project? We will guide you in choosing the right type of finish to suit your project's style and point you to the perfect vendor that can ease your worries with zero stress.

We have made you a list of some types of surface finish that can be used along with your type of project, and after that, we would bring you a little more closely to the right vendor. Yes! The perfect one.

Contents

- 1、HASL VS ENIG--HALL

- 1.1 Definition:

- 1.2 HASL Finish

- 2、HASL VS ENIG--ENIG

- 2.1 Definition:

- 2.2 ENIG finish

- 2.3 ENIG plating

- 3、HASL VS ENIG (Advantages and Disadvantages)

- 3.1 Advantages of the hot air solder leveling (HASL)

- 3.2 Disadvantages of the hot air solder leveling (HASL)

- 3.3 Advantages of the Electroless nickel immersion gold (ENIG)

- 3.4 Disadvantages of the Electroless nickel immersion gold (ENIG)

- 4、HASL VS ENIG--Other Surface Finish Process

- 4.1 ORGANIC SOLDERABILITY PRESERVATIVE (OSP)

- 4.1.1 Advantages of organic soldering preservative (OSP)

- 4.1.2 Disadvantages of organic soldering preservative (OSP)

- 4.2 HARD ELECTROLYTIC GOLD

- 4.2.1 Advantages of hard gold

- 4.2.2 Disadvantages of hard gold

- 4.3 IMMERSION TIN

- 4.3.1 Advantages of the immersion in

- 4.3.2 Disadvantages of the immersion in

- 4.4

- Hasl vs Enig--

- IMMERSION SILVER

- 4.4.1 Advantages of immersion silver

- 4.4.2

- Hasl vs Enig--

- Disadvantages of immersion silver

- 4.5

- Hasl vs Enig--

- NICKEL PALLADIUM (ENEPIG)

- 4.5.1

- Hasl vs Enig--

- Advantages of ENEPIG

- 4.5.2

- Hasl vs Enig--

- Disadvantages of ENEPIG

- 5、Conclusion

- Hasl vs Enig--

- Merge your plans

- Hasl vs Enig--Now is the time.

1、HASL VS ENIG--HALL

1.1 Definition:

The Hot Air Solder Leveling is often expressed in short as 'HASL.' It is a type of surface finish used on printed circuit boards in the industry, which provides a good shelf life and a dependable solder joint. The hot air soldering leveling enables the soldering of a component to more effective. Initially, the HASL finish is applied to enhance solderability and also cover copper circuitries that are exposed.

1.2 HASL Finish

It should not sound new to those conversant with the industry that the HASL was one of the significant surface finish options for decades now, carrying advantages that include low cost, availability, and repairability.

As discussed earlier, the HASL is a kind of surface finish with great solderability and offers an excellent shelf life. In the HASL step, the revealed copper surfaces are covered by immersing the printed circuit board in a container containing molten solder.

After this process, complete removing excess solder and leveling by running the printed circuit board between the hot air knife. It is essential to make sure that the printed circuit boards are covered, or else the copper can oxidize and worsen, resulting in the circuit board being useless.

The copper finishes are present on the printed circuit board; this finish on the surface develops a serious interface between the printed circuit board and the component.

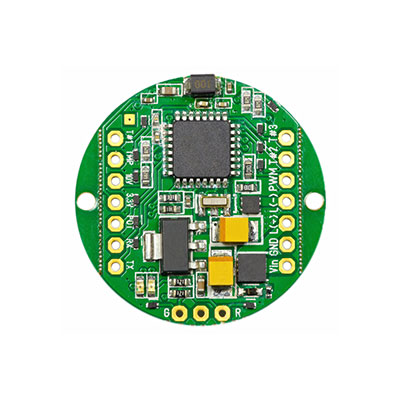

Image 1: Hall vs. Enig

Image 1: Hall vs. Enig

Special Offer: Get $100 off your order!

Email [email protected] to get started!

2、HASL VS ENIG--ENIG

2.1 Definition:

The ENIG is a common acronym that stands for Electroless Nickel Immersion Gold. TThe ENIG got its name because it comprises electroless nickel plating coated with a slim layer of immersion gold. The hot air solder leveling is also a surface finish of the printed circuit board industry. Continuously, it has secured market share resulting from its ability to be flexible in various component assembly processes.

2.2 ENIG finish

This type of finish involves a two-layer metallic coating; it consists of electroless plating that is covered with a thin layer of immersion gold, the function of the immersion gold is to safeguard the nickel from oxidizing during storage, and the nickel functions more like a barrier to the copper and a surface on which the components are soldered. Recently, due to the advantages provided by ENIG, ENIG is one of a printed circuit board (PCB) industry, the most common types of surface treatment, including a plane, lead-free, suitable for plated through holes (PTH), long shelf life.

2.3 ENIG plating

In the early stages of ENIG plating, reliability is still unclear, i.e., this type of leaf had dependability problems. Unlike the hot air solder leveling, the electroless immersion nickel-gold does not uniformly wet. This has resulted in the disuniting of the copper pads from the finish. To ensure that the conventional coating provides the proper temperature and concentration, the reducing agent consisting of nickel ions must be renewed.

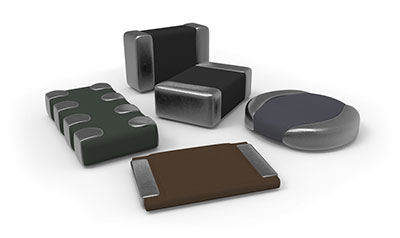

Image 2: Enig

Image 2: Enig

3、HASL VS ENIG (Advantages and Disadvantages)

So far, we have discussed what these two types of finishes are. In a way, we can say the hot air solder leveling (HASL) has some specific advantages over the electroless nickel immersion gold (ENIG) and vice versa. However, here in this section, we would specify each type of surface finish, the advantages, and the disadvantages. It is important to note that no surface finish has a gift without a penalty, and therefore, the selection of any surface finish is based on a particular application.

3.1 Advantages of the hot air solder leveling (HASL)

It is well known; hot air solder uniform HASL process type is one of the major surfaces of the printed circuit board used in the PCB industry. Some of the advantages attached to its use include;

- Ability to expose the printed circuit board to a temperature that can be up to 265°c. Exposing the printed circuit board to this

extent of weather allows for detecting any possible problem before the attachment of any component to the board. - The hot air solder leveling is uncomplicated to run.

- It is a type of surface finish that is pocket-friendly; that is, the cost is low.

- The hot air solder leveling is well known for its ability to offer a long storage life.

- It is generally available. It can be an excellent advantage over other types of surface finish.

- The hot air solder leveling disallows the oxidation of copper.

- A perfect wetting throughout the process of joining or soldering components.

- This type of surface finish can be inspected visually.

3.2 Disadvantages of the hot air solder leveling (HASL)

From one perspective, each advantage is always in a relationship with another disadvantage. There are strengths and weak points attached to every type of surface finish. Some of the weakness identified with the hot air solder leveling includes:

- This type of surface finish is not suitable for the Surface-mount technology (SMT) due to the irregular surfaces involved with

the hot air solder leveling. - It is not eligible for fine pitch, going in hand with the first point. Horizontal levelers are required to enhance flatness.

- Concerning boards that are additionally thin or thick, HASL has some specific restrictions, making it unsuitable for fabrication.

- Printed circuit boards may face some drawbacks due to high heat exposure in their processes.

- Inability to withstand tight tolerance on the plated holes.

- The hot air solder leveling is not appropriate for line binding.

- The plated through holes might get cracked due to high temperatures using this surface finish.

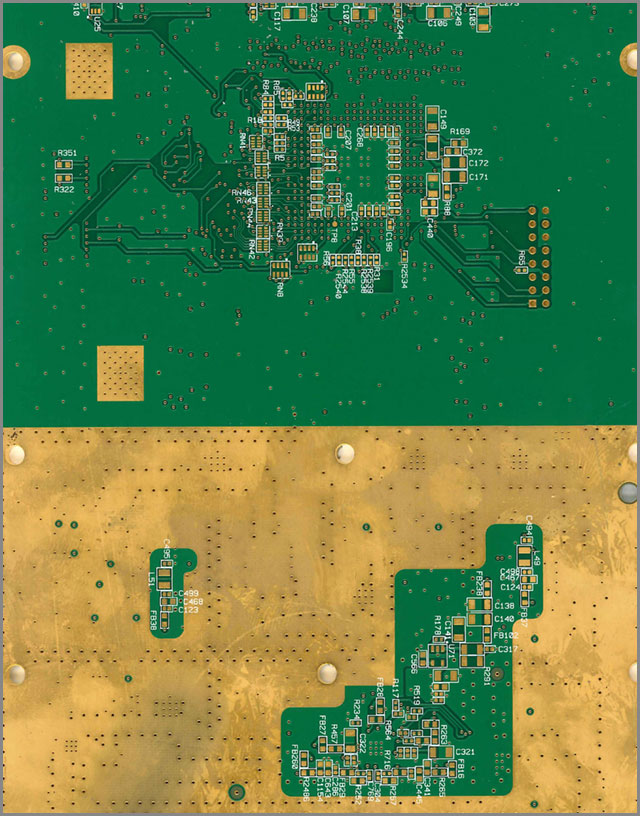

Image 3:Hasl

Image 3:Hasl

3.3 Advantages of the Electroless nickel immersion gold (ENIG)

- Unlike the hot air solder leveling, the electroless nickel immersion gold offers a flat surface.

- It is a type of surface finish suitable for plated through holes.

- More like the hot air solder leveling, it provides good storage life

- It has no lead

- This type of surface finish is suitable for use as bottom metal for cob wiring.

- ENIG has an excellent electrical conductivity ability

- The electroless nickel immersion gold is recognized for its capability to prevent oxidation.s

3.4 Disadvantages of the Electroless nickel immersion gold (ENIG)

- One major challenge is that it is expensive.

- Unlike the hot air solder leveling, the ENIG is not re-workable

- The electroless nickel immersion gold is associated with signal loss

- Unlike the HASL, ENIG has a more complicated process.

- ENIG is prone to the black pad due to its low wielding strength

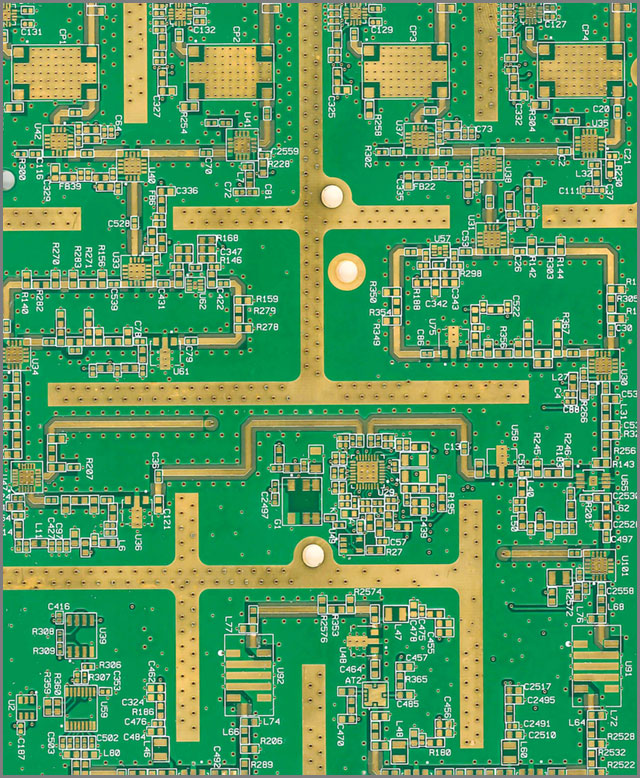

Image 4: Enig

Image 4: Enig

4、HASL VS ENIG--Other Surface Finish Process

4.1 ORGANIC SOLDERABILITY PRESERVATIVE (OSP)

The organic solderability preservative is also referred to as the anti-tarnish. This type of surface finish protects the surface of the copper from oxidation. It is done by adding a fragile layer material on the exposed copper, which is done with the aid of a particular process. This type of finish uses organic compounds usually based on water that selectively bonds to copper, giving an organic and metallic layer that shields the copper preceding the soldering.

4.1.1 Advantages of organic soldering preservative (OSP)

- Unlike hot air solder leveling (HASL), the organic soldering preservative offers a flat surface.

- The process of organic soldering preservatives is relatively simple

- It is re-workable

- It ensures a very smooth surface

- Is a great option to consider for surface mount technology, SMT

- It is suitable for lead-free soldering

- This type of finish is cost-effective.

- A top choice for horizontal production line

- It does not cause a hazard to the environment

- It can combine with another type of surface finish on one panel.

4.1.2 Disadvantages of organic soldering preservative (OSP)

- After soldering times, the film gets ruined

- It does not fit for electrical measurement

- It is not suitable for plated through holes

- Unlike the previously mentioned type of finishes, the OSP has short storage or shelf life.

- It requires a sensitive handling

- The thickness cannot be measured

- It has a full condition for storage requirement

4.2 HARD ELECTROLYTIC GOLD

This type comprises a sheet of gold that is coated over a barrier coat of nickel. This type is also known only as "hard gold." Most of its applications are commonly channeled to areas such as keypads and connector fingers. One of its advantages over the electroless nickel immersion gold (ENIG) is that it can vary in thickness. Generally, hard gold has low soldering ability, and it is not applied to solderable areas because it is expensive.

4.2.1 Advantages of hard gold

- It provides a reliable and robust surface

- Hard gold has a good storage life

- There is no lead

4.2.2 Disadvantages of hard gold

- This type of finish is costly.

- It requires additional processing

- Etching damage can result in flaking

- Hard gold makes use of the resist

- It has a limit of soldering; that is; it is not solderable above 17µin

- Excluding finger areas, this type of finish does not encapsulate trace sidewalls

4.3 IMMERSION TIN

It is a type of metallic finish that is used directly over the metal of the printed circuit board. It prevents the oxidation of the underlying copper, and of course, it has a good storage life to offer. Let's take a quick look at the advantages and disadvantages concerned with the immersion tin.

4.3.1 Advantages of the immersion in

- The immersion tin is re-workable

- It is highly suitable for press-fit pin insertion

- The immersion tin has no lead

- It ensures a flat surface

4.3.2 Disadvantages of the immersion in

- It is not the right choice for assembly processes

- It is sort of impossible to measure the thickness

- Corrosion of uncovered tin on final assembly

- The method makes use of agents or substances that can cause cancer

- Can quickly start processing damage

4.4

Hasl vs Enig--

IMMERSION SILVER

The immersion silver holds sure pros and cons compared to other surface finish, and in some cases, it is considered a better surface finish.

4.4.1 Advantages of immersion silver

- The process involved is simple.

- The immersion silver offers a flat surface.

- Immersion silver is a top choice for wonderful traces

- It is cost-friendly

4.4.2

Hasl vs Enig--

Disadvantages of immersion silver

- It may encounter some micro hole problem

- It can be easily polluted

4.5

Hasl vs Enig--

NICKEL PALLADIUM (ENEPIG)

For history's sake, the ENEPIG is not a very old type of surface finish process used in the PCB industry. Typically, ENEPIG is commonly used in the semiconductor but also to a combination of aluminum and gold.

4.5.1

Hasl vs Enig--

Advantages of ENEPIG

- Unlike the electroless nickel immersion gold, there is no black plate issue. That is the absence of nickel corrosion.

- It is an excellent choice for lead-free soldering

- ENEPIG offers a good shelf life

- It is a perfect choice for gold wire binding

- Is cost-friendly compared to electroless nickel immersion gold (ENIG)

- It fits in for a wide range of surface finish

4.5.2

Hasl vs Enig--

Disadvantages of ENEPIG

- Unlike some of the processes mentioned earlier, its function is complicated.

- Since this type of process came in not long; it is not yet well established

Image 5: Hall vs. Enig

Image 5: Hall vs. Enig

5、Conclusion

Hasl vs Enig--

Merge your plans

Several options have been discussed but did not rule out the cost of each option. One thing is planning on using a surface finish; the other thing is carefully selecting the appropriate surface finish that perfectly suits your project. In your best interest, it would be cool if you take a look at your project first before deciding on the type of surface finish. In instances whereby you are on a low budget, it is advisable to go for a surface finish like HASL, but in going for the HASL, you have to keep in mind that the HASL is not appropriate for ROHS-compliant products.

Hasl vs Enig--Now is the time.

We have brought some of the common types of surface finish to you, including the advantages and disadvantages attached to each one of them. We have started this, and we can help you see it to the very end. Trust me, you won't want to fall into the wrong hands, and that is why we are here 24/7 at your service. Why don't you contact us today? We would be more than glad to hear from you. Also, you can request a quotation, and if you have troubling questions or suggestions, please feel free to pass them across.

Image 6: Hall vs. Enig

Image 6: Hall vs. Enig

Special Offer: Get $100 off your order!

Email [email protected] to get started!