Special Offer: Get $100 off your order!

Email [email protected] to get started!

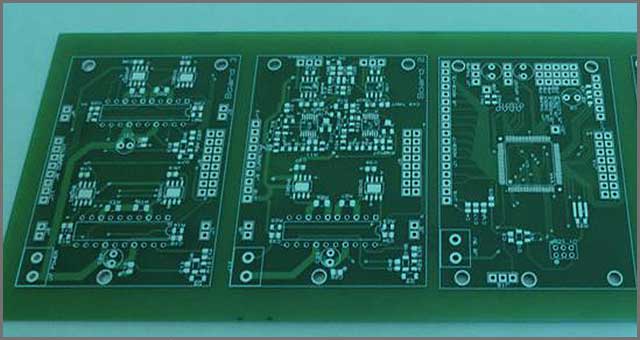

After completing the design stage of the PCB, comes the next big task of choosing the right Production house to make it functional. For beginners and hobbyists, there is quite a large volume of PCB board houses around the market.

To choose the right board house, one must look into several parameters determining the final PCB board house.

Not that one house produces quality products than other dwellings our requirement that makes a choice.

PCB requirements can range from the single-layer hobby of do-it-yourself projects to professional PCBs for high-end electronics.

Before choosing the Production firm, the designer must determine their need so that selection will be more natural.

Prepare the fabricate note for the proposed design that explains material selection to tests done to ensure the quality.

When it comes to quality, budget comes as the next priority, so PCB must also determine the quality and budget.

Before quotations, one must summarize the needs and set the negotiations and contracts for future deals.

Each PCB board house has its unique specialization, so we require that that determines the manufacturer.

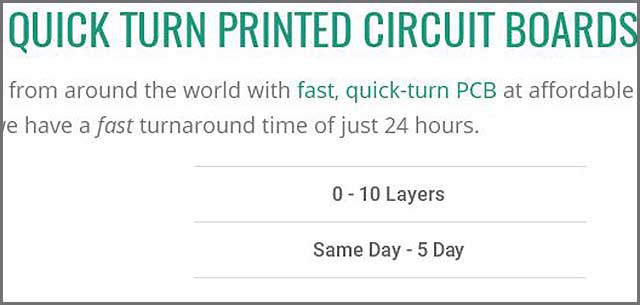

Let’s say we need a simple double-sided PCB to control appliances in a building through Wi-Fi. This project requires only fewer numbers in quantity with lesser component density.

Hence, instead of going for a more prominent firm with a vast production process, it’s more likely that a small-scale producer will deliver the project sooner with all the quality aspects.

Even larger volumes, OurPCB can choose small-scale PCB board houses to work with more significant dedication in a particular project.

OurPCB can finalize selection by analyzing the delivery time, average production quality, and their respective testimonies.

Special Offer: Get $100 off your order!

Email [email protected] to get started!