Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct while still meeting modern safety standards.

This guide breaks down the best manufacturers making classic car wiring harnesses today, what separates the good from the great, and how to pick the perfect one for your restoration project.

Contents

- Key Takeaways

- What are Classic Car Wiring Harnesses?

- Key Components and Materials

- Why are Quality Manufacturers Important for Classic Car Restoration?

- Safety vs. Authenticity Balance

- Who are the Top Classic Car Wiring Harness Manufacturers?

- 1. OurPCB - Integrated Electrical Solutions

- 2. Octagon Manufacturing / Bygone Spares and Restorations

- 3. Yazaki Corporation

- 4. Leoni AG

- 5. Aptiv PLC

- 6. Furukawa Electric

- 7. DRÄXLMAIER Group

- 8. American Autowire

- 9. Samvardhana Motherson Group

- 10. Painless Performance Products

- What Technical Standards Should Quality Manufacturers Follow?

- Key Standards and Specifications

- How do Manufacturers Ensure Authenticity in Classic Car Wiring?

- Authenticity Elements

- Manufacturing Location Advantages

- How Should You Choose a Wiring Harness Manufacturer?

- Selection Criteria Checklist

- Ready to Restore Your Classic Car's Electrical System?

- Frequently Asked Questions

- How do modern safety improvements integrate with classic car wiring harnesses?

- What is the manufacturing process for custom classic car wiring harnesses?

- Can wire harnesses be partially upgraded rather than completely replaced?

Key Takeaways

- Always go for pure copper wiring — the cheap stuff will cost you more in headaches later

- Check if they've got actual automotive certifications — there's a reason serious shops have them

- If you've got a rare muscle car variant, find someone who'll make custom harnesses

- Companies like OurPCB can handle both traditional wiring and modern electronics integration

What are Classic Car Wiring Harnesses?

Classic car wiring harnesses are those bundled electrical systems that tie together all the circuits in vintage automobiles. Think of them as the nervous system of your beloved old car. These chassis harness systems changed dramatically throughout automotive history — cars built before 1935 used pretty basic rubber insulation that's prone to cracking after decades. After '35, manufacturers started wrapping harnesses in that distinctive cotton braid that gives vintage engine bays their classic look. Then after World War II, early PVC coating started showing up, changing the game for durability.

The tricky part for today's restorers is finding reproduction wiring that strikes that perfect balance — harnesses that look period-correct enough to satisfy the judges at car shows but incorporate modern materials that won't leave you stranded on the side of the road. The best reproduction harnesses maintain that authentic appearance while quietly upgrading the internals for improved reliability. After all, the point of restoration is driving these classics, not just looking at them in the garage!

Key Components and Materials

| Component | Function | Material Options |

|---|---|---|

| Wire | Carries electrical current throughout car | Copper (best conductor) or Tinned Copper (better corrosion resistance) |

| Insulation | Keeps your wires from shorting and starting fires | PVC (modern), Rubber (original in older cars), Cotton (period-correct covering) |

| Terminal | Connects wires securely to components | Brass (won't corrode), Copper (excellent conductor), Zinc-plated (budget option) |

| Connector | Enables disconnection and reconnection of parts | Plastic (modern durability), Bakelite (authentic vintage look), Metal (period-correct for pre-60s cars) |

Why are Quality Manufacturers Important for Classic Car Restoration?

Quality manufacturers make or break antique car restoration. They prevent electrical fires while keeping your classic looking factory-original. That original wiring in vintage vehicles turns brittle and dangerous after decades sitting in engine bays. Those cracked wires create serious fire hazards that demand proper replacement built to exact specs.

The professional manufacturers worth their salt build harnesses using appropriate gauge wire (you want 16-20 AWG for those main circuits), proper metal terminals that won't corrode or loosen up, and factory-style materials that maintain authenticity. The difference between professional-grade harnesses and cheap knockoffs becomes painfully obvious the first time you troubleshoot an electrical gremlin at night on the side of the road.

Safety vs. Authenticity Balance

- Those original electrical components don't just look old — they literally crumble in your hands after 50+ years

- Modern flame-retardant materials might not be "numbers matching" but they won't burn your prized classic to the ground

- Getting that period-correct appearance isn't just for show — it maintains your restomod's value when appraisal time comes

- Proper crimping techniques aren't just mechanic's OCD — they prevent those maddening connection failures that leave you stranded

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Who are the Top Classic Car Wiring Harness Manufacturers?

Let's dive into the companies that actually deliver the goods when it comes to quality harnesses. These manufacturers have figured out the ideal balance, combining authentic vintage looks with modern manufacturing standards that won't leave you stranded.

The market for these specialty harnesses isn't small potatoes, either. Fortune Business Insights reports that the entire US automotive wiring harness market is increasing significantly. It's projected to hit 16.65 billion dollars by 2032. That's a serious industry, and it explains why we're seeing more companies getting into this niche.

1. OurPCB - Integrated Electrical Solutions

OurPCB leads the classic car wiring harness industry by uniquely combining PCB assembly expertise with comprehensive harness manufacture. This integrated approach allows for complete electrical system solutions where traditional automotive wiring connects seamlessly with modern circuit boards. Our Shijiazhuang facilities feature both advanced automation and skilled technicians for hand-crafting techniques.

Technical Capabilities:

- Wire Processing: Automated cutting and stripping (±0.5 mm precision)

- Terminal Application: 28 crimping stations with 4.5 kg pull-test verification

- Insulation Materials: PVC, PTFE, Silicone, Cotton Braiding

- Conductor Options: Bare Copper, Tinned Copper (0.35-8.0 mm² cross-section)

- Color Coding: Full OEM specification compatibility (66 colors)

- Testing: Automated electrical testing with 1000 V dielectric strength verification

2. Octagon Manufacturing / Bygone Spares and Restorations

Octagon Manufacturing specializes in exact reproduction wiring harnesses following original specifications for British classic cars. Operating since 1968, they focus on hand-crafted replacement parts using authentic vintage materials.

- Specialization: British classics (MG, Triumph, Jaguar)

- Materials: Original specification cotton braiding

- Technical Feature: Reproduces both 33 herringbone colors (pre-war) and 66 colors (post-war)

3. Yazaki Corporation

Yazaki Corporation provides comprehensive automotive wiring solutions as a global supplier to major OEMs, leveraging this expertise for high-quality reproduction harnesses.

Manufacturing Standards:

- ISO/TS 16949 and ISO 14001 certified facilities

- Advanced crimping with pull-test verification

- Computer-aided design capabilities

- Multi-point quality inspection

4. Leoni AG

Leoni AG specializes in automotive wiring harness systems with extensive R&D capabilities, applying technical expertise to reproduction harnesses.

- Technical Strength: High-precision terminal application

- Quality Control: 100% continuity testing

- Specialization: German classics (Mercedes, BMW, Porsche)

- Material Options: Period-correct or modern alternatives

5. Aptiv PLC

Aptiv serves as a major Tier-1 supplier to automotive brands, known for innovative wiring systems and electrical distribution solutions.

Technical Capabilities:

- Advanced wire processing equipment

- Environmental testing chambers

- Computer-aided design for complex harnesses

- Ability to integrate modern injection systems

6. Furukawa Electric

This Japanese multinational offers diverse electric products including specialized wiring harnesses for classic Japanese vehicles.

- Specialization: Japanese classics (Toyota, Datsun, Honda)

- Technical Feature: High-temperature insulation (up to 125 °C)

- Quality Standard: JSA JIS certification

- Material Option: UV-resistant jacketing

7. DRÄXLMAIER Group

DRÄXLMAIER focuses on composite wiring harnesses with high integration capabilities, applying this expertise to premium street rods and classic car applications.

Premium Features:

- Luxury vehicle specialization

- Enhanced EMI shielding capabilities

- High-density connector systems

- Water-resistant sealing options

8. American Autowire

This company supplies wiring systems to major automakers, with a division dedicated to Ford, GM, and Chrysler applications.

- Production Scale: 22 circuit classic kits

- Testing: Automated functional verification

- Design Capability: Complex dash wiring solutions

- Certification: IATF 16949 compliance

9. Samvardhana Motherson Group

Motherson Wiring provides major wiring harnesses for passenger vehicles, with specialized classic car manufacturing capabilities, including Mustang and Corvette applications.

Manufacturing Strengths:

- IATF 16949 certified production

- High-volume capabilities with custom options

- Global manufacturing footprint

- Specialized plug reproduction

10. Painless Performance Products

US-based Painless specializes in custom wiring harness solutions serving automotive sectors with IPC/WHMA-A-620 certification.

- Kit Options: 21 circuit universal systems

- Specialization: American classics (truck and pickup models)

- Batch Size: Small production runs

- Custom Capability: One-off prototype development

What Technical Standards Should Quality Manufacturers Follow?

Quality manufacturers must follow multiple technical specifications to ensure both safety and authenticity. IATF 16949 certification establishes automotive-specific quality management requirements that guarantee consistent manufacturing processes. IPC/WHMA-A-620 standards specifically govern wire harness assembly, defining quality benchmarks for crimping, soldering, and insulation.

Key Standards and Specifications

| Standard | Purpose | Key Requirements |

|---|---|---|

| IATF 16949 | Quality management | Material traceability, process control |

| IPC/WHMA-A-620 | Assembly standards | Crimp height ±0.05 mm, tensile strength |

| ISO 9001 | Process Specifications | Documented information & control of outputs, as well as performance evaluation |

| RoHS/REACH | Environmental | Restricted materials compliance |

How do Manufacturers Ensure Authenticity in Classic Car Wiring?

Manufacturers ensure authenticity through material selection and manufacturing techniques that match original specifications. Period-correct materials including specific cotton braid patterns, exact wire gauges (typically 18 AWG for lighting circuits, 16 AWG for charging), and authentic color coding systems maintain historical accuracy. Professional manufacturers source specialized materials and maintain extensive catalog documentation of original factory specifications.

Authenticity Elements

- Exact color matching to original manufacturer specifications

- Proper wire gauging according to original load requirements

- Authentic terminal and relay reproduction

- Correct routing paths and attachment points

- Period-appropriate chrome switch compatibility

Manufacturing Location Advantages

OurPCB's Shijiazhuang facilities benefit from being located in one of China's specialized manufacturing clusters. This region offers:

- Complete component supply chain access

- Specialized material sourcing networks

- Technical workforce with automotive expertise

- Advanced testing equipment availability

- Efficient logistics for battery cables and accessories

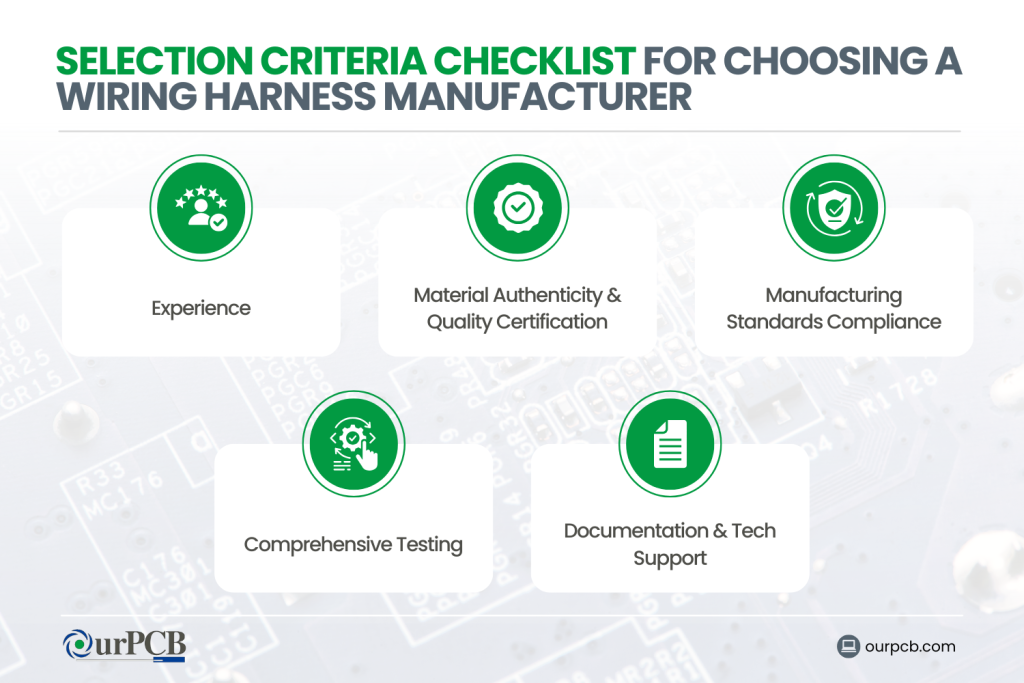

How Should You Choose a Wiring Harness Manufacturer?

You should choose a wiring harness manufacturer based on their technical capabilities with your specific classic car make and model. Manufacturers specializing in your vehicle type will understand original specifications, proper installation, and connector requirements. Technical capabilities should include appropriate material selection, manufacturing precision, and quality testing protocols.

Selection Criteria Checklist

- Experience with your specific vehicle make/model (Jeep CJ, GM, Chrysler)

- Material authenticity and quality certification

- Manufacturing standards compliance (IATF 16949)

- Custom design capabilities for rewire projects

- Comprehensive testing of electrical components

- Documentation and tech support

Ready to Restore Your Classic Car's Electrical System?

Contact OurPCB today for expert classic car wiring harness manufacturing that combines authentic reproduction with modern reliability. Our integrated PCB and wiring harness capabilities provide complete electrical system solutions for your restoration project.

Request a consultation to discuss your specific classic car wiring needs.

Frequently Asked Questions

How do modern safety improvements integrate with classic car wiring harnesses?

Modern safety improvements integrate with classic car wiring harnesses through upgraded fuse boxes and enhanced insulation materials. Manufacturers incorporate circuit protection where original designs had none, utilize flame-retardant materials that maintain vintage appearance, and redesign charging systems to prevent overheating. These improvements maintain period-correct aesthetics while significantly reducing fire risks.

What is the manufacturing process for custom classic car wiring harnesses?

The manufacturing process involves design documentation, wire preparation, specialized terminal crimping, and systematic assembly on custom fixtures. Manufacturers create detailed wiring diagrams based on original specifications, prepare materials including wire cutting to ±0.5 mm precision, and terminate connections with verified pull-test strength. Assembly takes place on specialized boards followed by comprehensive testing including continuity verification and load capacity validation.

Can wire harnesses be partially upgraded rather than completely replaced?

Wire harnesses can be partially upgraded through sectional manufacturing and connector adaptation techniques. Manufacturers can assemble sub-harnesses for specific vehicle sections (dashboard, engine bay) while maintaining compatibility with original spark plug wires and switches. This approach allows targeted replacement of deteriorated sections while preserving functional original wiring, providing excellent customer service with cost-effective solutions.

Back to Top: Top 10 Classic Car Wiring Harness Manufacturers | Full Guide

Special Offer: Get $100 off your order!

Email [email protected] to get started!