Solderability Test: In the manufacture of PCBs, two things matter the most: the product’s quality and the choice of PCB materials.

If you want to ensure that PCB production runs smoothly, then some tests are necessary. As a PCB manufacturer, you need to reduce PCB failures to elevate the quality levels of your final product. Among other types of tests, the solderability test tops the list.

As a practitioner in the PCB industry, you need a clear understanding of the specific processes involved in solderability testing. By going through this article, you’ll gain valuable insights into solderability testing, the problems it can solve, and its operation process, to mention just a few aspects of PCB fabrication and assembly that are crucial for enhancing product reliability.

Below is what you need to know about the solderability test.

Contents

- What is the PCB Solderability Test?

- The Primary Types of Solderability Tests

- “Immersion” approach

- The surface mount simulation test

- Wet balance analysis

- What Is the Standard Solderability Test for PCBs?

- Dip-and-Look vs. Wetting Balance Methods for Solderability Testing: Which Types Do I Need?

- Equipment and Tools Needed for the Solderability Tests

- Solder Flux

- Solder Paste

- Solder suckers

- Wire cutters

- Soldering iron tip cleaner

- Desoldering Wick

- Circuit board holder

- The Printed Circuit Board

- The Importance of PCB Solderability Tests

- Evaluation of PCB coating, solder, and flux

- Perform quality control

- Reduce assembly problems, including misapplication of solder mask

- Improve the possibility of reliable solder joints

- Verify secure storage

- Advantages of PCB solderability tests

- Check all openings in the designated area.

- A comprehensive inspection of solder residue

- Measure surface tension

- Reduce the risk of damaging thermal components

- Solderability can save costs.

- Are the solderability tests required for all PCB projects?

- Fridge Door Alarm

- DIY Clap Switch Circuit

- Music Reactive LED Circuit

- Electronic Piano Printed Circuit Board

- Call Detector Printed Circuit Board

- Crystal Testers

- Battery Voltage Monitor

- Is this test necessary?

- Is Solderability a Destructive Test?

- How To Improve the Possibility of Reliable PCB Soldering

- Can you afford the price of the solderability tests?

- Solderability tests–The high cost of equipment

- Summary

What is the PCB Solderability Test?

The solderability test determines the solderability of terminals and leads through a specific soldering operation.

Solderability measures how perfect or imperfect the metal is wet by molten solder to secure all connections.

Evaluating solderability tells your PCB tester whether the attached parts, such as terminations and leads, can withstand high temperatures.

High temperatures may occur during welding. Tests also determine whether these components’ storage will adversely affect their ability to solder to circuit boards.

Understanding matters to do with PCB solderability tests can significantly minimize board failures while improving the product’s final quality.

In short, solderability is the molten solder’s ability to maintain a uniform liquid state unbroken and even during the soldering process.

The Primary Types of Solderability Tests

There are three primary types of solderability tests. They include the following:

“Immersion” approach

This method also goes by the name Dip and Look. The “immersion” approach subjects the termination and leads up to 8 hours of steam conditioning.

The steam conditioning is over; what follows is the dipping of components’ termination into the solder.

This factor accelerates the aging process. Finally, inspection follows to ensure that they meet the required standards.

The surface mount simulation test

It is another primary type of solderability test. It’s available for all SMT components, such as those that aren’t compatible with other types of PCB test methods, such as the “immersion” approach.

Wet balance analysis

Lastly, there’s wet balance analysis, a type of test that ages the circuit board components.

Here, the testers get to plot the wetting force, beginning at negative (non-wet).

(SMT simulation test)

What Is the Standard Solderability Test for PCBs?

The standard solderability test methods for PCBs are dip-and-look and wetting balance.

Dip-and-look is a qualitative test that involves applying flux on Leaded or Leadless PCB terminations and then immersing them in molten solder for comparative analysis.

An electronics engineer looking through a magnifying glass to inspect a PCB

On the other hand, wetting balance testing is a quantitative test that involves dipping the testing surface in a bath of molten solder and imposing wetting forces to plot the wetting force as a function of time.

This graph creates a wetting curve (force against time), which you can compare before re-tinning and after re-tinning.

Dip-and-Look vs. Wetting Balance Methods for Solderability Testing: Which Types Do I Need?

Both testing methods accelerate the aging process of device package terminations on circuit boards before testing.

The wetting balance testing method is more precise because it measures the wetting forces between the liquid (molten) solder and the testing surface as a function of time.

However, the wetting curve interpretation requires a skilled technician who understands the results.

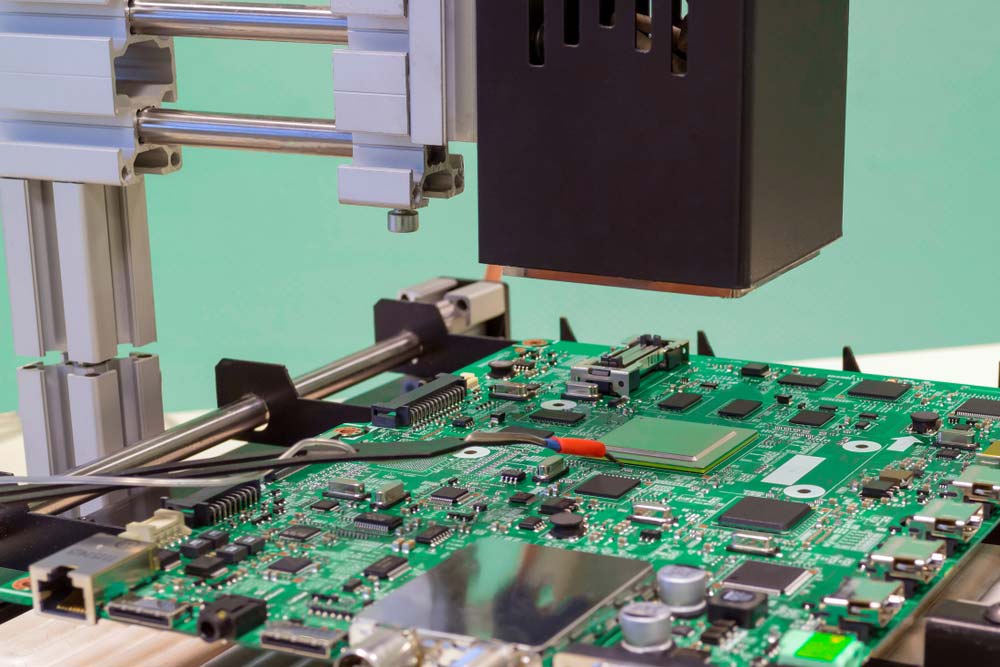

Chip replacement on a circuit board in a rework station

Dip-and-look testing is not as precise as wetting balance testing but is subjective because it involves comparative analysis. Also, you can do the test quickly after minimal training.

Therefore, you should consider the wetting balance testing method for your PCBs if you are making sophisticated products that require maximum reliability.

It will cost more because it is quantitative and requires technical analysis.

But dip-and-look testing is sufficient for simple electronics like toys.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Equipment and Tools Needed for the Solderability Tests

The right tools and equipment are one of those factors which will see you staying relevant in a competitive environment.

Without a doubt, one of the essential tools that you must have is the soldering iron.

A soldering iron provides the heat source to melt the solder. But again, the soldering iron doesn’t need to be expensive as such.

If you look around, you’ll find some that go for as little as $10.

Besides the soldering iron, other tools that you may need during soldering include the following:

Solder Flux

The Solder Flux acts as a purifying agent, and it purifies the components while closing out extra air to prevent rust.

The Solder Flux is one of the essential tools to have at hand when soldering.

Manufacturers love it as it goes further to better the dripping individuality of the solder itself.

Solder Paste

Solder Paste joins various leads of chip packages to connection ends of boards.

The solder paste appears like a gray putty-like substance.

During soldering, the paste joins the multiple charges of chip packages to the connection ends on a PCB.

Solder suckers

Solder suckers also go by the name solder pumps. These mechanical vacuum pumps suck solder away from solder joints.

They enable the removal of solder from a joint for components desoldering for rework.

Wire cutters

Even though they tend to be small, wire cutters are convenient tools. You can use the wire cutter to cut off long component legs.

Also, you can use these wire cutters to strip the end of the wires.

Wire cutters again go by names such as diagonal cutters, flush-cutters, clippers, electronic snippers, and more.

Soldering iron tip cleaner

Soldering tip cleaners are necessary during soldering. They are for cleaning iron tips from any old solder or carbon accumulation. If you want your soldering iron to last for long, then you’ll need soldering iron tip cleaners.

Desoldering Wick

Manufacturers use this to clean the leftovers of solder that remained behind during soldering.

A desoldering wick is a finely braided copper wire. The copper wire has a rosin coating flux that can finely remove excess copper.

Circuit board holder

It is the perfect equipment for holding the PCB into place during soldering.

Some refer to this equipment as a soldering helping hand and comes in handy when soldering adequate equipment.

The circuit board holder fixes the objects at the required angles for soldering.

The Printed Circuit Board

Of course, you’ll need a printed circuit board where your components will sit. Depending on your project’s needs, the circuit board could be rigid, flexible, or rigid-flex.

The above isn’t all the tools that you’ll need. Others you may find ideal include Soldering Iron Stand, Preheaters, Thin nose pliers, etc.

Depending on your project’s size, you may find yourself requiring more tools and equipment than you imagined.

If the project is somewhat DIY, then the tools needed may not be too many and detailed.

(A close pic of solderability equipment)

The Importance of PCB Solderability Tests

Solderability test on a printed circuit board is critical. If you fail to undertake some tests, then you are inviting trouble.

There’s nothing riskier and expensive than rolling out faulty boards to the market.

You can avoid such by only undertaking solderability tests. So what’s the importance of the PCB solderability test? Here they are:

Evaluation of PCB coating, solder, and flux

Solderability tests ensure that you assess the quality of your coating, solder, and flux before introducing them to the market.

Having great coating solder and flux will give the end-user ample time during repairs while also ensuring the product is long-lasting.

Perform quality control

Solderability tests confirm that there’s quality control of the circuit boards that PCB manufacturers make.

By doing so, manufacturers ensure that they produce high-quality products that meet customer satisfaction.

Reduce assembly problems, including misapplication of solder mask

During assembly, problems are likely to occur. Some of the typical assembly problems include insufficient copper-to-edge clearance and lousy soldering.

Others include the misapplication of the mask, the solder mask, and non-wetting challenges. Fortunately, though, such isn’t the case with solderability tests.

Manufacturers that get to undertake solderability tests will realize reduced assembly problems, an aspect that gives them an edge over their competitors.

Improve the possibility of reliable solder joints

In the field of electronics, the quality of the solder matters a lot. Therefore, with poor solder joints, then the transmission of signals from one point of the board to the next would almost be impossible.

Reliability in solder joints is necessary for the proper functionality of the whole board.

These tests point out faulty solder joints that need attention, thereby bringing out the possibility of having reliable solder joints.

Verify secure storage

It’s essential to store these circuits within the shortest time possible as means of reducing possible damages.

Solderability tests are crucial here because they help verify that suppliers meet solderability requirements.

They help in proving that storage conditions don’t degrade solderability.

With solderability tests, it’s easy to estimate some of the long-term effects that accompany storage.

(The process of PCB solderability)

Advantages of PCB solderability tests

Check all openings in the designated area.

A circuit board must have openings at some places. These openings play different roles, such as transmitting current to other sites on the board.

Solderability tests are advantageous as they check if all the spaces on a board’s designated area are there.

Without solderability tests, then it would be challenging to review the entire openings on board.

A comprehensive inspection of solder residue

With solderability testing, you get to inspect all the solder residue left on the board upon completing the soldering process.

Even though it is typically hard for manufacturers to thoroughly check for the residues during production, you can’t avoid the tests’ inspections.

Removing the excess solder residue improves the board’s quality and appeal and makes it easy to operate during repairs.

Measure surface tension

Solderability tests are ideal ways of measuring a boards’ surface tension. Even though many circuit manufacturers use dyne pens, solderability tests are also suitable for measuring surface tension.

Reduce the risk of damaging thermal components

There’s nothing worse than damaging the thermal components of your circuit board. Such may end up being a very costly affair that will see you spending unnecessary costs.

However, such isn’t the case when it comes to solderability testing. Here, the parts undergo soldering for short periods.

Such will reduce the risk of damaging heat-sensitive components.

Solderability can save costs.

Without a doubt, solderability is much easier and less costly for manufacturers to prevent poorly soldered boards from reaching full production.

(High-quality solderability-tested boards)

Are the solderability tests required for all PCB projects?

There are plenty of printed circuit board projects out there. Some are for hobbyists and DIY enthusiasts, while others are professional and meant for big projects. Some apt examples of PCB electronic projects for beginners include:

Fridge Door Alarm

It is one of those simple PCB projects. It can detect and subsequently inform the status of the refrigeration unit’s door. If the door is open for long, then there’s the production of a long and monotonous beeping noise.

DIY Clap Switch Circuit

It is a simple electronic circuit known for making use of dynamic control applications by use of sound. It’s relatively easy to understand and cheap to create.

Music Reactive LED Circuit

This device responds to rhythmic changes of any musical instrument. They are suitable for those starting in the world of PCBs.

Electronic Piano Printed Circuit Board

The electronic piano is also a simple PCB project. This piano tends to produce a melodic sound with every press of a button.

Call Detector Printed Circuit Board

The call detector PCB can easily detect the presence of any nearby RF transmitting mobile device nearby. It can also provide easy alerts concerning it.

Crystal Testers

They play the role of oscillators aimed at generating high frequencies. In major electronic projects, crystal finds heavy usage as opposed to coils. Here, the use of PCBs is also every day.

Battery Voltage Monitor

This one monitors the charging and discharging of the battery. It makes sure that the battery voltage does not exceed the specified level. Again, the use of PCBs is evident here.

The above does not constitute the entire beginner projects that may require the use of printed circuit boards. There are plenty of other beginner’s/DIY projects where the use of printed circuit boards finds heavy use.

Is this test necessary?

Regardless of the project at hand, solderability tests are necessary. As mentioned earlier, solderability is more of a cost-saving mechanism. It also reduces the risks of damaging the internal components and ensure that the members have a stable electrical contact—professionals and DIY alike need to ensure that they subject all their projects to solderability tests.

Based on the advantages above and the importance of solderability tests, no project needs to ignore such tests. In short, solderability tests are ideal for all PCB projects. Without them, manufacturers may end up rolling out faulty boards that aren’t fit for market use.

(Professional PCBs under solderability test)

Is Solderability a Destructive Test?

Yes, it is. Solderability testing damages the circuit board, making it destructive.

However, it is cheaper in the long run because it helps you analyze product samples before you embark on component assembly to identify and solve the issues relating to poorly soldered parts that require reworking.

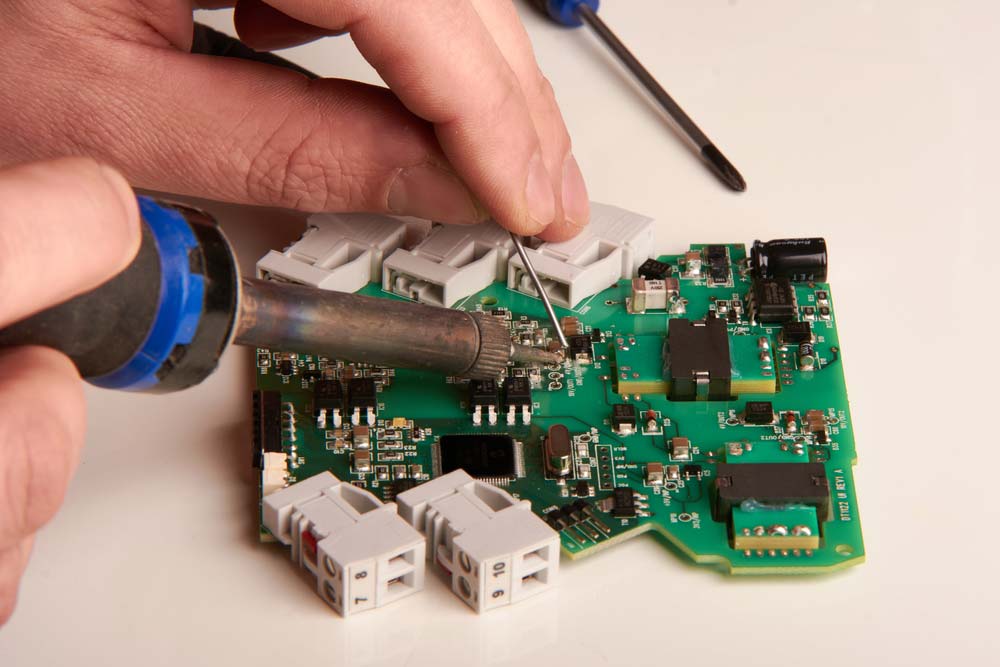

A close-up image of component soldering on a printed circuit board

Without it, your products will have manufacturer defects that lead to recalls, poor sales, questionable reliability, and a damaged reputation.

How To Improve the Possibility of Reliable PCB Soldering

Preparation is as important as the soldering process itself. Therefore, you should clean the board using isopropyl alcohol to eliminate fingerprints, debris, and oxidation.

Also, trim the component pins to prevent shorting with adjacent pads. They should not extend beyond the pad.

Remember to apply flux before soldering or use a rosin-core solder to remove oxides from the surface. This acidic material enhances wetting and maximizes solder flow by eliminating surface tension and forming sturdy intermolecular bonds.

A roll of rosin-core Tin-Lead solder wire

You’ll also have to pre-heat the surface before soldering to eliminate surface tension.

Lastly, have a solder wick to absorb excess solder. The joint should have just the right amount to be reliable.

Can you afford the price of the solderability tests?

Do you think that the cost of the solderability test is cheap? If so, then you are in for a rude shock. The price of undertaking solderability tests is relatively high, especially if you are starting. Most printed circuit board designers give up way before they even venture on their projects.

For instance, looking around, you’ll notice that solder paste doesn’t come cheap, as you may imagine. The cheapest ones go for about $100, and that’s just a single-pound roll.

If you seek such services from PCB makers, then rest assured of high solderability costs. Besides the solder paste, the soldering station is also expensive.

While you may think of sourcing them cheaply from offshore countries, you’ll still have to pay huge shipping costs.

Solderability tests–The high cost of equipment

Soldering equipment doesn’t also come relatively cheap. For instance, some of the most affordable and mostly low-quality soldering irons go for $10. How about the best ones in the market, then?

Most of them are so expensive, with manufacturing affording them. That’s not all when it comes to solderability expenses.

The cost of repairing errors occurring during the soldering process is also high.

As you can see from above, solderability tests are slightly a costly affair. But that doesn’t mean that you cannot afford it.

You can suit your needs depending on your budget. If you are on a budget, then you can go for cheaper tests.

(A highly expensive multi-layer PCB)

Summary

Now more than ever, we cannot ignore the importance of solderability testing, especially across the circuit board industry.

Solderability comes with many benefits, such as the ones mentioned above.

We at OurPCB understand the importance of solderability testing. We have the equipment to do such tests with ease.

Better yet, it doesn’t have to be expensive on your end. We can have a discussion and meet in the middle. Do you have any upcoming PCB solderability test needs?

We can help you with such in addition to more PCB production. Call us today for a discussion about what you need to know about solderability testing and PCB production.

Special Offer: Get $100 off your order!

Email [email protected] to get started!