Contents

- What is Conformal Coating?

- How Conformal Coating Protects Electronics

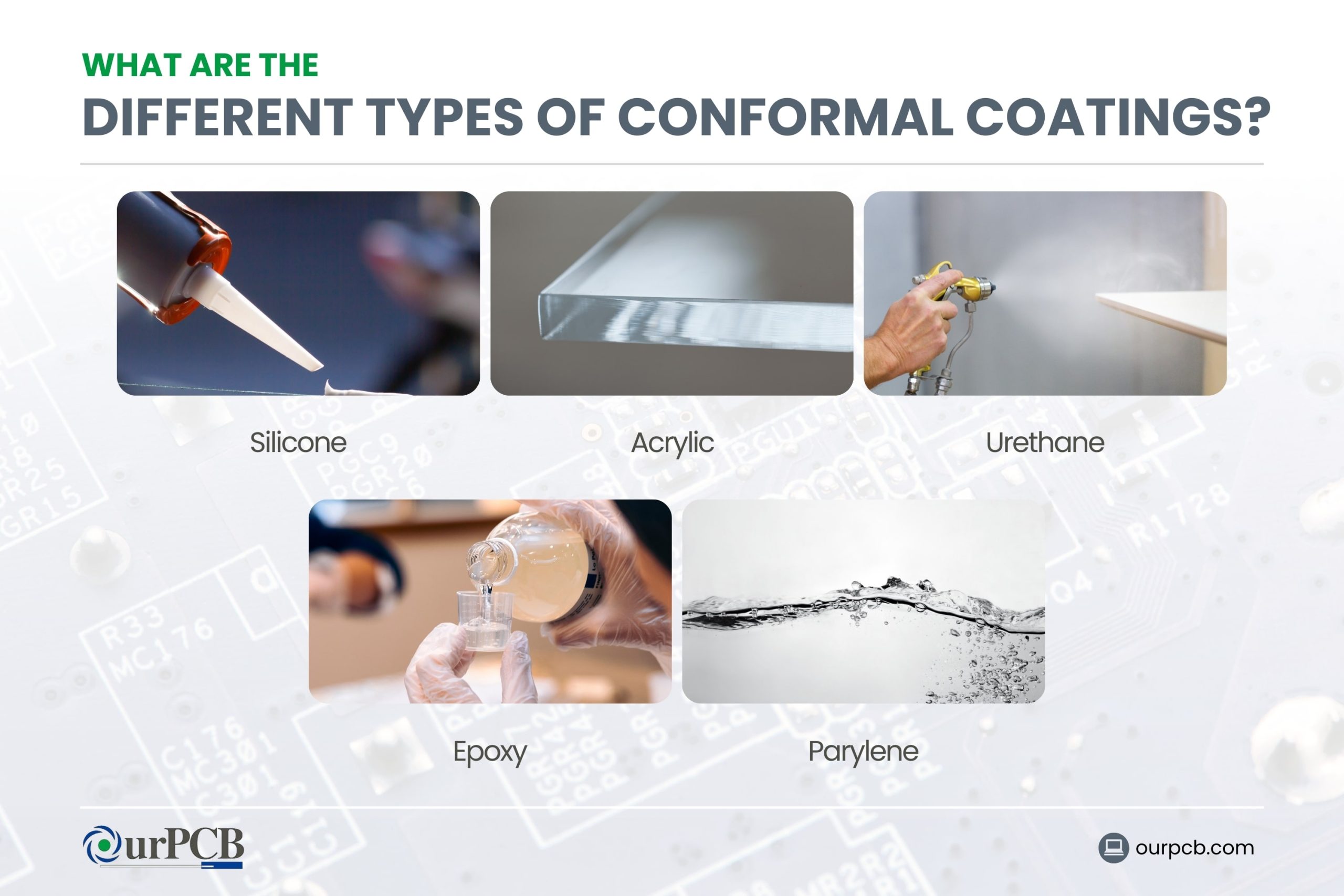

- Types of Conformal Coatings

- Acrylic Coatings (AR)

- Silicone Coatings (SR)

- Urethane Coatings (UR)

- Epoxy Coatings (ER)

- Parylene Coatings (XY)

- Benefits of Conformal Coating

- Application Methods

- Application Best Practices

- Masking Techniques

- Curing Methods

- UV Curing

- Thickness Considerations

- Standards and Certifications

- Troubleshooting Common Issues

- De-wetting and Fish Eyes

- Bubbles and Voids

- Cracking and Delamination

- Rework Procedures

- Selection Guide and FAQs

- How do I choose the right conformal coating for my application?

- How long will different coating types last?

- Do I need to address flux residue before applying a conformal coating?

- How will conformal coatings affect my assembly’s thermal performance?

What is Conformal Coating?

A conformal coating is a thin polymeric film (25-250 μm thick) that conforms to PCB contours, providing environmental protection while allowing trapped moisture to escape. Originally developed for aerospace and military applications, conformal coating is now widely used across automotive, industrial, medical, and consumer electronics industries.

How Conformal Coating Protects Electronics

Conformal coating provides multiple protective mechanisms:

- Creates a barrier against moisture, dust, chemicals, and contaminants

- Provides dielectric isolation (400-1500 volts/mil) preventing current leakage

- Adds physical reinforcement against vibration and impact

- Helps distribute heat more evenly across components

- Prevents biological growth and tin whisker formation

Types of Conformal Coatings

| Property | Acrylic (AR) | Silicone (SR) | Urethane (UR) | Epoxy (ER) | Parylene (XY) |

|---|---|---|---|---|---|

| Temp. Range | -55 to 125°C | -65 to 200°C | -40 to 130°C | -55 to 150°C | -65 to 200°C |

| Dielectric Strength | 1500 V/mil | 1100 V/mil | 1800 V/mil | 1700 V/mil | 7000 V/mil |

| Moisture Resistance | Good | Excellent | Very Good | Excellent | Excellent |

| Chemical Resistance | Poor | Good | Very Good | Excellent | Excellent |

| Solvent Resistance | Poor | Good | Very Good | Excellent | Excellent |

| Abrasion Resistance | Fair | Poor | Good | Excellent | Good |

| Ease of Rework | Excellent | Poor | Poor | Very Poor | Poor |

| Typical Thickness | 25-75 μm | 50-200 μm | 25-75 μm | 25-75 μm | 12.5-50 μm |

| Relative Cost | $ | $$ | $$ | $$ | $$$$$ |

| Curing Method | Solvent evap. | Moisture | Moisture/Heat | Heat | N/A (CVD) |

| Typical Cure Time | 30 min-24h | 24-72 hours | 24-48 hours | 2-3 hours | N/A |

Acrylic Coatings (AR)

Economical solution with good moisture resistance and excellent reworkability using common solvents. Ideal for consumer electronics and devices requiring maintenance. Limited chemical and abrasion resistance make it unsuitable for harsh environments.

Silicone Coatings (SR)

Exceptional performance in extreme temperatures (-65°C to +200°C) with excellent humidity protection. Their elastomeric properties absorb mechanical and thermal stress. Particularly valuable in automotive applications but difficult to rework and have longer curing times.

Urethane Coatings (UR)

Offer balanced protection with superior chemical, solvent, and abrasion resistance. Well-suited for industrial environments and automotive applications. Difficult to rework and less tolerant of high humidity during application.

Epoxy Coatings (ER)

Two-part systems providing excellent abrasion, moisture, and chemical resistance with high temperature tolerance (up to 150°C). Ideal for industrial applications with harsh chemicals. Extremely difficult to remove for rework and may shrink during curing.

Parylene Coatings (XY)

Applied through chemical vapor deposition, creating extremely uniform, pinhole-free coatings with remarkable dielectric strength (7,000 V/mil). FDA-approved for medical implants. Requires expensive equipment ($100,000+) and difficult to selectively apply or rework.

Benefits of Conformal Coating

- Environmental Protection: Extends device lifespan 5-10× in humid environments and shields against chemicals and contaminants

- Electrical Benefits: Enables 80% reduction in conductor spacing, improves high-voltage performance, and prevents shorts from conductive particles

- Mechanical Benefits: Reinforces solder joints, reduces failures from vibration, and eliminates need for bulky enclosures

- Cost Benefits: Decreases field failures by 50-80%, simplifies mechanical design, and enables miniaturization

Application Methods

| Method | Production Volume | Thickness Control | Coverage Quality | Equipment Cost | Best For |

|---|---|---|---|---|---|

| Brushing | Low | Poor | Fair | Very Low | Prototypes, repairs, touch-ups |

| Spraying (Manual) | Low/Medium | Fair | Good | Low | Small production runs |

| Spraying (Automated) | Medium/High | Good | Very Good | High | Medium-volume production |

| Dipping | High | Very Good | Excellent | Medium | High-volume, total coverage |

| Selective Coating | Medium/High | Excellent | Very Good | Very High | Precision application without masking |

| Vapor Deposition | Any | Excellent | Excellent | Extremely High | Medical, aerospace applications |

Application Best Practices

- Brushing: Use high-quality lint-free brushes and apply multiple thin coats

- Spraying: Maintain 20-30 cm distance, control temperature (20-25°C) and humidity (<65% RH)

- Dipping: Control withdrawal speed (3-30 cm/minute) and maintain consistent viscosity

- Selective Coating: Optimize viscosity for the dispensing system and validate programming

- Vapor Deposition: Ensure thorough cleaning and proper masking before processing

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Masking Techniques

For areas that must remain uncoated (connectors, test points):

- Masking Tapes: High-temperature polyester or polyimide tapes with silicone adhesives

- Masking Boots/Caps: Pre-formed silicone or latex covers for specific components

- Peelable Masks: Liquid latex-based materials applied via dispensing systems

- Masking Fixtures: Custom mechanical shields for automated processes

Remove masking after coating reaches tack-free stage but before full cure.

Curing Methods

| Curing Method | Speed | Energy Usage | Compatible Coatings | Best For |

|---|---|---|---|---|

| Room Temperature | Very Slow | None | All types | Low volume, simple setups |

| Thermal (Oven) | Moderate | High | All types | Consistent results |

| UV | Very Fast | Low | UV-formulated types only | High-volume production |

| Moisture | Slow | None | Silicones, some urethanes | Field applications |

UV Curing

UV curing offers extremely rapid processing (seconds to minutes) using photoinitiators that trigger polymerization when exposed to UV light (365-385nm). This solvent-free approach reduces energy consumption by 80% compared to thermal methods. Consider shadow areas where components block UV light.

Thickness Considerations

| Environmental Severity | Recommended Thickness | Example Applications |

|---|---|---|

| Mild (Indoor) | 25-50 μm (1-2 mils) | Consumer electronics |

| Moderate | 50-75 μm (2-3 mils) | Industrial controls |

| Severe | 75-127 μm (3-5 mils) | Automotive, outdoor |

| Extreme | >127 μm (>5 mils) | Military, aerospace |

When thickness exceeds 127 μm (5 mils), the protection strategy transitions from conformal coating to encapsulation/potting, which adds substantial mechanical reinforcement but increases weight and reduces flexibility.

Standards and Certifications

Key standards regulating conformal coating include:

- IPC-CC-830: Primary commercial standard establishing performance requirements through environmental, electrical, and physical testing

- MIL-I-46058C: Military qualification standard (now inactive but referenced)

- UL 746E: Underwriters Laboratories standard for electrical insulation properties

- ASTM E595: Outgassing characteristics for space applications

Troubleshooting Common Issues

De-wetting and Fish Eyes

Causes: Surface contamination, incompatible materials, improper preparation Solutions: Thorough cleaning with appropriate solvents, plasma treatment, or primer application

Bubbles and Voids

Causes: Trapped air, outgassing, rapid curing, moisture in air supply Solutions: Vacuum degassing, thinner coats with adequate flash-off time, improved air filtration

Cracking and Delamination

Causes: Excessive thickness, thermal mismatch, insufficient cleaning, rapid curing Solutions: Multiple thin coats, gradual temperature ramping, thorough substrate preparation

Rework Procedures

Rework approaches vary by coating type:

- Acrylic: Easily removed with solvents (acetone, MEK) in 1-5 minutes

- Silicone: Requires specialized strippers, swells rather than dissolves, needs mechanical scraping

- Urethane/Epoxy: Requires aggressive chemicals combined with mechanical methods

- Parylene: Very difficult to remove, typically requiring mechanical abrasion

After component replacement:

- Thoroughly clean the rework area

- Apply new coating that overlaps original coating by at least 3mm

- Match original coating type when possible

- Verify coverage under UV light before returning to service

Selection Guide and FAQs

How do I choose the right conformal coating for my application?

Consider:

- Environmental exposure (temperature, humidity, chemicals)

- Rework requirements (frequency of maintenance/modifications)

- Application method availability and production volume

- Component compatibility with coating and curing

- Regulatory requirements for your industry

How long will different coating types last?

- Silicones and parylenes: 10-20+ years in controlled environments

- Acrylics: 5-10 years typical

- Harsh environments significantly reduce lifespan

- Proper application and thickness directly impact durability

Do I need to address flux residue before applying a conformal coating?

While some coatings claim compatibility with no-clean fluxes, thorough cleaning before coating application remains best practice:

- Even "no-clean" fluxes can cause adhesion problems and corrosion under coating

- Traditional rosin fluxes contain activators that remain corrosive when trapped

- Water-soluble fluxes are highly conductive and corrosive when moisture is present

How will conformal coatings affect my assembly’s thermal performance?

Coatings affect heat dissipation:

- Silicones offer best thermal conductivity (0.15-0.30 W/m·K)

- Thicker coatings increase thermal resistance

- Consider selective coating to leave high-power components uncoated

- Test actual temperature differences in coated vs. uncoated assemblies

Back to top: PCB Conformal Coating: Types, Applications & Best Practices?

Special Offer: Get $100 off your order!

Email [email protected] to get started!