After assembling your PCB board and testing it to ensure everything works as required, the next step is mounting it. You need several items to ensure the board sits and performs optimally in its housing.

For this, you need PCB hardware, and we have listed what you need to mount your board successfully.

Contents

- Why is PCB Hardware Important?

- PCB Mounting Methods

- Components of PCB Mounting Hardware

- PCB Supports

- PCB Spacers

- Card Guides

- Card Ejectors and Pullers

- PCB Mounting Blocks

- Fuse Covers

- PCB Fan Accessories

- LED Mounting Hardware

- Screw Grommets

- Transistor Insulators

- Common Materials for PCB Hardware

- Polyvinyl Chloride (PVC)

- Nylon

- Acetal

- Acrylonitrile-butadiene-styrene (ABS)

- How to Choose PCB Hardware?

- Application Area

- Mounting Type

- PCB Substrate Type

- Material Type

- PCB Hardware Design vs. PCB Design: Difference

- Summary

Why is PCB Hardware Important?

When assembling a PCB, you need some hardware pieces to help you mount the board in its cabinet, junction box, or appliance.

In other words, you cannot place the board without securing it and attaching extra hardware to ensure it works optimally. The hardware pieces needed for these purposes are the PCB hardware.

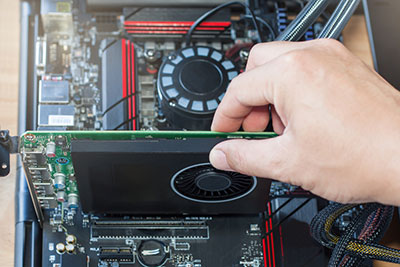

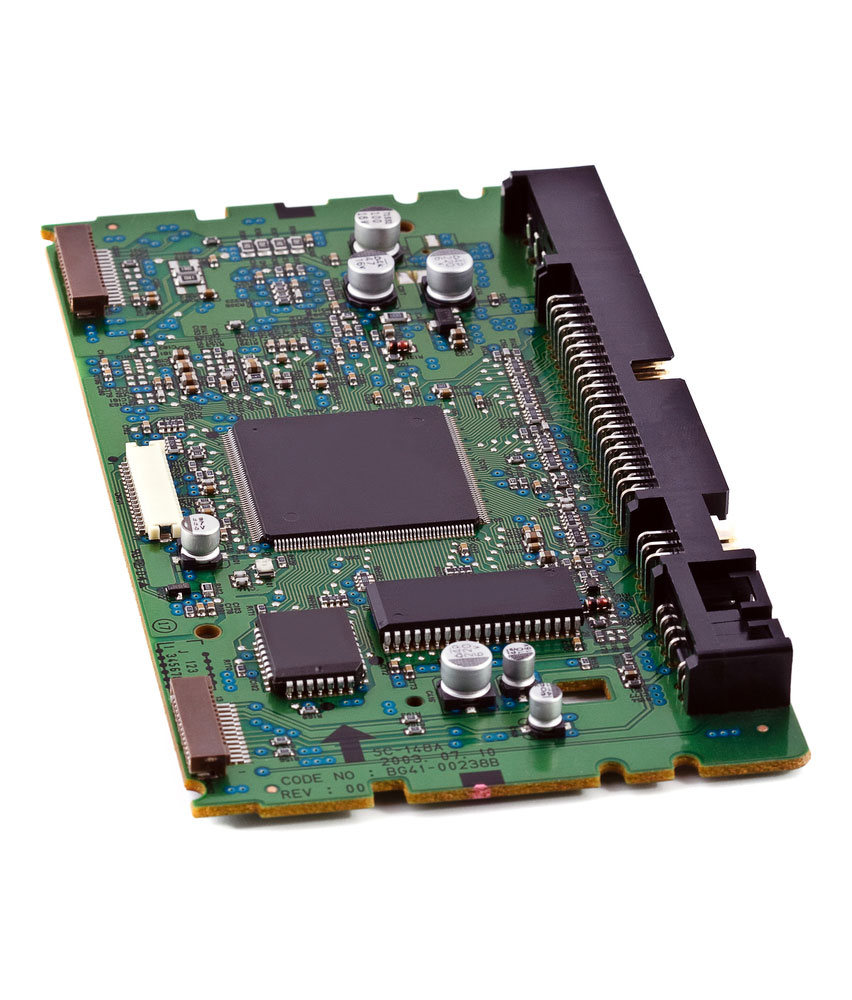

Assembled PCB

PCB Mounting Methods

PCB mounting in a factory.

Mounting the PCB on its encasing body requires a sturdy solution to ensure it is secure.

You must choose between plastic and metallic mounting options depending on your preference.

Notably, the plastic mount produces a lighter PCB than the metallic one.

Mounting options include the following:

- Snap Lock: It's the go-to option when you want to mount the PCB onto the panel hole or the chassis. Its upside is that you can easily unsnap it if needed.

- Blind Holes: Also called pres fits, include fins with binding holes where you drive in the PCB.

- Snap Fit: Similar to snap lock fittings, snap-fit fittings allow quick installations, which can save time during installation.

- Adhesive Base: This is the most dependable option if you don’t fancy having mounting holes to install the PCB. It's also a space-saving alternative to the other mounting methods.

Components of PCB Mounting Hardware

You need the following items.

PCB Supports

Also known as PCB support pillars or posts, these supports hold a circuit board in place, providing a stable, secure hold. Additionally, they provide insulation and protection from the soldered electrical joints

The component can be plastic or metallic. Plastic supports are lighter and easier to install than their metallic counterparts. The mounting options/types are different and include the following.

Self-Adhesive PCB Support

Adhesive base supports don't require mounting holes, creating time and space efficiencies.

Snap-Lock

Snap-lock posts fit and lock into a panel/chassis hole, creating a secure but easy-to-release fix.

Snap-Fit

Snap-fit pillars push quickly into a chassis hole, saving time during installation. Generally, they provide sturdy and efficient support and include types like a bayonet, edge lock, and fir tree.

Press Fit/ Blind Hole

This pillar contains blind hole fins that hold securely into the panel hole. Also, they feature a painted style that fits easily into slots with space restrictions.

Threaded

- Undercut: These pillars give a more secure fit by fixing the board into the thread.

- Standard: Such supports hold the board via a nut that you can release or tighten.

- Self-Tapping: Require no nuts or washers because they have self-tapping threads.

PCB Spacers

As the name suggests, spacers help keep some spacing between PCBs and their positioning. They are common in consumer electronics and data cabinets with limited spaces.

Spacers fall into different categories, which include the following.

Material

Ceramic spacers are ideal for high-temperature applications. On the other hand, plastic spacers are affordable and corrosion-resistant. Also, they are lightweight and provide good mechanical properties.

Body Shape

The spacer length and internal diameter can vary, but the available shapes include round standoff or hexagonal spacers. These can either be threaded or unthreaded with male or female connector ends. Other varieties include self-tapping and metric threaded standoff.

Card Guides

PCB card guides are mounting hardware used to fit circuit boards in tight spaces, usually in electrical cabinets or racks. Additionally, they keep the PCB from bending. They come in different types, which include the following.

- Adhesive backs

- Snap-in

- Screw card guides

- Push-fit guides

Also, you can categorize them by material, leaving you with acetal, nylon, polycarbonate, ABS, polystyrene, and PVC. These have operating temperatures ranging between -40°C to 140°C (-40°F to 284°F).

Card Ejectors and Pullers

Also known as extractors, inserters, or circuit card pullers, card ejectors help relieve stress in circuits. They do so by pulling the board out of restricted spaces. They mount on the board and have handles you can use to pull out the PCB.

Essentially, they act as levers, utilizing mechanical strength against the chassis/guide rack to force out the board.

Also, you can use the piece of hardware to push the board back into position. Therefore, it comes in handy if you are experiencing extraction/insertion issues.

These issues typically occur when dealing with tight-gripping multi-pin edge connectors and large boards.

PCB Mounting Blocks

Mounting blocks create a secure connection if using solderless connectors. They are ideal for mounting PCBs and tiny panels at right angles. Also, they provide both electrical properties and mechanical strength.

Fuse Covers

Fuse covers envelop electrical fuses for insulation and protection from liquids and contamination. They include rigid/solid, flexible, transparent, quick fit, and holder covers.

PCB Fan Accessories

Fan accessories are essential because they assist with heat management. Technically, they don't help transfer heat, but they safeguard the fan, whose work is to blow or transfer heat out of the PCB. They include the following.

Fan Gasket

This accessory provides noise and vibration insulation while preventing air leaks. It seals the tiny gap between the fan and housing, improving efficiency, minimizing feedback airflow, and reducing pressure losses.

Fan Guard

Fan guards keep dust and water particles from getting to the PCB. Most are plastic or metallic, and the choice between the two should depend on your preferred strength or appearance.

Besides that, plastic fan guards are more versatile because you can mount them by screwing or snap-in. However, you can only install metal fan guards by screw-mount application.

Fan Mounts

This accessory helps secure and position your fan. The anti-vibration rubber fan mounts are usually elastomer made (ABS or silicone rubber) and assist in noise reduction.

Fan Filters

Filters prevent dust and small particles in the fan's airflow from getting into its internal mechanisms and causing internal damage.

Aluminum and stainless-steel filters allow more air to flow freely than the felt type, but the increased airflow comes with more dust. However, they are easier to clean, take up less space, and feature a sleeker design.

However, it is more convenient to get a filter set because it contains a filter cover, finger guard, felt filter, and mesh filter.

Fan Rivets

Instead of using screws and nuts when mounting the fan, it is easier to use rivets.

You can either use push-fan or fan-snap rivets for this installation.

LED Mounting Hardware

LED mounting hardware like LED spacer mounts hold the position and restrict the movement of your LED lights. The spacers also elevate the LEDs from the board's surface for better stability, height conformity, and rigidity.

Other components include LED mounts, which contain holes to pass the leads through before soldering the LED. Even though thru-hole LED sizes can vary, the spacer must have the precise hole number to accommodate the attached leads.

SMD LEDs on PCB

Screw Grommets

These pieces help secure panels. Most are metallic, but you can also use plastic screw grommets to fasten PCBs on racks or cabinets.

Transistor Insulators

Lastly, transistor insulators help transfer heat efficiently from the transistors to the heatsinks. The alternative is to use thermal grease, but this option is messy and laborious.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Common Materials for PCB Hardware

Polyvinyl Chloride (PVC)

PVC Clips.

It's a good material for PCB hardware, with low heat stability. But mixing it with strengthening additives makes it strong, ensuring it can withstand rough conditions.

PVC also has great density and is not easily deformed and its tensile strength is also excellent.

Nylon

Nylon anchor wall plugs

It is a great PCB hardware material with excellent heat resistance properties. Nylon cannot corrode or be digested by chemicals such as acids. There are three main nylon variations,

- Impact-modified nylon

- Heat-stabilized nylon

- Glass-filled nylon.

Each type is specially modified to improve the material’s strength. Also important is that the three variations give PCB manufacturers a range of materials to pick.

Acetal

Acetal is a very strong material renowned for its rigidity. However, it is an excellent PCB hardware material with features such as a relatively low coefficient of friction.

Acetal is also resistant to wear and can withstand immense heat exposure. Finally, it is not affected by organic acids.

Acrylonitrile-butadiene-styrene (ABS)

PC ABS resin plastic substrate.

ABS has excellent abrasion resistance and exemplary stiffness. It is also easy to mold, and its electrical properties are top-notch.

However, its temperature resistance is relatively low as it cannot withstand heat above 150 degrees Celsius.

While the above are some common PCB hardware materials, they are not the only ones. Others include stainless steel, brass, and polystyrene, all of which are high quality. Steel is specifically useful in military-grade PCBs.

How to Choose PCB Hardware?

There are four things to consider when choosing which PCB hardware to buy.

Application Area

If installing the PCB in white goods, go for hardware components that provide aesthetics and heat stability. For automotive applications, look for lightweight, miniaturized, and reliable components with the advantage of heat stabilization.

PCBs in data/electrical cabinets or other applications with space restrictions require limited space solutions. On the other hand, office machinery and consumer electronics need highly conductive and insulative PCB hardware design.

Mounting Type

As described earlier, there are five mounting types. The snap-in, threaded, blind-hole, and snap-lock options require mounting holes, but the adhesive base type does not need them.

PCB Substrate Type

Flexible PCBs work well with snap-fit or snap-in components, while rigid boards require spacers for support.

Material Type

PCB hardware can either be plastic or metallic. With plastic, the materials used are usually ABS, PVC, nylon, acetal, polycarbonate, or polystyrene materials. They have the advantage of being lightweight, corrosion-resistant, non-conductive, and affordable.

Metallic hardware can be stainless steel, brass, steel, or aluminum. Such components help maintain electrical conductivity in a circuit, have high tensile strength, and can withstand high temperatures.

PCB Hardware Design vs. PCB Design: Difference

Differentiating between PCB design and hardware design is no mean feat because they are similar in some respects. The table below provides a detailed presentation of their differences:

| PCB Hardware Design | PCB Design |

| It is critical in assisting an electronics company in identifying the ideal organization of components in a device for optimal functionality. | It is more about the interconnection of the individual electrical components on a printed circuit board. |

| A hardware engineer should have immense knowhow of electronics to craft a design that delivers the best architectural model.

Besides, they also need to understand the hardware design tools for easy and automated processing of the electronics. |

A PCB designer must know PCB design software and intricacies such as thermal properties, best PCB soldering practices, and impedance matching.

They should also know the various designs necessary for power supply and analog/digital circuitry. |

Most importantly, the PCB designer and the hardware designer must work in conjunction with each other. Otherwise it will be a tall order coming up with a cohesive plan.

Summary

To sum up, PCB hardware is critical for efficient circuit board mounting. This hardware includes several components, each with a specific function. If you need further advice on which hardware to purchase for your project, send your message in the chats or contact form.

Special Offer: Get $100 off your order!

Email [email protected] to get started!