If you've ever worked with solder, you know a big difference between a good solder joint and a bad one. A bad solder joint can result from many things, but one of the most common problems is insufficient solder. Above all, low solder is a problem because it can cause electrical problems and, in some cases, can be dangerous.

In the PCBA(Printed Circuit Board Assembly) manufacturing process, insufficient solder is one of the most common problems. In this article, we'll look at what lousy solder is, how to identify it, and what you can do about it.

Contents

- Differences Between Insufficient and Excess Solder

- Insufficient Solder

- Excess Solder

- Process and Design-Related Causes of Insufficient Solder

- Reflow-related Causes of Insufficient Solder

- What is the Standard of Tin?

- Solution of the Two Problems

- Insufficient Solder Solution

- Excess Solder solution

- Other Common Soldering Defects

- Summary

Differences Between Insufficient and Excess Solder

-

Insufficient Solder

When the tin isn't enough in the solder points during board-tinning, it indicates a lousy solder condition. It can occur for various reasons, but the most common sense is insufficient heat applied throughout the process. Too little solder can cause poor connection and may cause arcing or electrical shorts. The bad solder appears bright and shiny, and the lead may even be visible.

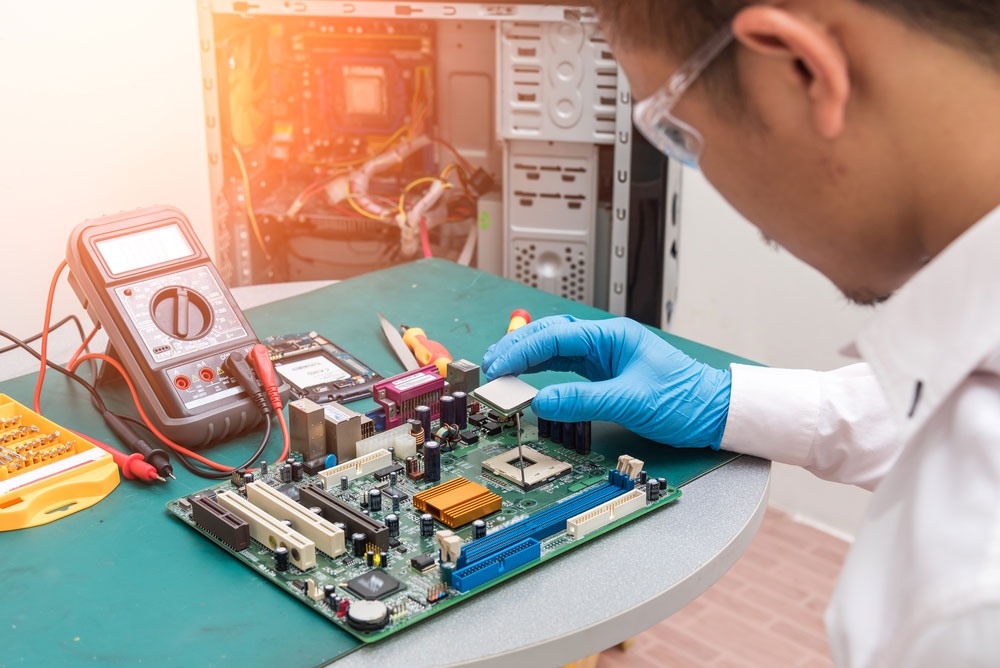

Insufficient Solder Fixing

-

Excess Solder

In contrast, too much solder is known as excess solder. Excess solder can also cause problems, although it's not as joint as insufficient solder. Excess solder usually occurs when there's too much heat applied during the soldering process. If the solder flows into areas where it's not supposed to go, this can create shorts or other electrical issues. Excess solder usually appears dull and glossy.

There are a few different reasons why insufficient solder can occur. The most common cause is insufficient heat during the soldering process, which can happen for several reasons, including:

- Insufficient flux preheating of the board or discrete components

- Inadequate thermal mass of the soldering iron

- Poor thermal contact between the iron and the joint

- Poor contact between the soldering iron and the board or component

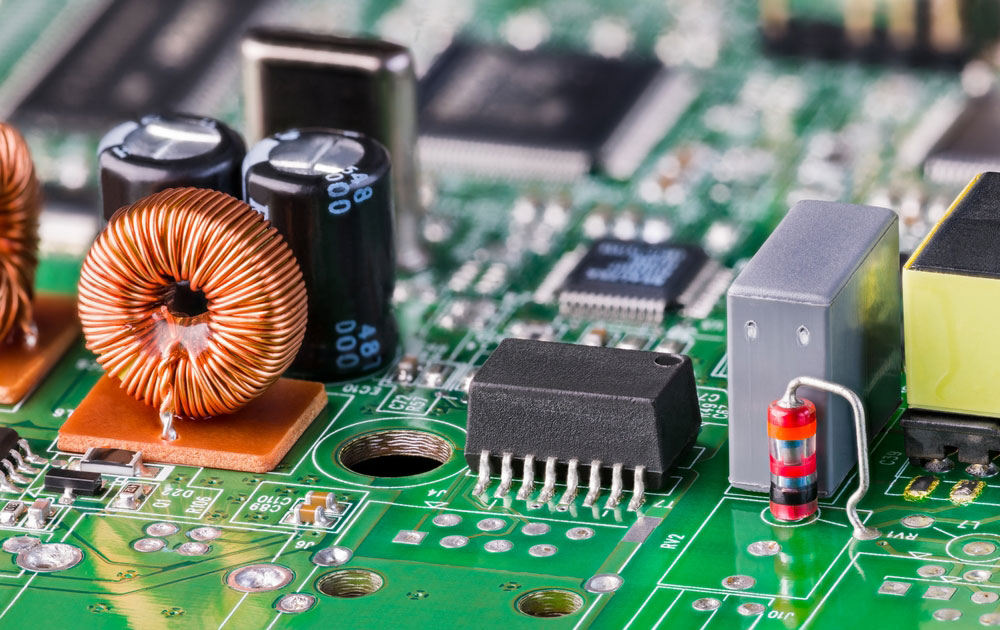

Green Printed Circuit Board

Another common cause of insufficient solder is poor design. It can happen when the pads are too small or too close together. It can also occur when the traces are too thin or compact. These design problems can make it challenging to get enough heat to the area, which can cause insufficient solder.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Reflow-related causes of insufficient solder are primarily due to the lack of complete wetting of the solder paste to the substrate.

The three most common causes are:

- Preheat too aggressively: If the preheat section of the reflow process is too aggressive, it can drive off volatile organic compounds (VOCs) before the solder paste can wet out.

- The liquidus temperature was less during the reflow process: This can be due to some factors, such as insufficient heat application, too much heat, or lousy solder paste.

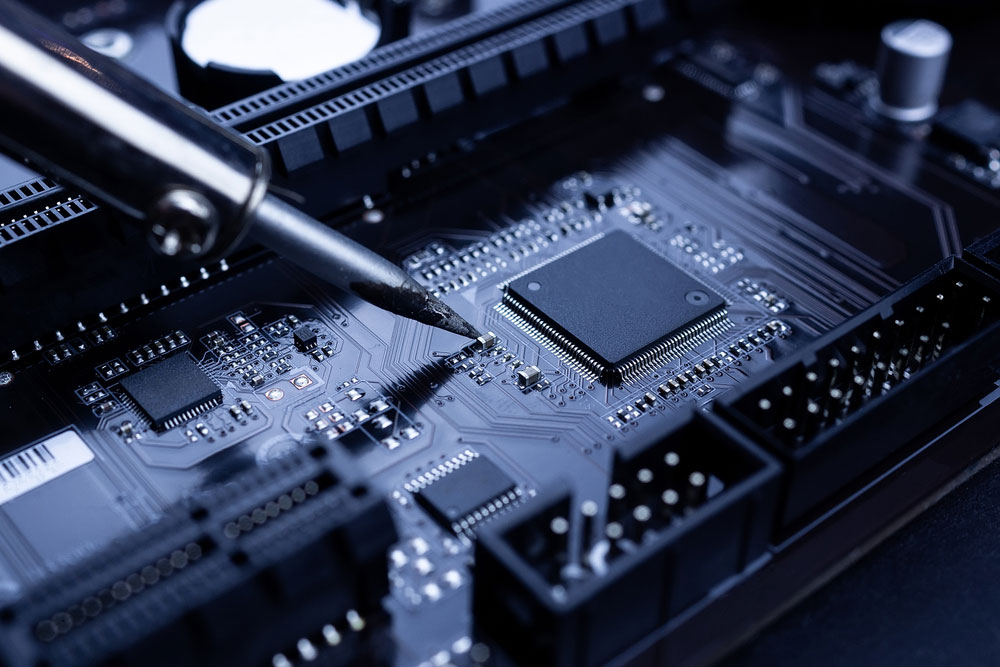

Technician Repairing Oven

- The oven is not adjusting to the proper temperature: This is caused by a faulty heating element, inadequate ventilation, or a dirty range.

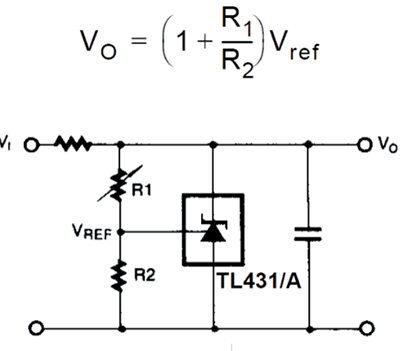

What is the Standard of Tin?

To be called "pure tin," a tin must have a purity of at least 99.3 percent, which is the minimum requirement for soldering. Many alloys are available for solderings, such as leaded tin-silver and lead-free alloys.

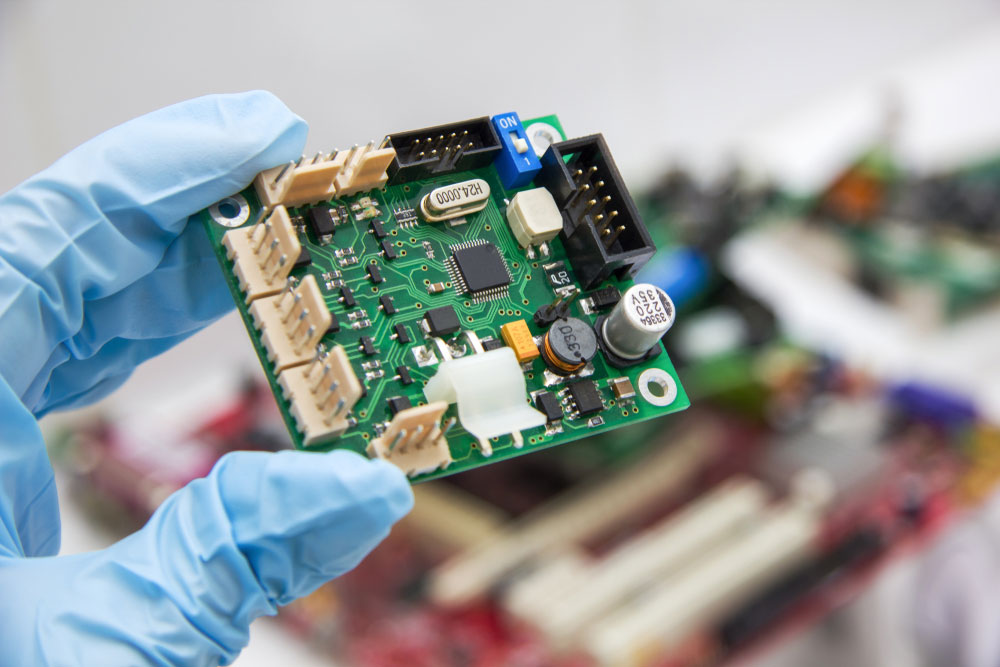

Hand Holding Tin Iron Solder

Here are a few points to sum up the acceptable standard of the tin:

- The tin polishing perfection should be 95% and above.

- The connections should be wet and shiny with the welded parts.

- Discrete Components that are similar in appearance should be distinguishable.

- The edges of the soldered regions should be smooth and concave.

- Make sure to tin the entire surface tension of each through the hole.

- The tin points should be gleaming.

Solution of the Two Problems

Problems can arise if your PCB construction does not include sufficient or too much solder. The best way to deal with these problems is to avoid them altogether.

Insufficient Solder Solution

The most excellent approach to prevent insufficient solder is to employ a contractor with the SMT provider that specifies 100% AOI and x-ray verification for BGA packaged chips. And this will guarantee that the soldering job is done correctly and completely.

PCB Chip

Manufacturer. Ings essential. Issues can also occur during the construction of your PCB. To avoid these problems, be sure to consult with a professional contract. Moreover, verifying that your stencil design pulls away from the component misalignment after soldering is essential.

Excess Solder solution

For excess solder, the solution is to use a solder mask. It will protect your PCB from shorts and other problems. Another approach is to use a via-in-pad design. It will allow you to place your vias under the component, eliminating the possibility of excess solder.

Other Common Soldering Defects

There are a few other common soldering problems that you may encounter. These include:

- solder balling

- solder bridges

- Poor Wetting(Surface Mount)

- Untrimmed Leads

-Insufficient Wetting (Pin)

-Insufficient Wetting (Pad)

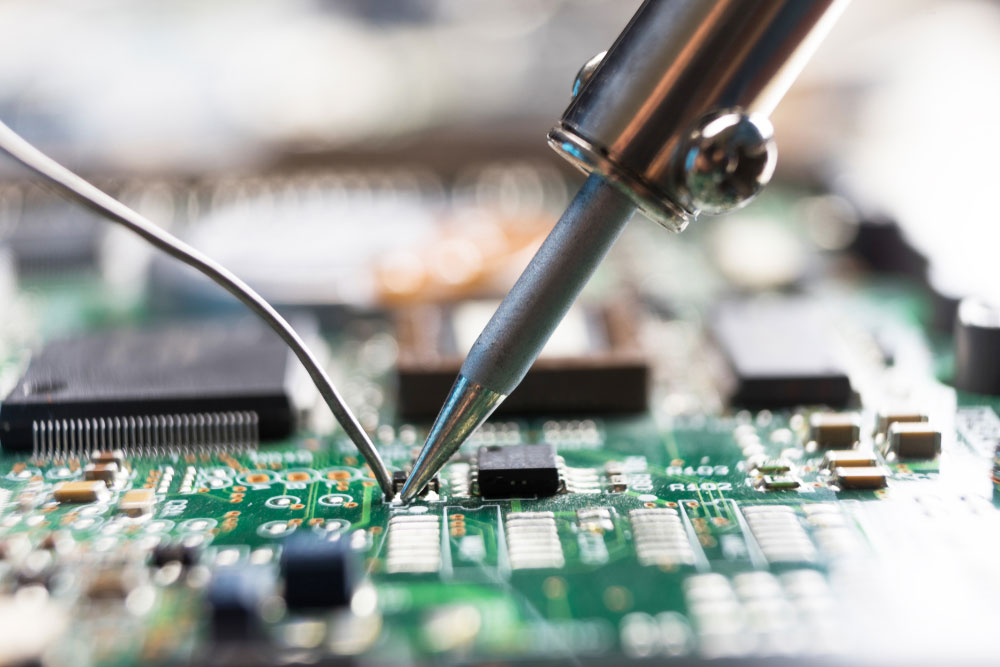

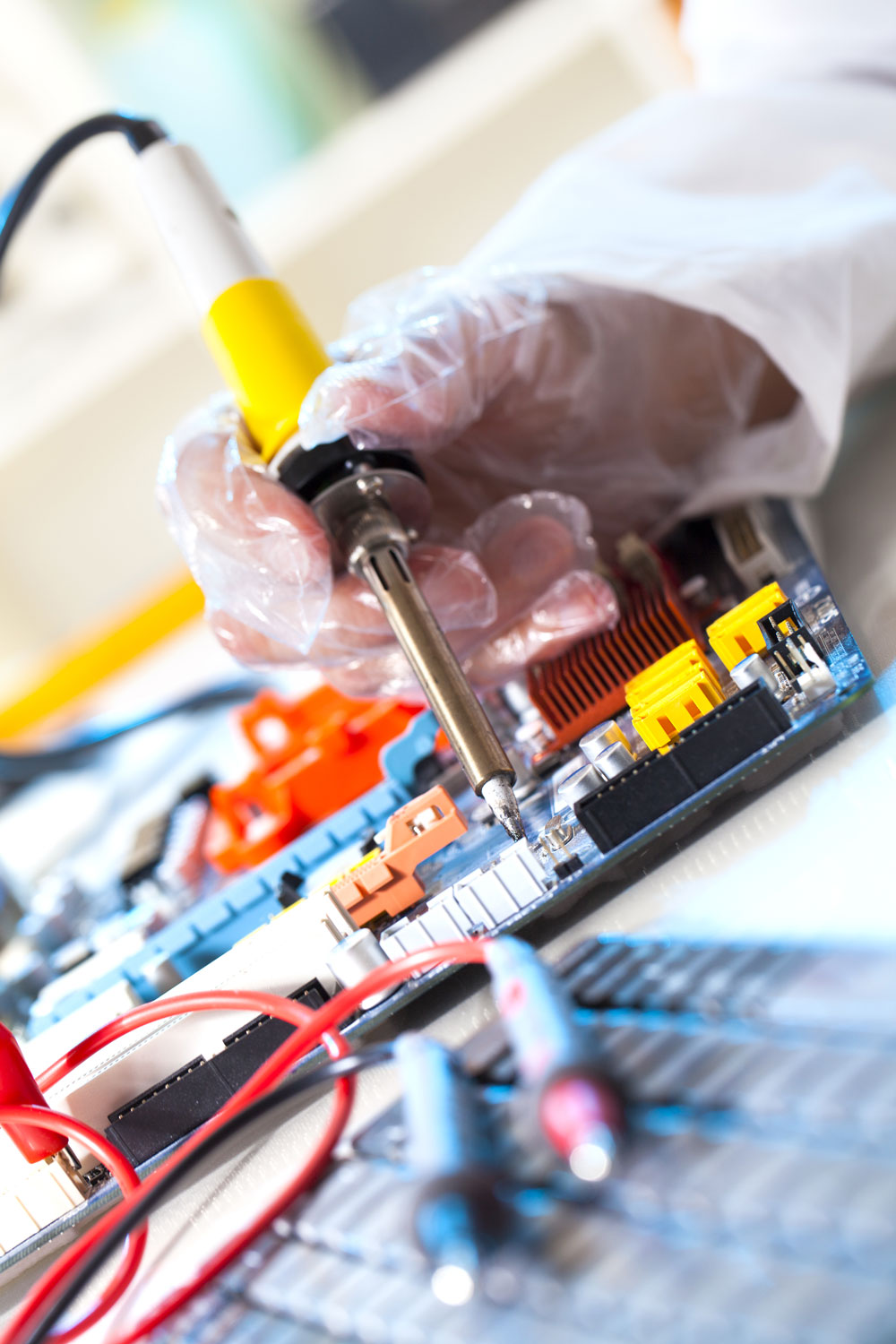

Soldering Electronic Parts On a Printed Circuit Board

-Sunken Joints

-Solder Bridging

-Overheated Joint

-Lifted solder Pad

-Stray Solder Spatters

-Insufficient Solder Joints

-Insufficient Flux

Summary

Soldering in the recent past has been increasingly complex due to the miniaturization of electronic devices. As a result, there are more opportunities for problems to occur during the soldering process. The most common problem is insufficient soldiers. The best way to avoid inferior soldiers is to consult a professional contract manufacturer. Moreover, it is essential to use a solder mask and an ideal solder joint to protect your PCB from excess solder.

If you have any questions about our services, please get in touch with us. We would be happy to help you with all your PCB needs!

Special Offer: Get $100 off your order!

Email [email protected] to get started!