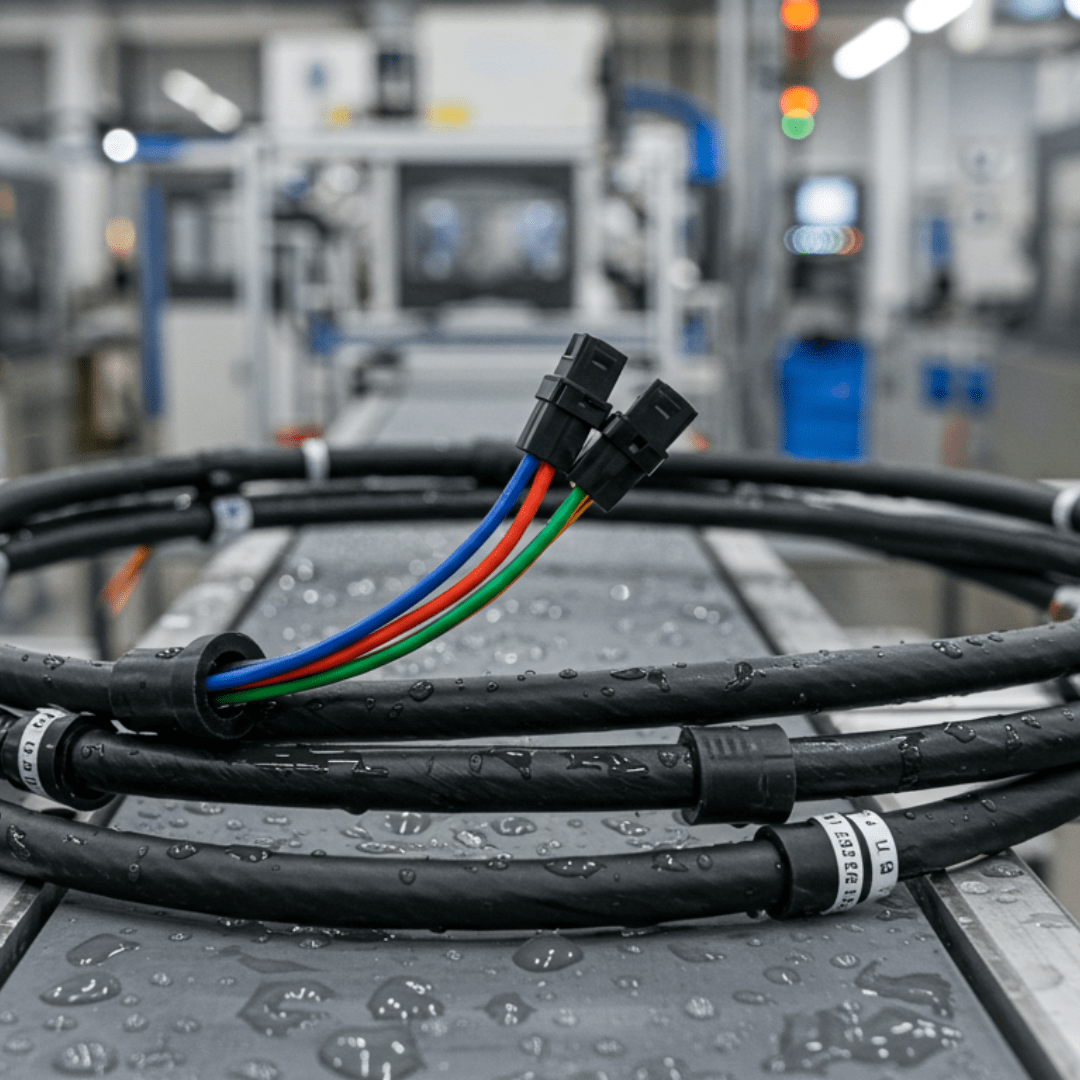

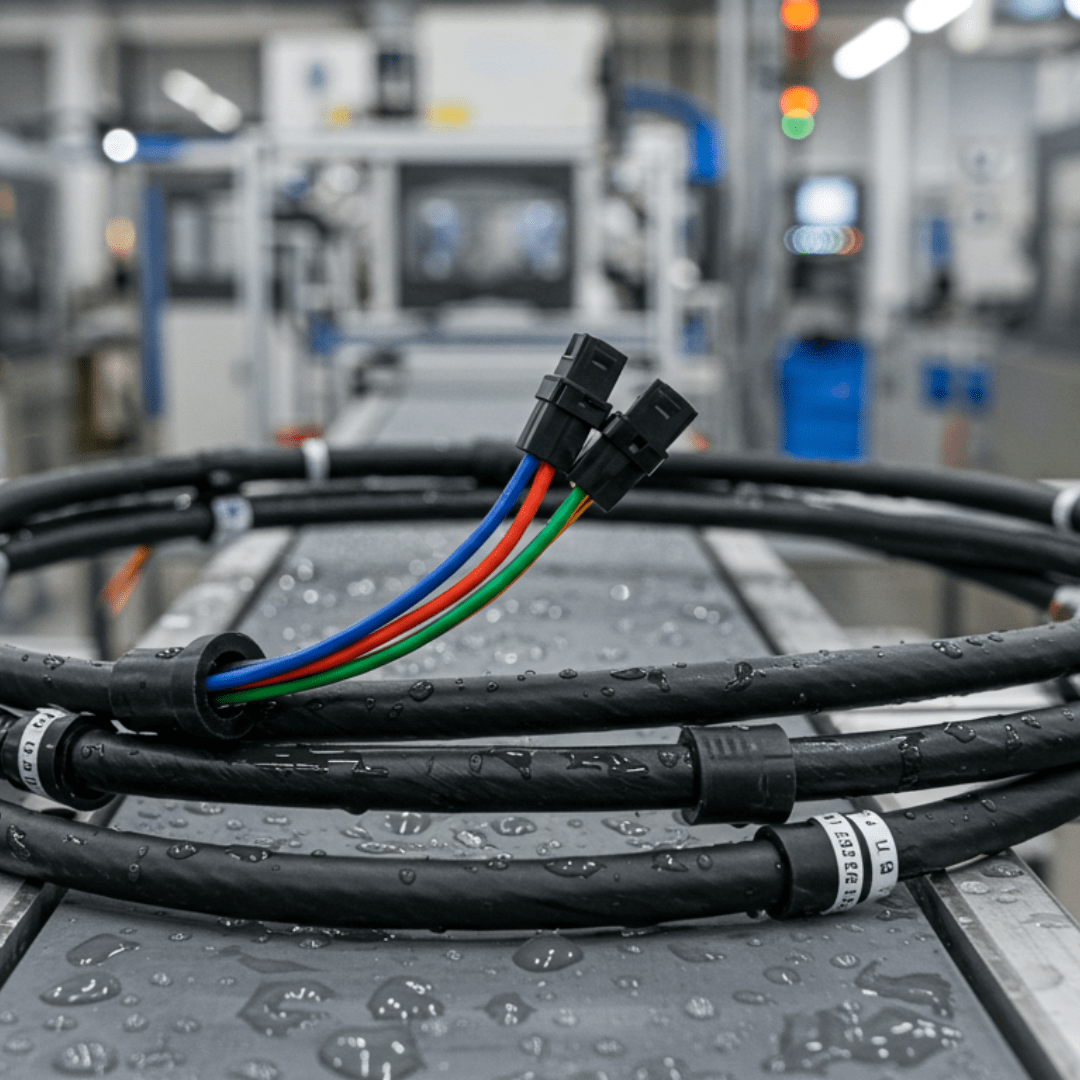

Waterproof Wire Harness Manufacturers

When standard wire assemblies are exposed to water, they corrode, short out, and fail when you need them most. At OurPCB, we build waterproof wire harnesses specifically for environments that have moisture. That includes automotive underbodies, marine equipment, or industrial washdown areas.

Insulation handles anywhere from 105 °C to 200 °C. We’ve perfected our sealing techniques over years of real-world testing. Every custom harness we build meets ISO 9001 quality standards. For automotive clients, we follow IATF 16949 requirements, too.

What is a Waterproof Wire Harness?

A waterproof wire harness bundles electrical wires, terminals, and connectors with protective sealing to prevent water intrusion. Designs incorporate cross-linked polyolefin tubing, rubber seals, and overmolded designs to block moisture from causing shorts or system failure.

This level of protection is essential in engine compartments, marine lighting systems, and equipment exposed to high-pressure washdowns.

Benefits of Waterproof Wire Harnesses

- Waterproof sealing reduces maintenance frequency and service calls by preventing environmental degradation

- Heat-shrink covers and overmolded seals protect junction points from environmental damage that causes premature failure

- Proper sealing maintains insulation resistance during pressure tests simulating depths up to 100 meters, eliminating ground faults and shorts.

- Products manufactured meet OEM requirements for automotive and industrial use

- IP67-rated assemblies satisfy protection standards required for EV components and safety-critical electronics

Superior Field Reliability

- IP67-rated connectors resist complete dust ingress and withstand water immersion up to 1 m for 30 minutes.

- Marine-grade insulation materials provide chemical resistance against fertilizers, pesticides, and fuel exposure.

Extended Equipment Lifespan

- Temperature-resistant components function reliably from -40 °C to 105 °C, preventing heat damage in engine compartments.

- Reinforced strain relief and secure terminal connections prevent failures from constant diesel engine vibration.

Simplified Troubleshooting

- Color-coded wiring with clear detail reduces diagnostic time by up to 60%.

- Comprehensive documentation includes wiring diagram specifications specific to your tractor model.

Customization Options

- Exact-fit design ensures perfect compatibility with your specific Farmall or Cub Cadet restoration.

- Additional capacity options accommodate future implements or aftermarket electrical accessories you may add later.

Why Choose OurPCB for Waterproof Wire Harness Manufacturing

You need a manufacturing partner who understands both technical challenges and practical realities. Here’s what sets us apart.

- We tailor harnesses to your electrical specifications and operating conditions, selecting the right wire types, connector ratings, and sealing methods, from tape wrapping to full overmolding

- Every harness undergoes continuity testing, insulation resistance checks, and heat rise validation (Delta 30 °C standard)

- Waterproof integrity is proven through gas-tightness pressure tests and 24-hour submersion trials

- We use high-purity copper conductors (tin-plated for corrosion resistance) rated for 105 °C to 200 °C operating temperatures

- Our connector selection includes options with rubber sealing plugs and vibration-proof features for automotive durability

- Whether you need prototypes or full production runs, we deliver assemblies quickly while maintaining IPC/WHMA-A-620 compliance

Our Custom Wiring Harness Features

ROHS-Compliant Materials

All components adhere to rigorous environmental and safety certifications required worldwide. We build harnesses that are ready for global markets and responsible manufacturing.

Connectors for Every Need

From Tyco and AMP to Delphi, Molex, JAE, JST, and beyond, we provide access to top-tier connectors.

Custom Materials and Coverings

We engineer each harness with materials designed to resist abrasion, oil exposure, extreme heat, or water damage. Covering options include PVC, nylon, XLPE, rubber, braided sleeving, heat shrink tubing, and additional protective layers.

Variable Wire Options

Available in multiple wire gauges, fabricated to precise lengths for optimal fitment and electrical performance.

Across Many Industries

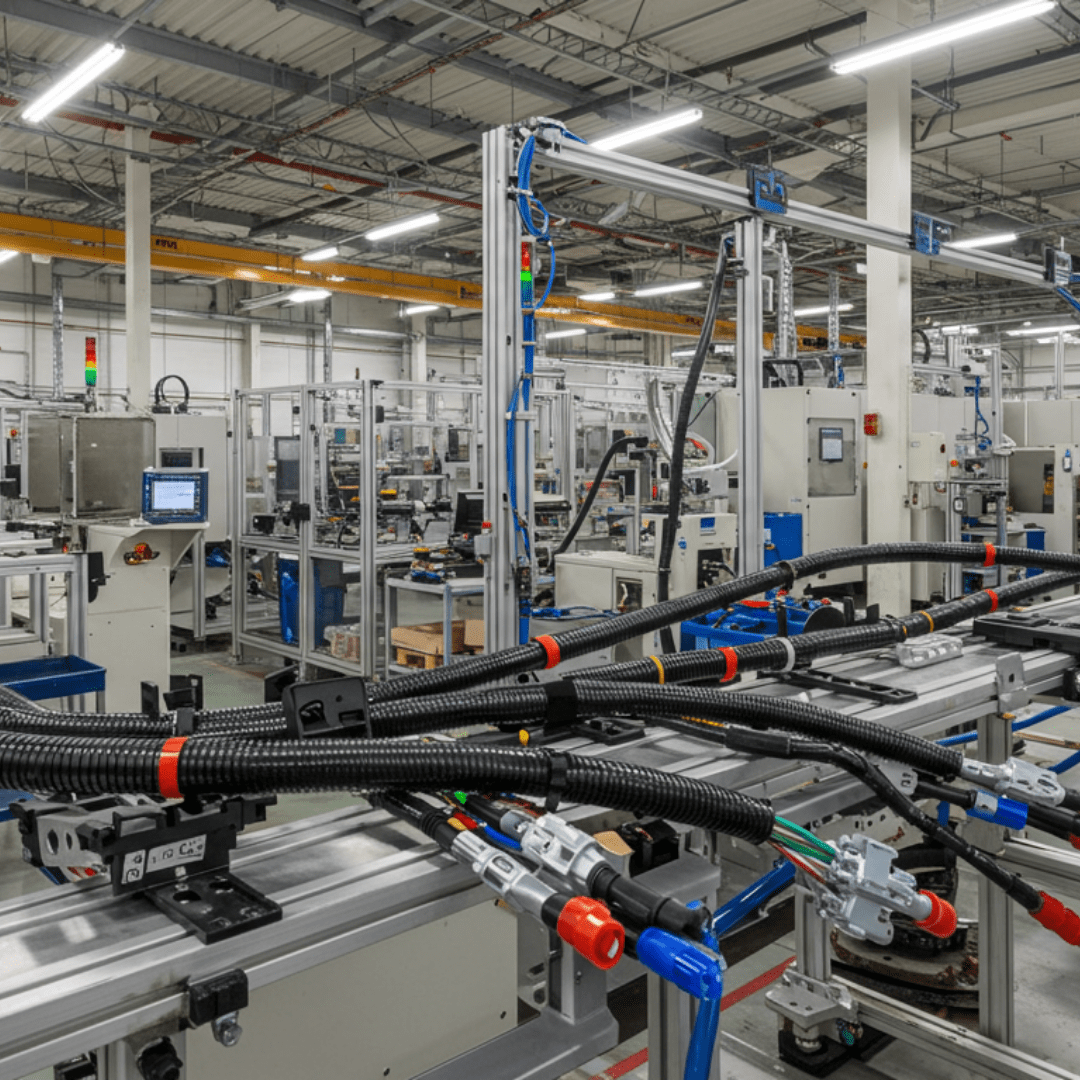

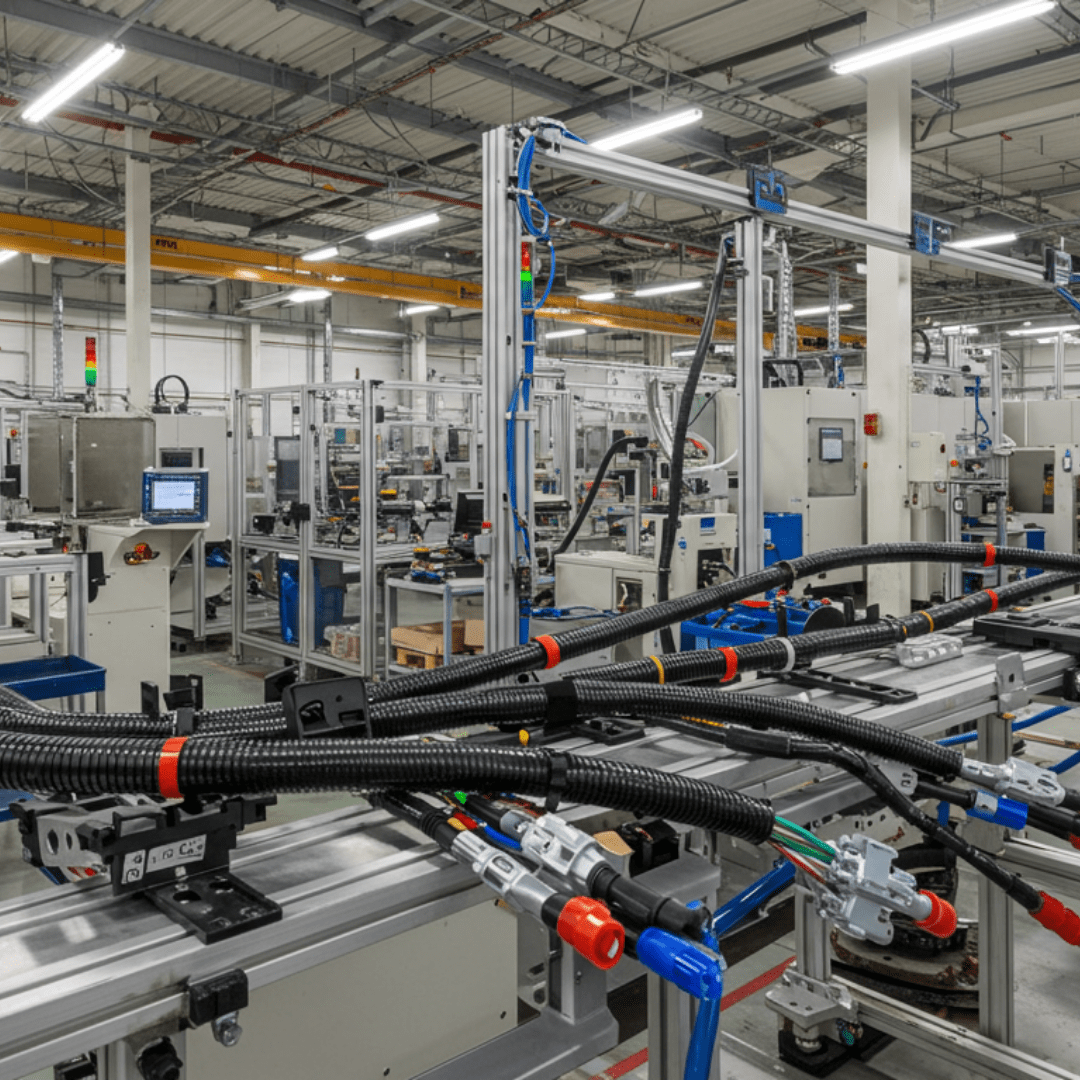

We’ve built harnesses for automotive, aerospace, medical technology, industrial equipment, and many other fields.

Millions of business and innovators use OurPCB

Our Custom Wiring Harness Process

Fast, free, and includes a production timeline

Our engineers create your design schematic and select the right materials

We’ll manufacture a high-quality prototype within 7 days

The prototype goes through various functionality and stress tests

Cutting, stripping, and assembly to the highest standard

After final testing and packaging, your custom wiring harnesses are delivered

Technical Capabilities

OurPCB maintains capabilities and facilities equipped for waterproof wire loom production at scale. Our crimping stations use precision tooling to attach terminals without damaging conductors. Overmolding equipment encapsulates connectors for complete moisture sealing. We employ semi-encapsulated winding for harnesses in wet environments, and our routing processes include protective sleeves resisting abrasion while helping heat dissipation.

Our quality lab tests every assembly, including continuity checks, insulation resistance measurement, and heat rise testing under rated current loads. For waterproof validation, we run pressure resistance tests simulating underwater conditions and extended submersion trials. Components come from verified suppliers, and we maintain full traceability through batch tracking and end-of-line inspection records.

Capabilities & Services

- Wire Gauge: 40AWG-120mm²

- Production Capacity: 10,000 pieces/hour

- Wire Cutting Service

- Wire Stripping Service

- Wire Marking Service

- Label Types

- Wire Ends Treatment

Custom Wire/Cable Service:

- Wire/Cable types

- Wire gauge

- Wire/Cable length

- Insulation/Jacket color

- Core numbers etc.

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

- Electrical cable assembly

- Coaxial cable assembly

- Multi-core cable assembly

- Connector to board cable assembly

- Automobile communication cable assembly

- Power transmission cable assembly

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Waterproof Wire Harness Manufacturers FAQs

How do waterproof wire harnesses achieve IP67 protection?

IP67 protection uses multiple sealing techniques working together. We use IP67-rated connectors with rubber sealing plugs, apply heat-shrink tubing at wire junctions, and employ overmolding to encapsulate connector bodies. For assemblies without molding, we use bulkhead-mounted connectors sealed to IP standards and back-filled potting at critical connection points.

What connector types work best for waterproof applications?

We use sealed connector systems from TE Connectivity, Amphenol, Deutsch, and LEMO designed specifically for harsh environments. These connectors feature integrated O-ring seals, threaded locking mechanisms, and corrosion-resistant plating. Circular connectors with bayonet locks provide reliable mating in high-vibration applications. Rectangular sealed connectors work well for multi-circuit power and signal combinations. Overmolded cable exits eliminate potential water entry points at the connector-cable interface.

What industries use waterproof wire harnesses?

Automotive applications represent the largest segment—under-hood electronics, EV battery packs, and safety systems. Marine equipment requires assemblies that resist saltwater corrosion. Industrial machinery in washdown areas depends on tight seals protecting electrical installation from cleaning fluids. Outdoor lighting systems need weather-resistant connections. The automotive wiring market alone grows from USD 72.4 billion in 2025 to USD 125.7 billion by 2032, driven by electrification and stricter safety standards requiring reliable protection in harsh operating conditions.