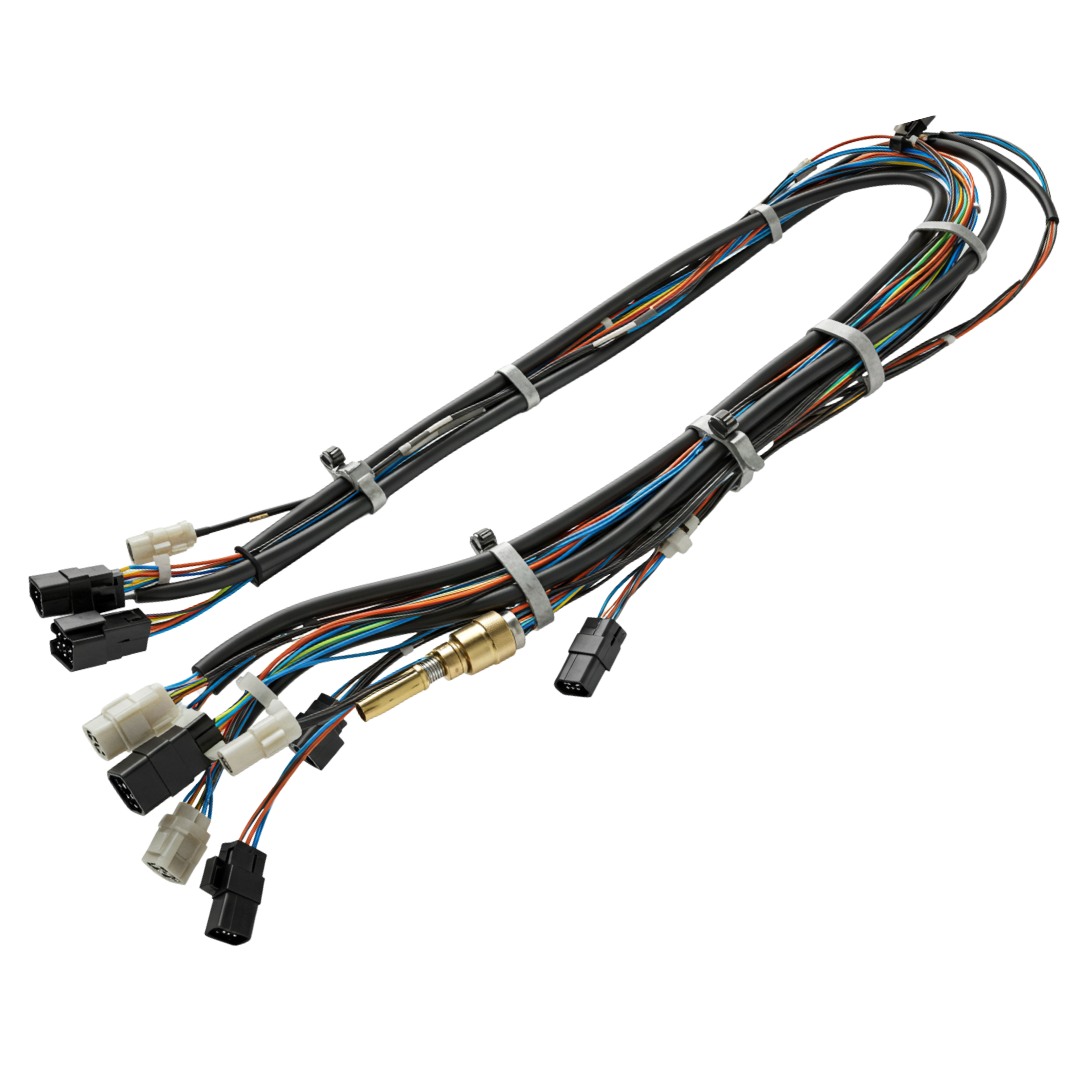

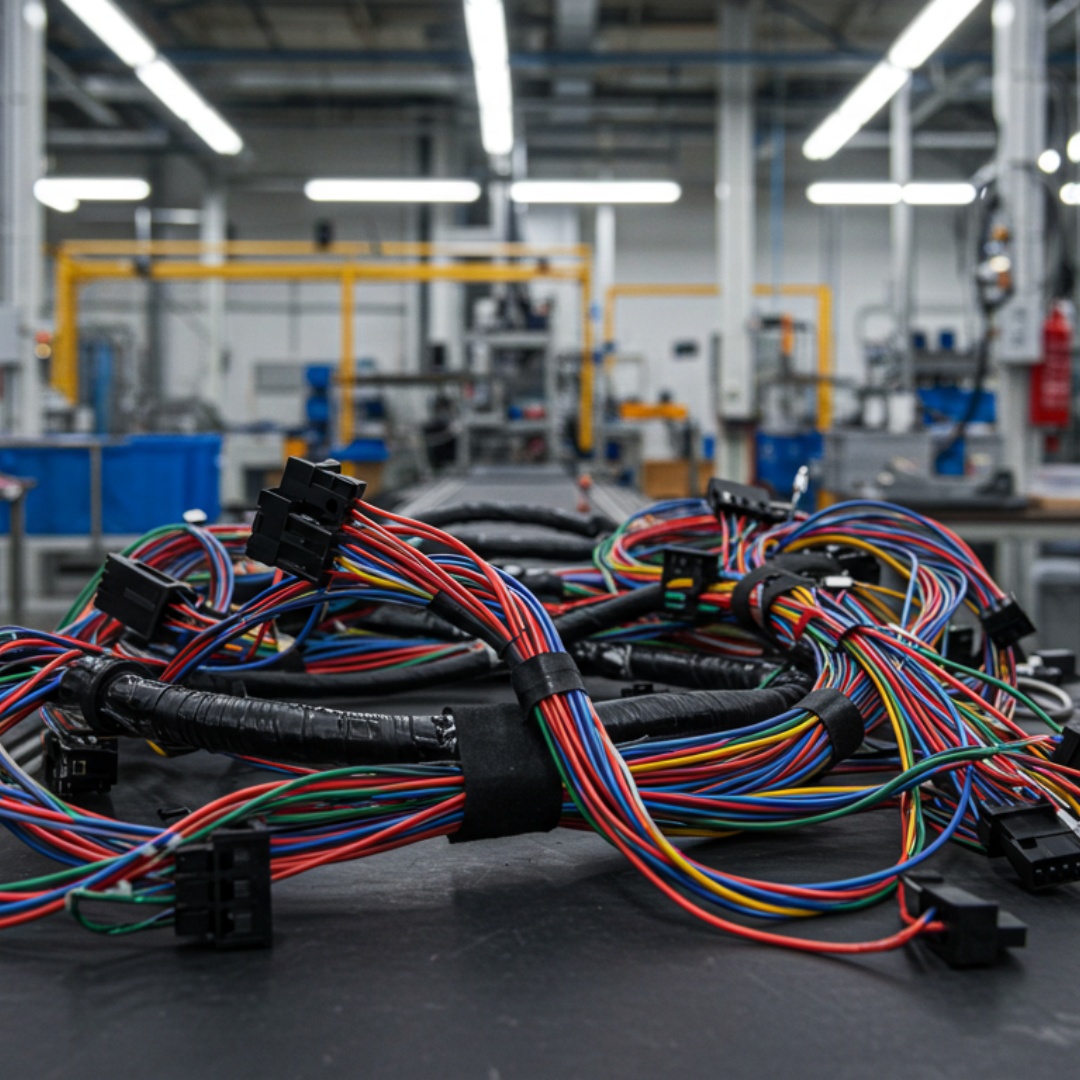

Train Wire Harnesses Manufacturing

Train wire harnesses are automotive wiring electrical assemblies that deliver power and signals. This is across locomotives, metro systems, and high-speed rail. We’re talking about extreme vibration from constant track movement, temperature swings from -40°C to 125°C. Environmental exposure includes moisture, chemicals, and physical abuse.

To meet such demands, OurPCB manufactures custom wire harnesses that meet IPC-A-620 standards. Every harness we build goes through rigorous testing to make sure it’ll hold up in passenger and freight applications. Failures in this environment can shut down entire rail lines.

What are Train Wire Harnesses?

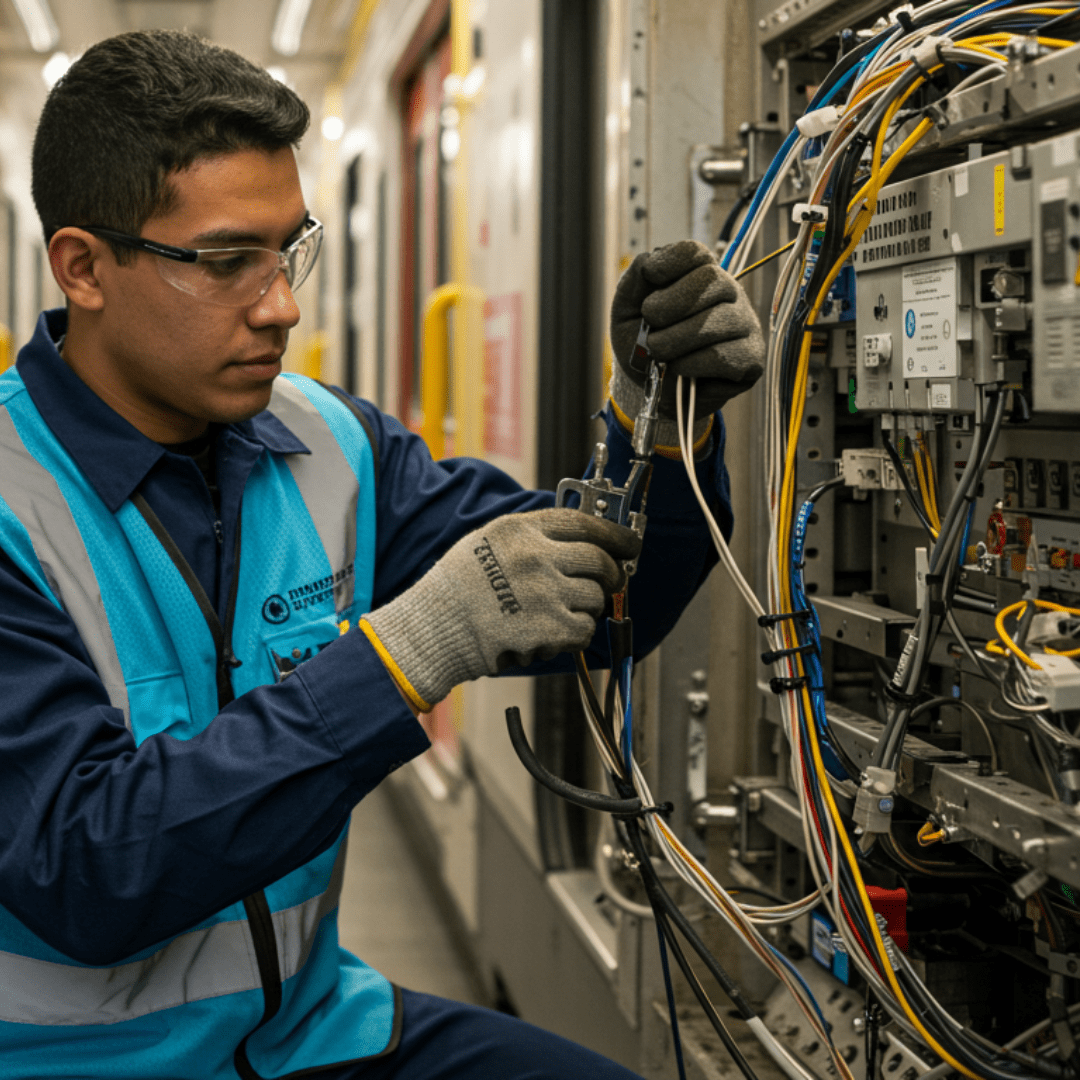

Rail and locomotive wire harness assemblies transmit power and control signals throughout train systems. These electrical wiring bundles power lighting, HVAC, propulsion, and control panel functions across all rail vehicles. Modern railway wiring integrates copper conductors with fire-retardant insulation. Each harness assembly resists continuous shock and electromagnetic interference while maintaining signal integrity.

Modular harness layouts facilitate maintenance and enable new technologies integration throughout the service life. Custom harness designs accommodate everything from passenger cars to freight locomotives, ensuring reliable performance across diverse applications.

The Benefits of Train Wire Harnesses

Custom wire harnesses deliver critical advantages for rail transportation operations, reducing installation time and improving energy efficiency, and supporting digital transformation.

- Fire-retardant materials prevent short circuits and fire propagation in enclosed environments

- High-voltage insulation testing ensures electrical systems maintain integrity under extreme conditions

- Harnesses are built to withstand temperature extremes and weather conditions across global climates, and continuous vibration, preventing connection failures during continuous railway operation

- Modular wiring systems enable quick component replacement, standardized design and engineering approaches simplify technician training, and reduce service intervals

- Accommodates infotainment systems and IoT sensors for predictive maintenance

- Supports data transfer capabilities alongside traditional power delivery for communication and control

Superior Field Reliability

- IP67-rated connectors resist complete dust ingress and withstand water immersion up to 1 m for 30 minutes.

- Marine-grade insulation materials provide chemical resistance against fertilizers, pesticides, and fuel exposure.

Extended Equipment Lifespan

- Temperature-resistant components function reliably from -40 °C to 105 °C, preventing heat damage in engine compartments.

- Reinforced strain relief and secure terminal connections prevent failures from constant diesel engine vibration.

Simplified Troubleshooting

- Color-coded wiring with clear detail reduces diagnostic time by up to 60%.

- Comprehensive documentation includes wiring diagram specifications specific to your tractor model.

Customization Options

- Exact-fit design ensures perfect compatibility with your specific Farmall or Cub Cadet restoration.

- Additional capacity options accommodate future implements or aftermarket electrical accessories you may add later.

Why Choose OurPCB for Train Wire Harnesses

- IPC-A-620 certified harness production with complete traceability from materials to final assembly

- Comprehensive quality checks validate electrical components and mechanical connections

- Harnesses are tailored to the specific needs of different train cable applications and new vehicle model requirements

- Flexible manufacturing handles complex design projects from prototypes to high-volume new builds

- Streamlined harness layouts and efficient processes reduce lead times and meet project deadlines

- Combined capabilities simplify supply chains for complete electrical wiring projects

- Single-source automation reduces coordination overhead across multiple suppliers

Our Custom Wiring Harness Features

ROHS-Compliant Materials

We use safe, certified, and environmentally responsible materials in every harness. Your products stay compliant and eco-friendly.

Connectors for Every Need

We stock industry-leading brands including Tyco, AMP, Delphi, Molex, JAE, JST, and more. Whatever your application demands, we have the connector solution.

Custom Materials to Suit the Environment

Our materials are engineered for abrasion, oil, heat, or water resistance based on your needs. We match protection levels to your exact operating conditions.

Your Choice of Coverings

Choose from PVC, nylon, XLPE, rubber, braided sleeving, heat shrink tubing, and more. Each option provides distinct benefits for your specific application.

Variable Wire Options

We offer multiple wire gauges and custom lengths to match your specifications. This ensures optimal performance without waste or compromise.

Across Many Industries

We serve virtually every sector, from automotive to aerospace, medical to manufacturing. Contact us today to discuss your industry’s unique requirements.

Millions of business and innovators use OurPCB

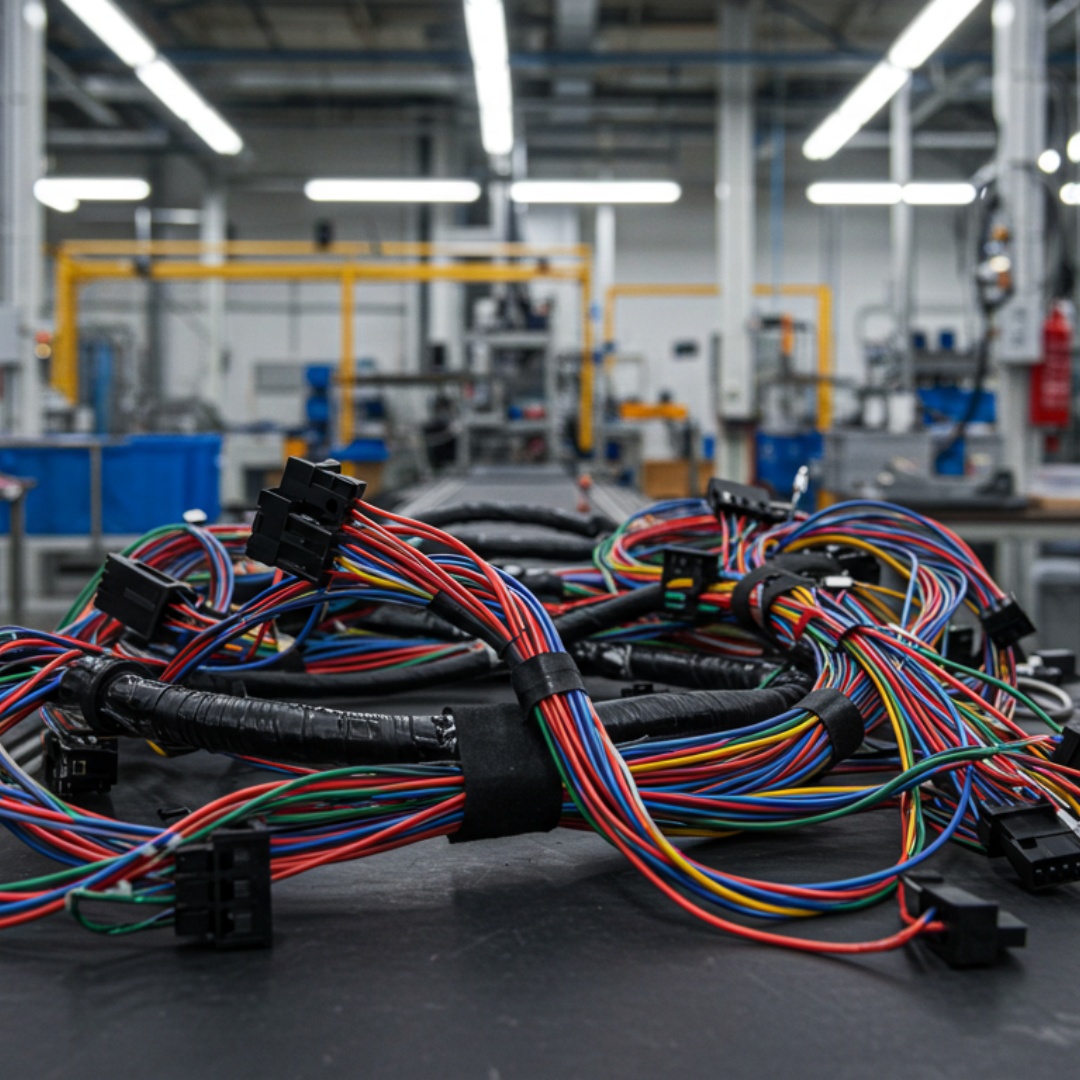

Our Custom Wiring Harness Process

Fast, free, and includes a production timeline

Our engineers create your design schematic and select the right materials

We’ll manufacture a high-quality prototype within 7 days

The prototype goes through various functionality and stress tests

Cutting, stripping, and assembly to the highest standard

After final testing and packaging, your custom wiring harnesses are delivered

Technical Capabilities

OurPCB operates climate-controlled production facilities designed for consistent wire harness assembly. Our automated equipment handles wire gauges from 30 AWG to 4/0 AWG with precision cutting and stripping. We work with tinned copper, bare copper, and silver-plated conductors. Insulation materials include XLPE, silicone rubber, and Teflon rated for -40°C to +125°C operation. Harnesses incorporate braided copper or aluminum foil shielding for EMI protection in railway control systems. Assembly capabilities support both low-voltage signal circuits and high-current traction power applications.

Every harness undergoes rigorous testing before shipment. High-voltage testing verifies insulation integrity up to 5,000V. Pull force testing confirms the mechanical strength of all terminations. Automated systems check 100% continuity with minimal resistance. Railway-specific validation includes thermal cycling, vibration testing at railway operation frequencies, and flex life testing exceeding 1 million cycles. Production capacity ranges from prototype quantities with a 5-10 day turnaround to high-volume runs of 10,000+ units. IPC-A-620 certified inspectors verify quality using X-ray and optical inspection.

Capabilities & Services

- Wire Gauge: 40AWG-120mm²

- Production Capacity: 10,000 pieces/hour

- Wire Cutting Service

- Wire Stripping Service

- Wire Marking Service

- Label Types

- Wire Ends Treatment

Custom Wire/Cable Service:

- Wire/Cable types

- Wire gauge

- Wire/Cable length

- Insulation/Jacket color

- Core numbers etc.

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

- Electrical cable assembly

- Coaxial cable assembly

- Multi-core cable assembly

- Connector to board cable assembly

- Automobile communication cable assembly

- Power transmission cable assembly

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Train Wire Harnesses Manufacturing FAQs

What applications can OurPCB train wire harnesses support?

Our wire harnesses for rail support diverse applications, including locomotives, passenger cars, mass transit systems, and freight operations—covering simple lighting circuits to complex high-voltage traction systems with multiple connectors and terminal configurations.

How does OurPCB ensure wire harness manufacturing quality?

Material certification, in-process inspection, and final testing provide full traceability. Electrical, mechanical, and environmental validations meet railway standards.

What lead times should I expect for custom train wire harness orders?

Lead times vary based on project complexity and order volume. Prototype harnesses typically require 5-10 business days from approved specifications. Low-volume production runs of 50-500 units ship within 2–3 weeks. High-volume orders exceeding 500 units require 4–6 weeks for complete manufacturing and testing. Rush orders receive priority scheduling, with expedited production available for urgent replacement needs.