Solar Wire Harness Manufacturer

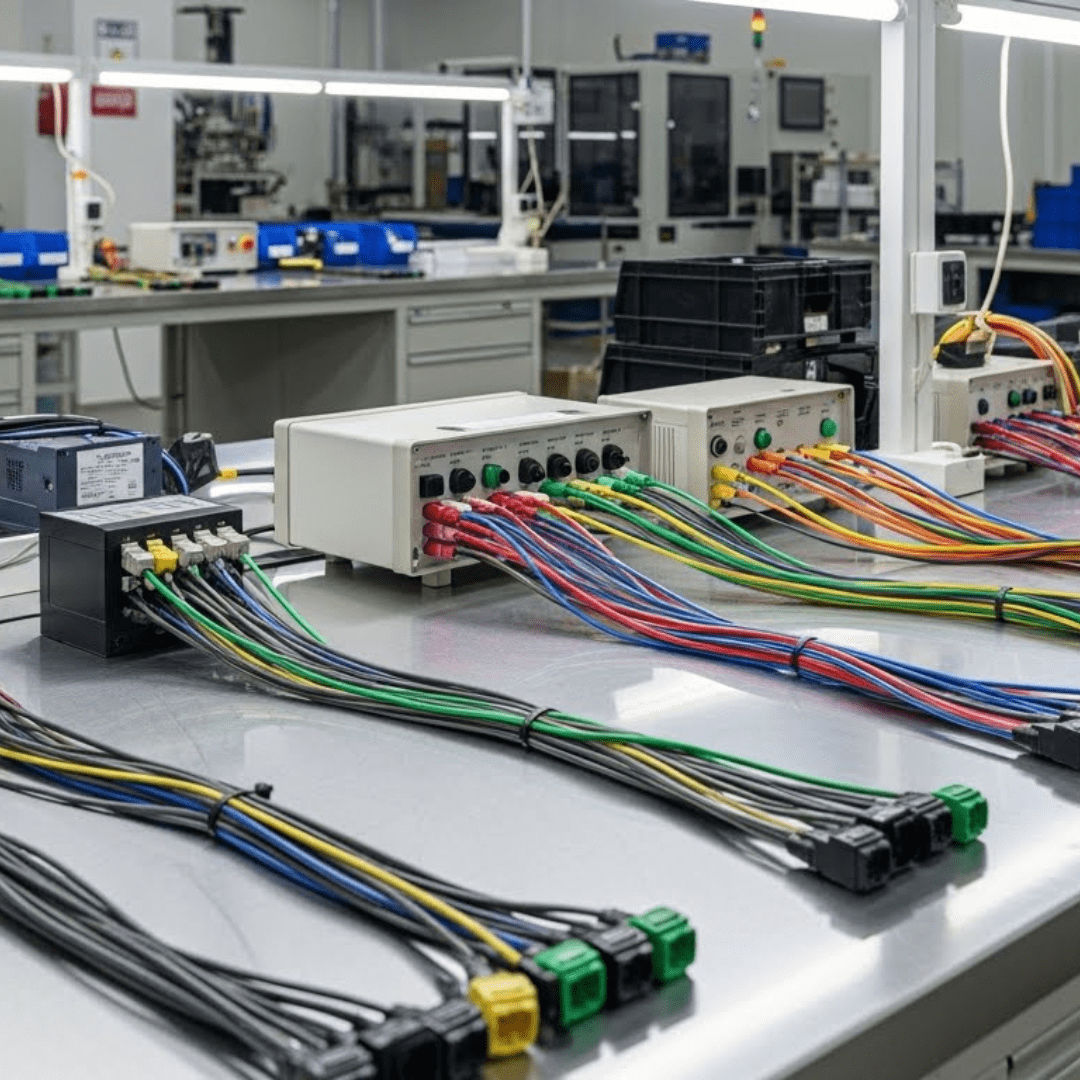

Solar wire harnesses are DC and control wiring assemblies that route power and signals across photovoltaic systems. They connect PV strings, combiner boxes, inverters, trackers, monitoring devices, and energy storage equipment into one coordinated system. These harnesses operate in high UV exposure environments, with wide temperature swings from -40 °C to 90+ °C on rooftops, and constant environmental stress from moisture, dust, wind, and mechanical movement.

OurPCB is your solar wire harness manufacturer, with over 15 years of experience building custom harnesses engineered for harsh outdoor conditions and long system lifetimes. Our assemblies are produced to IPC-A-620 standards, with materials selected to meet common PV and solar balance-of-system requirements.

What are Solar Wire Harnesses?

Solar wire harnesses are pre-engineered bundles of DC and control cables, connectors, with protective coverings that connect the main elements of a solar installation. They replace loose field wiring with organized, factory-built assemblies.

Typically, solar harness assemblies link PV modules, route strings to combiner boxes, connect inverters, storage, monitoring, and integrate trackers and sensors. Many modern harnesses use tinned copper conductors, double-insulated 600–1500 VDC PV cables, and locking, touch-safe outdoor DC connectors.

What are the Benefits of Solar Wire Harnesses?

The benefits of solar wire harnesses include their improved safety, reliability, and operational durability, while cutting down on installation time and lifetime costs. By combining rugged, UV-resistant materials with touch-safe connectors and integrated data lines, harnesses support durable, smart, easily monitored PV systems.

- DC-rated, double-insulated cables and flame-retardant jackets reduce the risk of arcing and fire

- Factory-controlled crimping and terminations minimize loose connections and hot spots

- Touch-safe connectors and proper strain relief help maintain long-term connection integrity

- UV-, ozone-, and weather-resistant materials for 20+ year field exposure

- Harnesses designed for temperature extremes, wind, and thermal cycling on rooftops and open fields

- Robust mechanical protection reduces jacket damage from sharp edges, movement, and maintenance activities

- Pre-cut lengths and pre-terminated ends eliminate on-site measuring and crimping

- Clearly labeled connectors and cables simplify stringing and equipment hookup

- Standardized harness designs reduce installation variability and rework across multiple sites

- Integrated data and control lines for inverters, optimizers, trackers, and sensors

- Hybrid harnesses that combine power, communication, and control in a single routed assembly

- Support for smart PV systems, monitoring platforms, and energy storage control interfaces

Superior Field Reliability

- IP67-rated connectors resist complete dust ingress and withstand water immersion up to 1 m for 30 minutes.

- Marine-grade insulation materials provide chemical resistance against fertilizers, pesticides, and fuel exposure.

Extended Equipment Lifespan

- Temperature-resistant components function reliably from -40 °C to 105 °C, preventing heat damage in engine compartments.

- Reinforced strain relief and secure terminal connections prevent failures from constant diesel engine vibration.

Simplified Troubleshooting

- Color-coded wiring with clear detail reduces diagnostic time by up to 60%.

- Comprehensive documentation includes wiring diagram specifications specific to your tractor model.

Customization Options

- Exact-fit design ensures perfect compatibility with your specific Farmall or Cub Cadet restoration.

- Additional capacity options accommodate future implements or aftermarket electrical accessories you may add later.

Why Choose OurPCB for your Solar Wire Harnesses Manufacturing?

- Harness production based on IPC-A-620 with documented work instructions

- Material and component traceability from cable and connectors to final assembly

- Electrical and mechanical checks to verify every critical termination and circuit

- Custom harnesses for rooftop, ground-mount, tracker, carport, and floating solar systems

- Designs compatible with a wide range of inverters, optimizers, and module types

- Flexible engineering support for new project layouts and evolving product lines

- Prototype and pilot harness builds to support project design and validation

- Scalable manufacturing for repeat deployments and multi-site rollouts

- Efficient planning to align deliveries with construction schedules and milestones

- Ability to integrate solar harnesses with control cables, low-voltage assemblies, and PCBs

Single-source partner for multiple electrical sub-assemblies on your project - Reduced coordination effort across vendors and more predictable project logistics

Our Custom Wiring Harness Features

ROHS-Compliant, UV-Stable Materials

- RoHS-compliant wires, connectors, and protection components

- UV- and weather-resistant materials suitable for long-term outdoor exposure

- Options for halogen-free, low-smoke materials when required by specification

Connectors for Solar Applications

- Support for industry-standard PV connectors used on modules and inverters

- DC and AC connector options for combiner boxes, string inverters, and AC mains

- Custom connector configurations for integrated storage and microgrid systems

Materials to Suit the Environment

- Cables and jackets matched to desert, coastal, high-altitude, or cold-climate projects

- Enhanced resistance to salt spray, humidity, and airborne contaminants when required

- Mechanical protections selected based on mounting style and routing paths

Your Choice of Coverings

- UV-stable jackets, corrugated conduit, and flexible tubing for exposed runs

- Braided sleeving and heat shrink for extra abrasion and impact resistance

- Localized reinforcement and boots at entry points, terminations, and transitions

Variable Wire Options

- Multiple conductor sizes to minimize voltage drop and power loss

- Configurations for 1–2 pole DC runs, multicore control cables, and hybrid assemblies

- Custom lengths and branching tailored to array layout, row spacing, and equipment locations

Across Solar and Energy Industries

- Residential and commercial rooftop systems

- Utility-scale ground-mount and tracker plants

- Solar-plus-storage installations and microgrids

- EV charging canopies and solar carports

Millions of business and innovators use OurPCB

Our Custom Wiring Harness Process

Fast, free, and includes a production timeline

Our engineers create your design schematic and select the right materials

We’ll manufacture a high-quality prototype within 7 days

The prototype goes through various functionality and stress tests

Cutting, stripping, and assembly to the highest standard

After final testing and packaging, your custom wiring harnesses are delivered

Technical Capabilities

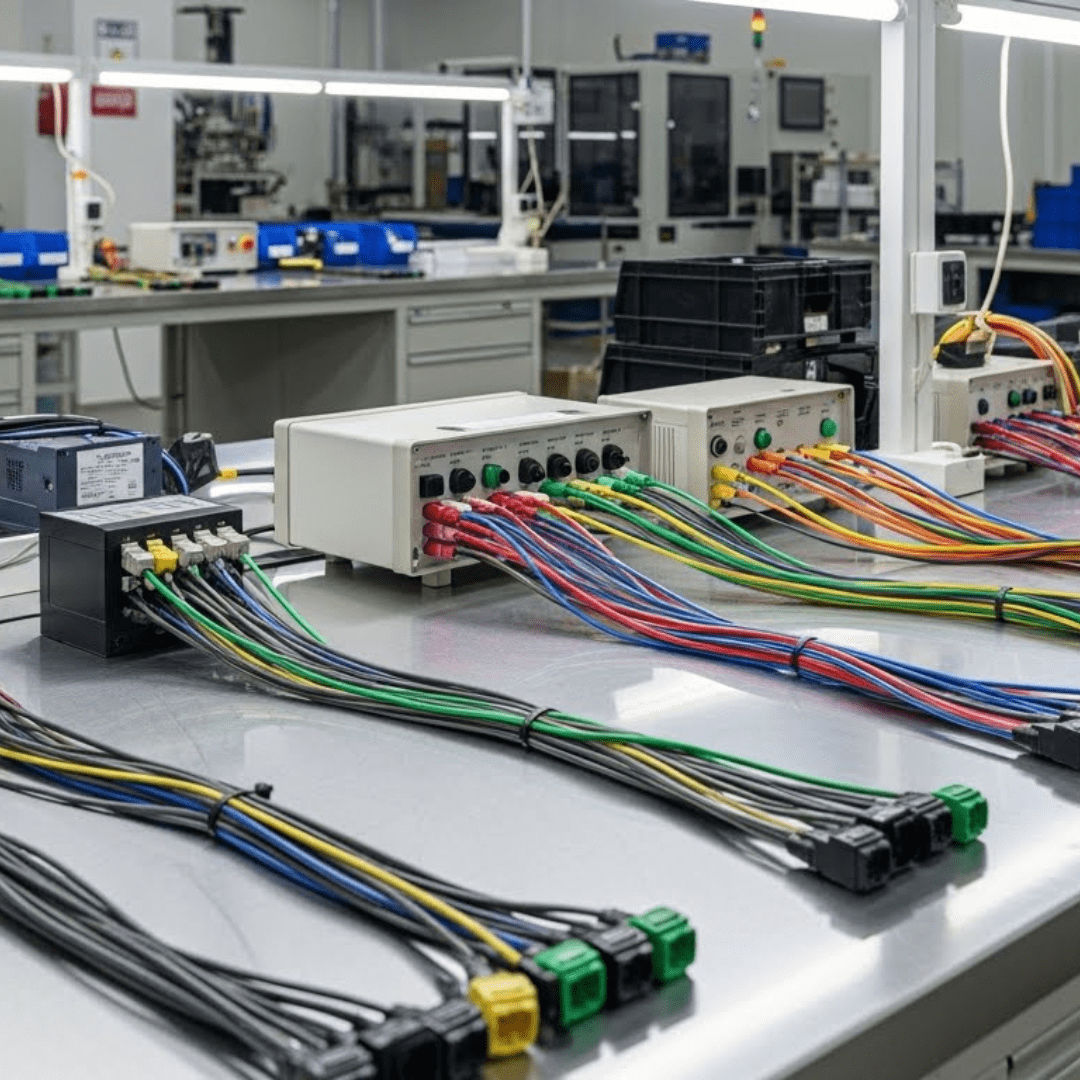

OurPCB operates climate-controlled production facilities configured for consistent solar wire harness assembly. Automated cutting and stripping equipment processes a broad range of wire sizes used in PV and control circuits. We manufacture harnesses using tinned copper or bare copper conductors with insulation systems. We also provide shielded and twisted-pair cables available for communication and control wiring between inverters, trackers, and monitoring systems.

Each harness undergoes structured testing before shipment. High-voltage testing verifies insulation integrity and polarity for DC circuits. Pull-force testing checks the mechanical strength of crimped terminations.

Automated test systems perform 100% continuity checks for specified harnesses to confirm correct connections and detect shorts. Where required, we also offer additional validation that can include thermal cycling, UV exposure testing, and vibration tests representative of tracker or structure movement. Production capacity covers small prototype batches with short turnaround times through to high-volume runs for large multi-site rollouts.

Capabilities & Services

- Wire Gauge: 40AWG-120mm²

- Production Capacity: 10,000 pieces/hour

- Wire Cutting Service

- Wire Stripping Service

- Wire Marking Service

- Label Types

- Wire Ends Treatment

Custom Wire/Cable Service:

- Wire/Cable types

- Wire gauge

- Wire/Cable length

- Insulation/Jacket color

- Core numbers etc.

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

- Electrical cable assembly

- Coaxial cable assembly

- Multi-core cable assembly

- Connector to board cable assembly

- Automobile communication cable assembly

- Power transmission cable assembly

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Solar Wire Harness Manufacturer FAQs

What applications can OurPCB solar wire harnesses support?

OurPCB solar wire harnesses support residential and commercial rooftop PV systems with inverters, optimizers, and energy storage. We also serve ground-mounted and utility-scale solar farms that require trackers, sensors, monitoring networks, and hybrid power-control cabling.

How does OurPCB ensure solar wire harness manufacturing quality?

OurPCB ensures solar harness quality by using qualified outdoor-rated materials and components from trusted suppliers. We have in-process inspections at cutting, crimping, assembly, and electrical testing to verify continuity, insulation integrity, and correct terminations. Our final visual and mechanical checks confirm every harness matches approved drawings and samples before shipment.

What lead times should I expect for custom solar wire harness orders?

Lead times at OurPCB depend on harness complexity, component choices, and order size. Prototype harnesses usually take 5–10 business days, low volumes 2–3 weeks, and high volumes 4–6 weeks. For urgent replacements or time-sensitive projects, we can often arrange expedited scheduling. Simply contact us for more information.